1. Introduction

Thermocapillary flows are driven by tangential shear stresses acting on non-isothermal liquid–gas interfaces. They are due to the thermocapillary effect that describes the variation of the surface tension with temperature (Scriven & Sternling Reference Scriven and Sternling1960). These flows are important in a number of applications, like crystal growth from the melt (Schwabe Reference Schwabe1981), welding (Amberg & Do-Quang Reference Amberg and Do-Quang2008) or droplet evaporation from inkjet printing (Ristenpart et al. Reference Ristenpart, Kim, Domingues, Wan and Stone2007). The flow in thermocapillary liquid bridges, originally devised as a model system for the floating-zone crystal-growth process (Pfann Reference Pfann1962) has evolved as a paradigm. In particular, the critical conditions for the onset of a time-dependent flow in transparent high-Prandtl-number liquids has received considerable interest (Kuhlmann Reference Kuhlmann1999), since an oscillator flow is known to cause crystal striation (Cröll et al. Reference Cröll, Müller-Sebert, Benz and Nitsche1991). In these model systems, an axisymmetric liquid bridge between two coaxial support discs is heated differentially from the discs such that axial thermocapillary stresses drive a toroidal vortex in the liquid.

Transparent liquids with a moderate Prandtl number, but still ![]() ${\textit {Pr}} >1$, tend to be volatile that makes experimental investigations difficult (Simic-Stefani, Kawaji & Yoda Reference Simic-Stefani, Kawaji and Yoda2006). Therefore, molten salts (Preisser, Schwabe & Scharmann Reference Preisser, Schwabe and Scharmann1983) or silicone oils with a high Prandtl number

${\textit {Pr}} >1$, tend to be volatile that makes experimental investigations difficult (Simic-Stefani, Kawaji & Yoda Reference Simic-Stefani, Kawaji and Yoda2006). Therefore, molten salts (Preisser, Schwabe & Scharmann Reference Preisser, Schwabe and Scharmann1983) or silicone oils with a high Prandtl number ![]() ${\textit {Pr}}=28$ or larger (Kamotani et al. Reference Kamotani, Wang, Hatta, Wang and Yoda2003; Ueno, Tanaka & Kawamura Reference Ueno, Tanaka and Kawamura2003) are frequently used in experiments. Since the viscosity of silicone oils increases with Prandtl number, the required temperature difference

${\textit {Pr}}=28$ or larger (Kamotani et al. Reference Kamotani, Wang, Hatta, Wang and Yoda2003; Ueno, Tanaka & Kawamura Reference Ueno, Tanaka and Kawamura2003) are frequently used in experiments. Since the viscosity of silicone oils increases with Prandtl number, the required temperature difference ![]() $\Delta T = T_{hot} - T_{cold}$ to drive the flow into the time-dependent regime increases. For length scales of millimetres and a Prandtl number of

$\Delta T = T_{hot} - T_{cold}$ to drive the flow into the time-dependent regime increases. For length scales of millimetres and a Prandtl number of ![]() ${\textit {Pr}}=28$, the critical temperature difference can easily amount to

${\textit {Pr}}=28$, the critical temperature difference can easily amount to ![]() $\Delta T_c = 30$ K or larger. Under such temperature variation the thermophysical properties of the liquid may vary considerably and the often used assumption of constant material parameters may no longer yield reliable numerical results for the critical Reynolds number. The present work is intended to overcome the limitations imposed by assuming constant material properties by taking into account the full, in general nonlinear, dependence of all material properties of the liquid and the gas on the temperature.

$\Delta T_c = 30$ K or larger. Under such temperature variation the thermophysical properties of the liquid may vary considerably and the often used assumption of constant material parameters may no longer yield reliable numerical results for the critical Reynolds number. The present work is intended to overcome the limitations imposed by assuming constant material properties by taking into account the full, in general nonlinear, dependence of all material properties of the liquid and the gas on the temperature.

The first linear stability analysis of the flow in single-phase adiabatic thermocapillary liquid bridges for variable material properties is due to Kozhoukharova et al. (Reference Kozhoukharova, Kuhlmann, Wanschura and Rath1999). For a liquid bridge with ![]() ${\textit {Pr}}=4$ under zero gravity and a radius-to-height ratio of one, they numerically computed the critical Reynolds number for the onset of three-dimensional (and oscillatory) flow, assuming a linear variation with temperature of the kinematic viscosity

${\textit {Pr}}=4$ under zero gravity and a radius-to-height ratio of one, they numerically computed the critical Reynolds number for the onset of three-dimensional (and oscillatory) flow, assuming a linear variation with temperature of the kinematic viscosity ![]() $\nu (T)=\nu ^* +\zeta (T-T^*)$, with reference viscosity

$\nu (T)=\nu ^* +\zeta (T-T^*)$, with reference viscosity ![]() $\nu ^*=\nu (T^*)$ and

$\nu ^*=\nu (T^*)$ and ![]() $\zeta =(\partial \nu /\partial T)_{T^*}$. Evaluating the reference viscosity

$\zeta =(\partial \nu /\partial T)_{T^*}$. Evaluating the reference viscosity ![]() $\nu ^*$ at the arithmetic mean temperature of the heaters

$\nu ^*$ at the arithmetic mean temperature of the heaters ![]() $T^* = (T_{hot}-T_{cold})/2$, they found the critical temperature difference

