Article contents

Effects of angular misalignment on material property characterization by nanoindentation with a cylindrical flat-tip indenter

Published online by Cambridge University Press: 19 December 2016

Abstract

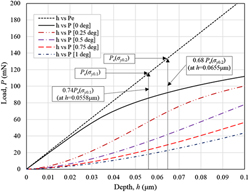

Nanoindentation techniques are commonly used to characterize nanomechanical properties of microscaled and nanoscaled materials. Nanoindentation using a cylindrical flat-tip indenter has a constant contact area which makes it a reliable source to find material’s yield strength as well as other mechanical properties. However, an angular misalignment of the indenter with the specimen results in experimental error. In this work, the effects of angular misalignment on the nanoindentation testing with a cylindrical flat-tip indenter were numerically analyzed. A three-dimensional nanoindentation solid model was generated, computer modeling based on finite element analysis was conducted. The angle of misalignment ranged from 0° to 1°. Young’s modulus and hardness were evaluated. Based on the hemispherical stress–strain distribution assumption of an elastic plastic indentation, corrected depths and modifiers were proposed for adjusting material’s 0.1% offset and 0.2% offset yield strengths. Low carbon steel AISI 1018 was selected as sample material for indentation testing and modeling validation.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

Footnotes

Contributing Editor: George M. Pharr

References

REFERENCES

- 12

- Cited by