1. Introduction

The deposition of a material on surfaces in a controlled manner is a key aspect in a broad range of applications. Among the coating techniques, the deposition of suspended particles, which can also be solute particles such as salts and polymers, through the evaporation of the carrying liquid, here called the solvent, is a common approach (Routh Reference Routh2013; Brutin & Starov Reference Brutin and Starov2018). When a volatile drop is deposited on a surface, particles are carried towards the contact line. This so-called coffee stain effect, introduced by Deegan et al. (Reference Deegan, Bakajin, Dupont, Huber, Nagel and Witten1997) and recently reviewed by Gelderblom, Diddens & Marin (Reference Gelderblom, Diddens and Marin2022) and Wilson & D'Ambrosio (Reference Wilson and D'Ambrosio2023), is the consequence of a radial flow induced by evaporation. To rationalise this phenomenon, the fluid flow in the drop must be determined to explain the dynamics of the particle motion. The resolution of the liquid flow is subordinated to the knowledge of the drop shape resulting from capillary phenomena, which is to a good approximation a spherical cap, for a drop on a flat substrate, when its size is smaller than the capillary length. In addition, the derivation of the evaporative flux is necessary. The evaporative flux of a circular disk, i.e. a sessile drop with a vanishing contact angle, has been derived analytically by Cooke (Reference Cooke1967), and generalisations to non-zero contact angle are also available in the literature (Sreznevsky Reference Sreznevsky1882; Picknett & Bexon Reference Picknett and Bexon1977). Thus, the fluid flow in the sessile drop has been derived theoretically through different contributions, e.g. (Deegan et al. Reference Deegan, Bakajin, Dupont, Huber, Nagel and Witten2000; Hu & Larson Reference Hu and Larson2005; Popov Reference Popov2005; Zheng Reference Zheng2009; Larson Reference Larson2014).

In addition, Hamamoto, Christy & Sefiane (Reference Hamamoto, Christy and Sefiane2011) and then Marin et al. (Reference Marin, Gelderblom, Lohse and Snoeijer2011a,Reference Marin, Gelderblom, Lohse and Snoeijerb) revealed the rush-hour effect, which consists in an increase of the average particle velocity towards the contact line as the contact angle decreases in time. This particle velocity increase has an impact on the ordering of the particles in the final deposit (Marin et al. Reference Marin, Gelderblom, Lohse and Snoeijer2011a,Reference Marin, Gelderblom, Lohse and Snoeijerb). The time evolution of the particle accumulation at the contact line has been satisfactorily predicted and measured by various authors (Deegan Reference Deegan2000; Popov Reference Popov2005; Monteux & Lequeux Reference Monteux and Lequeux2011; Berteloot et al. Reference Berteloot, Hoang, Daerr, Kavehpour, Lequeux and Limat2012; Larson Reference Larson2014; Boulogne, Ingremeau & Stone Reference Boulogne, Ingremeau and Stone2017). The resulting deposition pattern forms a ring shape (Deegan Reference Deegan2000; Routh Reference Routh2013; Brutin & Starov Reference Brutin and Starov2018) that triggered various investigations to find strategies for tuning, limiting or suppressing this effect. For instance, studies focused on the liquid properties especially with solutal Marangoni flows (Kajiya et al. Reference Kajiya, Kobayashi, Okuzono and Doi2009; Sempels et al. Reference Sempels, De Dier, Mizuno, Hofkens and Vermant2013; Kim et al. Reference Kim, Boulogne, Um, Jacobi, Button and Stone2016; Pahlavan et al. Reference Pahlavan, Yang, Bain and Stone2021), on the substrate hydrophobicity (Gelderblom et al. Reference Gelderblom, Marin, Nair, van Houselt, Lefferts, Snoeijer and Lohse2011), on the substrate permeability (Boulogne et al. Reference Boulogne, Ingremeau, Dervaux, Limat and Stone2015) and on the multiple drops interaction (Pradhan & Panigrahi Reference Pradhan and Panigrahi2015; Wray, Duffy & Wilson Reference Wray, Duffy and Wilson2020; Wray et al. Reference Wray, Wray, Duffy and Wilson2021). See Mampallil & Eral (Reference Mampallil and Eral2018) for a recent review.

Most of the literature is focused on drops on flat surfaces. However, drops on fibres also represent a relevant situation for applications such as the drying of filters, clothing (Duprat Reference Duprat2022) and insulating materials (Sauret et al. Reference Sauret, Boulogne, Soh, Dressaire and Stone2015). A liquid deposited on fibres can adopt a rich variety of morphologies. We distinguish the clamshell shape, which corresponds to a small drop wetting a portion of the fibre perimeter from the barrel shape where the drop wets the fibre as a pearl on a necklace (Chou et al. Reference Chou, Hong, Liang, Tsao and Sheng2011). More complex liquid shapes can be obtained on fibrous networks. Fibres can be either crossed or parallel, which leads to a rich variety of equilibrium morphologies including liquid columns, distorted drops and drops coexisting with columns (Protiere, Duprat & Stone Reference Protiere, Duprat and Stone2012; Sauret et al. Reference Sauret, Boulogne, Soh, Dressaire and Stone2015).

The deposition of particles dissolved in an evaporating clamshell drop on a fibre has already been investigated by Pham et al. (Reference Pham, McHale, Newton, Carroll and Rowan2002), where a similar behaviour to sessile drops has been observed. In the barrel case, the liquid morphology is remarkable due to the substrate geometry. The fibre curvature induces an inflection point of the interface and a drop aspect ratio of the order of the unity even for a perfectly wetting fluid in contrast to sessile drops (Carroll Reference Carroll1976; Brochard-Wyart et al. Reference Brochard-Wyart, Di Meglio, Quere and De Gennes1991; Lorenceau, Senden & Quéré Reference Lorenceau, Senden and Quéré2006). By minimising the surface energy, Carroll (Reference Carroll1976) has obtained an analytical expression of the drop profile. In addition, Corpart et al. (Reference Corpart, Dervaux, Poulard, Restagno and Boulogne2022) recently obtained by numerical calculations the evaporative flux of an axisymmetric drop on a fibre, demonstrating that the divergence of the evaporative flux is localised near the contact line. Thus, due to the differences in shape and evaporative flux induced by the substrate, we propose to investigate theoretically the particle deposition from a drop deposited on a fibre. In this paper, our approach will favour analytical calculations when possible and we will limit ourselves to the regime where the contact line is pinned on the substrate. Thus, we will rationalise the particle transport and the deposit left at the initial position of the contact lines, which will be compared to the well-established sessile drop.

To do so, we investigate theoretically the transport of particles due to evaporation in a drop wetting a fibre in an axisymmetric barrel configuration. The obtained model is compared to the case of a sessile drop in terms of volume loss dynamics, characteristic velocities and efficiency of the particles transport toward the contact line. In § 2, we introduce the phenomenological equations for the drop shape and the evaporative flux to obtain analytical predictions. Then, we derive the hydrodynamics equation in the liquid phase under the lubrication approximation to provide the velocity field toward the pinned contact line. In § 3, we compare the drop on a fibre with the sessile drop, and we comment about the main differences between these systems. In § 4, we present some qualitative experimental observations on the particle dynamics in both geometries that we compare to the theoretical investigations.

2. Fluid flow of an evaporating drop on a fibre

We consider a volatile drop of density ![]() $\rho$, viscosity

$\rho$, viscosity ![]() $\eta$, surface tension

$\eta$, surface tension ![]() $\gamma$ and volume

$\gamma$ and volume ![]() $\varOmega$, on a fibre of radius

$\varOmega$, on a fibre of radius ![]() $a$. The contact angle of the liquid on the material, defined by Young's law, is denoted

$a$. The contact angle of the liquid on the material, defined by Young's law, is denoted ![]() $\theta$. On a horizontal single fibre, two configurations exist: a drop pierced by a fibre, the barrel shape, or a drop wetting a portion of the fibre circumference, the clamshell shape. As shown by Chou et al. (Reference Chou, Hong, Liang, Tsao and Sheng2011), this barrel shape is stable for a certain range of contact angles whose upper limit depends on the drop volume. For sufficiently small contact angles, this configuration is therefore realistic. Also, studies indicate that gravity, when sufficient, can off-centre the drop leading to an asymmetric shape (Chou et al. Reference Chou, Hong, Liang, Tsao and Sheng2011; Gupta et al. Reference Gupta, Konicek, King, Iqtidar, Yeganeh and Stone2021). The role of gravity over capillarity can be quantified by the Worthington number

$\theta$. On a horizontal single fibre, two configurations exist: a drop pierced by a fibre, the barrel shape, or a drop wetting a portion of the fibre circumference, the clamshell shape. As shown by Chou et al. (Reference Chou, Hong, Liang, Tsao and Sheng2011), this barrel shape is stable for a certain range of contact angles whose upper limit depends on the drop volume. For sufficiently small contact angles, this configuration is therefore realistic. Also, studies indicate that gravity, when sufficient, can off-centre the drop leading to an asymmetric shape (Chou et al. Reference Chou, Hong, Liang, Tsao and Sheng2011; Gupta et al. Reference Gupta, Konicek, King, Iqtidar, Yeganeh and Stone2021). The role of gravity over capillarity can be quantified by the Worthington number ![]() ${Wo}= \rho g \varOmega / ({\rm \pi} \gamma a)$ (Worthington Reference Worthington1885; Ferguson Reference Ferguson1912). We assume a negligible effect of the gravity, i.e.

${Wo}= \rho g \varOmega / ({\rm \pi} \gamma a)$ (Worthington Reference Worthington1885; Ferguson Reference Ferguson1912). We assume a negligible effect of the gravity, i.e. ![]() ${Wo} \ll 1$. The drop is therefore considered perfectly axisymmetric in this study.

${Wo} \ll 1$. The drop is therefore considered perfectly axisymmetric in this study.