$T^* = (T_{hot}-T_{cold})/2$, they found the critical temperature difference ![]() $\Delta T_c$, or the critical Reynolds number

$\Delta T_c$, or the critical Reynolds number ![]() ${\textit {Re}}_c \sim \Delta T_c/\nu ^{*2}$, is typically reduced in liquids (

${\textit {Re}}_c \sim \Delta T_c/\nu ^{*2}$, is typically reduced in liquids (![]() $\zeta < 0$) as compared with the case of a constant kinematic viscosity

$\zeta < 0$) as compared with the case of a constant kinematic viscosity ![]() $(\zeta =0)$. The reduction of

$(\zeta =0)$. The reduction of ![]() $\Delta T_c$ (or

$\Delta T_c$ (or ![]() ${\textit {Re}}_c$) for

${\textit {Re}}_c$) for ![]() $\zeta < 0$ was interpreted to be due to a reduction of the effective viscosity that was taken as the kinematic viscosity averaged over the interface

$\zeta < 0$ was interpreted to be due to a reduction of the effective viscosity that was taken as the kinematic viscosity averaged over the interface ![]() $\nu _S(\zeta <0) < \nu ^*$. Under the hypothesis that a modified Reynolds number

$\nu _S(\zeta <0) < \nu ^*$. Under the hypothesis that a modified Reynolds number ![]() $\widetilde {{\textit {Re}}}_c \sim \Delta T_c/\nu _S^2$ using the effective kinematic viscosity (mean surface viscosity) would be almost independent of

$\widetilde {{\textit {Re}}}_c \sim \Delta T_c/\nu _S^2$ using the effective kinematic viscosity (mean surface viscosity) would be almost independent of ![]() $\zeta$, they suggested a correction factor

$\zeta$, they suggested a correction factor ![]() $(\nu _S/\nu ^*)^2$ to estimate the variable viscosity effect as

$(\nu _S/\nu ^*)^2$ to estimate the variable viscosity effect as ![]() ${\textit {Re}}_c(\zeta ) = (\nu _S/\nu ^*)^2 {\textit {Re}}_c(\zeta =0)$. While this correction always yields a reduction of the critical Reynolds number with

${\textit {Re}}_c(\zeta ) = (\nu _S/\nu ^*)^2 {\textit {Re}}_c(\zeta =0)$. While this correction always yields a reduction of the critical Reynolds number with ![]() ${\textit {Re}}_c(\zeta < 0) < {\textit {Re}}_c(\zeta =0)$, the estimate

${\textit {Re}}_c(\zeta < 0) < {\textit {Re}}_c(\zeta =0)$, the estimate ![]() $(\nu _S/\nu ^*)^2 {\textit {Re}}_c(\zeta =0)$ can overpedict or underpredict the exact result

$(\nu _S/\nu ^*)^2 {\textit {Re}}_c(\zeta =0)$ can overpedict or underpredict the exact result ![]() ${\textit {Re}}_c(\zeta < 0)$ by about 10 %. (The right-hand side of (34) in Kozhoukharova et al. (Reference Kozhoukharova, Kuhlmann, Wanschura and Rath1999) is lacking a factor

${\textit {Re}}_c(\zeta < 0)$ by about 10 %. (The right-hand side of (34) in Kozhoukharova et al. (Reference Kozhoukharova, Kuhlmann, Wanschura and Rath1999) is lacking a factor ![]() $\nu _0^{-2}$.)

$\nu _0^{-2}$.)

Shevtsova & Melnikov (Reference Shevtsova and Melnikov2001) and Shevtsova, Melnikov & Legros (Reference Shevtsova, Melnikov and Legros2001) investigated the effect of a linear temperature dependence (LTD) of the kinematic viscosity on the critical temperature difference through numerical simulation for a liquid bridge with ![]() ${\textit {Pr}}=35$. They also found a reduction of the critical temperature difference. Different from Kozhoukharova et al. (Reference Kozhoukharova, Kuhlmann, Wanschura and Rath1999), however, they defined the Reynolds number

${\textit {Pr}}=35$. They also found a reduction of the critical temperature difference. Different from Kozhoukharova et al. (Reference Kozhoukharova, Kuhlmann, Wanschura and Rath1999), however, they defined the Reynolds number ![]() ${\textit {Re}} \sim \Delta T/\nu _{cold}^2$ using a reference kinematic viscosity evaluated at the cold-wall temperature

${\textit {Re}} \sim \Delta T/\nu _{cold}^2$ using a reference kinematic viscosity evaluated at the cold-wall temperature ![]() $\nu _{cold}=\nu (T_{cold})$. This leads to a much larger reduction of the critical Reynolds number with

$\nu _{cold}=\nu (T_{cold})$. This leads to a much larger reduction of the critical Reynolds number with ![]() $\zeta$, because the correction of

$\zeta$, because the correction of ![]() ${\textit {Re}}_c(\zeta =0)$ is much stronger with

${\textit {Re}}_c(\zeta =0)$ is much stronger with ![]() $1 < (\nu _S/\nu ^*)^2 < (\nu _S/\nu _{cold})^2$ for

$1 < (\nu _S/\nu ^*)^2 < (\nu _S/\nu _{cold})^2$ for ![]() $\zeta < 0$. In other words, the kinematic viscosity

$\zeta < 0$. In other words, the kinematic viscosity ![]() $\nu _{cold}$ is not a good estimate of the effective viscosity, that is much better approximated by the mean viscosity

