Introduction

Nanocomposites are composed of two or more phases engineered to have nanoscale architectures with a high density of interfaces, and often with nested, hierarchical geometries. By engineering the length scales, morphology, crystal structure, and chemistry of interfaces, nanocomposites can deliver mechanical properties that exceed what could be achieved from a single-phase material alone. Metal nanolayered composites consisting of alternating layers of two different metals with nanoscale repeat layer spacing exhibit ultrahigh strengths that greatly exceed the strength from simple volume fraction estimation.Reference Mara, Bhattacharyya, Dickerson, Hoagland and Misra1 Using severe plastic deformation, interface-engineered nanocrystalline steel has been produced with a far-from-equilibrium structure containing supersaturated carbon at iron subgrain boundaries and a tensile strength of 7 GPa, which is perhaps the strongest bulk ductile metallic nanocomposite reported.Reference Li, Raabe, Herbig, Choi, Goto, Kostka, Yarita, Borchers and Kirchheim2 Biological systems such as nacre, a composite consisting of aragonite platelets separated by a thin organic layer, are known to have superior toughness.Reference Mao, Gao, Yao, Liu, Cölfen, Liu, Chen, Li, Yan, Liu and Yu3 Bioinspired hierarchical and nanolaminated multiphase steels have been developed that exhibit superior fatigue resistance at ultrahigh flow strengths.Reference Koyama, Zhang, Wang, Ponge, Raabe, Tsuzaki, Noguchi and Tasan4

The articles in this issue of MRS Bulletin highlight recent developments in the mechanics of nanocomposites that are composed of a combination of metallic, polymer, biological, and ceramic materials. They also outline the challenges and opportunities for future research directions. Advances in computational and experimental approaches to guide the synthesis and elucidate novel and unusual aspects of nanomechanical behavior of composites are highlighted.

Metal-based nanocomposite systems

Earlier work on metallic nanocomposites focused on simple geometries such as laminates, which contain metals with cubic crystal symmetries to explore size effects in plasticity following the “smaller is stronger” paradigm,Reference Hoagland, Hirth and Misra5,Reference Anderson, Bingert, Misra and Hirth6 and later on, expanded to other material systems such as metal–ceramicReference Salehinia, Shao, Wang and Zbib7,Reference Yang, Mayer, Li, Baldwin, Mara, Chawla, Molina-Aldareguia and Llorca8 and metal–metallic glass.Reference Cheng and Trelewicz9–Reference Knorr, Cordero, Lilleodden and Volkert11 Recently, interest in this field has broadened to explore new forms of metal-based nanocomposites such as metal/nanocarbon, cubic/noncubic, and designed three-dimensional (3D) morphologies. A new paradigm of interface-dominant or interface-enabled mechanical behavior (“it is all about interfaces”) has emerged.Reference Beyerlein, Demkowicz, Misra and Uberuaga12–Reference Mara and Beyerlein16

Metallic nanolayered composites exhibit ultrahigh yield strengths, typically an order of magnitude higher than annealed bulk metals. This is due to interfacial confinement of dislocations and suppression of dislocation pileup-based behavior at the nanoscale. However, at the limit of a few nanometers, nanolaminates fail by shear bands initiated when the interfacial confinement breaks down and single dislocations, without the mechanical advantage of a pileup, transmit shear across the interphase boundaries.Reference Han, Phillips and Nix17 Suppression of shear bands in nanocomposites while taking advantage of the unprecedented high strengths enabled by nanostructuring has been a significant challenge. Recent work on morphological design of metallic nanocomposites, discussed in the Demkowicz article in this issue,Reference Demkowicz18 shows that the shape of the interfaces, in conjunction with the interface spacing, is critical in designing materials to suppress shear bands at ultrahigh yield strengths.Reference Demkowicz18,Reference Cui, Derby, Li, Mara and Misra19

The exploration of noncubic/cubic composites (e.g., lamellar Al2Cu-Al; hexagonal close-packed-Mg/body-centered cubic [bcc]-Nb) has provided insights into the plasticity mechanisms in confined systems where the crystal symmetry breaks down at nanometer-spaced interfaces. The interplay between dislocation slip and deformation twinning in the noncubic side of the interface and the interface-dominant behavior at the nanoscale imply that new models are needed to explain and predict the stress–strain response and texture evolution. Integration of models at different length scales that incorporate the physics of the unit mechanisms of dislocation and twin nucleation, blockage, storage, and recovery at interfaces to predict the anisotropic behavior of noncubic/cubic nanocomposites continues to be a challenge and the focus of many ongoing investigations, as discussed by Beyerlein and Wang in their article in this issue.Reference Beyerlein and Wang20