Thus, we adopt the cylindrical coordinate system shown in figure 1(a). The profile of the liquid–vapour interface is described by a function ![]() $h(z,t)$. The evaporation of the liquid generates a volume variation, and therefore an internal flow. When the liquid is seeded with particles of radius

$h(z,t)$. The evaporation of the liquid generates a volume variation, and therefore an internal flow. When the liquid is seeded with particles of radius ![]() $b$, the liquid flow can carry these particles. Our aim is to predict analytically the particle transport in the liquid phase. In the present work, we focus our interest on the regime for which the contact line is pinned, i.e. the length

$b$, the liquid flow can carry these particles. Our aim is to predict analytically the particle transport in the liquid phase. In the present work, we focus our interest on the regime for which the contact line is pinned, i.e. the length ![]() $L$ is constant. In practice, this pinning occurs due to the contact angle hysteresis and the additional pinning force due to the particles accumulated at the contact line creating defects (Joanny & de Gennes Reference Joanny and de Gennes1984; di Meglio Reference di Meglio1992; Boulogne et al. Reference Boulogne, Ingremeau, Limat and Stone2016). As evaporation proceeds, the drop height and the contact angle decrease.

$L$ is constant. In practice, this pinning occurs due to the contact angle hysteresis and the additional pinning force due to the particles accumulated at the contact line creating defects (Joanny & de Gennes Reference Joanny and de Gennes1984; di Meglio Reference di Meglio1992; Boulogne et al. Reference Boulogne, Ingremeau, Limat and Stone2016). As evaporation proceeds, the drop height and the contact angle decrease.

Figure 1. (a) Sketch presenting the notation of an axisymmetric drop of length ![]() $2L$ on a fibre of radius

$2L$ on a fibre of radius ![]() $a$. Here,

$a$. Here, ![]() $c_{sat}$ is the saturation vapour mass concentration, the vapour mass concentration in air at the liquid air/interface, and

$c_{sat}$ is the saturation vapour mass concentration, the vapour mass concentration in air at the liquid air/interface, and ![]() $c_\infty$ is the mass concentration of vapour far from the droplet. (b) Comparison of the analytical solution obtained by Carroll (Reference Carroll1976) of the dimensionless profile

$c_\infty$ is the mass concentration of vapour far from the droplet. (b) Comparison of the analytical solution obtained by Carroll (Reference Carroll1976) of the dimensionless profile ![]() $h/a$ at

$h/a$ at ![]() $L/a = 6.5$ (solid lines), to the proposed ansatz (2.1) with

$L/a = 6.5$ (solid lines), to the proposed ansatz (2.1) with ![]() $L/a \approx 6.7$ (dotted lines) for

$L/a \approx 6.7$ (dotted lines) for ![]() $\theta = 0^\circ, 1^\circ, 5^\circ, 10^\circ, 15^\circ$. The apex height is obtained by fitting Carroll's profile by (2.1) and the length

$\theta = 0^\circ, 1^\circ, 5^\circ, 10^\circ, 15^\circ$. The apex height is obtained by fitting Carroll's profile by (2.1) and the length ![]() $L/a = 6.7$ is chosen to be the fitted length obtained for

$L/a = 6.7$ is chosen to be the fitted length obtained for ![]() $\theta = 0^\circ$. The dimensions chosen here correspond approximately to a microlitre drop deposited on a glass fibre of 100

$\theta = 0^\circ$. The dimensions chosen here correspond approximately to a microlitre drop deposited on a glass fibre of 100 ![]() $\mathrm {\mu } $m radius. The curves are arbitrarily shifted for clarity.

$\mathrm {\mu } $m radius. The curves are arbitrarily shifted for clarity.

The profile of the liquid interface (Carroll Reference Carroll1976) and evaporative flux (Corpart et al. Reference Corpart, Dervaux, Poulard, Restagno and Boulogne2022) are particularly complex in this geometry. Consequently, to perform an analytical analysis, we will model the drop shape and the evaporative flux with phenomenological expressions, for which the validity will be discussed. In addition, we will write the hydrodynamics equations to derive the main component of the liquid flow, along the fibre, while the contact lines remain pinned. Then, we will be in position to discuss the particle transport in the drop.

2.1. Profile of the liquid–vapour interface

An analytical solution of the drop shape has been derived by Carroll (Reference Carroll1976), but the elliptical integral involved in this solution would limit the analytical derivation of the present problem. Thus, we choose to describe the drop profile with an ansatz fitting Carroll's solution

\begin{equation} h(z,t) = h_0(t) \left( 1 - \frac{z^2}{L^2} \right)^2, \end{equation}

\begin{equation} h(z,t) = h_0(t) \left( 1 - \frac{z^2}{L^2} \right)^2, \end{equation}

where ![]() $h_0(t)$ is the drop height at the apex

$h_0(t)$ is the drop height at the apex ![]() $z=0$ and

$z=0$ and ![]() $L$ is the distance from the apex to the contact line (figure 1a). We consider the regime for which contact lines are pinned, so the length

$L$ is the distance from the apex to the contact line (figure 1a). We consider the regime for which contact lines are pinned, so the length ![]() $L$ remains constant. The contact angle is defined by Young's law and depends only on the liquid/solid properties. For an axisymmetric drop on a fibre, Carroll (Reference Carroll1976) demonstrated that the relation between the drop shape and the contact angle is not straightforward and, in particular, the contact angle cannot be read directly from the slope between the interface and the surface of the fibre as it is for sessile drops. Typically, for contact angles between 0

$L$ remains constant. The contact angle is defined by Young's law and depends only on the liquid/solid properties. For an axisymmetric drop on a fibre, Carroll (Reference Carroll1976) demonstrated that the relation between the drop shape and the contact angle is not straightforward and, in particular, the contact angle cannot be read directly from the slope between the interface and the surface of the fibre as it is for sessile drops. Typically, for contact angles between 0![]() $^\circ$ and 30

$^\circ$ and 30![]() $^\circ$, the slope of the interface vanishes in the vicinity of the contact line as shown in figure 1(b), where we compare drop profiles obtained from Carroll (Reference Carroll1976) at

$^\circ$, the slope of the interface vanishes in the vicinity of the contact line as shown in figure 1(b), where we compare drop profiles obtained from Carroll (Reference Carroll1976) at ![]() $L/a = 6.5$ to (2.1) for

$L/a = 6.5$ to (2.1) for ![]() $\theta = 0^\circ, 5^\circ, 10^\circ \ \textrm {and}\ 15^\circ$. To describe the drop profile, we fit Carroll's profile with (2.1), where

$\theta = 0^\circ, 5^\circ, 10^\circ \ \textrm {and}\ 15^\circ$. To describe the drop profile, we fit Carroll's profile with (2.1), where ![]() $L$ and

$L$ and ![]() $h_0$ are the two adjustable parameters. To keep the wetted-length constant over the dynamics, we choose to set

$h_0$ are the two adjustable parameters. To keep the wetted-length constant over the dynamics, we choose to set ![]() $L$ as the fitted length obtained for

$L$ as the fitted length obtained for ![]() $\theta = 0^\circ$,

$\theta = 0^\circ$, ![]() $L/a \approx 6.7$. Then, we use the values of

$L/a \approx 6.7$. Then, we use the values of ![]() $h_0$ obtained by the fit to calculate drop profile with (2.1) (see dashed lines in figure 1b). As shown in figure 1(b), the proposed description of the drop profile is reasonably close to the analytical solution and describes its main features. We tested the validity of the ansatz for various drop profiles and we found a good agreement for drop with small contact angles, typically lower than 30

$h_0$ obtained by the fit to calculate drop profile with (2.1) (see dashed lines in figure 1b). As shown in figure 1(b), the proposed description of the drop profile is reasonably close to the analytical solution and describes its main features. We tested the validity of the ansatz for various drop profiles and we found a good agreement for drop with small contact angles, typically lower than 30![]() $^\circ$ and dimensionless volume

$^\circ$ and dimensionless volume ![]() $\varOmega /a^3 < 1000$.

$\varOmega /a^3 < 1000$.

The liquid volume is defined as

With (2.1) and (2.2), we can estimate the volume of the drop and compare it to the volume calculated by Carroll (Reference Carroll1976) from his analytical description of the drop profile. The ansatz gives a good approximation of the drop volume with a relative error of approximately ![]() $10\,\%$ for the largest contact angle tested,

$10\,\%$ for the largest contact angle tested, ![]() $\theta = 15^\circ$, for which the difference between the fit and the analytical profile is the largest.

$\theta = 15^\circ$, for which the difference between the fit and the analytical profile is the largest.

2.2. Evaporative flux

The evaporation process is assumed to be limited by the diffusion of vapour in air (Cazabat & Guéna Reference Cazabat and Guéna2010), described by the vapour diffusion coefficient ![]() ${\mathcal {D}}_{v}$. The steady-state regime is reached on a time scale

${\mathcal {D}}_{v}$. The steady-state regime is reached on a time scale ![]() $L^2/{\mathcal {D}}_{v}$, which is, in most situations, short compared to the observation time scale. Thus, the vapour mass concentration field

$L^2/{\mathcal {D}}_{v}$, which is, in most situations, short compared to the observation time scale. Thus, the vapour mass concentration field ![]() $c(r,z)$ is the solution of the Laplace equation

$c(r,z)$ is the solution of the Laplace equation ![]() ${\rm \Delta} c = 0$. The boundary conditions are

${\rm \Delta} c = 0$. The boundary conditions are ![]() $c=c_{sat}$ at the liquid–vapour interface,

$c=c_{sat}$ at the liquid–vapour interface, ![]() $c=c_{\infty }$ far from the interface and a no flux condition

$c=c_{\infty }$ far from the interface and a no flux condition ![]() $\boldsymbol {n} \boldsymbol {{\cdot }} \boldsymbol {\nabla } c = 0$ on the solid–gas interface characterised by its normal

$\boldsymbol {n} \boldsymbol {{\cdot }} \boldsymbol {\nabla } c = 0$ on the solid–gas interface characterised by its normal ![]() $\boldsymbol {n}$ (see figure 1a). Once the mass concentration field is obtained, the evaporation velocity at the liquid–vapour interface is defined as

$\boldsymbol {n}$ (see figure 1a). Once the mass concentration field is obtained, the evaporation velocity at the liquid–vapour interface is defined as ![]() $v_{e}(z) = ({{\mathcal {D}}_{ v}}/{\rho }) \boldsymbol {n} \boldsymbol {{\cdot }} \boldsymbol {\nabla } c|_{h(z,t)}$, where the derivative is calculated at the liquid–vapour interface and

$v_{e}(z) = ({{\mathcal {D}}_{ v}}/{\rho }) \boldsymbol {n} \boldsymbol {{\cdot }} \boldsymbol {\nabla } c|_{h(z,t)}$, where the derivative is calculated at the liquid–vapour interface and ![]() $\rho$ is the density of the liquid.