$\nu _{cold}$ is not a good estimate of the effective viscosity, that is much better approximated by the mean viscosity ![]() $\nu ^*$. Regardless of the viscosity contrast, both Kozhoukharova et al. (Reference Kozhoukharova, Kuhlmann, Wanschura and Rath1999) and Shevtsova & Melnikov (Reference Shevtsova and Melnikov2001) found the instability arises as a hydrothermal wave (Smith Reference Smith1986; Wanschura et al. Reference Wanschura, Shevtsova, Kuhlmann and Rath1995). Owing to the influence of the viscosity variation on the critical temperature difference, a linear dependence of

$\nu ^*$. Regardless of the viscosity contrast, both Kozhoukharova et al. (Reference Kozhoukharova, Kuhlmann, Wanschura and Rath1999) and Shevtsova & Melnikov (Reference Shevtsova and Melnikov2001) found the instability arises as a hydrothermal wave (Smith Reference Smith1986; Wanschura et al. Reference Wanschura, Shevtsova, Kuhlmann and Rath1995). Owing to the influence of the viscosity variation on the critical temperature difference, a linear dependence of ![]() $\nu$ on

$\nu$ on ![]() $T$ was also employed in succeeding simulations (see, e.g. Melnikov, Shevtsova & Legros Reference Melnikov, Shevtsova and Legros2004; Shevtsova, Melnikov & Nepomnyashchy Reference Shevtsova, Melnikov and Nepomnyashchy2009). Also Saifi, Mundhada & Tripathi (Reference Saifi, Mundhada and Tripathi2022) and Shitomi, Yano & Nishino (Reference Shitomi, Yano and Nishino2019) used a temperature-dependent viscosity, albeit assuming an exponential dependence on

$T$ was also employed in succeeding simulations (see, e.g. Melnikov, Shevtsova & Legros Reference Melnikov, Shevtsova and Legros2004; Shevtsova, Melnikov & Nepomnyashchy Reference Shevtsova, Melnikov and Nepomnyashchy2009). Also Saifi, Mundhada & Tripathi (Reference Saifi, Mundhada and Tripathi2022) and Shitomi, Yano & Nishino (Reference Shitomi, Yano and Nishino2019) used a temperature-dependent viscosity, albeit assuming an exponential dependence on ![]() $T$.

$T$.

On the experimental side Ueno et al. (Reference Ueno, Tanaka and Kawamura2003), as well as most other investigators (see, e.g. Nishino et al. Reference Nishino, Yano, Kawamura, Matsumoto, Ueno and Ermakov2015; Yano et al. Reference Yano, Nishino, Kawamura, Ueno and Matsumoto2015), took into account an exponential variation of the kinematic viscosity in order to determine the reference viscosity for the definition of the Reynolds or the Marangoni number. Like Kozhoukharova et al. (Reference Kozhoukharova, Kuhlmann, Wanschura and Rath1999) they selected the reference viscosity ![]() $\nu^*$, evaluated at the algebraic mean temperature.

$\nu^*$, evaluated at the algebraic mean temperature.

While the critical Reynolds number of the thermocapillary flow in liquid bridges depends on the temperature dependence of the kinematic viscosity, the critical Rayleigh number in the Rayleigh–Bénard problem does not, because the basic flow is at rest. However, the sign of ![]() $\zeta$ has a qualitative influence on the planform of the supercritical convection. This was demonstrated experimentally by Tippelskirch (Reference Tippelskirch1956) who found polygonal convection cells in open layers of liquid sulfur heated from below. In temperature ranges in which the variation of the dynamic viscosity

$\zeta$ has a qualitative influence on the planform of the supercritical convection. This was demonstrated experimentally by Tippelskirch (Reference Tippelskirch1956) who found polygonal convection cells in open layers of liquid sulfur heated from below. In temperature ranges in which the variation of the dynamic viscosity ![]() $\partial _T\mu <0$ the cells had upflow in their centres, whereas for temperature ranges with

$\partial _T\mu <0$ the cells had upflow in their centres, whereas for temperature ranges with ![]() $\partial _T\mu >0$, the flow in the cell centres was directed downwards. The findings of Tippelskirch confirmed the earlier observations of Graham (Reference Graham1933) for water and air according to which the flow in the centre of the cells is always directed towards increasing viscosity. The flow direction in the convection cells has been explained theoretically by Palm (Reference Palm1960) and Segel & Stuart (Reference Segel and Stuart1962). According to Busse (Reference Busse1978) and Busse & Frick (Reference Busse and Frick1985) the flow direction minimises the viscosity in the highly strained region near the cell centres.

$\partial _T\mu >0$, the flow in the cell centres was directed downwards. The findings of Tippelskirch confirmed the earlier observations of Graham (Reference Graham1933) for water and air according to which the flow in the centre of the cells is always directed towards increasing viscosity. The flow direction in the convection cells has been explained theoretically by Palm (Reference Palm1960) and Segel & Stuart (Reference Segel and Stuart1962). According to Busse (Reference Busse1978) and Busse & Frick (Reference Busse and Frick1985) the flow direction minimises the viscosity in the highly strained region near the cell centres.

