Article contents

Modeling the effects of pore arrays on the electrical and mechanical properties of copper

Published online by Cambridge University Press: 03 July 2013

Abstract

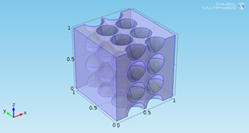

The development of porous metals has led to the need for an accurate prediction of the physical and mechanical properties of the many possible fabricated structures. For applications where yield stress needs to be reduced, while maintaining a high conductivity, the optimization of the pore dimensions, volume fraction, and pore spacing is required. A finite element model has been developed to simulate the effects of these factors on the electromechanical behavior of porous copper. This model was validated against samples of copper with mechanically induced pores as well as a copper GASAR sample. Good agreement (within an error of ±3%) was shown between the model and experimental data for the resistivity and effective modulus for both the mechanically induced pore and the GASAR samples, although the low ductility of the samples was not predicted and restricts the application of the simulation.

Keywords

- Type

- Articles

- Information

- Journal of Materials Research , Volume 28 , Issue 17: Focus Issue: Advances in the Synthesis, Characterization, and Properties of Bulk Porous Materials , 14 September 2013 , pp. 2539 - 2544

- Copyright

- Copyright © Materials Research Society 2013

References

REFERENCES

- 1

- Cited by