$\rho$ is the density of the liquid.

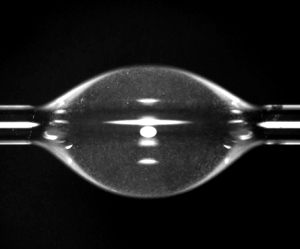

Corpart et al. (Reference Corpart, Dervaux, Poulard, Restagno and Boulogne2022) have recently performed numerical simulations using the finite element method to determine the local evaporative flux of a drop on a fibre. In particular, this study revealed that the evaporation velocity differs from the well-known sessile drop in two aspects. First, the divergence is localised in the close vicinity of the contact line and second, the contact angle has a weak effect on the evaporation velocity. A typical result of these computations is presented in figure 2. The localisation of the divergence near the contact line implies that the evaporation velocity cannot be written as a power law (Corpart et al. Reference Corpart, Dervaux, Poulard, Restagno and Boulogne2022). Instead, we propose to fit the results of the numerical simulations by

\begin{equation} v_{e}(z) = v_{e}^0 \left[\beta\left( 1 - \frac{z^2}{L^2} \right)^{-\alpha} + 1 - \beta\right], \end{equation}

\begin{equation} v_{e}(z) = v_{e}^0 \left[\beta\left( 1 - \frac{z^2}{L^2} \right)^{-\alpha} + 1 - \beta\right], \end{equation}

where ![]() $\alpha$ and

$\alpha$ and ![]() $\beta$ are constants, independent of the contact angle, for

$\beta$ are constants, independent of the contact angle, for ![]() $\theta < 20^\circ$ (Corpart et al. Reference Corpart, Dervaux, Poulard, Restagno and Boulogne2022). The prefactor

$\theta < 20^\circ$ (Corpart et al. Reference Corpart, Dervaux, Poulard, Restagno and Boulogne2022). The prefactor ![]() $v_{e}^0=v_{e}(z=0)$ is the single parameter that depends on the environmental conditions and is proportional to

$v_{e}^0=v_{e}(z=0)$ is the single parameter that depends on the environmental conditions and is proportional to ![]() ${\mathcal {D}}_{v} (c_{sat} - c_\infty ) / \rho$. The total evaporative flux writes

${\mathcal {D}}_{v} (c_{sat} - c_\infty ) / \rho$. The total evaporative flux writes ![]() $Q_{e}(t) = \int v_{e}\,{\rm d} S = 2{\rm \pi} \int _{-L}^{L} v_{e}(z) (a + h(z,t) )\,{\rm d} z$, which leads after integration to

$Q_{e}(t) = \int v_{e}\,{\rm d} S = 2{\rm \pi} \int _{-L}^{L} v_{e}(z) (a + h(z,t) )\,{\rm d} z$, which leads after integration to

with

$$\begin{gather} A_1=\sqrt{\rm \pi} \beta \frac{ \varGamma(1-\alpha) }{ \varGamma\left(\dfrac{3}{2} - \alpha\right)} + 2 (1 - \beta), \end{gather}$$

$$\begin{gather} A_1=\sqrt{\rm \pi} \beta \frac{ \varGamma(1-\alpha) }{ \varGamma\left(\dfrac{3}{2} - \alpha\right)} + 2 (1 - \beta), \end{gather}$$ $$\begin{gather}A_2=\sqrt{\rm \pi} \beta \frac{ \varGamma(3-\alpha) }{ \varGamma\left(\dfrac{7}{2}- \alpha\right)} + \frac{16}{15} (1-\beta), \end{gather}$$

$$\begin{gather}A_2=\sqrt{\rm \pi} \beta \frac{ \varGamma(3-\alpha) }{ \varGamma\left(\dfrac{7}{2}- \alpha\right)} + \frac{16}{15} (1-\beta), \end{gather}$$

where ![]() $\varGamma$ is the Gamma-function (Abramowitz & Stegun Reference Abramowitz and Stegun1972).

$\varGamma$ is the Gamma-function (Abramowitz & Stegun Reference Abramowitz and Stegun1972).

Figure 2. Local dimensionless evaporation velocity ![]() $v_{e}(z)/v_{e}^0$ as a function of

$v_{e}(z)/v_{e}^0$ as a function of ![]() $1-z^2 / L^2$, where

$1-z^2 / L^2$, where ![]() $v_{e}^0$ is the evaporation velocity at the drop apex. The points are obtained from numerical simulations using finite element methods presented by Corpart et al. (Reference Corpart, Dervaux, Poulard, Restagno and Boulogne2022) for

$v_{e}^0$ is the evaporation velocity at the drop apex. The points are obtained from numerical simulations using finite element methods presented by Corpart et al. (Reference Corpart, Dervaux, Poulard, Restagno and Boulogne2022) for ![]() $a=125\,\mathrm {\mu }$m,

$a=125\,\mathrm {\mu }$m, ![]() $\theta = 10^\circ$,

$\theta = 10^\circ$, ![]() $\varOmega = 1\,\mathrm {\mu }$L, which corresponds to

$\varOmega = 1\,\mathrm {\mu }$L, which corresponds to ![]() $L/a \approx 6.7$. The dashed line is (2.3) with the fitted parameters

$L/a \approx 6.7$. The dashed line is (2.3) with the fitted parameters ![]() $\alpha = 0.7$ and

$\alpha = 0.7$ and ![]() $\beta = 0.1$.

$\beta = 0.1$.

2.3. Hydrodynamics

2.3.1. Lubrication approximation

Now that the geometry and the evaporation dynamics are described, we analyse the flow in the liquid phase. By considerations of symmetries, the velocity field can be written in the cylindrical coordinates ![]() $(v_r(r, z), v_z(r, z))$. The continuity equation is

$(v_r(r, z), v_z(r, z))$. The continuity equation is

and the Navier–Stokes equations in the stationary regime are

where ![]() $p(r,z)$ is the liquid pressure. The boundary conditions are no fluid slippage on the fibre and no stress at the liquid–vapour interface, i.e.

$p(r,z)$ is the liquid pressure. The boundary conditions are no fluid slippage on the fibre and no stress at the liquid–vapour interface, i.e.

Equation (2.8b) means that tracers are assumed to have no surfactant effect, due to their size. We apply the lubrication approximation to (2.7a), (2.7b), which is valid for ![]() $({h_0}/{L})({\rho h(z,t) v_z}/{\eta }) \ll 1$ (Batchelor Reference Batchelor2000) and we get

$({h_0}/{L})({\rho h(z,t) v_z}/{\eta }) \ll 1$ (Batchelor Reference Batchelor2000) and we get

Based on the differential equation (2.9) and the boundary conditions (2.8a) and (2.8b), we can calculate the velocity field ![]() $v_z$:

$v_z$:

\begin{equation} v_z(r, z, t) ={-} \frac{1}{\eta} \frac{{\rm d} p}{{\rm d} z} \left[\frac{ \left(a + h(z,t) \right)^2}{2} \ln\left(\frac{r}{r_0}\right) - \frac{r^2}{4} \right], \end{equation}

\begin{equation} v_z(r, z, t) ={-} \frac{1}{\eta} \frac{{\rm d} p}{{\rm d} z} \left[\frac{ \left(a + h(z,t) \right)^2}{2} \ln\left(\frac{r}{r_0}\right) - \frac{r^2}{4} \right], \end{equation}

with ![]() $r_0 = a \exp ( - a^2 / ( 2 (a+h(z,t))^2 ) )$. We remark that the radial dependence of

$r_0 = a \exp ( - a^2 / ( 2 (a+h(z,t))^2 ) )$. We remark that the radial dependence of ![]() $v_z$ is not a quadratic function in contrast to the sessile drop that will be recalled thereafter in Appendix A.

$v_z$ is not a quadratic function in contrast to the sessile drop that will be recalled thereafter in Appendix A.

2.3.2. Mass conservation

To fully obtain the fluid velocity ![]() $v_z$, the pressure gradient

$v_z$, the pressure gradient ![]() ${\rm d} p / {\rm d} z$ must be determined. To do so, we write the mass conservation over a slice between

${\rm d} p / {\rm d} z$ must be determined. To do so, we write the mass conservation over a slice between ![]() $z$ and

$z$ and ![]() $z + {\rm d} z$,

$z + {\rm d} z$,

where ![]() $\bar {v}_z(z,t)$ is the velocity

$\bar {v}_z(z,t)$ is the velocity ![]() $v_z(r,z,t)$ averaged over a cross-section perpendicular to the fibre,

$v_z(r,z,t)$ averaged over a cross-section perpendicular to the fibre,

Now, we can establish the relation between ![]() $\bar {v}_z$ and

$\bar {v}_z$ and ![]() $v_z$. First, we integrate (2.12) with (2.10) to express

$v_z$. First, we integrate (2.12) with (2.10) to express ![]() $\bar {v}_z$ as a function of

$\bar {v}_z$ as a function of ![]() ${\rm d} p / {\rm d} z$. Equation (2.12) is written

${\rm d} p / {\rm d} z$. Equation (2.12) is written

where the geometrical function ![]() $\mathcal {G}(a,h(z, t))$ is given by

$\mathcal {G}(a,h(z, t))$ is given by

Substituting the pressure derivative from (2.10) in (2.13) yields

\begin{equation} v_z(r, z, t) = \frac{ h \bar{v}_z}{\mathcal{G}(a, h(z,t))} \left[ \frac{ \left(a + h(z,t) \right)^2}{2} \ln\left(\frac{r}{r_0} \right) - \frac{r^2}{4} \right]. \end{equation}

\begin{equation} v_z(r, z, t) = \frac{ h \bar{v}_z}{\mathcal{G}(a, h(z,t))} \left[ \frac{ \left(a + h(z,t) \right)^2}{2} \ln\left(\frac{r}{r_0} \right) - \frac{r^2}{4} \right]. \end{equation} In the next subsections, we derive the time evolution of the drop profile ![]() $\partial h / \partial t$, which will be used along the evaporation velocity

$\partial h / \partial t$, which will be used along the evaporation velocity ![]() $v_{e}(z)$ in the mass conservation (2.11) to obtain the average velocity

$v_{e}(z)$ in the mass conservation (2.11) to obtain the average velocity ![]() $\bar {v}_z$ as a function of the evaporation dynamics.