Except for Kozhoukharova et al. (Reference Kozhoukharova, Kuhlmann, Wanschura and Rath1999) and Carrión, Herrada & Montanero (Reference Carrión, Herrada and Montanero2020) most stability analyses have been carried out assuming a constant viscosity (e.g. Wanschura et al. Reference Wanschura, Shevtsova, Kuhlmann and Rath1995; Chen & Hu Reference Chen and Hu1998; Nienhüser & Kuhlmann Reference Nienhüser and Kuhlmann2002; Stojanović, Romanò & Kuhlmann Reference Stojanović, Romanò and Kuhlmann2022). Therefore, the influence of the temperature dependence of the material properties on the critical conditions has not been thoroughly investigated. In this work we extend the previous analyses by carrying out linear stability analyses for the two-phase flow of a commonly used liquid–gas combination (2-cSt silicone oil and air) confined to a cylindrical tube. The full (nonlinear) temperature dependence of all thermophysical properties in the liquid and in the gas phase is taken into account. The critical Reynolds numbers obtained are then compared with results for a linear dependence of all thermophysical parameters and with those for the Oberbeck–Boussinesq (OB) approximation. For all calculations, the basic state is computed for a dynamically deforming interface.

In § 2 the geometry is described and the mathematic problem is formulated. The numerical methods to solve the governing equations are discussed in § 3. In § 4 the reference parameters are defined and the temperature dependence of the fluid properties are provided. Results are presented in § 5. In a first step the linear stability is computed for a sealed cylindrical tube surrounding the liquid bridge. The effects of the volume ratio of the liquid, the aspect ratio of the liquid bridge and the length scale are discussed separately. Thereafter, the effect of an imposed axial flow in the gas phase on the linear stability boundary is considered. Finally, the results obtained are summarised in § 6 and conclusions are drawn.

2. Problem formulation

2.1. Set-up

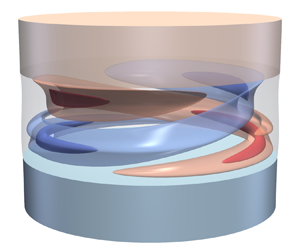

We consider a droplet of an incompressible Newtonian silicone oil captured between two coaxial, cylindrical discs of radius ![]() $r_{i}$ (i: inner) and length

$r_{i}$ (i: inner) and length ![]() $d_{s}$ (s: support). The discs supporting the liquid bridge are separated axially by a distance

$d_{s}$ (s: support). The discs supporting the liquid bridge are separated axially by a distance ![]() $d$ as shown in figure 1. Short liquid bridges can be hydrostatically stable, even in a terrestrial gravity field, depending on the wetting conditions and the geometry. Here we consider an axisymmetric geometry with the axial acceleration of gravity

$d$ as shown in figure 1. Short liquid bridges can be hydrostatically stable, even in a terrestrial gravity field, depending on the wetting conditions and the geometry. Here we consider an axisymmetric geometry with the axial acceleration of gravity ![]() $\boldsymbol {g}=-g\boldsymbol {e}_z$, where

$\boldsymbol {g}=-g\boldsymbol {e}_z$, where ![]() $\boldsymbol {e}_z$ is the axial unit vector, while the liquid is heated from above. We assume the liquid bridge is pinned to the sharp circular edges of the two support discs. The gas phase (air) is Newtonian as well and it is bounded radially by a cylindrical tube of radius

$\boldsymbol {e}_z$ is the axial unit vector, while the liquid is heated from above. We assume the liquid bridge is pinned to the sharp circular edges of the two support discs. The gas phase (air) is Newtonian as well and it is bounded radially by a cylindrical tube of radius ![]() $r_{o}>r_{i}$ (o: outer) and height

$r_{o}>r_{i}$ (o: outer) and height ![]() $2d_{s}+d$, placed coaxially around the liquid bridge and the support discs. The shield cylinder was first used in experiments by Preisser et al. (Reference Preisser, Schwabe and Scharmann1983) and, more recently, by, e.g. Simic-Stefani et al. (Reference Simic-Stefani, Kawaji and Yoda2006) and Gaponenko et al. (Reference Gaponenko, Mialdun, Nepomnyashchy and Shevtsova2021). To a good approximation, it can be considered thermally insulating. Thus, the geometry of the problem is characterised by

$2d_{s}+d$, placed coaxially around the liquid bridge and the support discs. The shield cylinder was first used in experiments by Preisser et al. (Reference Preisser, Schwabe and Scharmann1983) and, more recently, by, e.g. Simic-Stefani et al. (Reference Simic-Stefani, Kawaji and Yoda2006) and Gaponenko et al. (Reference Gaponenko, Mialdun, Nepomnyashchy and Shevtsova2021). To a good approximation, it can be considered thermally insulating. Thus, the geometry of the problem is characterised by

where ![]() $\varGamma$ and

$\varGamma$ and ![]() $\varGamma _{s}$ describe the aspect ratios of the liquid bridge and the discs, respectively, and

$\varGamma _{s}$ describe the aspect ratios of the liquid bridge and the discs, respectively, and ![]() $\eta$ is the radius ratio of the annular space between the tube and the support discs.

$\eta$ is the radius ratio of the annular space between the tube and the support discs.

Figure 1. Schematic of the axisymmetric thermocapillary liquid bridge including the coordinate system. The sketch shows the situation when the liquid bridge is exposed to a hot gas stream with mean axial velocity ![]() $\bar {W}_{g,in}$. The gravity vector

$\bar {W}_{g,in}$. The gravity vector ![]() $\boldsymbol {g}$ is always aligned with the negative

$\boldsymbol {g}$ is always aligned with the negative ![]() $z$ axis. The thermocapillary effect is illustrated schematically through velocity vectors close to the interface.

