Article contents

Mechanical and failure behaviors of lattice–plate hybrid structures

Published online by Cambridge University Press: 03 December 2019

Abstract

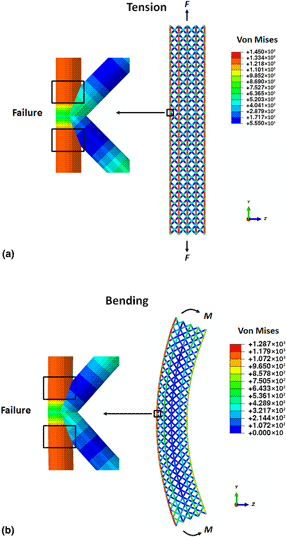

The authors design six alumina hybrid structures consisting of stretching-dominated plates and different space-filling lattices comprised of hollow tubes and perform finite element simulations to study mechanical and failure behaviors of such hybrid structures. The authors investigate the effects of three geometrical parameters on the stiffness and failure of these hybrid structures and further compare their advantages and disadvantages. The authors find that the failure modes of these hybrid structures can be tuned by altering cell unit type and geometrical parameters. Among these hybrid structures, the ones with effective support from the lattice unit cells in the stretching direction exhibit better specific stiffness and strength. By varying the lattice and plate thickness, the authors find that the relations between stiffness/failure strength and density follow a power law. When intrinsic material failure occurs, the power law exponent is 1; when buckling failure arises, the power law exponent is 3. However, by varying tube thickness, their relations follow unusual power relations with the exponent changing from nearly 0 to nearly infinity. In addition, the hybrid structures also exhibit defect insensitivity. This study shows that such hybrid structures are able to greatly expand the design space of architectured cellular materials for engineering applications.

- Type

- Prospective Articles

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 3

- Cited by