1. Introduction

Solutions of polymers and surfactants exhibit non-Newtonian features that depart dramatically from the behaviours of the solvent alone. The eccentricity of the non-Newtonian features are largely driven by: (a) the rheological complexity of the fluid; and (b) the complexity of the flow (Ewoldt & Saengow Reference Ewoldt and Saengow2022). Trivial canonical flow types, such as viscometric flows, can help decipher the various non-Newtonian traits that are inherent within complex fluids – some of which include viscoelasticity, shear-thinning, normal stress differences and extensional strain hardening. At the other extreme, highly complex flows, such as turbulence, can produce unexplained alterations to the flow dynamics despite involving fluids of seemingly low rheological complexity. For example, dilute solutions of surfactants (less than 0.01 % mass concentration) can induce an 80 % reduction in skin friction drag relative to a Newtonian fluid in a high-Reynolds-number (![]() $Re$) turbulent wall flow (Qi & Zakin Reference Qi and Zakin2002). Due to the diluteness of these non-Newtonian solutions, teasing out the rheological feature(s) responsible for drag reduction can be challenging. In fact, viscometric flows of these dilute surfactant solutions demonstrate seemingly indistinguishable features from the Newtonian solvent (Lin Reference Lin2000; Qi & Zakin Reference Qi and Zakin2002; Warwaruk & Ghaemi Reference Warwaruk and Ghaemi2021).

$Re$) turbulent wall flow (Qi & Zakin Reference Qi and Zakin2002). Due to the diluteness of these non-Newtonian solutions, teasing out the rheological feature(s) responsible for drag reduction can be challenging. In fact, viscometric flows of these dilute surfactant solutions demonstrate seemingly indistinguishable features from the Newtonian solvent (Lin Reference Lin2000; Qi & Zakin Reference Qi and Zakin2002; Warwaruk & Ghaemi Reference Warwaruk and Ghaemi2021).

To better understand the features of dilute non-Newtonian solutions, there is merit in considering flows of moderate complexity – those that are not trivial enough to be considered viscometric, but not overly complex such as turbulence. Bird & Wiest (Reference Bird and Wiest1995) referred to these flows as ‘nontrivial flows’, as they involved the laminar flow of non-Newtonian fluids through complex geometries. Some of these geometries include an abrupt contraction, periodically constricted tube, porous media and undulating surfaces (Deiber & Schowalter Reference Deiber and Schowalter1979; Pilitsis, Souvaliotis & Beris Reference Pilitsis, Souvaliotis and Beris1991; Poole, Escudier & Oliveira Reference Poole, Escudier and Oliveira2005; Page & Zaki Reference Page and Zaki2016). Bird & Wiest (Reference Bird and Wiest1995) referred to a few of these nontrivial flows as benchmark experiments that could aid in the development of numerical methods for modelling the flow of non-Newtonian fluids. The features and phenomena observed from these nontrivial flows, particularly those involving dilute polymer solutions, are also believed by some to be of significance to polymer drag reduction or related to the onset of the self-sustaining chaotic state known as elasto-inertial-turbulence (EIT) (Joseph Reference Joseph1990; Haward et al. Reference Haward, Page, Zaki and Shen2018a). Experiments of dilute polymer solutions, at relatively low ![]() $Re$, in pressure-driven contraction and periodic contraction-expansion channels demonstrated an increased streamwise pressure gradient, near-wall velocity overshoots and an augmented vorticity, not observed for Newtonian fluids (Poole et al. Reference Poole, Escudier and Oliveira2005; Ober et al. Reference Ober, Haward, Pipe, Soulages and McKinley2013; Haward et al. Reference Haward, Page, Zaki and Shen2018a). Few experiments have considered dilute surfactant solutions in these nontrivial flow geometries.

$Re$, in pressure-driven contraction and periodic contraction-expansion channels demonstrated an increased streamwise pressure gradient, near-wall velocity overshoots and an augmented vorticity, not observed for Newtonian fluids (Poole et al. Reference Poole, Escudier and Oliveira2005; Ober et al. Reference Ober, Haward, Pipe, Soulages and McKinley2013; Haward et al. Reference Haward, Page, Zaki and Shen2018a). Few experiments have considered dilute surfactant solutions in these nontrivial flow geometries.

The present investigation explores the flow of three drag-reducing non-Newtonian fluids, with unique rheology, in a periodically constricted tube. The following introduction serves to review the rheology of these polymer and surfactant solutions, then to summarize previous investigations of non-Newtonian fluids in periodic contraction-expansion channels and over wavy surfaces.

1.1. Polymer and surfactant rheology

Polymers can be classified as having a flexible or rigid molecular structure. Flexible polymers are long-chain molecules such as polyethylene oxide or polyacrylamide. Generally, dilute solutions of flexible polymers are shear-thinning, viscoelastic, and demonstrate normal stress differences and extensional strain hardening (Argumedo, Tung & Chang Reference Argumedo, Tung and Chang1978; Owolabi, Dennis & Poole Reference Owolabi, Dennis and Poole2017; Warwaruk & Ghaemi Reference Warwaruk and Ghaemi2021). However, sufficiently dilute solutions of flexible polymer have been shown to have a Newtonian shear rheogram, but an appreciable non-Newtonian first-normal stress coefficient and Trouton ratio (i.e. the ratio between the extensional and shear viscosities). These solutions are often called Boger fluids and are popularly studied due to their likeness to the Oldroyd-B constitutive model (James Reference James2009). Rigid polymer solutions, however, are generally naturally occurring biopolymers such as proteins and polysaccharides. The rigid polymer xanthan gum is abundantly used as a viscosity enhancer in various industrial and food processing applications (Sanderson Reference Sanderson1981). Dilute solutions of rigid polymers exhibit prevalent shear-thinning and linear viscoelasticity (Pereira, Andrade & Soares Reference Pereira, Andrade and Soares2013; Mohammadtabar, Sanders & Ghaemi Reference Mohammadtabar, Sanders and Ghaemi2020). Previous evidence has shown that rigid polymer solutions have positive first-normal stress differences and a non-Newtonian Trouton ratio (Fuller et al. Reference Fuller, Cathey, Hubbard and Zebrowski1987; Escudier, Presti & Smith Reference Escudier, Presti and Smith1999; Zirnsak, Boger & Tirtaatmadja Reference Zirnsak, Boger and Tirtaatmadja1999). Despite rigid polymer solutions having measurable non-Newtonian extensional properties, these features are small in comparison to the extensional properties of flexible polymer solutions. Semi-dilute solutions of xanthan gum have been shown to have a Trouton ratio that is orders of magnitude smaller than those measured for polyacrylamide solutions (Fuller et al. Reference Fuller, Cathey, Hubbard and Zebrowski1987; Jones, Walters & Williams Reference Jones, Walters and Williams1987).

Relative to polymeric solutions, surfactants add an extra level of rheological complexity due to their ability to evolve and form complex microstructures known as micelles within the flow (Wunderlich & James Reference Wunderlich and James1987). Dilute solutions of surfactants, relevant to applications involving turbulent drag reduction, can exhibit various rheological characteristics depending on the type of surfactant, the temperature, and the canonical flow. Qi & Zakin (Reference Qi and Zakin2002) summarized the three chemical or rheological features of dilute surfactant solutions that are of significance to drag reduction: shear-induced structures (SISs), viscoelasticity and a large Trouton ratio. The latter two properties share similarities with polymeric solutions, while SISs allude to the structural transformation of micelles caused by deformation of the fluid. Shear-induced structures are best demonstrated in shear rheograms (Ohlendorf, Interthal & Hoffmann Reference Ohlendorf, Interthal and Hoffmann1986). At sufficiently low shear rates, the shear viscosity is Newtonian, but above a critical shear rate, the viscosity increases (i.e. shear-thickening). After increasing the shear rate further, the viscosity begins to decrease, becoming shear-thinning. While certain surfactant solutions do show all three rheological properties (i.e. SISs, viscoelasticity and prevalent extensional features), some surfactant solutions only show one, or occasionally none, of these rheological traits (Qi & Zakin Reference Qi and Zakin2002). Lin (Reference Lin2000) observed that several dilute surfactant solutions had a Newtonian shear viscosity distribution (i.e. no SISs or shear-thinning), no first normal stress differences and a Newtonian Trouton ratio. Yet, the same dilute solutions could produce a 70 % reduction in the skin friction drag of a turbulent wall flow (Lin Reference Lin2000). The implication is that the complex dynamics and conditions of the turbulent flow stimulates a transition to non-Newtonian fluid features not realized through viscometric experiments.

Creative experiments have been performed to pre-shear surfactant solutions and reveal these non-Newtonian features in more controlled settings. For example, Wunderlich & James (Reference Wunderlich and James1987) demonstrated that sufficiently pre-shearing a surfactant solution produced a significant enhancement in the extensional viscosity measured through an axisymmetric contraction. Bhardwaj et al. (Reference Bhardwaj, Richter, Chellamuthu and Rothstein2007), and recently Fukushima et al. (Reference Fukushima, Kishi, Suzuki and Hidema2022), pre-sheared surfactant solutions using a parallel plate rheometer, then separated the plates rapidly to instil extension on the fluid sample. Both works observed evidence of an enhanced extensional viscosity in the surfactant solution after pre-shearing, similar to Wunderlich & James (Reference Wunderlich and James1987). This demonstrated that SISs are indeed present in most surfactant solutions and their formation may promote an enhanced extensional viscosity, in addition to the shear-thickening commonly observed in shear viscosity measurements. Examining flows with combined shear and extension might help to decode the shear-induced dynamics of dilute surfactant solutions.

1.2. Laminar flows over undulating walls

Several experimental and numerical investigations have examined the pressure-driven flow of non-Newtonian fluids through axisymmetric tubes with periodic contraction–expansions or wavy-walls. Forrester & Young (Reference Forrester and Young1970a,Reference Forrester and Youngb) investigated this canonical flow for its relevance in blood flows through a stenosis caused from the build up of plaque along artery walls. Several other works have considered the wavy-walled tube a suitable analogue for the flow of complex fluids in porous media (Deiber & Schowalter Reference Deiber and Schowalter1979, Reference Deiber and Schowalter1981; Lahbabi & Chang Reference Lahbabi and Chang1986; Pilitsis & Beris Reference Pilitsis and Beris1991; Pilitsis et al. Reference Pilitsis, Souvaliotis and Beris1991). Lastly, Yoo & Joseph (Reference Yoo and Joseph1985) and De Gennes (Reference De Gennes1990) suggested that the dynamics of non-Newtonian fluids through an undulating tube might be of particular significance to turbulent drag reduction. Most of the antiquated experimental investigations of non-Newtonian flows through undulating tubes have focused on measuring the streamwise pressure gradient and mapping the ![]() $Re$ in which secondary inertial instabilities and transition to turbulence first appear (Forrester & Young Reference Forrester and Young1970b; Deiber & Schowalter Reference Deiber and Schowalter1979, Reference Deiber and Schowalter1981; Phan-Thien & Khan Reference Phan-Thien and Khan1987). The relevant works that have investigated undulating wall flows are summarized below.

