Article contents

Rheological behavior of semisolid hypereutectic Al–Si alloys

Published online by Cambridge University Press: 12 March 2019

Abstract

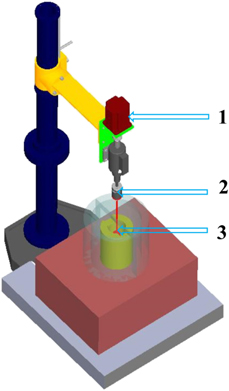

Refinement and homogenization of primary Si particles in hypereutectic Al–Si alloys is an effective route to enhance the tensile strength and wear resistance and satisfy the industrial requirements for a wide range of applications. Herein, two kinds of semisolid hypereutectic Al–Si alloys are synthesized by using a rotating-rod-induced nucleation technology. The influence of different cooling conditions and shear rates on the apparent viscosity of molten melt of slurry are examined by self-made high-precision and high-temperature apparent viscosity test equipment. The correlation between the shear rate and the uniformity of hard phases has been investigated from the obtained results, fitting curves, and optical microscope. With the increase in the shear rate, the particles tend to become rounder and the apparent viscosity becomes lower. The enhanced shape factor resulted in more rounded grains, which further reduced the apparent viscosity. During the same cooling time, the higher cooling rate resulted in higher solid fraction, generating higher apparent viscosity. The present study provides unique insight into the filling behavior of semisolid hypereutectic Al–Si alloys and serves as a baseline for future work.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 4

- Cited by