Article contents

Development and properties evaluation of Mg–6% Zn/Al multilayered composites processed by accumulative roll bonding

Published online by Cambridge University Press: 18 May 2017

Abstract

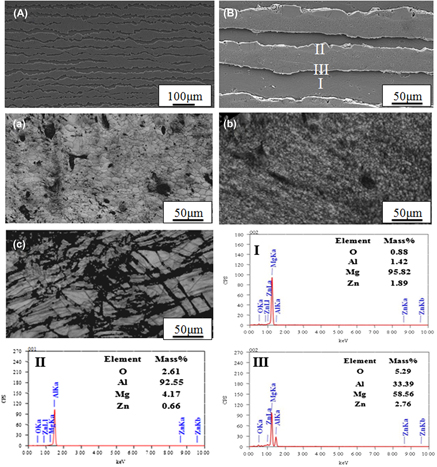

Accumulative roll bonding (ARB) process was used to develop Mg–6% Zn/Al and Mg–6% Zn/anodized–Al multilayered composites. Microstructural characterization was done using scanning electron microscopy, energy-dispersive X-ray spectroscopy, electron backscattered diffraction, and transmission electron microscopy. An average grain size measured in the roll-bonded layers of Al, anodized Al, and Mg–2% Zn was found to be 1.8 μm, 1.6 μm, and 0.6 μm, respectively. Phases Al17Mg12, AlMg4Zn11, and Al2O3 after 5-pass of ARB were confirmed by X-ray diffraction analysis. The Mg–6% Zn/Al and Mg–6% Zn/anodized Al composites exhibited tensile strengths ∼252 MPa and ∼256 MPa, respectively, after a 5-pass ARB process. Hardness of the individual layers of composite increased linearly with an increase in the number of ARB passes. Fractographs of the multilayered composite illustrated the ductile failure in Al and anodized Al layers and transgranular brittle fracture in Mg–6% Zn layers.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Mathias Göken

References

REFERENCES

- 9

- Cited by