$\bar {v}_z$ as a function of the evaporation dynamics.

2.3.3. Liquid evaporation

First, we calculate the time derivative of the liquid profile, ![]() $\partial h / \partial t$, which appears in (2.11). The time derivative of the drop profile defined in (2.1) considering a constant drop length

$\partial h / \partial t$, which appears in (2.11). The time derivative of the drop profile defined in (2.1) considering a constant drop length ![]() $L$ gives

$L$ gives

\begin{equation} \frac{\partial h(z,t)}{\partial t} = \frac{{\rm d} h_0 }{ {\rm d} t } \left( 1 - \frac{z^2}{L^2} \right)^2. \end{equation}

\begin{equation} \frac{\partial h(z,t)}{\partial t} = \frac{{\rm d} h_0 }{ {\rm d} t } \left( 1 - \frac{z^2}{L^2} \right)^2. \end{equation} In addition, the loss of liquid by evaporation compensates the total evaporative flux as ![]() ${\rm d} \varOmega / {\rm d} t= - Q_{e}(t)$. Substituting the volume defined in (2.2), we have

${\rm d} \varOmega / {\rm d} t= - Q_{e}(t)$. Substituting the volume defined in (2.2), we have

which fully defines the time derivative of the liquid profile.

Integrating (2.17) from 0 to ![]() $t$ and

$t$ and ![]() $h_{i}$ to

$h_{i}$ to ![]() $h_0$ leads to

$h_0$ leads to

At the first leading order in ![]() $(h_{i} - h_0)/h_{i}$, we obtain the time variation of the height of the apex:

$(h_{i} - h_0)/h_{i}$, we obtain the time variation of the height of the apex:

2.3.4. Mean liquid velocity

Now, we derive the mean liquid velocity ![]() $\bar {v}_z$. By substituting (2.16) and (2.17) in the mass conservation (2.11), we have

$\bar {v}_z$. By substituting (2.16) and (2.17) in the mass conservation (2.11), we have

\begin{equation} \frac{1}{2(a+h)} \frac{\partial }{\partial z} ((2ah + h^2) \bar{v}_z) = \frac{315}{ 32 {\rm \pi}} \frac{Q_{e}(t)}{L(21a + 16 h_0)} \left( 1 - \frac{z^2}{L^2} \right)^2 - v_{e}(z). \end{equation}

\begin{equation} \frac{1}{2(a+h)} \frac{\partial }{\partial z} ((2ah + h^2) \bar{v}_z) = \frac{315}{ 32 {\rm \pi}} \frac{Q_{e}(t)}{L(21a + 16 h_0)} \left( 1 - \frac{z^2}{L^2} \right)^2 - v_{e}(z). \end{equation}

The integration of this differential equation from ![]() $0$ to

$0$ to ![]() $z$ yields

$z$ yields

where ![]() ${\mathcal {P}}_1(x) = 1 - \frac {2}{3} x^2 + \frac {1}{5}x^4$ and

${\mathcal {P}}_1(x) = 1 - \frac {2}{3} x^2 + \frac {1}{5}x^4$ and ![]() ${\mathcal {P}}_2(x) = 1 - \frac {4}{3}x^2 + \frac {6}{5}x^4 - \frac {4}{7}x^6 + \frac {1}{9}x^8$.

${\mathcal {P}}_2(x) = 1 - \frac {4}{3}x^2 + \frac {6}{5}x^4 - \frac {4}{7}x^6 + \frac {1}{9}x^8$.

The plane perpendicular to the fibre at ![]() $z=0$ is a plane of symmetry, thus

$z=0$ is a plane of symmetry, thus ![]() $\bar {v}_z(z=0) = 0$.

$\bar {v}_z(z=0) = 0$.

From (2.3), we can calculate the remaining integral of (2.21):

\begin{align} 2 \int_0^z (a+h) v_{e}\, {\rm d}z &= 2 v_{e}^0 z \left[ a \left( \beta {}_2F_1\left(\frac{1}{2},\alpha; \frac{3}{2};\frac{z^2}{L^2}\right) + (1-\beta) \right) \right. \nonumber\\ &\quad + \left. h_0 \left(\beta\, {}_2F_1\left(\frac{1}{2},\alpha-2;\frac{3}{2};\frac{z^2}{L^2}\right) + (1-\beta) {\mathcal{P}}_1\left( \frac{z}{L} \right)\right)\right], \end{align}

\begin{align} 2 \int_0^z (a+h) v_{e}\, {\rm d}z &= 2 v_{e}^0 z \left[ a \left( \beta {}_2F_1\left(\frac{1}{2},\alpha; \frac{3}{2};\frac{z^2}{L^2}\right) + (1-\beta) \right) \right. \nonumber\\ &\quad + \left. h_0 \left(\beta\, {}_2F_1\left(\frac{1}{2},\alpha-2;\frac{3}{2};\frac{z^2}{L^2}\right) + (1-\beta) {\mathcal{P}}_1\left( \frac{z}{L} \right)\right)\right], \end{align}

where the hypergeometric function ![]() ${}_2F_1(a,b;c;z)$ writes (Abramowitz & Stegun Reference Abramowitz and Stegun1972)

${}_2F_1(a,b;c;z)$ writes (Abramowitz & Stegun Reference Abramowitz and Stegun1972)

\begin{equation} {}_2F_1(a,b;c;z) = \sum_{n=0}^\infty \frac{(a)_n (b)_n}{(c)_n} \frac{z^n}{n!} = 1 + \frac{ab}{c}\frac{z}{1!} + \frac{a(a+1)b(b+1)}{c(c+1)}\frac{z^2}{2!} + \cdots. \end{equation}

\begin{equation} {}_2F_1(a,b;c;z) = \sum_{n=0}^\infty \frac{(a)_n (b)_n}{(c)_n} \frac{z^n}{n!} = 1 + \frac{ab}{c}\frac{z}{1!} + \frac{a(a+1)b(b+1)}{c(c+1)}\frac{z^2}{2!} + \cdots. \end{equation} The combination of (2.21) and (2.22) provides the mean velocity ![]() $\bar {v}_z(z,t)$. The velocity profile

$\bar {v}_z(z,t)$. The velocity profile ![]() $v_z(r,z,t)$ is therefore obtained by a straightforward substitution in (2.15). This description of the fluid flow permits analysis of the induced particle transport, which will be discussed in § 3.

$v_z(r,z,t)$ is therefore obtained by a straightforward substitution in (2.15). This description of the fluid flow permits analysis of the induced particle transport, which will be discussed in § 3.

3. Comparison between geometries

In this section, we discuss the results obtained in § 2 on a fibre that we compare to the well-established results for a drop on a flat surface (See Appendix A) (Deegan Reference Deegan2000; Popov Reference Popov2005; Larson Reference Larson2014; Stauber et al. Reference Stauber, Wilson, Duffy and Sefiane2014; Boulogne et al. Reference Boulogne, Ingremeau and Stone2017). To adopt a versatile notation for the two geometries, let ![]() $x$ be the

$x$ be the ![]() $z$ or

$z$ or ![]() $r$ coordinate for the fibre or the sessile case, respectively. Hence, the velocity towards the contact line is denoted

$r$ coordinate for the fibre or the sessile case, respectively. Hence, the velocity towards the contact line is denoted ![]() $\bar {v}_x$. Similarly, the length

$\bar {v}_x$. Similarly, the length ![]() ${\mathcal {L}}$ denotes the wetted length

${\mathcal {L}}$ denotes the wetted length ![]() $L$ or

$L$ or ![]() $R$, respectively.

$R$, respectively.

First, we compare the time evolution of the drop profiles for pinned contact lines to reveal the effect of the substrate curvature on the duration of this regime of evaporation with respect to the total time of evaporation. Next, we analyse the fluid velocity toward the contact line and its efficiency to transport the particles through a Péclet number. Finally, we compute the total number of particles accumulated at the contact line during the pinned regime.

3.1. Methodology

To be able to compare the two geometries, a choice on the initial parameters has to be made. The possible parameters are ![]() $\theta _{i}$ the initial contact angle,

$\theta _{i}$ the initial contact angle, ![]() $\mathcal {L}$ the wetted length,

$\mathcal {L}$ the wetted length, ![]() $\varOmega (t=0)$ the initial volume and

$\varOmega (t=0)$ the initial volume and ![]() $Q_{e}(t=0)$ the initial evaporation rate. A common practice for comparison is to consider the same liquid–solid system such that the initial contact angle

$Q_{e}(t=0)$ the initial evaporation rate. A common practice for comparison is to consider the same liquid–solid system such that the initial contact angle ![]() $\theta _{i}$ is fixed. In addition, a similar evaporation rate

$\theta _{i}$ is fixed. In addition, a similar evaporation rate ![]() $Q_{e}$ for both systems brings the advantage of a comparable driving force for the particle transport. With (2.4), we can calculate the evaporation rate of a drop on a fibre whose geometry is given by (2.1) at

$Q_{e}$ for both systems brings the advantage of a comparable driving force for the particle transport. With (2.4), we can calculate the evaporation rate of a drop on a fibre whose geometry is given by (2.1) at ![]() $L/a \approx 6.7$ and

$L/a \approx 6.7$ and ![]() $\theta = \theta _{i} = 15^\circ$ (see figure 1b). Numerical simulation in a previous study by Corpart et al. (Reference Corpart, Dervaux, Poulard, Restagno and Boulogne2022) provides

$\theta = \theta _{i} = 15^\circ$ (see figure 1b). Numerical simulation in a previous study by Corpart et al. (Reference Corpart, Dervaux, Poulard, Restagno and Boulogne2022) provides ![]() $v_{e}^0$ for a water droplet in the initial geometry described here and evaporating in dry air (

$v_{e}^0$ for a water droplet in the initial geometry described here and evaporating in dry air (![]() $c_\infty = 0$) at 20