Given the large fraction of interface area per unit volume in nanocomposites, interfaces enable the evolution of defects, such as defect (dislocation or deformation twin) nucleation, blockage, absorption (storage), and annihilation (recovery), which determines the overall mechanical behavior—strength, strain hardening, ductility, toughness, deformation textures, and morphological stability—under extremes of irradiation, temperature, and high strain rates.Reference Beyerlein, Demkowicz, Misra and Uberuaga12

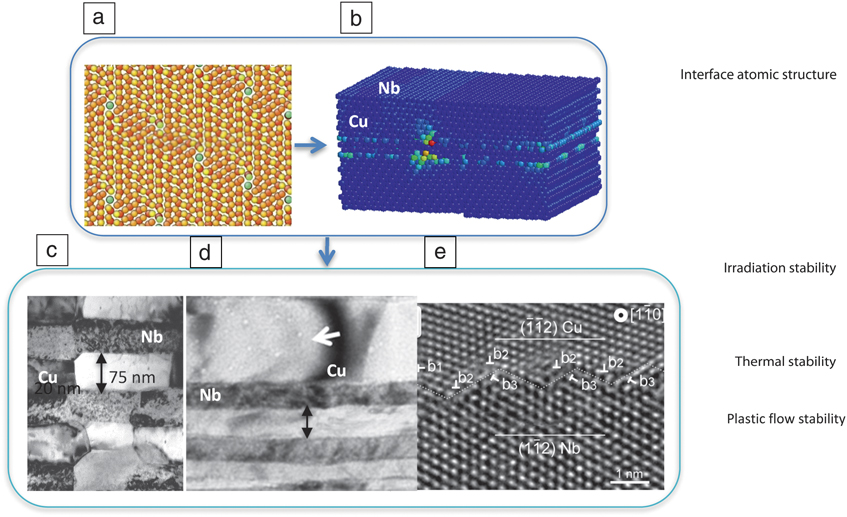

Using a series of immiscible, noncompound-forming Cu-X model systems, where X is a bcc metal (Nb, V, Cr, Mo, W, Ta, and Fe), it has been shown that semicoherent interfaces exhibit unique atomic structures involving multiple atomic arrangements with low and nearly degenerate interface energies.Reference Hoagland, Hirth and Misra5,Reference Demkowicz, Wang and Hoagland14 As a result of this unique atomic-scale design, interfaces in Cu-Nb and related systems exhibit unusual behavior (e.g., very high cohesive strength but relatively low shear strength in the interface plane), which leads to localized shear in response to impinging glide dislocations and trapping of dislocations in the interface plane with delocalized (spread) coreReference Hoagland, Hirth and Misra5 (Figure 1a–b). This also results in a very high interface barrier to slip transmission that can be tailored via design of the interface atomic structure to influence the interface shear strength.Reference Wang, Misra, Hoagland and Hirth21 The flow strength of such nanocomposites for normal loading or parallel to interfaces is extremely high.Reference Mara, Bhattacharyya, Dickerson, Hoagland and Misra1,Reference Nizolek, Beyerlein, Mara, Avallone and Pollock22 The core delocalization of line as well as point defects in the interface plane combined with low interface energies and multiple atomic arrangements in the interface with degenerate energies is the fundamental basis for maintaining the morphological and crystallographic stability of interfaces. Cu-Nb metallic nanocomposites were shown to be stable after annealing at temperatures up to 800°C, Figure 1c,Reference Misra, Hoagland and Kung23 after helium ion irradiation at 400°C where radiation-induced voids formed in the bulk Cu, but not in the nanolaminates, Figure 1d,Reference Han, Demkowicz, Mara, Fu, Sinha, Rollett, Wang, Carpenter, Beyerlein and Misra24 and after high plastic strains during severe plastic deformation processing via accumulative roll bonding, Figure 1e.Reference Beyerlein, Mayeur, Wang, Zheng, Mara and Misra25

Figure 1. Example of interface-enabled behavior in model Cu-Nb metallic nanocomposites. (a) Interface atomic structures that lead to low shear strength interfaces that (b) shear under the local stress field of an impinging glide dislocation that gets trapped via core spreading in the interface plane. In addition to high yield strength, these interfaces give rise to unprecedented morphological stability at elevated temperatures (c), under ion irradiation (d), and under high plastic strains during severe plastic deformation processing (e).

