Article contents

Finite element analysis of nanowire indentation on a flat substrate

Published online by Cambridge University Press: 16 December 2011

Abstract

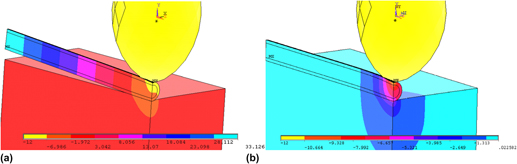

Nanowires have attracted tremendous research interests due to their potential applications. Their mechanical properties are critical for the reliability and durability of the nanowire-based devices. Compared to many other characterization techniques, the lateral probing of a nanowire using nanoindentation has the advantage of relatively simple sample preparation. However, the data analysis is difficult due to the complex contact mechanics. In all previous studies, some questionable approximations have been made to proceed with data analysis. In this study, a quantitative physical picture of nanowire lateral probing is proposed, which we believe is the first time in the literature. Three-dimensional finite element analysis (FEA) is performed and compared to a double-contact analytical model in which the two contacts, namely contact 1 (indenter/nanowire) and contact 2 (nanowire/substrate), are considered. Both the FEA and analytical models are for a specific case: an elastic spherical indention of a GaN nanowire on a Si substrate. We find that contact 1 cannot be well approximated by a Hertzian elliptical contact as assumed in many studies. We also find a large contact deformation at contact 2, which has been ignored in almost all previous studies. Finally, the adhesion condition and nanowire-receding at contact 2 are found to have insignificant effects on the data analysis.

- Type

- Articles

- Information

- Journal of Materials Research , Volume 27 , Issue 3: Focus Issue: Advances in Mechanics of One-Dimensional Micro/Nanomaterials , 14 February 2012 , pp. 586 - 591

- Copyright

- Copyright © Materials Research Society 2011

References

REFERENCES

- 10

- Cited by