$c_\infty = 0$) at 20 ![]() $^\circ$C (

$^\circ$C (![]() $c_{sat} = 1.72 \times 10^{-2}$ kg s

$c_{sat} = 1.72 \times 10^{-2}$ kg s![]() $^{-1}$ and

$^{-1}$ and ![]() ${\mathcal {D}}_{v} = 2.36 \times 10^{-5}$ m

${\mathcal {D}}_{v} = 2.36 \times 10^{-5}$ m![]() $^2$ s

$^2$ s![]() $^{-1}$) (Lide Reference Lide2008). We obtained

$^{-1}$) (Lide Reference Lide2008). We obtained ![]() $v_{e}^0 \approx 4 \times 10^{-7}$ m s

$v_{e}^0 \approx 4 \times 10^{-7}$ m s![]() $^{-1}$. From (A4), we can calculate the wetted length of the sessile droplet having the same evaporation rate for the same ambient conditions. We find a similar length scale

$^{-1}$. From (A4), we can calculate the wetted length of the sessile droplet having the same evaporation rate for the same ambient conditions. We find a similar length scale ![]() $R \approx L$. For instance, the barrel-shaped drop on a fibre of radius

$R \approx L$. For instance, the barrel-shaped drop on a fibre of radius ![]() $a = 125\,\mathrm {\mu }$m has, initially, a wetted-length

$a = 125\,\mathrm {\mu }$m has, initially, a wetted-length ![]() $L \approx 8.4 \times 10^{-4}$ m and a sessile drop evaporating at the same initial rate has a wetted length

$L \approx 8.4 \times 10^{-4}$ m and a sessile drop evaporating at the same initial rate has a wetted length ![]() $R \approx 8.9 \times 10^{-4}$ m. We thus choose to make comparisons at the same wetted length

$R \approx 8.9 \times 10^{-4}$ m. We thus choose to make comparisons at the same wetted length ![]() $L/a \approx 6.7$ which is given by fitting Carroll's profile with (2.1), as explained in § 2 (see figure 1b). For the same wetted length and the same initial contact angle, the initial volume of the droplet is different in the two geometries. For example, for

$L/a \approx 6.7$ which is given by fitting Carroll's profile with (2.1), as explained in § 2 (see figure 1b). For the same wetted length and the same initial contact angle, the initial volume of the droplet is different in the two geometries. For example, for ![]() $L = R \approx 8.4\times 10^{-4}$ m and

$L = R \approx 8.4\times 10^{-4}$ m and ![]() $\theta _{i} = 15^\circ$, the initial volume is

$\theta _{i} = 15^\circ$, the initial volume is ![]() $\varOmega (t = 0) \approx 0.1\,\mathrm {\mu }$L for the sessile case and

$\varOmega (t = 0) \approx 0.1\,\mathrm {\mu }$L for the sessile case and ![]() $\varOmega (t = 0) \approx 0.6\,\mathrm {\mu }$L for the drop on a fibre. The sessile drop has a smaller initial volume and thus a shorter lifetime than the drop on a fibre even if the initial evaporation rate is the same in the two geometries. Additionally, since the particle transport depends on the particle size, we consider a particle diameter

$\varOmega (t = 0) \approx 0.6\,\mathrm {\mu }$L for the drop on a fibre. The sessile drop has a smaller initial volume and thus a shorter lifetime than the drop on a fibre even if the initial evaporation rate is the same in the two geometries. Additionally, since the particle transport depends on the particle size, we consider a particle diameter ![]() $2b=1\,\mathrm {\mu }$m motivated by the large number of studies on the coffee-stain using micrometer-sized particles.

$2b=1\,\mathrm {\mu }$m motivated by the large number of studies on the coffee-stain using micrometer-sized particles.

To summarise, we choose to compare drops of same wetting length and same initial contact angle. This corresponds to drops having different initial volumes but the same initial evaporation rate for the two different geometries when evaporating in the same ambient conditions. In this framework, we can compare the mean velocities toward the contact line for the two systems. The competition between the particle transport and the Brownian motion will be rationalised by a Péclet number.

3.2. Time evolution of the drop shapes

We analyse the evolution of the drop shape in both configurations. The temporal evolution of drop heights, plotted in figure 3(c), are given by (2.18) (blue solid line) approximated by (2.19) (dashed line) for the drop on a fibre and (A2) (black line) for the sessile drop.

Figure 3. (a,b) Evolution of the drop shape at different contact angles in (a) the sessile case (A1) and (b) the fibre configuration for which the drop profile is described by elliptic integrals given by Carroll (Reference Carroll1976). (c) Time evolution of the drop height at the apex ![]() $h_0$ normalised by the initial height

$h_0$ normalised by the initial height ![]() $h_{i}$ for the two configurations. The black line corresponds to the sessile drop (A2). The blue lines are for an axisymmetric drop on a fibre, the solid line is (2.18) and the dashed line is the approximation given by (2.19). (d) Dynamics of the contact angle

$h_{i}$ for the two configurations. The black line corresponds to the sessile drop (A2). The blue lines are for an axisymmetric drop on a fibre, the solid line is (2.18) and the dashed line is the approximation given by (2.19). (d) Dynamics of the contact angle ![]() $\theta$ for a sessile drop. (c,d) Circles represent (c) the apex heights and (d) contact angles of the profiles of drops on fibres obtained with our ansatz (2.1) and plotted in figure 1(b). Here, the comparisons are performed for the same wetted length

$\theta$ for a sessile drop. (c,d) Circles represent (c) the apex heights and (d) contact angles of the profiles of drops on fibres obtained with our ansatz (2.1) and plotted in figure 1(b). Here, the comparisons are performed for the same wetted length ![]() ${\mathcal {L}}/a \approx 6.7$ and an initial contact angle

${\mathcal {L}}/a \approx 6.7$ and an initial contact angle ![]() $\theta _{i} = 15^\circ$. This corresponds to water on a glass substrate of initial volume

$\theta _{i} = 15^\circ$. This corresponds to water on a glass substrate of initial volume ![]() $\varOmega (t=0) \approx 0.6\,\mathrm {\mu }$L for the fibre configuration (

$\varOmega (t=0) \approx 0.6\,\mathrm {\mu }$L for the fibre configuration (![]() $a = 125\,\mathrm {\mu }$m) and

$a = 125\,\mathrm {\mu }$m) and ![]() $\varOmega (t=0) \approx 0.1\,\mathrm {\mu }$L for the sessile case. The initial evaporation rate

$\varOmega (t=0) \approx 0.1\,\mathrm {\mu }$L for the sessile case. The initial evaporation rate ![]() $Q_{e}(t=0)$ is nearly the same for the two configurations. For both geometries, the ambient conditions are taken to be those of water evaporating in dry air at 20

$Q_{e}(t=0)$ is nearly the same for the two configurations. For both geometries, the ambient conditions are taken to be those of water evaporating in dry air at 20 ![]() $^\circ$C,

$^\circ$C, ![]() $c_{sat} = 1.72 \times 10^{-2}$ kg m

$c_{sat} = 1.72 \times 10^{-2}$ kg m![]() $^{-3}$,

$^{-3}$, ![]() $c_\infty = 0$ and

$c_\infty = 0$ and ![]() ${\mathcal {D}}_{v} = 2.36 \times 10^{-5}$ m

${\mathcal {D}}_{v} = 2.36 \times 10^{-5}$ m![]() $^2$ s

$^2$ s![]() $^{-1}$ (Lide Reference Lide2008). In these conditions, for a drop on a fibre (

$^{-1}$ (Lide Reference Lide2008). In these conditions, for a drop on a fibre (![]() $\varOmega = 1\,\mathrm {\mu }$L,

$\varOmega = 1\,\mathrm {\mu }$L, ![]() $\theta = 10^\circ$ and

$\theta = 10^\circ$ and ![]() $a = 125\,\mathrm {\mu }$m), we obtained by numerical simulations

$a = 125\,\mathrm {\mu }$m), we obtained by numerical simulations ![]() $v_{e}^0 \approx 4 \times 10^{-7}$ m s

$v_{e}^0 \approx 4 \times 10^{-7}$ m s![]() $^{-1}$,

$^{-1}$, ![]() $\alpha = 0.7$ and

$\alpha = 0.7$ and ![]() $\beta = 0.1$ (figure 2).

$\beta = 0.1$ (figure 2).

The evolution of the drop shape for different contact angles for a sessile drop is illustrated in figure 3(a). Due to the particle accumulation at the contact line that increases the pinning force (Joanny & de Gennes Reference Joanny and de Gennes1984; di Meglio Reference di Meglio1992; Boulogne et al. Reference Boulogne, Ingremeau, Limat and Stone2016), we consider that the depinning nearly occurs at a zero contact angle, which corresponds to a vanishing drop volume. Now, considering the drop on a fibre, we plot in figure 3(b) the drop shape on a fibre having the same wetted length and the same contact angles as the sessile drops in figure 3(a). By fitting the profiles of figure 3(b) with (2.1), we get the apex heights and the corresponding times by inserting them in (2.18). The results are represented by the circles in figure 3(c). This figure shows that the temporal evolution of the apex height of a drop on a fibre is well described by the approximated equation (2.19) (the dashed line in figure 3c) during the pinned-regime.