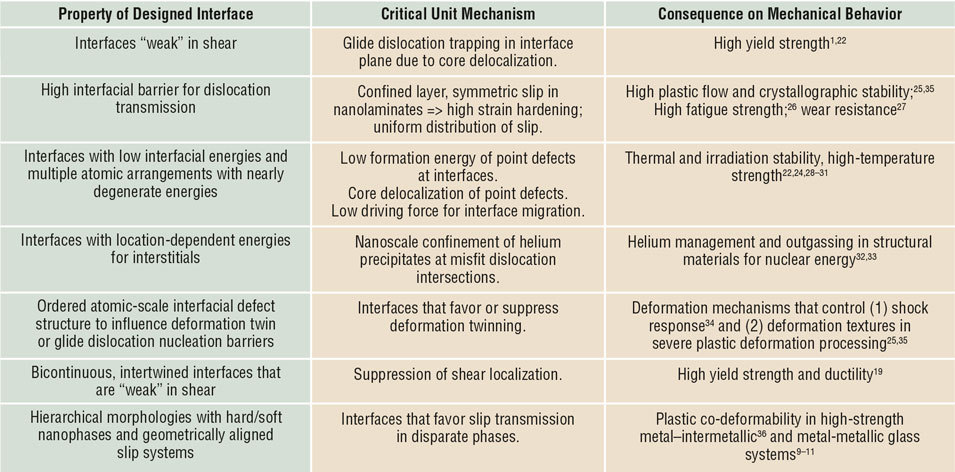

Several examples of interface-enabled behavior for metallic nanocomposites are summarized in Table I. Recent works have also explored fatigue and wear resistance,Reference Wang, Misra and Hoagland26,Reference Madhavan, Bellon and Averback27 and high-temperature strength and radiation behavior.Reference Monclus, Zheng, Mayeur, Beyerlein, Mara, Polcar, Llorca and Molina-Aldareguia28–Reference Chen, Li, Yuryev, Baldwin, Wang and Demkowicz33 The defect structure of interphase boundaries at the atomic scale has been shown to correlate with nucleation of glide dislocations and deformation twinning that is relevant to controlling the “twinnability” of interfaces under shockReference Han, Cerreta, Mara, Beyerlein, Carpenter, Zheng, Trujillo, Dickerson and Misra34 and severe plastic deformation.Reference Beyerlein, Mayeur, Wang, Zheng, Mara and Misra25,Reference Misra and Hoagland35 Finally, the morphology of the interfaces in nanocomposites has been shown to be effective in controlling plastic deformability—bicontinuous, intertwined nanocomposites seem to suppress shear localization better than nanolaminates,Reference Wang, Liu, Xie, Lei, Ramakrishnan, Mazumder, Wang and Misra36 and hierarchical morphologies can lead to plastic co-deformability in nanocomposites with soft/hard phases.Reference Wang, Liu, Xie, Lei, Ramakrishnan, Mazumder, Wang and Misra36

Table I. Summary of interface-enabled mechanical behavior in metallic nanocomposites comprised of immiscible elements and semicoherent interfaces.

Nanocarbon, soft, and bioinspired nanocomposites

The integration of nanocarbons such as graphene and nanotubes with metals to synthesize nanocomposites has resulted in new materials with ultrahigh strengths, toughness, and electrical conductivity values.Reference Yang, Weng, Zhu, Fan and Zhang37–Reference Nieto, Bisht, Lahiri, Zhang and Agarwal39 Graphene-reinforced (2.5 vol%) Cu matrix composites with a nacre-inspired nanolaminated architecture and improved interfacial bonding were shown to increase yield strength by approximately 177% and elastic modulus by approximately 25% compared to the unreinforced Cu matrix, while maintaining the ductility and electrical conductivity of the copper.Reference Cao, Xiong, Tan, Ji, Amin-Ahmadi, Guo, Fan, Guo, Li and Zhang38

In metal/graphene/metal nanocomposites, the graphene sheets provide a new way to engineer metallic grain boundaries to provide increased strength by blocking dislocations as well as hindering crack propagation, leading to toughening and fatigue resistance, as described in article by Guo et al. in this issue.Reference Guo, Kondoh and Han40 Graphene-reinforced polymer-matrix nanocomposites have been extensively studied and are reviewed elsewhere.Reference Papageorgiou, Kinloch and Young41 The challenge of alignment of graphene sheets was addressed by a stacking and folding method to generate aligned graphene/polycarbonate compositesReference Liu, Jin, Katsukis, Drahushuk, Shimizu, Shih, Wetzel, Taggart-Scarff, Qing, Van Vliet, Li, Wardle and Strano42 up to 0.11 mm in thickness with increased effective elastic modulus and strength, and retention of anisotropic electrical conduction along the graphene planar axis.