$Re$ in which secondary inertial instabilities and transition to turbulence first appear (Forrester & Young Reference Forrester and Young1970b; Deiber & Schowalter Reference Deiber and Schowalter1979, Reference Deiber and Schowalter1981; Phan-Thien & Khan Reference Phan-Thien and Khan1987). The relevant works that have investigated undulating wall flows are summarized below.

For a Newtonian fluid, Deiber & Schowalter (Reference Deiber and Schowalter1979) used qualitative flow visualization and pressure drop measurements to demonstrate that inertial secondary flows (realized by a toroidal vortex in the expanding portion of the undulating tube) and transition to turbulence largely depended on the amplitude and wavelength of the tube oscillations. As expected, large amplitudes and short wavelengths promote flow separation. In a follow-up publication, Deiber & Schowalter (Reference Deiber and Schowalter1981) demonstrated that dilute aqueous solutions of polyacrylamide had a larger streamwise pressure drop than Newtonian fluids at a similar ![]() $Re$. The implication was that an elastically driven flow instability might be at play. They also observed that toroidal secondary flows and transition to turbulence occurred at lower

$Re$. The implication was that an elastically driven flow instability might be at play. They also observed that toroidal secondary flows and transition to turbulence occurred at lower ![]() $Re$ for the polyacrylamide solutions compared to the Newtonian fluids – consistent with modern observations of EIT (Samanta et al. Reference Samanta, Dubief, Holzner, Schäfer, Morozov, Wagner and Hof2013). Pilitsis et al. (Reference Pilitsis, Souvaliotis and Beris1991) and Pilitsis & Beris (Reference Pilitsis and Beris1991) used computational fluid dynamics to model the flow of inelastic and elastic non-Newtonian solutions in an undulating tube using generalized Newtonian and viscoelastic constitutive equations. Simulations involving shear-thinning models yielded higher amounts of flow resistance (streamwise pressure drop divided by volumetric flow rate) when elasticity was present as opposed to when it was absent. However, these simulations severely under-predicted the flow resistance demonstrated experimentally by Deiber & Schowalter (Reference Deiber and Schowalter1981), regardless of the chosen constitutive model (elastic or inelastic). Inconsistencies between experiments of non-Newtonian solutions and simulations using non-Newtonian constitutive models are common in various pressure-driven non-uniform flow problems; even in modern simulations that use constitutive models of higher rheological complexity. In a recent publication, Boyko & Stone (Reference Boyko and Stone2022) provided a thorough review of the inconsistencies among the pressure-drop versus flow rate relationship derived from experimental findings, numerical simulations and analytical works involving non-Newtonian flows through contractions, rectifiers and periodic contraction–expansion geometries. To our knowledge, the problem of non-Newtonian fluids through an axisymmetric wavy-walled tube has not been revisited experimentally since the pressure drop measurements of Deiber & Schowalter (Reference Deiber and Schowalter1981), little over 40 years ago. Experiments that use particle image velocimetry (PIV) can provide better insight into the dynamics of these flows, especially in flow regimes where elastic irregularities take hold.

$Re$ for the polyacrylamide solutions compared to the Newtonian fluids – consistent with modern observations of EIT (Samanta et al. Reference Samanta, Dubief, Holzner, Schäfer, Morozov, Wagner and Hof2013). Pilitsis et al. (Reference Pilitsis, Souvaliotis and Beris1991) and Pilitsis & Beris (Reference Pilitsis and Beris1991) used computational fluid dynamics to model the flow of inelastic and elastic non-Newtonian solutions in an undulating tube using generalized Newtonian and viscoelastic constitutive equations. Simulations involving shear-thinning models yielded higher amounts of flow resistance (streamwise pressure drop divided by volumetric flow rate) when elasticity was present as opposed to when it was absent. However, these simulations severely under-predicted the flow resistance demonstrated experimentally by Deiber & Schowalter (Reference Deiber and Schowalter1981), regardless of the chosen constitutive model (elastic or inelastic). Inconsistencies between experiments of non-Newtonian solutions and simulations using non-Newtonian constitutive models are common in various pressure-driven non-uniform flow problems; even in modern simulations that use constitutive models of higher rheological complexity. In a recent publication, Boyko & Stone (Reference Boyko and Stone2022) provided a thorough review of the inconsistencies among the pressure-drop versus flow rate relationship derived from experimental findings, numerical simulations and analytical works involving non-Newtonian flows through contractions, rectifiers and periodic contraction–expansion geometries. To our knowledge, the problem of non-Newtonian fluids through an axisymmetric wavy-walled tube has not been revisited experimentally since the pressure drop measurements of Deiber & Schowalter (Reference Deiber and Schowalter1981), little over 40 years ago. Experiments that use particle image velocimetry (PIV) can provide better insight into the dynamics of these flows, especially in flow regimes where elastic irregularities take hold.

Although few recent experiments exist for flows in axisymmetric undulating tubes, there are experimental observations of plane Poiseuille flow with one wavy-walled surface (Haward et al. Reference Haward, Page, Zaki and Shen2018a,Reference Haward, Page, Zaki and Shenb). These experiments were motivated by the numerical investigations done by Page & Zaki (Reference Page and Zaki2016), which explored the structure of the vorticity field in a Couette flow of an Oldroyd-B fluid over a wavy surface of small amplitude. These small amplitude wall oscillations induce spanwise vorticity within the flow. Page & Zaki (Reference Page and Zaki2016) demonstrated that elasticity can amplify the vorticity and inject it farther into the core of the channel. Subsequent experiments by Haward et al. (Reference Haward, Page, Zaki and Shen2018a,Reference Haward, Page, Zaki and Shenb) using dilute solutions of polyethylene oxide supported these observations, albeit using a penetration depth parameter derived from an integration of the wall-normal velocity. We should note that Page & Zaki (Reference Page and Zaki2016) and Haward et al. (Reference Haward, Page, Zaki and Shen2018a,Reference Haward, Page, Zaki and Shenb) focus on small amplitude wall perturbations, where the amplitude of the wall oscillations are significantly smaller than the channel height. However, experiments by Deiber & Schowalter (Reference Deiber and Schowalter1981) and the simulations of Pilitsis et al. (Reference Pilitsis, Souvaliotis and Beris1991) and Pilitsis & Beris (Reference Pilitsis and Beris1991) focus on much larger wall oscillations, perceived to be more relevant to flows through porous media. The present investigation involves relatively large wall oscillations similar to those reported by Deiber & Schowalter (Reference Deiber and Schowalter1981), and much greater than those of Haward et al. (Reference Haward, Page, Zaki and Shen2018a,Reference Haward, Page, Zaki and Shenb). It is unclear if the canonical flows are related – those by Haward et al. (Reference Haward, Page, Zaki and Shen2018a,Reference Haward, Page, Zaki and Shenb) are likely more shear dominated, while experiments by Deiber & Schowalter (Reference Deiber and Schowalter1981) have considerable extensional deformation. Nonetheless, one area of focus for the present investigation considers the amplification of vorticity.

1.3. Outline

The objective of the present investigation is to quantify the distorted state of velocity and vorticity caused by trace amounts of polymer and surfactant additives within a laminar, but geometrically non-trivial flow – that being flow in a periodically constricted tube (PCT). We consider three aqueous non-Newtonian solutions, each of which are derived from an additive with a unique chemical microstructure: a flexible polymer, a rigid biopolymer and a cationic surfactant. Five concentrations are considered for each non-Newtonian fluid (15 solutions in total). Steady and dynamic shear viscosity measurements are used to characterize the steady shear viscosity and linear viscoelasticity of the non-Newtonian solutions. A dripping-onto-substrate apparatus is used to measure the extensional rheology of the solutions. Particle shadow velocimetry is used to directly measure the velocity of each fluid in the PCT at five different flow rates. Lastly, we experimentally derive profiles of the non-Newtonian torque from a deficit in the equation for conservation of angular momentum. Despite similar amounts of shear-thinning and linear viscoelasticity (i.e. storage and loss moduli), flexible polymers and rigid polymers react incredibly different in the PCT. However, viscometric flows for surfactants are almost water-like. Yet surfactants share a similar response as flexible polymers to the PCT, implying the PCT promotes some SIS with a similar end-effect as the flexible polymer.

2. Experimental methodology

The laminar flow of water and three non-Newtonian fluids in an axisymmetric PCT were experimentally quantified using a flow measurement technique known as particle shadow velocimetry (PSV) (Santiago et al. Reference Santiago, Wereley, Meinhart, Beebe and Adrian1998; Estevadeordal & Goss Reference Estevadeordal and Goss2006; Khodaparast et al. Reference Khodaparast, Borhani, Tagliabue and Thome2013). Flow measurements were supplemented with rheological measurements that quantify the steady shear, dynamic shear and extensional rheology of the different fluids. Details pertaining to the flow facility, non-Newtonian solutions and flow measurement technique are described in the following sections.

