Tofu is an affordable source of protein but is often rejected because of the beany flavour. Previous study had reduced this flavour by using Soy Protein Isolate as an alternative to soya beans( Reference Murekatete, Zhang, Karangwa and Hua 1 ). Therefore, the focus of this project was to reduce the intensity of beany by flavour application. To establish this flavoured-tofu, cracker-like process flavour was prepared as cracker is a generally-known snack( Reference Sadowska-Rociek 2 ). The successful fraction of flavour incorporated into tofu were compared with the tofu immersed in water and if succeed, might indirectly deliver positive impact to the nutritional society.

The processed flavour was prepared under conventional thermal treatment (CTP) and high-pressure high-temperature treatment (HTHP), analysing the volatile compounds using headspace-gas-chromatography coupled with mass-spectrometry. The two thermal treatment was proved to have different physical characteristics( Reference Kebede, Grauwet, Andargie, Sempiri, Palmers and Hendrickx 3 ). The sensory analysis of flavoured-tofu was carried out using Quantitative Descriptive Analysis by 10 semi-trained panellists, evaluated using a two-way ANOVA and SPSS statistical software.

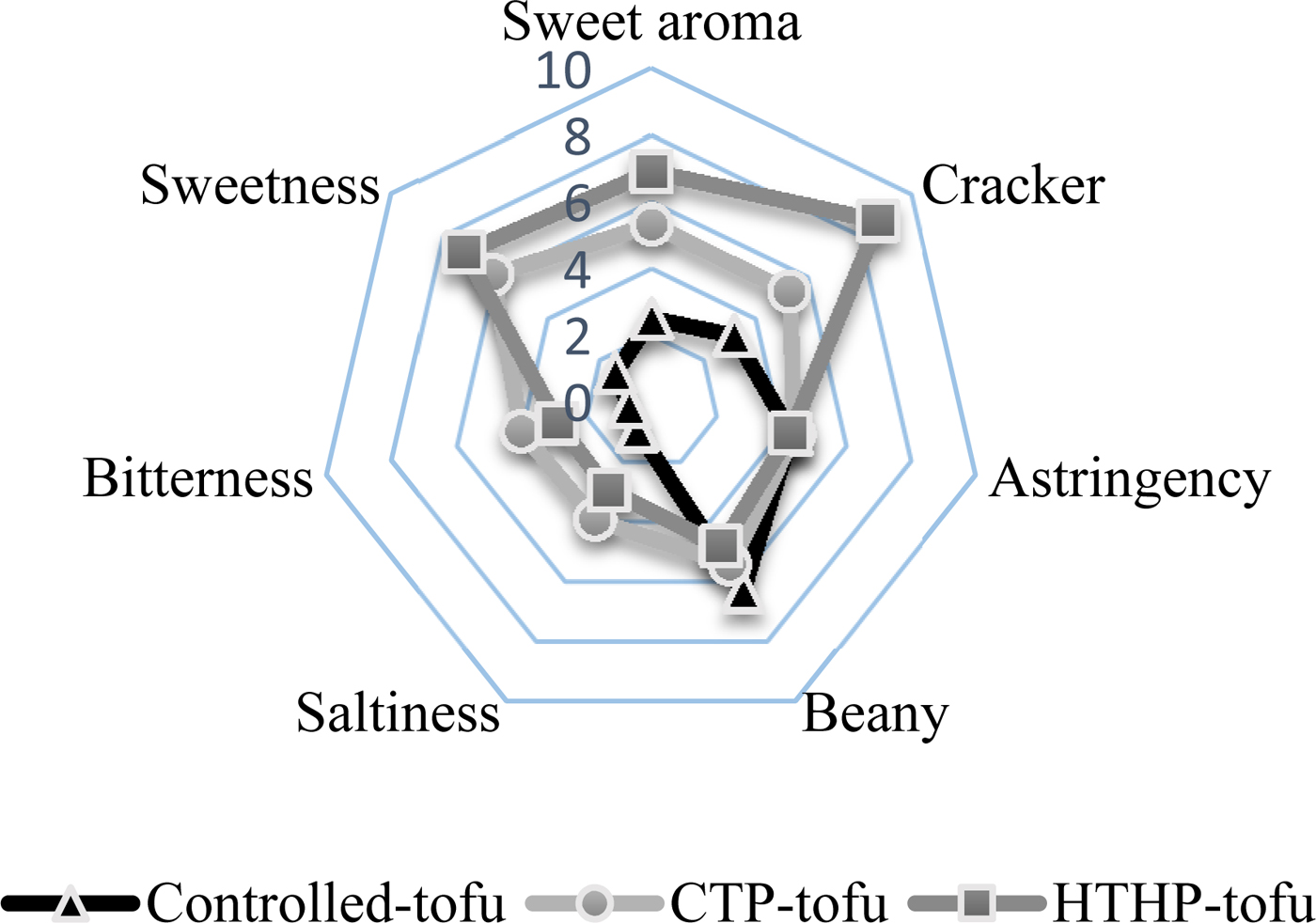

The maillard reaction product from processed flavour resulted in different melanoidin intensity (CTP > HTHP) (differences not shown). Based on sensory result, the incorporation resulted in seven significantly higher attributes, out of the total of sixteen attributes (F-assessors > F-tabulated) (Fig. 1). Among these attributes, only two attributes (cracker taste and sweetness) were significantly different, P = 0·033 (between controlled and HTHP-TOFU) and P = 0·001 (controlled and CTP), P = 0·006 (controlled and HTHP) for respective attributes. The flavour prepared under HTHP was successfully incorporated into tofu compared to controlled-tofu (P < 0·05) and no differences were observed between the two thermal treatments (P > 0·05).

Fig. 1. QDA of tofu. F < 0·05

In a flavour application, thermal treatment is a sub-factor that contributes to the process flavour; HTHP treatment being more effective in infusing the flavour than CTP. Although the cracker-like flavour managed to improve the flavour, it did not, however, manage to reduce the beany flavour.