Nacre-inspired Al-graphene nanocomposites with interlocked nanolaminated architectures were reported to exhibit enhancement in hardness, tensile strength, and fatigue life; these were synthesized via a multistep powder-metallurgy/extrusion/laser shock peening route.Reference Kumar, Prabhakaran, Xavior, Kalainathan, Lin, Shukla and Vasudevan43 The production of a lamellar morphology, control of interface “weakness” for sliding through an interlock mechanism, and confinement of dislocation loops to interlamellar regionsReference Kumar, Prabhakaran, Xavior, Kalainathan, Lin, Shukla and Vasudevan43 were all shown to be crucial for producing the observed enhancements in mechanical properties.

Soft materials represent an active area of materials investigations in important contexts such as robotics, biomaterials, and sensors. Recent advances allow for the integrated computational, theoretical, and manufacturing of complex materials by design. Through the articles by Ren et al.Reference Ren, Liu, Kaplan and Ling44 and Pro and BarthelatReference Pro and Barthelat45 in this issue, we highlight a selection of advances in this area, focused especially on the combination of structure and dissimilar material constituents in composites to achieve new properties.

The paradigm of interface-enabled mechanical behavior is also emerging in the mechanical behavior of soft and biomaterials-based nanocomposites.Reference Ren, Liu, Kaplan and Ling44 For example, in silk/carbon nanocomposites, as described in an article by Ren et al. in their article,Reference Ren, Liu, Kaplan and Ling44 “weak” interfaces induce nonlinear deformations and deflect cracks making propagation more difficult, and gradient interfaces channel programmed deformation of materials to enable environment-adaptive behavior. The combination of silk and hard materials, especially new generations of carbon materials, offers exciting prospects to achieve superior multifunctional properties. Such new material designs are particularly noteworthy because they combine material classes that are not usually integrated, either in nature or in engineering. Silk is one of the strongest and toughest, as well as the most versatile protein-based biofiber (dominated by weak H-bonds), while carbon materials represent a class of synthetically engineered building blocks for some of the strongest materials known (dominated by covalent bonds). Engineering of the interfaces between these disparate materials offers a rich class of design solutions and new interaction phenomena that drive larger-scale material functions. Of particular interest in this area is the interplay of strong and weak bonds.

Likewise, the phenomenon of nanoscale ductility caused by weak interfaces is found to be ubiquitous in biological composites, as described in the Pro and Barthelat article.Reference Pro and Barthelat45 However, efforts to mimic such materials such as nacre in artificial systems has the limitation that statistical variations and imperfections in the material architecture lead to strain localization and brittle fracture, pointing to the challenge of duplicating nature’s amazing synthesis capacity in lab-synthesized materials. Novel strategies involving 3D printed, large-scale bioinspired materials are presented that have shown significant promise.