2.1. Periodically constricted tube

Figure 1(a) demonstrates a two-dimensional (2-D) cross-section of the flow setup used for the experiments. The flow consists of several stages. Each stage is detailed starting from the farthest upstream location on the left-hand side of figure 1(a) and moving downstream or to the right. The entrance region was of radius ![]() $R_o = 1.07$ mm, and was 68

$R_o = 1.07$ mm, and was 68![]() $R_o$ in length – a sufficient length to ensure a fully-developed Poiseuille flow entered the sections to follow. Farther downstream of the entrance, the flow entered the PCT, where the radius of the tube wall,

$R_o$ in length – a sufficient length to ensure a fully-developed Poiseuille flow entered the sections to follow. Farther downstream of the entrance, the flow entered the PCT, where the radius of the tube wall, ![]() $R_w$, varied sinusoidally along the streamwise direction, x, according to

$R_w$, varied sinusoidally along the streamwise direction, x, according to

where the sinusoidal amplitude of wall radius was ![]() $\epsilon = 0.14$ mm, and the wavelength,

$\epsilon = 0.14$ mm, and the wavelength, ![]() $\lambda$, was 4.7 mm. The maximum radius of the PCT was

$\lambda$, was 4.7 mm. The maximum radius of the PCT was ![]() $R_o$, the minimum radius

$R_o$, the minimum radius ![]() $R_i$ was 0.79 mm and the average radius

$R_i$ was 0.79 mm and the average radius ![]() $R$ was 0.93 mm. The length of the PCT section was

$R$ was 0.93 mm. The length of the PCT section was ![]() $7\lambda$. Figure 1(b) demonstrates a magnified depiction of the PCT portion of the test section. The cylindrical coordinate system is shown for reference in figure 1(b). The streamwise, radial and azimuthal directions are denoted as x, r and

$7\lambda$. Figure 1(b) demonstrates a magnified depiction of the PCT portion of the test section. The cylindrical coordinate system is shown for reference in figure 1(b). The streamwise, radial and azimuthal directions are denoted as x, r and ![]() $\theta$, respectively. The radius of the tube downstream of the PCT returned to

$\theta$, respectively. The radius of the tube downstream of the PCT returned to ![]() $R_o$ for a length of

$R_o$ for a length of ![]() $28R_o$. The radius then gradually increased to 5.5 mm via a 3-degree axisymmetric conical expansion farther downstream from the PCT.

$28R_o$. The radius then gradually increased to 5.5 mm via a 3-degree axisymmetric conical expansion farther downstream from the PCT.

Figure 1. Two-dimensional schematic of the (a) complete acrylic test section and (b) the periodically constricted tube.

The three-dimensional (3-D) axisymmetric tube was built from two halves of 12.7 mm thick acrylic. The radial profile shown in figure 1 was cut into the two acrylic halves using a computer numerical control router with a precision ball nose end mill. The scallop height – the height of the surface imperfections caused by the curvature and step length of the ball nose tool – was less than 1 ![]() $\mathrm {\mu }$m or 0.1 % of

$\mathrm {\mu }$m or 0.1 % of ![]() $R_{i}$. The two halves were pressed together to form the 3-D axisymmetric tube without using any adhesive. Custom milled steel flanges with lag bolts and nuts were used to apply sufficient compression to the two halves, such that fluid did not expel out the sides of the test section.

$R_{i}$. The two halves were pressed together to form the 3-D axisymmetric tube without using any adhesive. Custom milled steel flanges with lag bolts and nuts were used to apply sufficient compression to the two halves, such that fluid did not expel out the sides of the test section.

Fluid entered the test section from a straight, 1.2 m long stainless-steel tube with an inner radius of ![]() $R_o$ that was face-sealed to the left-hand side of the test section shown in figure 1(a). Fluid that exited the test section entered a 0.3 m long stainless-steel tube with an inner radius of 5.5 mm that was joined to the downstream portion of the test section. Fluid temperature was monitored using a K-type thermocouple and a data logger (HH506, Omega Engineering). The average fluid temperature of all experiments was

$R_o$ that was face-sealed to the left-hand side of the test section shown in figure 1(a). Fluid that exited the test section entered a 0.3 m long stainless-steel tube with an inner radius of 5.5 mm that was joined to the downstream portion of the test section. Fluid temperature was monitored using a K-type thermocouple and a data logger (HH506, Omega Engineering). The average fluid temperature of all experiments was ![]() $20.1\,^{\circ }\mathrm {C} \pm 0.2\,^{\circ }{\rm C}$. A syringe pump (Legacy 200, KD Scientific Inc.) with an accuracy of

$20.1\,^{\circ }\mathrm {C} \pm 0.2\,^{\circ }{\rm C}$. A syringe pump (Legacy 200, KD Scientific Inc.) with an accuracy of ![]() $\pm$1 % was used to propel fluid through the flow facility. Glass syringes (Micro-Mate, Popper & Sons Inc.) with 10 and 30 ml volumes were equipped in the syringe pump; the choice in the syringe volume depended on the required volumetric flow rate

$\pm$1 % was used to propel fluid through the flow facility. Glass syringes (Micro-Mate, Popper & Sons Inc.) with 10 and 30 ml volumes were equipped in the syringe pump; the choice in the syringe volume depended on the required volumetric flow rate ![]() $Q$. Flexible PVC tube with an inner radius of 3.18 mm connected the syringe to the 1.2 m long stainless-steel tube. Five flow rates were considered for each Newtonian and non-Newtonian fluid: 1, 3, 6, 9 and 12 ml min

$Q$. Flexible PVC tube with an inner radius of 3.18 mm connected the syringe to the 1.2 m long stainless-steel tube. Five flow rates were considered for each Newtonian and non-Newtonian fluid: 1, 3, 6, 9 and 12 ml min![]() $^{-1}$.

$^{-1}$.

The Reynolds number was defined based on ![]() $Re = 2 \langle U_0 \rangle R/\nu _w$, where

$Re = 2 \langle U_0 \rangle R/\nu _w$, where ![]() $\nu _w = \eta _w/\rho$ is the kinematic wall viscosity,

$\nu _w = \eta _w/\rho$ is the kinematic wall viscosity, ![]() $\eta _w$ is the dynamic wall viscosity and

$\eta _w$ is the dynamic wall viscosity and ![]() $\rho$ is the density. This definition of

$\rho$ is the density. This definition of ![]() $Re$ is similar to that used by Ahrens, Yoo & Joseph (Reference Ahrens, Yoo and Joseph1987), where the flow of viscoelastic fluids was simulated through a wavy-walled tube. Within the PCT, the centreline velocity

$Re$ is similar to that used by Ahrens, Yoo & Joseph (Reference Ahrens, Yoo and Joseph1987), where the flow of viscoelastic fluids was simulated through a wavy-walled tube. Within the PCT, the centreline velocity ![]() $U_0$ oscillates with respect to

$U_0$ oscillates with respect to ![]() $x$. As such, the average centreline velocity

$x$. As such, the average centreline velocity ![]() $\langle U_0 \rangle$ along

$\langle U_0 \rangle$ along ![]() $x$ was determined from flow measurements in the PCT. Here, angle brackets

$x$ was determined from flow measurements in the PCT. Here, angle brackets ![]() $\langle \cdots \rangle$ are used to denote spatial averaging along the

$\langle \cdots \rangle$ are used to denote spatial averaging along the ![]() $x$ direction. Within the straight-walled development region, where

$x$ direction. Within the straight-walled development region, where ![]() $R_w = R_o$,

$R_w = R_o$, ![]() $U_0$ does not vary along

$U_0$ does not vary along ![]() $x$ and the Reynolds number is defined as

$x$ and the Reynolds number is defined as ![]() $Re_d = 2 U_0 R_o / \nu _w$. For the flow of water,

$Re_d = 2 U_0 R_o / \nu _w$. For the flow of water, ![]() $Re_d$ was between 13 and 184, which was laminar. The wall shear rate within the straight-walled development region can be derived from a differentiation of the parabolic Poiseuille profile for Newtonian fluids,

$Re_d$ was between 13 and 184, which was laminar. The wall shear rate within the straight-walled development region can be derived from a differentiation of the parabolic Poiseuille profile for Newtonian fluids, ![]() $\dot {\gamma }_w = 2 U_0/ R_o$. Within the PCT, the fluid is subjected to a combination of shear and extensional deformation. A characteristic near-wall shear rate within the PCT was defined similar to the straight-walled section as

$\dot {\gamma }_w = 2 U_0/ R_o$. Within the PCT, the fluid is subjected to a combination of shear and extensional deformation. A characteristic near-wall shear rate within the PCT was defined similar to the straight-walled section as ![]() $\dot {\gamma }_w = 2\langle U_0 \rangle /R$. A characteristic extensional strain rate

$\dot {\gamma }_w = 2\langle U_0 \rangle /R$. A characteristic extensional strain rate ![]() $\dot {\varepsilon }$ was defined as the range in

$\dot {\varepsilon }$ was defined as the range in ![]() $U_0$ (maximum subtracted by minimum) divided by

$U_0$ (maximum subtracted by minimum) divided by ![]() $\lambda /2$. In the present investigation,

$\lambda /2$. In the present investigation, ![]() $\dot {\gamma }_{w}$ was between 13 and 300 s

$\dot {\gamma }_{w}$ was between 13 and 300 s![]() $^{-1}$ and

$^{-1}$ and ![]() $\dot {\varepsilon }$ was between 2 and 58 s

$\dot {\varepsilon }$ was between 2 and 58 s![]() $^{-1}$ depending on the fluid and

$^{-1}$ depending on the fluid and ![]() $Re$. The dynamic wall viscosity

$Re$. The dynamic wall viscosity ![]() $\eta _w$ was derived from shear rheograms for non-Newtonian fluids and using

$\eta _w$ was derived from shear rheograms for non-Newtonian fluids and using ![]() $\dot {\gamma }_w$, as detailed in § 2.3. For water,

$\dot {\gamma }_w$, as detailed in § 2.3. For water, ![]() $\eta _w = \eta _s$, where

$\eta _w = \eta _s$, where ![]() $\eta _s$ is the viscosity of the solvent and was considered to be 1.00 mPa s according to Cheng (Reference Cheng2008).

$\eta _s$ is the viscosity of the solvent and was considered to be 1.00 mPa s according to Cheng (Reference Cheng2008).

2.2. Test fluids

Three non-Newtonian additives, with drag-reducing capabilities (Warwaruk & Ghaemi Reference Warwaruk and Ghaemi2021), were chosen for the experiments: a flexible polymer, a rigid biopolymer and a cationic surfactant. Additives in their solid powder form were weighed using a digital scale (Explorer Analytical, OHAUS Corporation) with a 1 mg resolution. Solid powders were then gradually added to 15 l of distilled water and agitated for 8 h using a stand mixer equipped with a 100 mm diameter impeller (Model 1750, Arrow Engineering Mixing Products). After mixing, the aqueous non-Newtonian solutions were left to rest for 16 h. Fluid samples were then collected for rheology measurements and experiments in the PCT. Experiments in the PCT for the non-Newtonian fluids were conducted at the same flow rates as water, ![]() $Q$ between 1 and 12 ml min

$Q$ between 1 and 12 ml min![]() $^{-1}$. For some of the fluids, their viscosities were different than water, therefore, a similar

$^{-1}$. For some of the fluids, their viscosities were different than water, therefore, a similar ![]() $Q$ did not constitute a similar

$Q$ did not constitute a similar ![]() $Re$.

$Re$.

