Article contents

Radiation stability of nanocrystalline single-phase multicomponent alloys

Published online by Cambridge University Press: 20 February 2019

Abstract

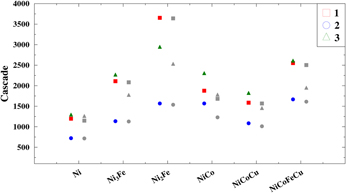

In search of materials with better properties, polycrystalline materials are often found to be superior to their respective single crystalline counterparts. Reduction of grain size in polycrystalline materials can drastically alter the properties of materials. When the grain sizes reach the nanometer scale, the improved mechanical response of the materials make them attractive in many applications. Multicomponent solid-solution alloys have shown to have a higher radiation tolerance compared with pure materials. Combining these advantages, we investigate the radiation tolerance of nanocrystalline multicomponent alloys. We find that these alloys withstand a much higher irradiation dose, compared with nanocrystalline Ni, before the nanocrystallinity is lost. Some of the investigated alloys managed to keep their nanocrystallinity for twice the irradiation dose as pure Ni.

- Type

- Article

- Information

- Journal of Materials Research , Volume 34 , Issue 5: Focus Issue: Nanocrystalline High Entropy Materials: Processing Challenges and Properties , 14 March 2019 , pp. 854 - 866

- Copyright

- Copyright © Materials Research Society 2019

References

- 10

- Cited by