From figure 3(a,b), we also get the height of the apex at the depinning ![]() $h_0^{dep} = h_0(\theta = 0)$. In the example studied here, we get

$h_0^{dep} = h_0(\theta = 0)$. In the example studied here, we get ![]() $h_0^{dep} = 0$ for the sessile drop and

$h_0^{dep} = 0$ for the sessile drop and ![]() $h_0^{dep} = 2.4a$ (corresponding to

$h_0^{dep} = 2.4a$ (corresponding to ![]() $h_0^{dep} = 0.8 h_{i}$) for the drop on a fibre. From that, we get the duration of the pinned regime

$h_0^{dep} = 0.8 h_{i}$) for the drop on a fibre. From that, we get the duration of the pinned regime ![]() $\tau _{dep}$ of the drop on a fibre by inserting

$\tau _{dep}$ of the drop on a fibre by inserting ![]() $h_0^{dep}$ into (2.18). In the example studied here, we find

$h_0^{dep}$ into (2.18). In the example studied here, we find ![]() $\tau _{dep} \approx 110$ s. In the case of the sessile drop, the volume tends to zero at the end of the pinned regime, meaning that

$\tau _{dep} \approx 110$ s. In the case of the sessile drop, the volume tends to zero at the end of the pinned regime, meaning that ![]() $\tau _{dep} = \tau _{e}$ (A5), the lifetime of a sessile drop evaporating entirely at constant contact radius. In the example studied here, we find

$\tau _{dep} = \tau _{e}$ (A5), the lifetime of a sessile drop evaporating entirely at constant contact radius. In the example studied here, we find ![]() $\tau _{e} \approx 90$ s. To establish the relationship between time and contact angle, we plot in figure 3(d) (circles) the temporal evolution of contact angle obtained from the drop profiles represented in figure 3(b) for which we know

$\tau _{e} \approx 90$ s. To establish the relationship between time and contact angle, we plot in figure 3(d) (circles) the temporal evolution of contact angle obtained from the drop profiles represented in figure 3(b) for which we know ![]() $h_0$ and

$h_0$ and ![]() $\theta$. By the solid black line, we represent

$\theta$. By the solid black line, we represent ![]() $\theta (t) = \theta _{i} (1 - {t}/{\tau _{dep}})$ valid for a sessile drop (A2) which also describes very well the temporal evolution of the contact angle of a drop on a fibre. We thus find for both geometries that

$\theta (t) = \theta _{i} (1 - {t}/{\tau _{dep}})$ valid for a sessile drop (A2) which also describes very well the temporal evolution of the contact angle of a drop on a fibre. We thus find for both geometries that ![]() $h_0 \propto \theta \propto t$.

$h_0 \propto \theta \propto t$.

Moreover, as observed in figure 3(b,c), the relative variation of the drop height ![]() $h_0$ (and drop volume) during the pinned regime is small for the drop on a fibre. During the pinned regime, a small amount of the initial volume has evaporated, which means that the duration of the pinned regime is short compared to the drop lifetime

$h_0$ (and drop volume) during the pinned regime is small for the drop on a fibre. During the pinned regime, a small amount of the initial volume has evaporated, which means that the duration of the pinned regime is short compared to the drop lifetime ![]() $\tau _{dep} \ll \tau _{e}$. The remarkable difference with the sessile drop is the significant liquid volume remaining at a zero contact angle, the contact angle at which the depinning is supposed to occur. We can estimate the remaining volume at the end of the pinned regime from (2.2). For the geometry represented in figure 3(b), we find that only

$\tau _{dep} \ll \tau _{e}$. The remarkable difference with the sessile drop is the significant liquid volume remaining at a zero contact angle, the contact angle at which the depinning is supposed to occur. We can estimate the remaining volume at the end of the pinned regime from (2.2). For the geometry represented in figure 3(b), we find that only ![]() $35\,\%$ of the initial volume has evaporated before the contact line depinning.

$35\,\%$ of the initial volume has evaporated before the contact line depinning.

From this comparison, we can state that the geometry imposes constraints on the dynamics of the drop profile. In particular, in contrast to the sessile drop, only a small fraction of the liquid volume can evaporate in the constant wetted length regime. Also, on a fibre, a drop has two contact lines such that we expect that only one of the two lines depins. At this time, the lower quantity of evaporated liquid implies that only a fraction of the particles are accumulated at the contact lines and that the complementary fraction of particles is still dispersed in the liquid phase. However, to compute the number of accumulated particles at the contact line, the velocity field inside the drop needs to be described, which is the object of the next section.

3.3. Transport of particles towards the contact line

3.3.1. Mean flow velocity towards the contact line

In figure 4(a), we plot ![]() $\bar {v}_x$ for both geometries,

$\bar {v}_x$ for both geometries, ![]() $x$ being either

$x$ being either ![]() $z$ or

$z$ or ![]() $r$ according to the geometry. In the centre,

$r$ according to the geometry. In the centre, ![]() $x=0$, the fluid velocity is equal to zero by symmetry. We observe that at the beginning of evaporation, i.e. for

$x=0$, the fluid velocity is equal to zero by symmetry. We observe that at the beginning of evaporation, i.e. for ![]() $\theta = 15^\circ$, the flow towards the contact line is one order of magnitude higher in the sessile drop at most of the radial positions. Near the contact line, the mean liquid velocity diverges due to the vanishing liquid thickness for both geometries. As the liquid evaporates, i.e.

$\theta = 15^\circ$, the flow towards the contact line is one order of magnitude higher in the sessile drop at most of the radial positions. Near the contact line, the mean liquid velocity diverges due to the vanishing liquid thickness for both geometries. As the liquid evaporates, i.e. ![]() $\theta$ decreases, the so-called rush-hour effect (Hamamoto et al. Reference Hamamoto, Christy and Sefiane2011; Marin et al. Reference Marin, Gelderblom, Lohse and Snoeijer2011a) occurs in the sessile drop, i.e.

$\theta$ decreases, the so-called rush-hour effect (Hamamoto et al. Reference Hamamoto, Christy and Sefiane2011; Marin et al. Reference Marin, Gelderblom, Lohse and Snoeijer2011a) occurs in the sessile drop, i.e. ![]() $\bar {v}_r$ increases in time. However,

$\bar {v}_r$ increases in time. However, ![]() $\bar {v}_z$ remains nearly constant for a drop on a fibre. This difference is due to the curvature of the substrate that enables the existence of the peculiar axisymmetric barrel morphology, for which the variation of the drop profile remains limited when

$\bar {v}_z$ remains nearly constant for a drop on a fibre. This difference is due to the curvature of the substrate that enables the existence of the peculiar axisymmetric barrel morphology, for which the variation of the drop profile remains limited when ![]() $\theta$ decreases (see figure 3b) unlike the case of the spherical cap on a flat substrate (figure 3a).

$\theta$ decreases (see figure 3b) unlike the case of the spherical cap on a flat substrate (figure 3a).

Figure 4. (a) Mean velocity of the flow towards the contact line ![]() $\bar {v}_x$ as a function of the dimensionless coordinate

$\bar {v}_x$ as a function of the dimensionless coordinate ![]() $x/{\mathcal {L}}$ along the solid surface. The comparison is performed for water drops in both configurations with the same dimensionless wetted length

$x/{\mathcal {L}}$ along the solid surface. The comparison is performed for water drops in both configurations with the same dimensionless wetted length ![]() $\mathcal {L}/a \approx 6.7$ and various contact angles (see caption). Dashed lines correspond to

$\mathcal {L}/a \approx 6.7$ and various contact angles (see caption). Dashed lines correspond to ![]() $\bar {v}_r$ (A6), the average fluid velocity towards the contact line in sessile drops. Solid lines are

$\bar {v}_r$ (A6), the average fluid velocity towards the contact line in sessile drops. Solid lines are ![]() $\bar {v}_z$, the average fluid velocity in a drop on a fibre, given by (2.21). The dependence of

$\bar {v}_z$, the average fluid velocity in a drop on a fibre, given by (2.21). The dependence of ![]() $\bar {v}_z$ in

$\bar {v}_z$ in ![]() $\theta$ is implicit and contained in the dimensions of the drop which are obtained by fitting Carroll's drop profile with (2.1) for each contact angle, as done in figure 1(b). (b) Péclet number

$\theta$ is implicit and contained in the dimensions of the drop which are obtained by fitting Carroll's drop profile with (2.1) for each contact angle, as done in figure 1(b). (b) Péclet number ![]() $\overline {Pe}$ deduced from the mean velocity and drop profile (2.1) and (A1) as a function of

$\overline {Pe}$ deduced from the mean velocity and drop profile (2.1) and (A1) as a function of ![]() $x/{\mathcal {L}}$. Solid lines correspond to a drop on a fibre and dashed lines to sessile drops having the same wetted length. The solid red line corresponds to

$x/{\mathcal {L}}$. Solid lines correspond to a drop on a fibre and dashed lines to sessile drops having the same wetted length. The solid red line corresponds to ![]() $\overline {Pe}=1$. For both geometries, the ambient conditions are taken to be those of water evaporating in dry air at 20

$\overline {Pe}=1$. For both geometries, the ambient conditions are taken to be those of water evaporating in dry air at 20 ![]() $^\circ$C, described in the § 3.1 and in figure 3.

$^\circ$C, described in the § 3.1 and in figure 3.

3.3.2. Péclet number

To describe the effective transport of particles towards the contact line, the action of the liquid flow on the particles must be compared to the Brownian motion. Particles are transported by the shear flow in the drop characterised by the mean shear rate ![]() $\bar {\dot \gamma } = \bar {v}(x,t) / h(x,t)$ and also by the Brownian motion

$\bar {\dot \gamma } = \bar {v}(x,t) / h(x,t)$ and also by the Brownian motion ![]() ${\mathcal {D}} = k_{B}T / (6{\rm \pi} \eta b)$, where

${\mathcal {D}} = k_{B}T / (6{\rm \pi} \eta b)$, where ![]() $k_{B}$ is the Boltzmann constant and

$k_{B}$ is the Boltzmann constant and ![]() $T$ the temperature. To compare these two competing forces, we introduce the mean Péclet number

$T$ the temperature. To compare these two competing forces, we introduce the mean Péclet number ![]() $\overline {Pe}$ defined as

$\overline {Pe}$ defined as ![]() $\overline {Pe} = \bar {\dot \gamma } b^2 / {\mathcal {D}}$ (Bossis & Brady Reference Bossis and Brady1989).

$\overline {Pe} = \bar {\dot \gamma } b^2 / {\mathcal {D}}$ (Bossis & Brady Reference Bossis and Brady1989).

In figure 4(b), we plot the mean Péclet number ![]() $\overline {Pe}$ as a function of the dimensionless position along the solid surface

$\overline {Pe}$ as a function of the dimensionless position along the solid surface ![]() $x/{\mathcal {L}}$. As previously, we observe that, initially, the mean Péclet number is comparable in the two geometries and diverges in the vicinity of the triple line where the liquid height vanishes. As the liquid evaporates, the mean Péclet number strongly increases in the sessile case while it remains constant for the barrel-shaped drop on a fibre. Again, we attribute these differences to the difference of morphology between the droplets due to the curvature of the substrate.