The flexible polymer used in the present experiment was polyacrylamide (PAM) from a sample batch contributed by SNF Floerger (6030S, molecular weight of 30–35 Mg mol![]() $^{-1}$). The rigid biopolymer was xanthan gum (XG) (43708, MilliporeSigma). Both polymers, PAM and XG, have been readily used in various experimental investigations involving rheology and turbulent drag reduction (Escudier et al. Reference Escudier, Presti and Smith1999; Mohammadtabar et al. Reference Mohammadtabar, Sanders and Ghaemi2020; Warwaruk & Ghaemi Reference Warwaruk and Ghaemi2021). Cationic surfactants are quarternary ammonium salts of the form C

$^{-1}$). The rigid biopolymer was xanthan gum (XG) (43708, MilliporeSigma). Both polymers, PAM and XG, have been readily used in various experimental investigations involving rheology and turbulent drag reduction (Escudier et al. Reference Escudier, Presti and Smith1999; Mohammadtabar et al. Reference Mohammadtabar, Sanders and Ghaemi2020; Warwaruk & Ghaemi Reference Warwaruk and Ghaemi2021). Cationic surfactants are quarternary ammonium salts of the form C![]() $_n$H

$_n$H![]() $_{2n+1}$N

$_{2n+1}$N![]() $^+$(CH

$^+$(CH![]() $_3$)

$_3$)![]() $^3$Cl, where

$^3$Cl, where ![]() $n$ is an integer, generally between 12 and 18 (Qi & Zakin Reference Qi and Zakin2002). When paired with a counterion, such as sodium salicylate (NaSal), the molecules combine to form complex micellar structures (Bewersdorff & Ohlendorf Reference Bewersdorff and Ohlendorf1988; Zhang et al. Reference Zhang, Schmidt, Talmon and Zakin2005). We found in previous experimental campaigns that trimethyltetradecylammonium chloride (

$n$ is an integer, generally between 12 and 18 (Qi & Zakin Reference Qi and Zakin2002). When paired with a counterion, such as sodium salicylate (NaSal), the molecules combine to form complex micellar structures (Bewersdorff & Ohlendorf Reference Bewersdorff and Ohlendorf1988; Zhang et al. Reference Zhang, Schmidt, Talmon and Zakin2005). We found in previous experimental campaigns that trimethyltetradecylammonium chloride (![]() $n = 14$) (T0926, Tokyo Chemical Industry Co., Ltd.) combined with NaSal (71945, MilliporeSigma) at a molar ratio of 1:2, produced considerable amounts of drag reduction (Warwaruk & Ghaemi Reference Warwaruk and Ghaemi2021). Therefore, the same additives and molar ratios were used in the present investigation. Much like other investigations, we abbreviate and refer to the surfactant additive as TTAC for the remainder of the manuscript (Roelants & De Schryver Reference Roelants and De Schryver1987). A parametric sweep of five concentrations were considered for each additive (i.e. PAM, XG and TTAC). The concentrations,

$n = 14$) (T0926, Tokyo Chemical Industry Co., Ltd.) combined with NaSal (71945, MilliporeSigma) at a molar ratio of 1:2, produced considerable amounts of drag reduction (Warwaruk & Ghaemi Reference Warwaruk and Ghaemi2021). Therefore, the same additives and molar ratios were used in the present investigation. Much like other investigations, we abbreviate and refer to the surfactant additive as TTAC for the remainder of the manuscript (Roelants & De Schryver Reference Roelants and De Schryver1987). A parametric sweep of five concentrations were considered for each additive (i.e. PAM, XG and TTAC). The concentrations, ![]() $c$, were the same for all additives: 0.01 %, 0.02 %, 0.03 %, 0.04 % and 0.05 %.

$c$, were the same for all additives: 0.01 %, 0.02 %, 0.03 %, 0.04 % and 0.05 %.

2.3. Fluid rheology

Steady and dynamic shear rheology measurements were performed using a controlled-stress single-head torsional rheometer (HR-2, TA Instruments). A single-gap concentric cylinder was used for all viscosity measurements, both steady and dynamic. The radius of the inner rotating cylinder ![]() $R_{min}$ was 14 mm, while the radius of the outer fixed cylinder

$R_{min}$ was 14 mm, while the radius of the outer fixed cylinder ![]() $R_{max}$ was 15.2 mm. The immersion height

$R_{max}$ was 15.2 mm. The immersion height ![]() $L$ was 42.04 mm. Steady shear viscosity measurements involved a logarithmic sweep in the shear rate

$L$ was 42.04 mm. Steady shear viscosity measurements involved a logarithmic sweep in the shear rate ![]() $\dot {\gamma }$ from 0.1 to 1000 s

$\dot {\gamma }$ from 0.1 to 1000 s![]() $^{-1}$ with 10 data points per decade, and the corresponding stress

$^{-1}$ with 10 data points per decade, and the corresponding stress ![]() $\tau$ was monitored. Note that the rotational velocity in rad s

$\tau$ was monitored. Note that the rotational velocity in rad s![]() $^{-1}$,

$^{-1}$, ![]() $\varOmega$, can be converted to

$\varOmega$, can be converted to ![]() $\dot {\gamma }$ using

$\dot {\gamma }$ using ![]() $\dot {\gamma } = F_{\gamma } \varOmega$, where

$\dot {\gamma } = F_{\gamma } \varOmega$, where ![]() $F_{\gamma } = R_{max}/(R_{max}-R_{min})$ is the strain coefficient derived for Taylor–Couette flow (Barnes, Hutton & Walters Reference Barnes, Hutton and Walters1989; Ewoldt, Johnston & Caretta Reference Ewoldt, Johnston and Caretta2015). Similarly, the torque measurements,

$F_{\gamma } = R_{max}/(R_{max}-R_{min})$ is the strain coefficient derived for Taylor–Couette flow (Barnes, Hutton & Walters Reference Barnes, Hutton and Walters1989; Ewoldt, Johnston & Caretta Reference Ewoldt, Johnston and Caretta2015). Similarly, the torque measurements, ![]() $T$, can be converted to stress,

$T$, can be converted to stress, ![]() $\tau$, using

$\tau$, using ![]() $\tau = F_{\tau } T$, where

$\tau = F_{\tau } T$, where ![]() $F_{\tau } = (2 {\rm \pi}R_o^2 L)^{-1}$ is the stress coefficient. The shear viscosity was derived based on

$F_{\tau } = (2 {\rm \pi}R_o^2 L)^{-1}$ is the stress coefficient. The shear viscosity was derived based on ![]() $\eta = \tau / \dot {\gamma } = (F_{\tau }/F_{\gamma })(T/\varOmega )$ (Barnes et al. Reference Barnes, Hutton and Walters1989; Ewoldt et al. Reference Ewoldt, Johnston and Caretta2015). The maximum shear rate limit of the steady shear viscosity measurements was determined based on the Taylor number limitation,

$\eta = \tau / \dot {\gamma } = (F_{\tau }/F_{\gamma })(T/\varOmega )$ (Barnes et al. Reference Barnes, Hutton and Walters1989; Ewoldt et al. Reference Ewoldt, Johnston and Caretta2015). The maximum shear rate limit of the steady shear viscosity measurements was determined based on the Taylor number limitation, ![]() $Ta = \rho ^2 \varOmega ^2(R_{max}-R_{min})^3R_{min} / \eta ^2 < 1700$ (Ewoldt et al. Reference Ewoldt, Johnston and Caretta2015). Usually, the minimum shear rate limit can be determined from the lower torque limit prescribed by the manufacturer of the rheometer. The lower limit in

$Ta = \rho ^2 \varOmega ^2(R_{max}-R_{min})^3R_{min} / \eta ^2 < 1700$ (Ewoldt et al. Reference Ewoldt, Johnston and Caretta2015). Usually, the minimum shear rate limit can be determined from the lower torque limit prescribed by the manufacturer of the rheometer. The lower limit in ![]() $T$ provided by TA instrument was 10 nN m, or

$T$ provided by TA instrument was 10 nN m, or ![]() $\tau = 0.2$ mPa. In practice, we found that the lower limit for steady shear viscosity measurements was higher,

$\tau = 0.2$ mPa. In practice, we found that the lower limit for steady shear viscosity measurements was higher, ![]() $T = 100$ nN m, or

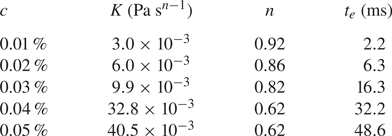

$T = 100$ nN m, or ![]() $\tau =2$ mPa. Lastly, a power-law model was fit to shear rheograms for fluids that exhibited shear thinning tendencies. The power law was of the form:

$\tau =2$ mPa. Lastly, a power-law model was fit to shear rheograms for fluids that exhibited shear thinning tendencies. The power law was of the form:

where ![]() $K$ is called the consistency and

$K$ is called the consistency and ![]() $n$ is the flow index. Fits were performed on profiles of

$n$ is the flow index. Fits were performed on profiles of ![]() $\eta (\dot {\gamma })$ with

$\eta (\dot {\gamma })$ with ![]() $\tau >2$ mPa and

$\tau >2$ mPa and ![]() $Ta < 1700$ using nonlinear least square regression. The values of

$Ta < 1700$ using nonlinear least square regression. The values of ![]() $K$ and

$K$ and ![]() $n$ for the solutions that were shear-thinning are reported in Appendix A. Recall from § 2.1 that

$n$ for the solutions that were shear-thinning are reported in Appendix A. Recall from § 2.1 that ![]() $Re = \rho{2}\langle U_0 \rangle R/\eta _w$, where

$Re = \rho{2}\langle U_0 \rangle R/\eta _w$, where ![]() $\eta _w$ is the viscosity evaluated at

$\eta _w$ is the viscosity evaluated at ![]() $\dot {\gamma }_w = 2\langle U_0 \rangle /R$. In other words, using (2.2) produces

$\dot {\gamma }_w = 2\langle U_0 \rangle /R$. In other words, using (2.2) produces ![]() $\eta _w = K \dot {\gamma }_w^{n-1} = K 2^{n-1}\langle U_0 \rangle ^{n-1}R^{1-n}$, and the Reynolds number in the PCT flow can be equally represented as

$\eta _w = K \dot {\gamma }_w^{n-1} = K 2^{n-1}\langle U_0 \rangle ^{n-1}R^{1-n}$, and the Reynolds number in the PCT flow can be equally represented as ![]() $Re = \rho 2^{2-n} \langle U_0 \rangle ^{2-n} R^n / K$ for shear-thinning fluids.

$Re = \rho 2^{2-n} \langle U_0 \rangle ^{2-n} R^n / K$ for shear-thinning fluids.

