Article contents

Observations on the Early Stages of Corrosion on AA2099-T83

Published online by Cambridge University Press: 09 June 2020

Abstract

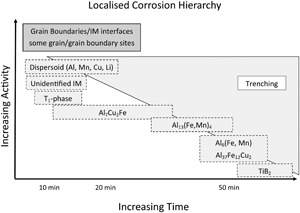

An Al–Cu–Li aerospace alloy has been investigated to determine the order in which corrosion at different types of sites occurs in AA2099-T83. Specifically, the sequence of galvanic attack on intermetallic (IM) particles and other sites of AA2099-T83 was determined as a function of time, in 0.1 M NaCl, through the use of scanning electron microscopy and electron backscatter diffraction characterization techniques. The earliest attack occurred at isolated grains and grain boundaries and on Li-containing dispersoids. Similarly, some constituent IM particles showed evidence of trenching in the surrounding alloy matrix. These IM particles included Al7Cu2Fe and another group of unidentified particles which displayed complete trenching within the first 10 min of exposure. Al13(Fe, Mn)4 were next most active followed by Al37Fe12Cu2 with Al6(Fe,Mn) and large TiB2 particles being the least active.

- Type

- Australian Microbeam Analysis Society Special Section AMAS XV 2019

- Information

- Copyright

- Copyright © Microscopy Society of America 2020

References

- 8

- Cited by