$x/{\mathcal {L}}$. As previously, we observe that, initially, the mean Péclet number is comparable in the two geometries and diverges in the vicinity of the triple line where the liquid height vanishes. As the liquid evaporates, the mean Péclet number strongly increases in the sessile case while it remains constant for the barrel-shaped drop on a fibre. Again, we attribute these differences to the difference of morphology between the droplets due to the curvature of the substrate.

3.4. Number of particles accumulating at the contact line

3.4.1. Advection of a slice of fluid

We consider a fluid layer at a position ![]() $x_0$ of an infinitesimal width

$x_0$ of an infinitesimal width ![]() ${\rm d}\kern 0.06em x$, which is advected towards the contact line at a velocity

${\rm d}\kern 0.06em x$, which is advected towards the contact line at a velocity ![]() $\bar {v}_x(x_0, t)$. The advection of a fluid layer is described by its position

$\bar {v}_x(x_0, t)$. The advection of a fluid layer is described by its position ![]() $x_0(t)$ that satisfies (Deegan Reference Deegan2000; Popov Reference Popov2005; Monteux & Lequeux Reference Monteux and Lequeux2011; Berteloot et al. Reference Berteloot, Hoang, Daerr, Kavehpour, Lequeux and Limat2012)

$x_0(t)$ that satisfies (Deegan Reference Deegan2000; Popov Reference Popov2005; Monteux & Lequeux Reference Monteux and Lequeux2011; Berteloot et al. Reference Berteloot, Hoang, Daerr, Kavehpour, Lequeux and Limat2012)

For the sessile drop, the solution is recalled in Appendix A (A9) and is represented in figure 5 as a solid black line. For the fibre, the complexity of (2.21) makes us unable to find an analytical solution of the differential equation (3.1). Instead, we proceed to a numerical integration with odeint from scipy (Jones, Oliphant & Peterson Reference Jones, Oliphant and Peterson2001). The solution is plotted as a solid blue line in figure 5.

Figure 5. Temporal evolution of the dimensionless positions of the advected fluid layer ![]() $x_0/{\mathcal {L}}$ (solid lines) and of

$x_0/{\mathcal {L}}$ (solid lines) and of ![]() $x^\star /{\mathcal {L}}$ (dashed lines), the positions beyond which the Péclet number is greater than unity. Blue lines are used for axisymmetric drops on fibres and black lines for sessile drops. Here, the comparison between the two geometries is performed in the conditions described in § 3.1 and in figure 3.

$x^\star /{\mathcal {L}}$ (dashed lines), the positions beyond which the Péclet number is greater than unity. Blue lines are used for axisymmetric drops on fibres and black lines for sessile drops. Here, the comparison between the two geometries is performed in the conditions described in § 3.1 and in figure 3.

We define ![]() $x^\star$ as the position along the solid surface for which

$x^\star$ as the position along the solid surface for which ![]() $\overline {Pe}(x^\star ) = 1$. For

$\overline {Pe}(x^\star ) = 1$. For ![]() $x > x^\star$, we have

$x > x^\star$, we have ![]() $\overline {Pe} > 1$ such that the particles advection by the flow overcome their Brownian diffusion. The particles in the volume of liquid enclosed between

$\overline {Pe} > 1$ such that the particles advection by the flow overcome their Brownian diffusion. The particles in the volume of liquid enclosed between ![]() $x = x^\star$ and

$x = x^\star$ and ![]() $x = {\mathcal {L}}$ are advected by the flow and transported to the triple line.

$x = {\mathcal {L}}$ are advected by the flow and transported to the triple line.

In figure 5, we plot by dashed lines ![]() $x^\star /{\mathcal {L}}$ as a function of the dimensionless time for the two geometries. At the beginning of the drying,

$x^\star /{\mathcal {L}}$ as a function of the dimensionless time for the two geometries. At the beginning of the drying, ![]() $x^\star /{\mathcal {L}}$ is close to unity for both geometries. This means that the region over which the particles are transported by the liquid flow, corresponding to the region between

$x^\star /{\mathcal {L}}$ is close to unity for both geometries. This means that the region over which the particles are transported by the liquid flow, corresponding to the region between ![]() $x =x^\star$ and

$x =x^\star$ and ![]() $x= {\mathcal {L}}$, is localised in the close vicinity of the contact line at the beginning of evaporation. We even note that initially, this region is smaller for a sessile drop than for a drop on a fibre

$x= {\mathcal {L}}$, is localised in the close vicinity of the contact line at the beginning of evaporation. We even note that initially, this region is smaller for a sessile drop than for a drop on a fibre ![]() $r^\star /R < z^\star /L$. Thus, at the beginning of evaporation, the transport of the particles towards the contact line is more efficient for the drop on a fibre. However, as the sessile drop evaporates, the region boundary position

$r^\star /R < z^\star /L$. Thus, at the beginning of evaporation, the transport of the particles towards the contact line is more efficient for the drop on a fibre. However, as the sessile drop evaporates, the region boundary position ![]() $r^\star /R$ continuously decreases to reach zero at the end of the pinned regime (

$r^\star /R$ continuously decreases to reach zero at the end of the pinned regime (![]() $t = \tau _{dep}$). On the fibre,

$t = \tau _{dep}$). On the fibre, ![]() $z^\star /L$ remains nearly constant, close to unity. In other words, the width of the attraction zone in a sessile drop grows as the liquid evaporates. Progressively, this zone occupies the entire drop, which leads to transport of the majority of the suspended particles towards the contact line. This is not the case for the drop on a fibre for which the zones in which the particles are effectively transported by the flow to the contact lines remain small and located in the close vicinity of the triple line.

$z^\star /L$ remains nearly constant, close to unity. In other words, the width of the attraction zone in a sessile drop grows as the liquid evaporates. Progressively, this zone occupies the entire drop, which leads to transport of the majority of the suspended particles towards the contact line. This is not the case for the drop on a fibre for which the zones in which the particles are effectively transported by the flow to the contact lines remain small and located in the close vicinity of the triple line.

The curves presented in figure 5 provide a comparison of the relative positions of ![]() $x^\star$ (dashed lines) and

$x^\star$ (dashed lines) and ![]() $x_0$ (solid lines). During most of the pinned contact line regime, the area bounded by the position of the advected fluid layer

$x_0$ (solid lines). During most of the pinned contact line regime, the area bounded by the position of the advected fluid layer ![]() $x_0$ includes small and large Péclet numbers domains (

$x_0$ includes small and large Péclet numbers domains (![]() $x_0 < x^\star <\mathcal {L}$). Exceptions are noticed at short time scales after evaporation starts and at the end of the pinned regime for the sessile drop.

$x_0 < x^\star <\mathcal {L}$). Exceptions are noticed at short time scales after evaporation starts and at the end of the pinned regime for the sessile drop.

3.4.2. Particle accumulation dynamics in the large Péclet domain –  $x^\star < x_0$

$x^\star < x_0$

If ![]() $x^\star < x_0$, i.e.

$x^\star < x_0$, i.e. ![]() $\overline {Pe} > 1$ between

$\overline {Pe} > 1$ between ![]() $x_0$ and

$x_0$ and ![]() $\mathcal {L}$, the particles in this layer are transported towards the contact line such that their number is conserved. On the fibre, from the initial concentration (number of particles per unit volume)

$\mathcal {L}$, the particles in this layer are transported towards the contact line such that their number is conserved. On the fibre, from the initial concentration (number of particles per unit volume) ![]() $c_{i}$ and the initial liquid profile

$c_{i}$ and the initial liquid profile ![]() $h(z, t = 0)$, the number of particles

$h(z, t = 0)$, the number of particles ![]() $N_{{CL}}$ accumulated at each contact line can be written as

$N_{{CL}}$ accumulated at each contact line can be written as

\begin{equation} N^{fibre}_{{CL}}(t) = c_{i} \int_a^{a+h(z, t = 0)} \int_0^{2{\rm \pi}} \int_{z_0(t)}^L r \,{\rm d} r \, {\rm d} \theta \, {\rm d} z, \end{equation}

\begin{equation} N^{fibre}_{{CL}}(t) = c_{i} \int_a^{a+h(z, t = 0)} \int_0^{2{\rm \pi}} \int_{z_0(t)}^L r \,{\rm d} r \, {\rm d} \theta \, {\rm d} z, \end{equation}which gives

with ![]() $\mathcal {P}_3(x) = - ({x^{9}}/{9}) + {4 x^{7}}/{7} - {6 x^{5}}/{5} + {4 x^{3}}/{3} - x + \frac {128}{315}$ and

$\mathcal {P}_3(x) = - ({x^{9}}/{9}) + {4 x^{7}}/{7} - {6 x^{5}}/{5} + {4 x^{3}}/{3} - x + \frac {128}{315}$ and ![]() $\mathcal {P}_4(x) =- ({x^{5}}/{5}) + {2 x^{3}}/{3} - x + \frac {8}{15}$. The above equation is shown as a dashed blue line in figure 6. The equivalent calculation for the sessile drop is recalled in Appendix A.1 (A11) and is represented by the dashed grey line in figure 6.

$\mathcal {P}_4(x) =- ({x^{5}}/{5}) + {2 x^{3}}/{3} - x + \frac {8}{15}$. The above equation is shown as a dashed blue line in figure 6. The equivalent calculation for the sessile drop is recalled in Appendix A.1 (A11) and is represented by the dashed grey line in figure 6.

Figure 6. Time evolution of the dimensionless number of particles at the contact line ![]() $N_{CL}/N_{tot}$. Blue lines represent axisymmetric drops on fibres and black lines sessile drops. Solid lines are obtained from (3.3) (fibre) or (A11) (sessile) when

$N_{CL}/N_{tot}$. Blue lines represent axisymmetric drops on fibres and black lines sessile drops. Solid lines are obtained from (3.3) (fibre) or (A11) (sessile) when ![]() $x_0 \geq x^\star$ and from (3.5) (fibre) or (A13) (sessile) when

$x_0 \geq x^\star$ and from (3.5) (fibre) or (A13) (sessile) when ![]() $x_0 \leq x^\star$. The dashed lines represent the results obtained under the assumption that all particles contained between

$x_0 \leq x^\star$. The dashed lines represent the results obtained under the assumption that all particles contained between ![]() $x_0$ and

$x_0$ and ![]() $\mathcal {L}$ are transported to the contact line and are plotted from (A11) for a sessile drop (grey dashed line) and (3.3) for a drop on a fibre (blue dashed line). Here, the comparison between the two geometries is performed in the conditions described in § 3.1 and in figure 3. The inset shows the temporal evolution of the number of particles

$\mathcal {L}$ are transported to the contact line and are plotted from (A11) for a sessile drop (grey dashed line) and (3.3) for a drop on a fibre (blue dashed line). Here, the comparison between the two geometries is performed in the conditions described in § 3.1 and in figure 3. The inset shows the temporal evolution of the number of particles ![]() $N_{CL}$ plotted in solid lines in the main figure for an initial particle concentration

$N_{CL}$ plotted in solid lines in the main figure for an initial particle concentration ![]() $c_{i} = 1 \times 10^8$ particles mL

$c_{i} = 1 \times 10^8$ particles mL![]() $^{-1}$.