Dynamic shear viscosity measurements were also performed on select PAM and XG solutions. Limitations of the rheometer made performing these measurements only possible for high-concentration solutions. The details and results of the dynamic shear viscosity measurements are provided in Appendix B.

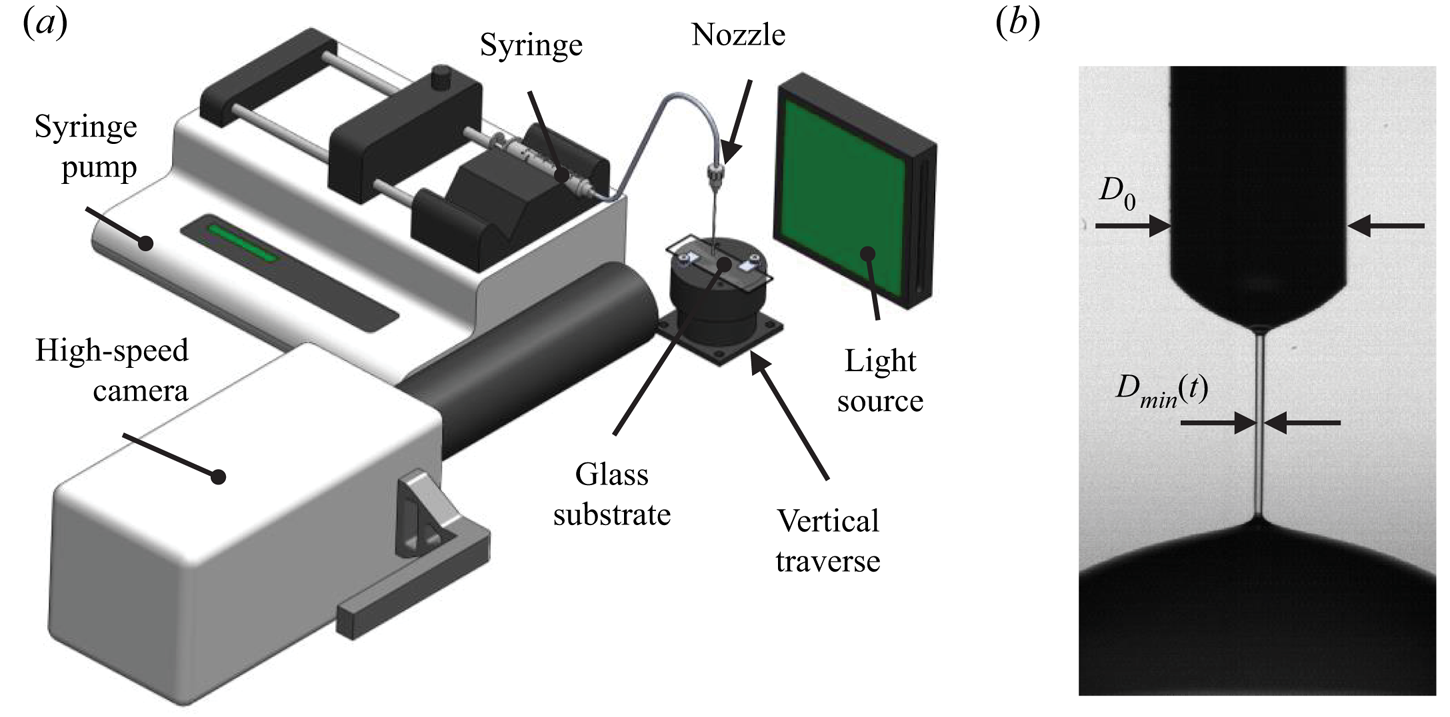

The extensional rheology of the solutions was evaluated using a custom dripping-onto-substrate (DoS) apparatus, depicted in figure 2(a). In this measurement technique, a small droplet was discharged from a blunt-end nozzle with a diameter ![]() $D_0$ of 1.27 mm. A syringe pump (Legacy 200, KD Scientific Inc.) was used to expel the droplet from the nozzle at a rate of 0.02 ml min

$D_0$ of 1.27 mm. A syringe pump (Legacy 200, KD Scientific Inc.) was used to expel the droplet from the nozzle at a rate of 0.02 ml min![]() $^{-1}$. Pumping was terminated once the droplet made contact with a glass substrate that was situated

$^{-1}$. Pumping was terminated once the droplet made contact with a glass substrate that was situated ![]() $3D_0$ or 3.81 mm below the blunt-end of the nozzle outlet. An apparatus with similar features was used by Dinic et al. (Reference Dinic, Zhang, Jimenez and Sharma2015), Dinic, Jimenez & Sharma (Reference Dinic, Jimenez and Sharma2017) and Zhang & Calabrese (Reference Zhang and Calabrese2022). After the droplet made contact with the substrate, a liquid bridge was formed between the nozzle outlet and the substrate. The diameter of the liquid bridge

$3D_0$ or 3.81 mm below the blunt-end of the nozzle outlet. An apparatus with similar features was used by Dinic et al. (Reference Dinic, Zhang, Jimenez and Sharma2015), Dinic, Jimenez & Sharma (Reference Dinic, Jimenez and Sharma2017) and Zhang & Calabrese (Reference Zhang and Calabrese2022). After the droplet made contact with the substrate, a liquid bridge was formed between the nozzle outlet and the substrate. The diameter of the liquid bridge ![]() $D_{min}$ decayed rapidly due to capillary forces. Images of the liquid bridge were collected using a high-speed camera (v611, Vision Research) and back-lit illumination from a light-emitting diode (LED). Figure 2(b) shows a sample image of the liquid bridge for the PAM solution with

$D_{min}$ decayed rapidly due to capillary forces. Images of the liquid bridge were collected using a high-speed camera (v611, Vision Research) and back-lit illumination from a light-emitting diode (LED). Figure 2(b) shows a sample image of the liquid bridge for the PAM solution with ![]() $c = 0.05\,\%$. The camera had a

$c = 0.05\,\%$. The camera had a ![]() $1280\times 800$ pixel complementary metal-oxide semiconductor sensor with pixels that were

$1280\times 800$ pixel complementary metal-oxide semiconductor sensor with pixels that were ![]() $20\times 20$

$20\times 20$ ![]() $\mathrm {\mu }$m

$\mathrm {\mu }$m![]() $^2$ in size and had a bit-depth of 12 bit. A zoom lens was used to achieve a magnification of 3.8 and a scale of 5.16

$^2$ in size and had a bit-depth of 12 bit. A zoom lens was used to achieve a magnification of 3.8 and a scale of 5.16 ![]() $\mathrm {\mu }$m pixel

$\mathrm {\mu }$m pixel![]() $^{-1}$. Images were collected at an acquisition rate of 2 kHz. The minimum diameter

$^{-1}$. Images were collected at an acquisition rate of 2 kHz. The minimum diameter ![]() $D_{min}$ of the liquid bridge was determined using a script developed in MATLAB (Mathworks Inc.).

$D_{min}$ of the liquid bridge was determined using a script developed in MATLAB (Mathworks Inc.).

Figure 2. (a) Isometric view of a 3-D model depicting the DoS setup. (b) A sample image taken for PAM with ![]() $c=0.05\,\%$ in elastocapillary thinning.

$c=0.05\,\%$ in elastocapillary thinning.

The pinch-off dynamics of the liquid bridge in the DoS apparatus depends on forces attributed to inertia, surface tension, viscosity and elasticity (Dinic et al. Reference Dinic, Jimenez and Sharma2017). The Ohnesorge number, ![]() $Oh = t_v/t_R$, relates the time scale associated with viscous forces to the Rayleigh time

$Oh = t_v/t_R$, relates the time scale associated with viscous forces to the Rayleigh time ![]() $t_R$, which pertains to surface tension and inertial forces. Here,

$t_R$, which pertains to surface tension and inertial forces. Here, ![]() $t_v = \eta D_0 / 2\sigma$ is the characteristic time scale of viscocapillary thinning,

$t_v = \eta D_0 / 2\sigma$ is the characteristic time scale of viscocapillary thinning, ![]() $t_R = (\rho D_0^3/8\sigma )^{1/2}$, and

$t_R = (\rho D_0^3/8\sigma )^{1/2}$, and ![]() $\sigma$ is the surface tension. Low-viscosity fluids typically have

$\sigma$ is the surface tension. Low-viscosity fluids typically have ![]() $Oh < 1$ and a necking process dominated by inertial and capillary forces. In this regime, inertiocapillary (IC) thinning is described by a 2/3 power law:

$Oh < 1$ and a necking process dominated by inertial and capillary forces. In this regime, inertiocapillary (IC) thinning is described by a 2/3 power law:

\begin{equation} \frac{D_{min}(t)}{D_0} = \alpha \left( \frac{t_b-t}{t_R} \right)^{2/3}, \end{equation}

\begin{equation} \frac{D_{min}(t)}{D_0} = \alpha \left( \frac{t_b-t}{t_R} \right)^{2/3}, \end{equation}

where ![]() $t_b$ is the filament break-up time, and

$t_b$ is the filament break-up time, and ![]() $\alpha$ is a multiplicative pre-factor between 0.4 and 1 (Zhang & Calabrese Reference Zhang and Calabrese2022). If

$\alpha$ is a multiplicative pre-factor between 0.4 and 1 (Zhang & Calabrese Reference Zhang and Calabrese2022). If ![]() $Oh>1$, viscous forces are significant, and the evolution of

$Oh>1$, viscous forces are significant, and the evolution of ![]() $D_{min}$ is described by viscocapillary thinning,

$D_{min}$ is described by viscocapillary thinning, ![]() $D_{min}(t)/D_0 = 0.0709(t_b-t)/t_v$ (McKinley & Tripathi Reference McKinley and Tripathi2000). For elastic fluids, the Deborah number,

$D_{min}(t)/D_0 = 0.0709(t_b-t)/t_v$ (McKinley & Tripathi Reference McKinley and Tripathi2000). For elastic fluids, the Deborah number, ![]() $De = t_e / t_R$, describes the ratio of the extensional relaxation time

$De = t_e / t_R$, describes the ratio of the extensional relaxation time ![]() $t_e$ and the Rayleigh time (Tirtaatmadja, McKinley & Cooper-White Reference Tirtaatmadja, McKinley and Cooper-White2006). If

$t_e$ and the Rayleigh time (Tirtaatmadja, McKinley & Cooper-White Reference Tirtaatmadja, McKinley and Cooper-White2006). If ![]() $De > 1$, the necking process is dominated by elastic and capillary forces. This elastocapillary (EC) regime is described by

$De > 1$, the necking process is dominated by elastic and capillary forces. This elastocapillary (EC) regime is described by

where ![]() $A = (GD_0/2\sigma )^{1/3}$. The fluids in the present investigation exhibit thinning in an IC (

$A = (GD_0/2\sigma )^{1/3}$. The fluids in the present investigation exhibit thinning in an IC (![]() $Oh<1$) or EC regime (

$Oh<1$) or EC regime (![]() $De>1$). Nonlinear least-square regression was used to establish

$De>1$). Nonlinear least-square regression was used to establish ![]() $t_e$ for fluids that exhibited EC thinning using measurements of

$t_e$ for fluids that exhibited EC thinning using measurements of ![]() $D_{min}$ and (2.4). Values of

$D_{min}$ and (2.4). Values of ![]() $t_e$ are listed in Appendix A.