Conclusion

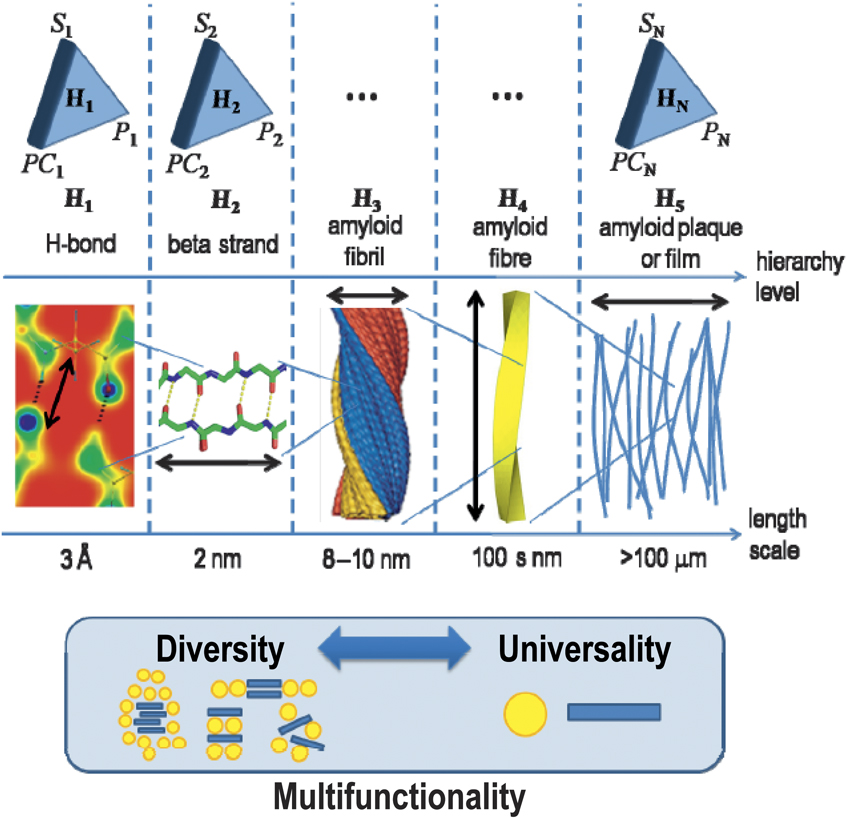

The field of composites has seen several major developments in recent years, especially in our ability to design and synthesize novel materials, and using the directed design of structure across multiple length scales, as depicted schematically in Figure 2.Reference Buehler46 As we expand the design space across length and time scales, we are now able to tune properties simultaneously. One of the early examples is the combination of strength and toughness, but the concept also offers the integration of mechanical, optical, electrical, and other properties. Further, with the ability to change structures at distinct scales, material properties can be tuned after a material is fabricated, for uses as actuators, sensors, or to adapt material properties. Such types of design objectives rely increasingly on structural complexity, which requires the need for new design tools to aid the parameter search in a vast space of possible solutions. An important aspect is the process by which materials are made, which becomes part of the design solution.

Figure 2. Creating functional diversity out of the systematic and directed assembly of material constituents at defined length scales. This nested, hierarchical approach allows one to engineer structure and properties at each scale by defining a specific process, leading to interactive and tunable material designs. PC N is the process at level N; S N is the structure at level N; and P N is the property at level N. Hydrogen bonds (H1) with characteristic lengths on the order of a fraction of a nanometer provide the chemical bonding that forms beta strands (H2), which in turn, form highly ordered, twisted fibrils (H3). The fibrils grow into long fibers (H4) that are then arranged into plaques or films through a casting process (H5). Reprinted with permission from Reference Reference Buehler46. © 2010 Springer Nature.