$z$ axis. The thermocapillary effect is illustrated schematically through velocity vectors close to the interface.

The support discs are kept at different but constant temperatures ![]() $T_{hot} = \bar {T}+\Delta T/2$ and

$T_{hot} = \bar {T}+\Delta T/2$ and ![]() $T_{cold} = \bar {T}-\Delta T/2$, respectively, where

$T_{cold} = \bar {T}-\Delta T/2$, respectively, where ![]() $\Delta T=T_{hot}-T_{cold}>0$ is an imposed temperature difference. The mean temperature

$\Delta T=T_{hot}-T_{cold}>0$ is an imposed temperature difference. The mean temperature ![]() $\bar {T}=(T_{hot}+T_{cold})/2$ is used as the reference temperature

$\bar {T}=(T_{hot}+T_{cold})/2$ is used as the reference temperature ![]() $T^* = \bar {T}$. Owing to the imposed temperature difference the surface tension

$T^* = \bar {T}$. Owing to the imposed temperature difference the surface tension ![]() $\sigma (T)$ varies along the interface. Tangential surface tension gradients create surface stresses (Levich Reference Levich1962) that drive a flow on both sides of the interface via the thermocapillary effect, as sketched in figure 1. Taylor expansion of

$\sigma (T)$ varies along the interface. Tangential surface tension gradients create surface stresses (Levich Reference Levich1962) that drive a flow on both sides of the interface via the thermocapillary effect, as sketched in figure 1. Taylor expansion of ![]() $\sigma (T)$ about

$\sigma (T)$ about ![]() $T^*$ yields the surface tension gradient

$T^*$ yields the surface tension gradient

\begin{align} \boldsymbol{\nabla}_\| \sigma(T)&= \frac{\partial\sigma}{\partial T} \boldsymbol{\nabla}_\| T = \frac{\partial}{\partial T}[\sigma^* -\gamma^* (T - T^*) + \dots]\boldsymbol{\nabla}_\| T \nonumber\\ &= \{-\gamma^* + O[(T-T^*)] \} \boldsymbol{\nabla}_\| T, \end{align}

\begin{align} \boldsymbol{\nabla}_\| \sigma(T)&= \frac{\partial\sigma}{\partial T} \boldsymbol{\nabla}_\| T = \frac{\partial}{\partial T}[\sigma^* -\gamma^* (T - T^*) + \dots]\boldsymbol{\nabla}_\| T \nonumber\\ &= \{-\gamma^* + O[(T-T^*)] \} \boldsymbol{\nabla}_\| T, \end{align}

where ![]() $\boldsymbol {\nabla }_\| = \boldsymbol {t} (\boldsymbol {t}\boldsymbol {\cdot }\boldsymbol {\nabla })$ is the Nabla operator in the plane tangent to the interface,

$\boldsymbol {\nabla }_\| = \boldsymbol {t} (\boldsymbol {t}\boldsymbol {\cdot }\boldsymbol {\nabla })$ is the Nabla operator in the plane tangent to the interface, ![]() $\boldsymbol {t}$ an arbitrary unit tangent vector,

$\boldsymbol {t}$ an arbitrary unit tangent vector, ![]() $\gamma ^* = -\partial \sigma / \partial T\vert _{T = T^*}$ is the negative linear surface tension coefficient and

$\gamma ^* = -\partial \sigma / \partial T\vert _{T = T^*}$ is the negative linear surface tension coefficient and ![]() $\sigma ^*=\sigma (T^*)$ is the reference (mean) surface tension. The asterisk indicates reference values of temperature-dependent thermophysical properties evaluated at

$\sigma ^*=\sigma (T^*)$ is the reference (mean) surface tension. The asterisk indicates reference values of temperature-dependent thermophysical properties evaluated at ![]() $T^*$. The Taylor expansion in (2.2) is truncated after the linear term, since literature data on the coefficients of the higher-order terms for silicone oil in air are lacking. Within our modelling, we take into account the full temperature dependence of all other thermophysical properties and neglect the pressure dependence, assuming reference conditions far from phase-change critical points.

$T^*$. The Taylor expansion in (2.2) is truncated after the linear term, since literature data on the coefficients of the higher-order terms for silicone oil in air are lacking. Within our modelling, we take into account the full temperature dependence of all other thermophysical properties and neglect the pressure dependence, assuming reference conditions far from phase-change critical points.

The flow in the liquid phase is driven by surface stresses that depend on the conditions in the gas phase. Thus, imposing a gas flow allows us to passively control the flow in the liquid phase by varying the temperature and velocity (magnitude, profile) of the forced gas flow at the inlet, which is located either at the upper or the lower end of the tube. Owing to the low viscosity of gases under standard conditions, the gas flow affects the motion in the liquid phase primarily by altering the surface temperature and, thus, the thermocapillary stresses, and to a lesser degree by mechanical stresses on the interface. In addition, buoyancy forces drive the flow due to horizontal density gradients. For very small liquid bridges, (thermocapillary) surface forces typically dominate (buoyant) volume forces. But for millimetric liquid bridges investigated under terrestrial conditions, buoyancy can significantly affect the interfacial shape and the fluid motion.