$t_e$ are listed in Appendix A.

2.4. Particle shadow velocimetry

Particle image velocimetry (PIV) with backlight illumination, denoted as particle shadow velocimetry (PSV), was used to measure the velocity of the fluid within the test section. In PSV, the thickness of the measurement domain is driven largely by the depth of focus (DOF) of the imaging system. Provided a sufficient magnification and lens aperture, images can be acquired with a thin focal plan that enables 2-D planar flow measurements along a select and narrow region of interest (Santiago et al. Reference Santiago, Wereley, Meinhart, Beebe and Adrian1998; Estevadeordal & Goss Reference Estevadeordal and Goss2006; Khodaparast et al. Reference Khodaparast, Borhani, Tagliabue and Thome2013).

The PSV system consisted of a digital camera (Imager Pro X, LaVision GmbH) with a ![]() $2048 \times 2048$ pixel charged-coupled device sensor. Each pixel was

$2048 \times 2048$ pixel charged-coupled device sensor. Each pixel was ![]() $7.4 \times 7.4$

$7.4 \times 7.4$ ![]() $\mathrm {\mu }$m

$\mathrm {\mu }$m![]() $^2$ in size and had a 14-bit digital resolution. A Nikon lens with a focal length of

$^2$ in size and had a 14-bit digital resolution. A Nikon lens with a focal length of ![]() $f=105$ mm was equipped to the camera with an aperture diameter of

$f=105$ mm was equipped to the camera with an aperture diameter of ![]() $f/2.8$. The camera focus was adjusted such that images were focused on the radial mid-span of the test section. Two fields of view (FOVs) were considered, as shown in figure 3(a). The first FOV, i.e. FOV1, considered the entrance or development region immediately upstream of the PCT, as demonstrated in the left-hand side of figure 3(a). The FOV1 captured the complete tube radius,

$f/2.8$. The camera focus was adjusted such that images were focused on the radial mid-span of the test section. Two fields of view (FOVs) were considered, as shown in figure 3(a). The first FOV, i.e. FOV1, considered the entrance or development region immediately upstream of the PCT, as demonstrated in the left-hand side of figure 3(a). The FOV1 captured the complete tube radius, ![]() $R_o$, and approximately 3

$R_o$, and approximately 3![]() $\lambda$ along the

$\lambda$ along the ![]() $x$ direction and immediately upstream of the first oscillation in the PCT. Only the Newtonian flow of water was considered in FOV1. The objective was to determine if the flow entering the PCT was a fully-developed laminar Poiseuille flow. Experimental results for FOV1 are presented separately in Appendix C. The second field of view, FOV2, measured the velocity between the second and fifth oscillation of the PCT, that is, from

$x$ direction and immediately upstream of the first oscillation in the PCT. Only the Newtonian flow of water was considered in FOV1. The objective was to determine if the flow entering the PCT was a fully-developed laminar Poiseuille flow. Experimental results for FOV1 are presented separately in Appendix C. The second field of view, FOV2, measured the velocity between the second and fifth oscillation of the PCT, that is, from ![]() $x \approx 2\lambda$ to

$x \approx 2\lambda$ to ![]() $5\lambda$. For FOV2, flows of the three non-Newtonian fluids through the PCT were measured. Both FOVs were approximately the same size,

$5\lambda$. For FOV2, flows of the three non-Newtonian fluids through the PCT were measured. Both FOVs were approximately the same size, ![]() $(\Delta x, \Delta r) = 3.24 \times 14.1$ mm

$(\Delta x, \Delta r) = 3.24 \times 14.1$ mm![]() $^2$, with a scale of 6.88

$^2$, with a scale of 6.88 ![]() $\mathrm {\mu }$m pixel

$\mathrm {\mu }$m pixel![]() $^{-1}$ after the sensor was cropped to remove unnecessary data for

$^{-1}$ after the sensor was cropped to remove unnecessary data for ![]() $r/R_o>1$. The magnification was 1.07 and the DOF was 87

$r/R_o>1$. The magnification was 1.07 and the DOF was 87 ![]() $\mathrm {\mu }$m, which was approximately 10 % the minimum radius in the PCT,

$\mathrm {\mu }$m, which was approximately 10 % the minimum radius in the PCT, ![]() $R_{i}$.

$R_{i}$.

Figure 3. (a) A two-dimensional schematic showing the different PSV fields of view. (b) Sample PSV image (TTAC at ![]() $c = 0.04\,\%$) for FOV2. (c) An enhanced version of the sample image in panel (b) for TTAC at

$c = 0.04\,\%$) for FOV2. (c) An enhanced version of the sample image in panel (b) for TTAC at ![]() $c=0.04\,\%$ and FOV2.

$c=0.04\,\%$ and FOV2.

Backlight illumination of the PIV recordings was achieved using a 15 mJ pulse![]() $^{-1}$ Nd:YAG laser (Solo I-15, New Wave Research Inc.) equipped with a diffuser. A diffuser expanded the laser beam, made the incident light incoherent and changed the wavelength to 610 nm using fluorescent disks. A programmable timing unit (PTU-9, LaVision GmbH) and DaVis 8.4 software (LaVision GmbH) were used to synchronize the camera and laser. Silver coated hollow glass spheres, with diameter

$^{-1}$ Nd:YAG laser (Solo I-15, New Wave Research Inc.) equipped with a diffuser. A diffuser expanded the laser beam, made the incident light incoherent and changed the wavelength to 610 nm using fluorescent disks. A programmable timing unit (PTU-9, LaVision GmbH) and DaVis 8.4 software (LaVision GmbH) were used to synchronize the camera and laser. Silver coated hollow glass spheres, with diameter ![]() $d_p = 10$

$d_p = 10$ ![]() $\mathrm {\mu }$m, were used as tracer particles in the flow (S-HGS-10, Dantec Dynamics). These particles were opaque, which was ideal for projecting a shadow on the camera in backlight illumination. The density of the particles,

$\mathrm {\mu }$m, were used as tracer particles in the flow (S-HGS-10, Dantec Dynamics). These particles were opaque, which was ideal for projecting a shadow on the camera in backlight illumination. The density of the particles, ![]() $\rho _p$, was 1400 kg m

$\rho _p$, was 1400 kg m![]() $^{-3}$. As a result the particle response time,

$^{-3}$. As a result the particle response time, ![]() $t_p = \rho _p d_p^2/18 \eta _s$, and particle settling velocity,

$t_p = \rho _p d_p^2/18 \eta _s$, and particle settling velocity, ![]() $u_p = (\rho _p - \rho )d_p^2g/18\eta _s$, could be established. Here,

$u_p = (\rho _p - \rho )d_p^2g/18\eta _s$, could be established. Here, ![]() $g$ is the gravitational acceleration. The particle response time,

$g$ is the gravitational acceleration. The particle response time, ![]() $t_p$, was 7.8

$t_p$, was 7.8 ![]() $\mathrm {\mu }$s and the particle settling velocity,

$\mathrm {\mu }$s and the particle settling velocity, ![]() $u_p$, was 21.8

$u_p$, was 21.8 ![]() $\mathrm {\mu }$m s

$\mathrm {\mu }$m s![]() $^{-1}$. We estimated the Stokes number to be

$^{-1}$. We estimated the Stokes number to be ![]() $St = t_p \dot {\gamma }_w$, and the Froude number to be

$St = t_p \dot {\gamma }_w$, and the Froude number to be ![]() $Fr = 2u_p/U_0$. The largest

$Fr = 2u_p/U_0$. The largest ![]() $St$ was 0.003 and the largest

$St$ was 0.003 and the largest ![]() $Fr$ was 0.005, depending on

$Fr$ was 0.005, depending on ![]() $Q$. Both the Stokes and Froude numbers are small (less than 0.1) and errors attributed to particle inertia and particle settling are negligible.

$Q$. Both the Stokes and Froude numbers are small (less than 0.1) and errors attributed to particle inertia and particle settling are negligible.

For FOV1, five sets of measurements were performed for water, each for the different values of ![]() $Q$ listed in § 2.1. The results for FOV1 are presented in Appendix C. The measurements of velocity within the entrance region show good agreement with the theoretical expectations for all values of

$Q$ listed in § 2.1. The results for FOV1 are presented in Appendix C. The measurements of velocity within the entrance region show good agreement with the theoretical expectations for all values of ![]() $Q$, providing good confidence in PSV to produce reasonable measurements. For FOV2, measurements were performed for three different non-Newtonian fluids, each having five different concentrations, and five flow rates

$Q$, providing good confidence in PSV to produce reasonable measurements. For FOV2, measurements were performed for three different non-Newtonian fluids, each having five different concentrations, and five flow rates ![]() $Q$ (75 datasets in total). Additionally, five measurements were performed for distilled water at FOV2 for each value of

$Q$ (75 datasets in total). Additionally, five measurements were performed for distilled water at FOV2 for each value of ![]() $Q$. Each dataset consisted of 600 pairs of double-frame images recorded at an acquisition frequency of 7.3 Hz. A sample image of the first frame for TTAC at a mass concentration of 0.04 % is shown in figure 3(b). The time delay,

$Q$. Each dataset consisted of 600 pairs of double-frame images recorded at an acquisition frequency of 7.3 Hz. A sample image of the first frame for TTAC at a mass concentration of 0.04 % is shown in figure 3(b). The time delay, ![]() $\Delta t$, between image frames was between 500 and 7000

$\Delta t$, between image frames was between 500 and 7000 ![]() $\mathrm {\mu }$s depending on the value of

$\mathrm {\mu }$s depending on the value of ![]() $Q$, such that the maximum particle displacement between the image frames was no greater than 15 pixel.

$Q$, such that the maximum particle displacement between the image frames was no greater than 15 pixel.

