Article contents

Mechanical enhancement of an aluminum layer by graphene coating

Published online by Cambridge University Press: 07 August 2018

Abstract

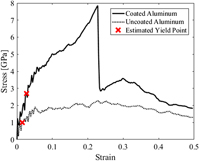

In this paper, mechanical characteristics of the aluminum layer coated with graphene are investigated by performing numerical tensile experiments through classical molecular dynamics simulations. Based on the results of the simulations, it is shown that coating with graphene enhances the Young’s modulus of aluminum by 88% while changing the tensile behavior of aluminum with hardening–softening mechanisms and significantly increased toughness. Furthermore, the effect of loading rate is examined and a transformation to an amorphous phase is observed in the coated aluminum structure as the loading rate is increased. Even though the dominant component of the coated hybrid structure is the aluminum core in the elastic region, the graphene layer shows its effects majorly in the plastic region by a 60% increase in the ultimate tensile strength. High loading rates at room temperature cause the structure transforms to an amorphous phase, as expected. Thus, effects of loading rate and temperature on amorphization are investigated by performing the same simulations at different strain rates and temperatures (i.e., 0, 300, and 600 K).

Keywords

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 5

- Cited by