2.2. Governing equations and boundary conditions

2.2.1. Transport equations

Due to the axisymmetric geometry, we use cylindrical coordinates ![]() $(r, \varphi, z)$ with the corresponding unit vectors

$(r, \varphi, z)$ with the corresponding unit vectors ![]() $(\boldsymbol {e}_r, \boldsymbol {e}_\varphi, \boldsymbol {e}_z)$, and an origin centred in the middle of the liquid bridge. The velocity field is represented as

$(\boldsymbol {e}_r, \boldsymbol {e}_\varphi, \boldsymbol {e}_z)$, and an origin centred in the middle of the liquid bridge. The velocity field is represented as ![]() $\boldsymbol {u}=u\boldsymbol {e}_r+v\boldsymbol {e}_\varphi +w\boldsymbol {e}_z$.

$\boldsymbol {u}=u\boldsymbol {e}_r+v\boldsymbol {e}_\varphi +w\boldsymbol {e}_z$.

The fluid motion inside the liquid bridge is governed by the Navier–Stokes, continuity and energy equations. For a Newtonian fluid with variable properties, they read in strong conservative form

where ![]() $t$ is time,

$t$ is time, ![]() $P$ is the pressure and

$P$ is the pressure and ![]() $\boldsymbol{\mathsf{S}} = \boldsymbol {\nabla }\boldsymbol {u} + (\boldsymbol {\nabla } \boldsymbol {u})^\mathrm {T}-(2/3) (\boldsymbol {\nabla }\boldsymbol {\cdot }\boldsymbol {u})\boldsymbol{\mathsf{I}}$ the deformation rate tensor with the identity matrix

$\boldsymbol{\mathsf{S}} = \boldsymbol {\nabla }\boldsymbol {u} + (\boldsymbol {\nabla } \boldsymbol {u})^\mathrm {T}-(2/3) (\boldsymbol {\nabla }\boldsymbol {\cdot }\boldsymbol {u})\boldsymbol{\mathsf{I}}$ the deformation rate tensor with the identity matrix ![]() $\boldsymbol{\mathsf{I}}$. In contrast to most previous numerical studies on liquid bridges, we consider the dynamic viscosity

$\boldsymbol{\mathsf{I}}$. In contrast to most previous numerical studies on liquid bridges, we consider the dynamic viscosity ![]() $\mu (T)$, the density

$\mu (T)$, the density ![]() $\rho (T)$, the specific heat capacity

$\rho (T)$, the specific heat capacity ![]() $c_p(T)$ and the thermal conductivity

$c_p(T)$ and the thermal conductivity ![]() $\lambda (T)$ to be fully temperature dependent (FTD) and call this the FTD approach in contrast to, e.g. the OB approximation. The equations governing the gas phase are formally identical to (2.3). The material parameters relating to the gas phase

$\lambda (T)$ to be fully temperature dependent (FTD) and call this the FTD approach in contrast to, e.g. the OB approximation. The equations governing the gas phase are formally identical to (2.3). The material parameters relating to the gas phase ![]() $\rho _{g}$,

$\rho _{g}$, ![]() $\mu _{g}$,

$\mu _{g}$, ![]() $\lambda _{g}$ and

$\lambda _{g}$ and ![]() $c_{p{g}}$ are indicated by the subscript ‘g’.

$c_{p{g}}$ are indicated by the subscript ‘g’.

Using the reference material parameters of the liquid (superscript ‘*’) evaluated at the reference temperature ![]() $T^*$, (2.3) are made dimensionless by the length, time, velocity, pressure and temperature scales

$T^*$, (2.3) are made dimensionless by the length, time, velocity, pressure and temperature scales ![]() $d$,

$d$, ![]() $d^2\rho ^*/\mu ^*$,

$d^2\rho ^*/\mu ^*$, ![]() $\gamma ^*\Delta T/\mu ^*$,

$\gamma ^*\Delta T/\mu ^*$, ![]() $\gamma ^*\Delta T/d$ and

$\gamma ^*\Delta T/d$ and ![]() $\Delta T$, respectively. This yields

$\Delta T$, respectively. This yields

where ![]() $p = (d/\gamma ^*\Delta T )(P - \rho ^* g z)$ is the reduced pressure and

$p = (d/\gamma ^*\Delta T )(P - \rho ^* g z)$ is the reduced pressure and

the reduced temperature. The Reynolds, Prandtl and dynamic Bond numbers are respectively defined as

Equations (2.4) hold for both the liquid and the gas phase. They are distinguished by the functions ![]() $\alpha (\vartheta )$ and the parameter

$\alpha (\vartheta )$ and the parameter ![]() $\varepsilon$. The parameters

$\varepsilon$. The parameters ![]() $\varepsilon =\beta ^*\Delta T$ and

$\varepsilon =\beta ^*\Delta T$ and ![]() $\varepsilon _{g}=\beta _{g}^*\Delta T$ measure the magnitude of the density variation in the respective phase, where

$\varepsilon _{g}=\beta _{g}^*\Delta T$ measure the magnitude of the density variation in the respective phase, where ![]() $\beta ^*=-(1/\rho ^*)(\partial \rho /\partial T)^*_P$ and

$\beta ^*=-(1/\rho ^*)(\partial \rho /\partial T)^*_P$ and ![]() $\beta ^*_{g}$ are the thermal expansion coefficients of the liquid and gas, respectively, evaluated at

$\beta ^*_{g}$ are the thermal expansion coefficients of the liquid and gas, respectively, evaluated at ![]() $\vartheta ^*=0$. As in Stojanović et al. (Reference Stojanović, Romanò and Kuhlmann2022), the phase is distinguished by selecting the respective set of thermophysical shape functions