Image processing was performed using DaVis 8.4 software (LaVision Gmbh). First, the images were inverted; the intensity signal at each pixel was subtracted from a constant intensity value. Next, the minimum intensity within each pixel and along the complete image ensemble was determined and subtracted from all images in each dataset. Third, the intensity signals at each pixel were normalized by the average intensity of the ensemble. A sample image (TTAC at a mass concentration of 0.04 %) after performing the previously detailed processing steps can be seen in figure 3(c). Compared to the native image, seen in figure 3(b), the processed image has more clearly defined bright particles for all values of ![]() $r$.

$r$.

Vector fields were established using the ensemble-of-correlation method with an initial interrogation window (IW) size of ![]() $64 \times 64$ pixel (

$64 \times 64$ pixel (![]() $0.44 \times 0.44$ mm

$0.44 \times 0.44$ mm![]() $^2$ or

$^2$ or ![]() $0.41R \times 0.41R$) and a final IW size of

$0.41R \times 0.41R$) and a final IW size of ![]() $16 \times 16$ pixel (

$16 \times 16$ pixel (![]() $0.11 \times 0.11$ mm

$0.11 \times 0.11$ mm![]() $^2$ or

$^2$ or ![]() $0.10R \times 0.10R$) with 75 % overlap between neighbouring IWs (Meinhart, Wereley & Santiago Reference Meinhart, Wereley and Santiago2000). The velocity vector was denoted as

$0.10R \times 0.10R$) with 75 % overlap between neighbouring IWs (Meinhart, Wereley & Santiago Reference Meinhart, Wereley and Santiago2000). The velocity vector was denoted as ![]() $\boldsymbol {u}$, with components in cylindrical coordinates being

$\boldsymbol {u}$, with components in cylindrical coordinates being ![]() $u_r, u_{\theta },u_x$, corresponding to the velocity along the

$u_r, u_{\theta },u_x$, corresponding to the velocity along the ![]() $r, \theta, x$ directions, respectively. The flow is laminar and steady, with presumably no swirl, i.e.

$r, \theta, x$ directions, respectively. The flow is laminar and steady, with presumably no swirl, i.e. ![]() $u_{\theta } = 0$, given the geometric dimensions of the PCT and the Reynolds numbers of the flows in the present investigation (Deiber & Schowalter Reference Deiber and Schowalter1979). We also did not observe evidence of secondary flow re-circulations, turbulence or swirl.

$u_{\theta } = 0$, given the geometric dimensions of the PCT and the Reynolds numbers of the flows in the present investigation (Deiber & Schowalter Reference Deiber and Schowalter1979). We also did not observe evidence of secondary flow re-circulations, turbulence or swirl.

Sources of uncertainty in the PSV measurements were assumed to include: (i) errors due to subpixel interpolation of the correlation function; (ii) the finite DOF; and (iii) optical distortion near the walls of the tube from radial curvature and differences in the refractive index. Each source of uncertainty was conservatively estimated, the details for which are listed below.

(i) Errors from subpixel interpolation are conservatively estimated to be 0.1 pixels according to Raffel et al. (Reference Raffel, Willert, Scarano, Kähler, Wereley and Kompenhans2018). A 0.1 pixel error in displacement translates to an error in velocity of 0.1–1.4 mm s

$^{-1}$ depending on

$^{-1}$ depending on  $\Delta t$. If this error is normalized by the average centreline velocity,

$\Delta t$. If this error is normalized by the average centreline velocity,  $\langle U_0 \rangle$, the largest velocity error among all flow conditions was 0.012

$\langle U_0 \rangle$, the largest velocity error among all flow conditions was 0.012 $\langle U_0 \rangle$.

$\langle U_0 \rangle$.(ii) Quantifying the uncertainties attributed to radial distortion and differences in the refractive index was challenging and would require ray tracing analysis (Minor, Oshkai & Djilali Reference Minor, Oshkai and Djilali2007). Instead, errors from radial distortion were conservatively estimated based on how well the velocity within FOV1 could match the theoretical Poiseuille profile, as discussed in Appendix C. The results of the analysis in Appendix C demonstrated that the largest deviation from the parabolic velocity profile was

$0.04\langle U_0\rangle$.

$0.04\langle U_0\rangle$.(iii) Slower moving particles within the DOF but outside the centre plane of the tube will bias velocity vectors to lower values. If we consider a parabolic velocity profile when the wall radius

$R_w$ is equal to

$R_w$ is equal to  $R_i$, a DOF that is

$R_i$, a DOF that is  $0.1R_i$ in thickness would produce a relative error in

$0.1R_i$ in thickness would produce a relative error in  $u_x$ of approximately

$u_x$ of approximately  $0.003\langle U_0 \rangle$ near the centreline of the PCT and

$0.003\langle U_0 \rangle$ near the centreline of the PCT and  $0.1\langle U_0 \rangle$ near the wall of the PCT. These errors reduce when considering regions of the PCT with a larger wall radius.

$0.1\langle U_0 \rangle$ near the wall of the PCT. These errors reduce when considering regions of the PCT with a larger wall radius.

The total uncertainty in measurements of ![]() $\boldsymbol {u}$ from PSV was estimated to be the root sum squared value of the three previously listed sources of uncertainty. This was approximately

$\boldsymbol {u}$ from PSV was estimated to be the root sum squared value of the three previously listed sources of uncertainty. This was approximately ![]() $0.042\langle U_0 \rangle$ near the PCT centreline and

$0.042\langle U_0 \rangle$ near the PCT centreline and ![]() $0.108\langle U_0 \rangle$ near the PCT walls, when considering regions of the PCT where

$0.108\langle U_0 \rangle$ near the PCT walls, when considering regions of the PCT where ![]() $R_w = R_i$. In subsequent plots of velocity within the PCT, error bars are used to display the uncertainty in the velocity measurements from PSV.

$R_w = R_i$. In subsequent plots of velocity within the PCT, error bars are used to display the uncertainty in the velocity measurements from PSV.

2.5. Flow field analysis

The steady flow of complex and Newtonian fluids in the PCT are governed by the following equations for mass and momentum conservation:

where ![]() $p$ is the indeterminate component of the Cauchy stress tensor and

$p$ is the indeterminate component of the Cauchy stress tensor and ![]() $\boldsymbol {\tau }$ is the deviatoric stress tensor. The velocity gradient tensor,

$\boldsymbol {\tau }$ is the deviatoric stress tensor. The velocity gradient tensor, ![]() $\boldsymbol{\mathsf{L}} = \boldsymbol {\nabla } \boldsymbol {u}$, can be decomposed into the symmetric rate of deformation tensor,

$\boldsymbol{\mathsf{L}} = \boldsymbol {\nabla } \boldsymbol {u}$, can be decomposed into the symmetric rate of deformation tensor, ![]() $\boldsymbol{\mathsf{D}} = (\boldsymbol{\mathsf{L}} + \boldsymbol{\mathsf{L}}^{{\dagger} })/2$, and anti-symmetric rate of rotation tensor,

$\boldsymbol{\mathsf{D}} = (\boldsymbol{\mathsf{L}} + \boldsymbol{\mathsf{L}}^{{\dagger} })/2$, and anti-symmetric rate of rotation tensor, ![]() $\boldsymbol{\mathsf{W}} = (\boldsymbol{\mathsf{L}} - \boldsymbol{\mathsf{L}}^{{\dagger} })/2$, where

$\boldsymbol{\mathsf{W}} = (\boldsymbol{\mathsf{L}} - \boldsymbol{\mathsf{L}}^{{\dagger} })/2$, where ![]() ${\dagger}$ represents the matrix transpose. The components of

${\dagger}$ represents the matrix transpose. The components of ![]() $\boldsymbol{\mathsf{D}}$ and

$\boldsymbol{\mathsf{D}}$ and ![]() $\boldsymbol{\mathsf{W}}$ are listed:

$\boldsymbol{\mathsf{W}}$ are listed:

\begin{gather} \left. \begin{array}{c} \displaystyle {\mathsf{D}}_{rr} = \dfrac{\partial u_r}{\partial r},\quad {\mathsf{D}}_{\theta \theta} = \dfrac{u_r}{r},\quad {\mathsf{D}}_{xx} = \dfrac{\partial u_x}{\partial x},\\ \displaystyle {\mathsf{D}}_{r x} = {\mathsf{D}}_{x r} = \dfrac{1}{2}\left( \dfrac{\partial u_r}{\partial x} + \dfrac{\partial u_x}{\partial r} \right), \end{array}\right\} \end{gather}

\begin{gather} \left. \begin{array}{c} \displaystyle {\mathsf{D}}_{rr} = \dfrac{\partial u_r}{\partial r},\quad {\mathsf{D}}_{\theta \theta} = \dfrac{u_r}{r},\quad {\mathsf{D}}_{xx} = \dfrac{\partial u_x}{\partial x},\\ \displaystyle {\mathsf{D}}_{r x} = {\mathsf{D}}_{x r} = \dfrac{1}{2}\left( \dfrac{\partial u_r}{\partial x} + \dfrac{\partial u_x}{\partial r} \right), \end{array}\right\} \end{gather}

where ![]() $\boldsymbol {\omega }$ is the vorticity vector, whose only non-zero component is

$\boldsymbol {\omega }$ is the vorticity vector, whose only non-zero component is ![]() $\omega _{\theta }$. Undisclosed components of

$\omega _{\theta }$. Undisclosed components of ![]() $\boldsymbol{\mathsf{D}}$ and

$\boldsymbol{\mathsf{D}}$ and ![]() $\boldsymbol{\mathsf{W}}$ are zero. Equation (2.5) reduces to the Navier–Stokes equation for Newtonian fluids when the deviatoric stress tensor is represented by the constitutive equation

$\boldsymbol{\mathsf{W}}$ are zero. Equation (2.5) reduces to the Navier–Stokes equation for Newtonian fluids when the deviatoric stress tensor is represented by the constitutive equation ![]() $\boldsymbol {\tau } = 2\eta _s \boldsymbol{\mathsf{D}}$. For non-Newtonian fluids, the constitutive relation is much more complex and can be a partial differential equation with nonlinear terms (e.g. Phan–Thien–Tanner and Giesekus models). For most non-Newtonian constitutive models, it is common to segregate the deviatoric stress tensor into a solvent and non-Newtonian stress, i.e.