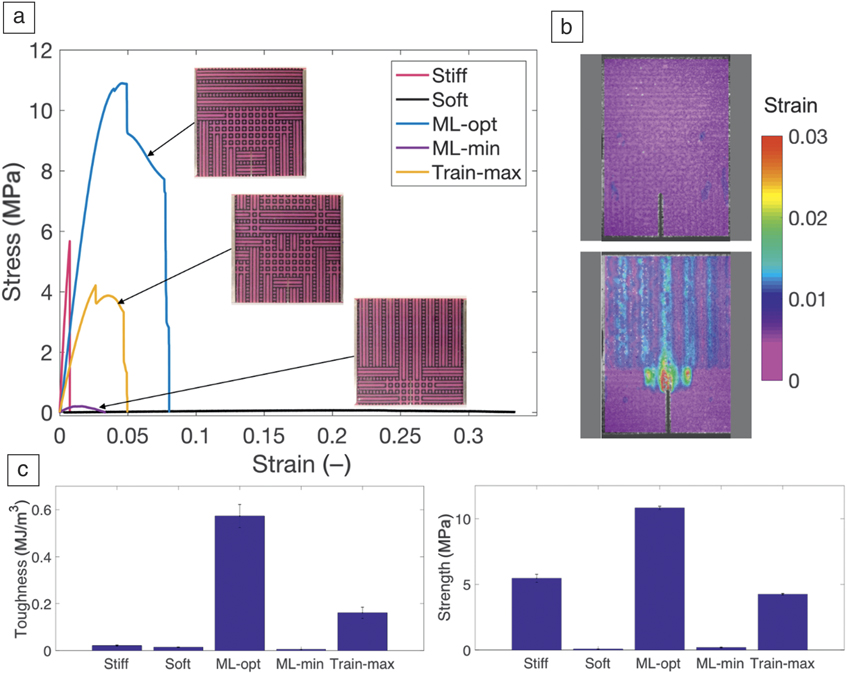

The use of novel modeling techniques, such as machine learning, combined with additive manufacturing, opens new avenues for future research that complements physics-based methods with data-driven approaches such as machine learning (Figure 3).Reference Gu, Chen and Buehler47,Reference Gu, Chen, Richmond and Buehler48 Machine learning offers the opportunity to capture the physics of a particular design space of interest in a neural network, trained by data derived from experiments or first-principles multiscale modeling, facilitating a rapid inquiry of performance measures for variations in the design. The key issue here is that neural networks perform much faster than typical multiscale methods and hence allow for rapid improvements of designs, which can be iterated using genetic algorithms or gradient-based methods.Reference Gu, Chen and Buehler47,Reference Gu, Chen, Richmond and Buehler48 Moreover, these methods can be designed as autonomous algorithms, where the neural network can be improved by adding more data to its training set by spawning new first-principles-based multiscale modeling, if more accuracy is needed.

Figure 3. Additive manufacturing and subsequent testing of hierarchical composites designed using machine learning (ML). (a) Comparison of stress–strain response of ML-generated 3D printed sample (ML-opt) to its (soft and stiff) building blocks, lowest toughness geometry obtained from machine learning (ML-min), and the maximum toughness geometry from the training set (train-max). Three-dimensional printed designs for ML-opt, ML-min, and train-max are shown as insets in the figure. (b) Strain field plots obtained from digital image correlation for ML-opt (top) and ML-min (bottom). (c) Toughness and strength values for the various designs.Reference Gu, Chen, Richmond and Buehler48

Another exciting opportunity that directly intersects with computing is in recent advances in additive manufacturing (Figure 3) and other novel methods. These can lead to numerous insights and practical applications in the context of materials by design. Laser-based processing, such as direct metal deposition and other related approaches, has significant potential in the synthesis of designed metallic nanocomposites of the future.Reference Huang and Schmid49,Reference Ramakrishnan, Lei, Mazumder and Misra50 Likewise, 3D printingReference Dimas, Bratzel, Eylon and Buehler51 has shown promise through high spatial fidelity, flexibility, and high throughput to process large-scale bioinspired architectured materials with improved mechanical properties.

An interesting concept is the integration of neural network-based algorithms with additive manufacturing, offering a path to allow autonomous networks to actually produce a physical artefact and then test it, and return the data back to the model for improvement and enhancing the predictive capability. This type of setup may involve the use of advanced robotics to perform material testing for the purpose of manufacturing and processing and material characterization. An autonomous system like this may be able to rapidly evolve material design, processing, and characterization in a truly autonomous manner without human intervention. The opportunities for composite design, but also the development of new polymers, alloys, and other material classes, are endless.Reference Kinloch, Suhr, Lou, Young and Ajayan52

Acknowledgments

A.M. acknowledges support from the US Department of Energy, Basic Energy Sciences, on plasticity in laser-processed nanoscale eutectics (DE-SC0016808), and NSF-DMREF on design of PVD-synthesized bicontinuous, intertwined nanocomposites (1533557). M.J.B. acknowledges support from the US Department of Defense, Office of Naval Research (N00014–16–1-233), the National Institutes of Health (U01 EB014976), and DOD-MURI (FA9550–15–1-0514).

Markus J. Buehler is a McAfee Professor of Engineering at the Massachusetts Institute of Technology (MIT). His research focuses on new modeling, design, and manufacturing approaches for advanced materials that offer greater resilience and controllable properties from the nano- to the macroscale. He has numerous publications, including his latest book, Biomateriomics. His awards include the MRS Outstanding Young Investigator Award, the MIT Harold E. Edgerton Faculty Achievement Award, the Alfred Noble Prize of the American Society of Civil Engineers, and the Leonardo da Vinci Award. Buehler can be reached by email at mbuehler@mit.edu.

Amit Misra has been a professor and chair of the Department of Materials Science and Engineering at the University of Michigan since June 2014. From 1996 to 2014, he was employed at Los Alamos National Laboratory (LANL). His research group studies nanomechanics and metallic interfaces focusing on the design and development of multiphase and nanocomposite materials for advanced structural applications. He is a Fellow of MRS, ASM International, and LANL. Misra can be reached by email at amitmis@umich.edu.