$\vartheta ^*=0$. As in Stojanović et al. (Reference Stojanović, Romanò and Kuhlmann2022), the phase is distinguished by selecting the respective set of thermophysical shape functions

\begin{align} \boldsymbol{\alpha} &= \left[ \alpha_\rho(\vartheta),\alpha_\mu(\vartheta),\alpha_\lambda(\vartheta),\alpha_{cp}(\vartheta) \right] \nonumber\\ &= \begin{cases} \left[\dfrac{\rho(\vartheta)}{\rho^*},\dfrac{\mu(\vartheta)}{\mu^*},\dfrac{\lambda(\vartheta)}{\lambda^*}, \dfrac{c_p(\vartheta)}{c^*_p}\right] & \text{for the liquid phase,}\\[12pt] \left[\dfrac{\rho_{g}(\vartheta)}{\rho^*},\dfrac{\mu_{g}(\vartheta)}{\mu^*},\dfrac{\lambda_{g}(\vartheta)} {\lambda^*},\dfrac{c_{pg}(\vartheta)}{c^*_p}\right] & \text{for the gas phase,} \end{cases} \end{align}

\begin{align} \boldsymbol{\alpha} &= \left[ \alpha_\rho(\vartheta),\alpha_\mu(\vartheta),\alpha_\lambda(\vartheta),\alpha_{cp}(\vartheta) \right] \nonumber\\ &= \begin{cases} \left[\dfrac{\rho(\vartheta)}{\rho^*},\dfrac{\mu(\vartheta)}{\mu^*},\dfrac{\lambda(\vartheta)}{\lambda^*}, \dfrac{c_p(\vartheta)}{c^*_p}\right] & \text{for the liquid phase,}\\[12pt] \left[\dfrac{\rho_{g}(\vartheta)}{\rho^*},\dfrac{\mu_{g}(\vartheta)}{\mu^*},\dfrac{\lambda_{g}(\vartheta)} {\lambda^*},\dfrac{c_{pg}(\vartheta)}{c^*_p}\right] & \text{for the gas phase,} \end{cases} \end{align}

which represent the temperature-dependent material parameters, normalised by the values that the parameters take in the liquid at the reference temperature. A shape function evaluated at the reference point is indicated by an asterisk, i.e. ![]() $\alpha _\rho ^* = \alpha _\rho (\vartheta ^*) = 1$ for the liquid and

$\alpha _\rho ^* = \alpha _\rho (\vartheta ^*) = 1$ for the liquid and ![]() $\alpha _\rho ^* = \rho _{g}^*/\rho ^*$ for the gas. The shape functions

$\alpha _\rho ^* = \rho _{g}^*/\rho ^*$ for the gas. The shape functions ![]() $\alpha _j$ with

$\alpha _j$ with ![]() $j \in [\rho, \mu, \lambda, c_p]$ used will be specified in § 4. Note that in (2.4a)

$j \in [\rho, \mu, \lambda, c_p]$ used will be specified in § 4. Note that in (2.4a) ![]() $(\alpha _\rho -\alpha _{\rho }^{*})/\varepsilon = -\vartheta + {O}(\vartheta ^2)$, recovering the buoyancy term in Boussinesq approximation at linear order. In a model assuming constant material parameters,

$(\alpha _\rho -\alpha _{\rho }^{*})/\varepsilon = -\vartheta + {O}(\vartheta ^2)$, recovering the buoyancy term in Boussinesq approximation at linear order. In a model assuming constant material parameters,

\begin{equation} \boldsymbol{\alpha} = \begin{cases} [1,1,1,1] & \text{for the liquid phase,}\\ \left[\dfrac{\rho^*_{g}}{\rho^*},\dfrac{\mu^*_{g}}{\mu^*},\dfrac{\lambda^*_{g}}{\lambda^*}, \dfrac{c^*_{pg}}{c^*_p}\right] & \text{for the gas phase,} \end{cases} \end{equation}

\begin{equation} \boldsymbol{\alpha} = \begin{cases} [1,1,1,1] & \text{for the liquid phase,}\\ \left[\dfrac{\rho^*_{g}}{\rho^*},\dfrac{\mu^*_{g}}{\mu^*},\dfrac{\lambda^*_{g}}{\lambda^*}, \dfrac{c^*_{pg}}{c^*_p}\right] & \text{for the gas phase,} \end{cases} \end{equation}

and the bulk equations only depend on ![]() ${\textit {Re}}$,

${\textit {Re}}$, ![]() ${\textit {Pr}}$ and

${\textit {Pr}}$ and ![]() ${\textit {Bd}}$.

${\textit {Bd}}$.

2.2.2. Linear stability equations

For sufficiently small driving forces, measured either by the Reynolds number ![]() ${\textit {Re}}$ or the Marangoni number

${\textit {Re}}$ or the Marangoni number ![]() ${\textit {Ma}}={\textit {Re}}{\textit {Pr}}$, an axisymmetric and time-independent solution

${\textit {Ma}}={\textit {Re}}{\textit {Pr}}$, an axisymmetric and time-independent solution ![]() $\boldsymbol {q}_0(r,z) = (u_0,0,w_0,p_0,\vartheta _0)$ (liquid) and

$\boldsymbol {q}_0(r,z) = (u_0,0,w_0,p_0,\vartheta _0)$ (liquid) and ![]() $\boldsymbol {q}_{g0}(r,z) = (u_{g0},0,w_{g0},p_{g0},\vartheta _{g0})$ (gas) of (2.4) exists. This basic flow is indicated by a subscript ‘0’. The shape of the interface

$\boldsymbol {q}_{g0}(r,z) = (u_{g0},0,w_{g0},p_{g0},\vartheta _{g0})$ (gas) of (2.4) exists. This basic flow is indicated by a subscript ‘0’. The shape of the interface ![]() $h_0(z)$, separating the gas from the liquid phase, is part of the basic flow solution.

