Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Fan, Kaimin

Yang, Li

Zhang, Zhiyuan

Peng, Shuming

Long, Xinggui

Zhou, Xiaosong

Zu, Xiaotao

and

Gao, Fei

2014.

Ab initio calculations of mechanical properties in β-MH2−xHex (M = Er, Sc).

The European Physical Journal B,

Vol. 87,

Issue. 12,

Kuba, P.

Lorinčík, J.

Lísal, M.

and

Urbassek, H.M.

2014.

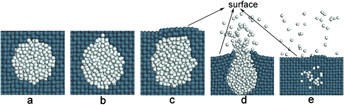

Molecular dynamics simulations of Ar gas ejection from a ruptured subsurface bubble in Cu(100) induced by impact of 200 eV Ar atoms.

Molecular Physics,

Vol. 112,

Issue. 15,

p.

2040.

Li, B.

Wang, L.

E, J. C.

Ma, H. H.

and

Luo, S. N.

2014.

Shock response of He bubbles in single crystal Cu.

Journal of Applied Physics,

Vol. 116,

Issue. 21,

Liang, Li

Ma, Mingwang

Xiang, Wei

Wang, Yuan

Cheng, Yanlin

and

Tan, Xiaohua

2015.

A molecular dynamics simulation study of temperature and depth effect on helium bubble releasing from Ti surface.

Journal of Alloys and Compounds,

Vol. 645,

Issue. ,

p.

S166.

Zhang Bao-Ling

Song Xiao-Yong

Hou Qing

and

Wang Jun

2015.

Molecular dynamics study on the phase transition of high density helium.

Acta Physica Sinica,

Vol. 64,

Issue. 1,

p.

016202.

Liang Li

Tan Xiao-Hua

Xiang Wei

Wang Yuan

Cheng Yan-Lin

and

Ma Ming-Wang

2015.

A molecular dynamics study of temperature and depth effect on helium bubble released from Ti surface.

Acta Physica Sinica,

Vol. 64,

Issue. 4,

p.

046103.

Yang, XiYuan

Quan, Jun

Liu, Siyun

and

Liu, Fusheng

2016.

The release behavior of helium in palladium nanowire: A molecular dynamics study.

Computational Materials Science,

Vol. 111,

Issue. ,

p.

190.

Cui, Jiechao

Wu, Zhangwen

and

Hou, Qing

2016.

Estimation of the lifetime of small helium bubbles near tungsten surfaces – A methodological study.

Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms,

Vol. 383,

Issue. ,

p.

136.

Qin, Wenjing

Ren, Feng

Doerner, Russell P.

Wei, Guo

Lv, Yawei

Chang, Sheng

Tang, Ming

Deng, Huiqiu

Jiang, Changzhong

and

Wang, Yongqiang

2018.

Nanochannel structures in W enhance radiation tolerance.

Acta Materialia,

Vol. 153,

Issue. ,

p.

147.

Zhou, Ting-Ting

He, An-Min

Wang, Pei

and

Shao, Jian-Li

2019.

Spall damage in single crystal Al with helium bubbles under decaying shock loading via molecular dynamics study.

Computational Materials Science,

Vol. 162,

Issue. ,

p.

255.

Lee, Brandon F.

and

Hammond, Karl D.

2021.

Temperature-dependent model of helium bubble expansion and bursting in tungsten.

Journal of Nuclear Materials,

Vol. 554,

Issue. ,

p.

153101.

Evin, Bérengère

Segard, Mathieu

Leroy, Éric

Baaziz, Walid

Paul-Boncour, Valérie

Challet, Sylvain

Fabre, Arnaud

Thiébaut, Stéphanie

Latroche, Michel

Moskura, Mélanie

and

Charpentier, Thibault

2023.

Aging of Pd under tritium: Influence of 3He generation and associated mechanisms.

Journal of Alloys and Compounds,

Vol. 938,

Issue. ,

p.

168589.

Jian, Jiarui

Shi, Liqun

and

Zhang, Bin

2024.

The behavior of helium bubble evolution under neutron irradiation in different tungsten surfaces.

Journal of Nuclear Materials,

Vol. 593,

Issue. ,

p.

154994.