$\boldsymbol {\tau } = 2\eta _s \boldsymbol{\mathsf{D}}$. For non-Newtonian fluids, the constitutive relation is much more complex and can be a partial differential equation with nonlinear terms (e.g. Phan–Thien–Tanner and Giesekus models). For most non-Newtonian constitutive models, it is common to segregate the deviatoric stress tensor into a solvent and non-Newtonian stress, i.e. ![]() $\boldsymbol {\tau } = \boldsymbol {\tau }_{\boldsymbol {s}} + \boldsymbol {\tau }_{\boldsymbol {nn}}$ (Alves, Oliveira & Pinho Reference Alves, Oliveira and Pinho2020). Here,

$\boldsymbol {\tau } = \boldsymbol {\tau }_{\boldsymbol {s}} + \boldsymbol {\tau }_{\boldsymbol {nn}}$ (Alves, Oliveira & Pinho Reference Alves, Oliveira and Pinho2020). Here, ![]() $\boldsymbol {\tau }_{\boldsymbol {s}} = 2\eta _s \boldsymbol{\mathsf{D}}$ is the solvent stress and

$\boldsymbol {\tau }_{\boldsymbol {s}} = 2\eta _s \boldsymbol{\mathsf{D}}$ is the solvent stress and ![]() $\boldsymbol {\tau }_{\boldsymbol {nn}}$ is the non-Newtonian stress introduced from the polymers or micelles. Note that if

$\boldsymbol {\tau }_{\boldsymbol {nn}}$ is the non-Newtonian stress introduced from the polymers or micelles. Note that if ![]() $\boldsymbol {\tau }_{\boldsymbol {nn}} = 0$, then

$\boldsymbol {\tau }_{\boldsymbol {nn}} = 0$, then ![]() $\boldsymbol {\tau } = \boldsymbol {\tau _{s}}$ and the constitutive equation is Newtonian. When substituted into (2.5), the divergence of the non-Newtonian stress,

$\boldsymbol {\tau } = \boldsymbol {\tau _{s}}$ and the constitutive equation is Newtonian. When substituted into (2.5), the divergence of the non-Newtonian stress, ![]() $\boldsymbol {\nabla } \boldsymbol {\cdot } \boldsymbol {\tau }_{\boldsymbol {nn}}$, acts as an additional forcing term and for polymeric flows is often referred to as a ‘polymer force’ (Kim et al. Reference Kim, Li, Sureshkumar, Balachandar and Adrian2007).

$\boldsymbol {\nabla } \boldsymbol {\cdot } \boldsymbol {\tau }_{\boldsymbol {nn}}$, acts as an additional forcing term and for polymeric flows is often referred to as a ‘polymer force’ (Kim et al. Reference Kim, Li, Sureshkumar, Balachandar and Adrian2007).

Equations (2.6) and (2.7) can be explicitly evaluated using the measured ![]() $u_x$ and

$u_x$ and ![]() $u_r$. To circumvent the need for pressure,

$u_r$. To circumvent the need for pressure, ![]() $p$, we considered the vorticity transport equation obtained from taking the curl of the momentum transport equation, shown in (2.5). The only non-zero component of the vorticity in the PCT flow is

$p$, we considered the vorticity transport equation obtained from taking the curl of the momentum transport equation, shown in (2.5). The only non-zero component of the vorticity in the PCT flow is ![]() $\omega _{\theta }$; therefore, we consider the vorticity transport equation along the azimuthal direction alone:

$\omega _{\theta }$; therefore, we consider the vorticity transport equation along the azimuthal direction alone:

\begin{equation} \underbrace{u_r \frac{\partial \omega_{\theta}}{\partial r} + u_x \frac{\partial \omega_{\theta}}{\partial x} - \frac{u_r \omega_{\theta}}{r}}_{VA} = \underbrace{\nu_s \left( \frac{\partial^2 \omega_{\theta}}{\partial r^2} + \frac{1}{r} \frac{\partial \omega_{\theta}}{\partial r} + \frac{\partial^2 \omega_{\theta}}{\partial x^2} - \frac{\omega_{\theta}}{r^2} \right)}_{VSD} + \hspace{0.3em} T_{\theta}. \end{equation}

\begin{equation} \underbrace{u_r \frac{\partial \omega_{\theta}}{\partial r} + u_x \frac{\partial \omega_{\theta}}{\partial x} - \frac{u_r \omega_{\theta}}{r}}_{VA} = \underbrace{\nu_s \left( \frac{\partial^2 \omega_{\theta}}{\partial r^2} + \frac{1}{r} \frac{\partial \omega_{\theta}}{\partial r} + \frac{\partial^2 \omega_{\theta}}{\partial x^2} - \frac{\omega_{\theta}}{r^2} \right)}_{VSD} + \hspace{0.3em} T_{\theta}. \end{equation}

The additional term on the right-hand side of (2.8), is the azimuthal component of the non-Newtonian torque, ![]() $\boldsymbol {T} = (\boldsymbol {\nabla } \times \boldsymbol {\nabla } \boldsymbol {\cdot } \boldsymbol {\tau }_{\boldsymbol {nn}})/\rho$. The non-Newtonian torque is a vector, whose only non-zero component in the PCT is

$\boldsymbol {T} = (\boldsymbol {\nabla } \times \boldsymbol {\nabla } \boldsymbol {\cdot } \boldsymbol {\tau }_{\boldsymbol {nn}})/\rho$. The non-Newtonian torque is a vector, whose only non-zero component in the PCT is ![]() $T_{\theta }$. Previous numerical investigations have denoted

$T_{\theta }$. Previous numerical investigations have denoted ![]() $\boldsymbol {T}$ the ‘polymer torque’ as it can be represented as the curl of the polymer force (Kim et al. Reference Kim, Li, Sureshkumar, Balachandar and Adrian2007, Reference Kim, Adrian, Balachandar and Sureshkumar2008; Kim & Sureshkumar Reference Kim and Sureshkumar2013; Page & Zaki Reference Page and Zaki2015, Reference Page and Zaki2016; Biancofiore, Brandt & Zaki Reference Biancofiore, Brandt and Zaki2017; Lee & Zaki Reference Lee and Zaki2017). Its simplified units are s

$\boldsymbol {T}$ the ‘polymer torque’ as it can be represented as the curl of the polymer force (Kim et al. Reference Kim, Li, Sureshkumar, Balachandar and Adrian2007, Reference Kim, Adrian, Balachandar and Sureshkumar2008; Kim & Sureshkumar Reference Kim and Sureshkumar2013; Page & Zaki Reference Page and Zaki2015, Reference Page and Zaki2016; Biancofiore, Brandt & Zaki Reference Biancofiore, Brandt and Zaki2017; Lee & Zaki Reference Lee and Zaki2017). Its simplified units are s![]() $^{-2}$ – when multiplied by moment of inertia, the units are force times unit distance, consistent with the true torque definition. The under-braces shown in (2.8) isolate the different combinations of terms within the vorticity transport equation. On the left-hand side of (2.8),

$^{-2}$ – when multiplied by moment of inertia, the units are force times unit distance, consistent with the true torque definition. The under-braces shown in (2.8) isolate the different combinations of terms within the vorticity transport equation. On the left-hand side of (2.8), ![]() $VA$ denotes the azimuthal vorticity advection. The first term on the right-hand side of (2.8),

$VA$ denotes the azimuthal vorticity advection. The first term on the right-hand side of (2.8), ![]() $VSD$, represents vorticity solvent diffusion, where

$VSD$, represents vorticity solvent diffusion, where ![]() $\nu _s = \eta _s/\rho$. For each flow, the azimuthal non-Newtonian torque was calculated based on the deficit between

$\nu _s = \eta _s/\rho$. For each flow, the azimuthal non-Newtonian torque was calculated based on the deficit between ![]() $VA$ and

$VA$ and ![]() $VSD$, i.e.

$VSD$, i.e. ![]() $T_{\theta } = VA - VSD$.

$T_{\theta } = VA - VSD$.

To establish the first-order spatial gradients of velocity, a moving second-order polynomial surface was fit on profiles of ![]() $u_x$ and

$u_x$ and ![]() $u_r$. The size of the second-order polynomial filter was

$u_r$. The size of the second-order polynomial filter was ![]() $20 \times 20$ pixels,

$20 \times 20$ pixels, ![]() $138\times 138$

$138\times 138$ ![]() $\mathrm {\mu } \textrm {m}^2$ or

$\mathrm {\mu } \textrm {m}^2$ or ![]() $0.15R \times 0.15R$. Coefficients of the polynomial surface were used to establish first-order spatial derivatives of

$0.15R \times 0.15R$. Coefficients of the polynomial surface were used to establish first-order spatial derivatives of ![]() $u_x$ and

$u_x$ and ![]() $u_r$. Azimuthal vorticity,

$u_r$. Azimuthal vorticity, ![]() $\omega _{\theta }$, was then established using (2.7). To determine the higher order spatial gradients in the flow, a moving third-order polynomial surface was fit on profiles of

$\omega _{\theta }$, was then established using (2.7). To determine the higher order spatial gradients in the flow, a moving third-order polynomial surface was fit on profiles of ![]() $u_x$ and

$u_x$ and ![]() $u_r$. The size of the cubic polynomial filter was

$u_r$. The size of the cubic polynomial filter was ![]() $76 \times 76$ pixels,

$76 \times 76$ pixels, ![]() $522\times 522$

$522\times 522$ ![]() $\mathrm {\mu } \textrm {m}^2$, or

$\mathrm {\mu } \textrm {m}^2$, or ![]() $0.56R \times 0.56R$. Coefficients of the third-order polynomial were used to the determine the second- and third-order spatial derivatives of

$0.56R \times 0.56R$. Coefficients of the third-order polynomial were used to the determine the second- and third-order spatial derivatives of ![]() $u_x$ and

$u_x$ and ![]() $u_r$. Three orders of differentiation in

$u_r$. Three orders of differentiation in ![]() $\boldsymbol {u}$ are required due to the

$\boldsymbol {u}$ are required due to the ![]() $VSD$ term in (2.8). These higher-order derivatives were then used to calculate the azimuthal non-Newtonian torque

$VSD$ term in (2.8). These higher-order derivatives were then used to calculate the azimuthal non-Newtonian torque ![]() $T_{\theta }$ using (2.8). Polynomial filters that overlapped with the PCT wall were neglected, and results of

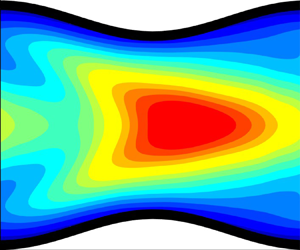

$T_{\theta }$ using (2.8). Polynomial filters that overlapped with the PCT wall were neglected, and results of ![]() $\omega _{\theta }$ and