$^{-1}$.

3.4.3. Particle accumulation dynamics over small and large Péclet domains –  $x^\star \geq x_0$

$x^\star \geq x_0$

Now, if positions ![]() $x^\star$ and

$x^\star$ and ![]() $x_0$ are swapped, the number of accumulated particles is decomposed from two contributions. The first contribution, from

$x_0$ are swapped, the number of accumulated particles is decomposed from two contributions. The first contribution, from ![]() $x^\star$ to

$x^\star$ to ![]() ${\mathcal {L}}$, is equivalent to (3.2). In this large Péclet domain, all the particles are advected with an increasing particle concentration as evaporation proceeds. Between

${\mathcal {L}}$, is equivalent to (3.2). In this large Péclet domain, all the particles are advected with an increasing particle concentration as evaporation proceeds. Between ![]() $x_0$ and

$x_0$ and ![]() $x^\star$, the small Péclet number indicates that Brownian motion maintains a uniform particle concentration. Once the fluid layer reaches

$x^\star$, the small Péclet number indicates that Brownian motion maintains a uniform particle concentration. Once the fluid layer reaches ![]() $x^\star$, particles are advected and concentrated as it is between

$x^\star$, particles are advected and concentrated as it is between ![]() $x^\star$ and

$x^\star$ and ![]() ${\mathcal {L}}$. Therefore, we evaluate the number of particles in the fluid layer at the position

${\mathcal {L}}$. Therefore, we evaluate the number of particles in the fluid layer at the position ![]() $x^\star$ with a particle concentration

$x^\star$ with a particle concentration ![]() $c_{i}$. The sum of these two contributions gives

$c_{i}$. The sum of these two contributions gives

\begin{equation} N^{fibre}_{{CL}}(t) = c_{i} \int_a^{a+h(z, t = 0)} \int_0^{2{\rm \pi}} \int_{z^\star}^L r {\rm d} r \, {\rm d} \theta \, {\rm d} z + c_{i} \int_a^{a+h(z^\star, t=0)} \int_0^{2{\rm \pi}} \int_{z_0(t)}^{z^\star} r \,{\rm d} r \, {\rm d} \theta \, {\rm d} z. \end{equation}

\begin{equation} N^{fibre}_{{CL}}(t) = c_{i} \int_a^{a+h(z, t = 0)} \int_0^{2{\rm \pi}} \int_{z^\star}^L r {\rm d} r \, {\rm d} \theta \, {\rm d} z + c_{i} \int_a^{a+h(z^\star, t=0)} \int_0^{2{\rm \pi}} \int_{z_0(t)}^{z^\star} r \,{\rm d} r \, {\rm d} \theta \, {\rm d} z. \end{equation}After integration, we obtain

\begin{align} N^{fibre}_{CL}(t) &= {\rm \pi}c_{i} h_{i} L \left[h_{i}\left(\mathcal{P}_3\left(\frac{z^\star}{L}\right) + \left(1 - \left(\frac{z^\star}{L}\right)^2\right)^4 \left(\frac{z^\star}{L} - \frac{z_0}{L}\right) \right) \right. \nonumber\\ &\left. + 2a\left(\mathcal{P}_4\left(\frac{z^\star}{L}\right) + \left(1 - \left(\frac{z^\star}{L}\right)^2\right)^2 \left(\frac{z^\star}{L} - \frac{z_0}{L}\right) \right) \right]. \end{align}

\begin{align} N^{fibre}_{CL}(t) &= {\rm \pi}c_{i} h_{i} L \left[h_{i}\left(\mathcal{P}_3\left(\frac{z^\star}{L}\right) + \left(1 - \left(\frac{z^\star}{L}\right)^2\right)^4 \left(\frac{z^\star}{L} - \frac{z_0}{L}\right) \right) \right. \nonumber\\ &\left. + 2a\left(\mathcal{P}_4\left(\frac{z^\star}{L}\right) + \left(1 - \left(\frac{z^\star}{L}\right)^2\right)^2 \left(\frac{z^\star}{L} - \frac{z_0}{L}\right) \right) \right]. \end{align}The same calculation is performed in Appendix A.1 for the sessile drop.

Using the appropriate conditions according to the relative positions of ![]() $x_0$ and

$x_0$ and ![]() $x^\star$ shown in figure 5, we plot by solid lines in figure 6 the dimensionless number of particles accumulated at the contact line. In the inset of figure 6, we plot the number of particles accumulated at the triple line over time for an initial concentration of

$x^\star$ shown in figure 5, we plot by solid lines in figure 6 the dimensionless number of particles accumulated at the contact line. In the inset of figure 6, we plot the number of particles accumulated at the triple line over time for an initial concentration of ![]() $c_{i} = 1 \times 10^8$ particles mL

$c_{i} = 1 \times 10^8$ particles mL![]() $^{-1}$.

$^{-1}$.

Figure 6 (grey dashed line) shows that the classical calculation (Deegan et al. Reference Deegan, Bakajin, Dupont, Huber, Nagel and Witten2000; Popov Reference Popov2005; Monteux & Lequeux Reference Monteux and Lequeux2011; Berteloot et al. Reference Berteloot, Hoang, Daerr, Kavehpour, Lequeux and Limat2012; Boulogne et al. Reference Boulogne, Ingremeau and Stone2017), made in the literature for a sessile drop, valid if all the particles contained between ![]() $x_0$ and

$x_0$ and ![]() $\mathcal {L}$ are transported by the flow, leads to overestimate the number of particles accumulated at the triple line during the first part of the pinned regime. However, at the end of the drying, the liquid height tends towards 0 which leads to

$\mathcal {L}$ are transported by the flow, leads to overestimate the number of particles accumulated at the triple line during the first part of the pinned regime. However, at the end of the drying, the liquid height tends towards 0 which leads to ![]() $\overline {Pe} > 1$ in almost the entire drop (cf. figure 5) i.e.

$\overline {Pe} > 1$ in almost the entire drop (cf. figure 5) i.e. ![]() $r^\star \leq r_0$. The result is that almost all the particles are transported and deposited at the initial position of the contact line during drying, which corresponds to a typical density of

$r^\star \leq r_0$. The result is that almost all the particles are transported and deposited at the initial position of the contact line during drying, which corresponds to a typical density of ![]() $N_{tot} / 2{\rm \pi} R \approx 2$ particles

$N_{tot} / 2{\rm \pi} R \approx 2$ particles ![]() $\mathrm {\mu }$m

$\mathrm {\mu }$m![]() $^{-1}$ in the final deposit. In practice, we must note also that the threshold value

$^{-1}$ in the final deposit. In practice, we must note also that the threshold value ![]() $\overline {Pe} = 1$ is arbitrary and must be adjusted for a fine quantitative description.

$\overline {Pe} = 1$ is arbitrary and must be adjusted for a fine quantitative description.

For a drop on a fibre, however, ![]() $z^\star$ is almost constant and therefore during most of the pinned regime,

$z^\star$ is almost constant and therefore during most of the pinned regime, ![]() $z^\star > z_0$ which means that the classical calculation of (3.3), represented by blue dashed line in figure 6, overestimates the number of particles accumulated at the contact line. Indeed, taking into account the fact that Brownian diffusion dominates in the zone between

$z^\star > z_0$ which means that the classical calculation of (3.3), represented by blue dashed line in figure 6, overestimates the number of particles accumulated at the contact line. Indeed, taking into account the fact that Brownian diffusion dominates in the zone between ![]() $z_0$ and

$z_0$ and ![]() $z^\star$, we obtain a number of particles accumulated at the edge of the drop that is ten times lower than the one obtained by considering that all the particles between

$z^\star$, we obtain a number of particles accumulated at the edge of the drop that is ten times lower than the one obtained by considering that all the particles between ![]() $z_0$ and

$z_0$ and ![]() $z^\star$ are advected by the flow.

$z^\star$ are advected by the flow.

Figure 6 also shows that the particles contained in the drop on a fibre are transported towards the contact lines. At the end of the pinned regime, the number of particles accumulated at the initial positions of the triple lines of a drop on a fibre corresponds to ![]() $N_{CL}(\tau _{dep}) / 2 {\rm \pi}a = 0.2$ particles

$N_{CL}(\tau _{dep}) / 2 {\rm \pi}a = 0.2$ particles ![]() $\mathrm {\mu }$m

$\mathrm {\mu }$m![]() $^{-1}$, which is approximately 10 times lower than the sessile drop. As shown in the inset, the duration of the pinned regime is approximately the same in both geometries

$^{-1}$, which is approximately 10 times lower than the sessile drop. As shown in the inset, the duration of the pinned regime is approximately the same in both geometries ![]() $\tau _{dep}^{fibre} \approx 110$ s and

$\tau _{dep}^{fibre} \approx 110$ s and ![]() $\tau _{dep}^{sessile} \approx 90$ s, but the rate of accumulation of particles at the contact line is lower in the drop on fibre than in the sessile drop. This lower rate can be attributed to the overall lower fluid velocity and the narrow size of the advection-dominated domain in the fibre geometry.

$\tau _{dep}^{sessile} \approx 90$ s, but the rate of accumulation of particles at the contact line is lower in the drop on fibre than in the sessile drop. This lower rate can be attributed to the overall lower fluid velocity and the narrow size of the advection-dominated domain in the fibre geometry.

Next we want to compare the results of the calculations with what is observed experimentally.

4. Experimental observations

4.1. Materials and method