Published online by Cambridge University Press: 18 March 2022

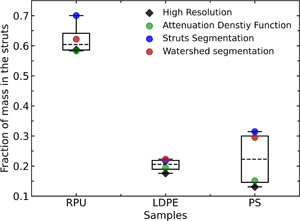

Three independent analysis methods were developed to investigate the distribution of solid mass in foams analyzed by X-ray tomography with effective pixel sizes larger than the thickness of the solid network (sub-pixel conditions). Validation of the methods was achieved by a comparison with the results obtained employing high-resolution tomography for the same set of foams. The foams showed different solid mass distribution, which varied from being preferentially located on the edges, with a fraction of mass in the struts nearing 0.6, to materials in which the fraction of mass in the struts was low, under 0.15. In all cases, the accuracy of the proposed approaches was greater for materials with a higher fraction of mass in the struts. The method based on deconvolution of the attenuation probability density function yielded the closest results to the high-resolution characterizations. In contrast, analysis of the solid matrix thickness distribution after watershed segmentation, and binarization of high thickness regions (struts segmentation) required normalization through macroscopic measurements and revealed higher deviations with respect to the high-resolution results. However, segmentation-based methods allowed investigation of the heterogeneity of the fraction of mass in the struts along the sample.