$h_0(z)$, separating the gas from the liquid phase, is part of the basic flow solution.

To investigate the linear stability of the basic flow, the dynamics of small deviations from the basic solution must be considered. These deviations also concern the interfacial shape. Recent experiments (Yano et al. Reference Yano, Nishino, Matsumoto, Ueno, Komiya, Kamotani and Imaishi2018b) revealed that the dynamic interfacial deformation caused by the perturbation flow is negligible. Therefore, we only consider perturbations of ![]() $\boldsymbol {q}_0$ and

$\boldsymbol {q}_0$ and ![]() $\boldsymbol {q}_{g0}$ within their domains separated by the phase boundary

$\boldsymbol {q}_{g0}$ within their domains separated by the phase boundary ![]() $h_0(z)$. To carry out the linear stability analysis, the general three-dimensional and time-dependent solution

$h_0(z)$. To carry out the linear stability analysis, the general three-dimensional and time-dependent solution ![]() $[\boldsymbol {q},\boldsymbol {q}_{g}]$ of (2.4) is decomposed into

$[\boldsymbol {q},\boldsymbol {q}_{g}]$ of (2.4) is decomposed into

separating the perturbation flow ![]() $[\tilde {\boldsymbol {q}},\tilde {\boldsymbol {q}}_{g}]$ (indicated by a tilde) from the basic flow

$[\tilde {\boldsymbol {q}},\tilde {\boldsymbol {q}}_{g}]$ (indicated by a tilde) from the basic flow ![]() $[\boldsymbol {q}_0,\boldsymbol {q}_{g0}]$.

$[\boldsymbol {q}_0,\boldsymbol {q}_{g0}]$.

The linear dynamics is obtained by inserting (2.9a,b) in (2.4) and linearising all terms with respect to all perturbation quantities, in particular, with respect to ![]() $\tilde {\vartheta }$. This requires linearising the shape functions

$\tilde {\vartheta }$. This requires linearising the shape functions ![]() $\alpha _j(\vartheta )$ about their local values

$\alpha _j(\vartheta )$ about their local values ![]() $\alpha _j[\vartheta _0(r,z)]$ determined by the basic flow. Taylor expansion about the local basic state temperature

$\alpha _j[\vartheta _0(r,z)]$ determined by the basic flow. Taylor expansion about the local basic state temperature ![]() $\vartheta _0(r,z)$ yields

$\vartheta _0(r,z)$ yields

where the zeroth- and first-order Taylor coefficients ![]() $\alpha _{j 0}[\vartheta _0(r,z)]$ and

$\alpha _{j 0}[\vartheta _0(r,z)]$ and ![]() $\alpha _{j 0}'[\vartheta _0(r,z)]$ are scalar fields that depend continuously on

$\alpha _{j 0}'[\vartheta _0(r,z)]$ are scalar fields that depend continuously on ![]() $(r,z)$ through the basic temperature field

$(r,z)$ through the basic temperature field ![]() $\vartheta _0(r,z)$. Using (2.10) we obtain the linearised version of (2.4) as

$\vartheta _0(r,z)$. Using (2.10) we obtain the linearised version of (2.4) as

\begin{gather}

\alpha_{\rho 0}\frac{\partial \tilde{\boldsymbol{u}}}{\partial

t}+\alpha_{\rho 0}'\boldsymbol{u}_0\frac{\partial

\tilde{\vartheta}}{\partial t}+{\textit{Re}}

\boldsymbol{\nabla} \boldsymbol{\cdot} \left( \alpha_{\rho

0}\boldsymbol{u}_0\tilde{\boldsymbol{u}} + \alpha_{\rho

0}\tilde{\boldsymbol{u}}\boldsymbol{u}_0 + \alpha_{\rho

0}'\boldsymbol{u}_0\boldsymbol{u}_0\tilde{\vartheta}

\right)\nonumber\\ ={-} \boldsymbol{\nabla}

\tilde{p}-\frac{{\textit{Bd}}}{\varepsilon}

\alpha_{\rho 0}'\tilde{\vartheta} \boldsymbol{e}_z

+\boldsymbol{\nabla}\boldsymbol{\cdot} (\alpha_{\mu 0}

\tilde{\boldsymbol{\mathsf{S}}} +\alpha_{\mu 0}'

\boldsymbol{\mathsf{S}}_0\tilde{\vartheta} ),

\end{gather}

\begin{gather}

\alpha_{\rho 0}\frac{\partial \tilde{\boldsymbol{u}}}{\partial

t}+\alpha_{\rho 0}'\boldsymbol{u}_0\frac{\partial

\tilde{\vartheta}}{\partial t}+{\textit{Re}}

\boldsymbol{\nabla} \boldsymbol{\cdot} \left( \alpha_{\rho

0}\boldsymbol{u}_0\tilde{\boldsymbol{u}} + \alpha_{\rho

0}\tilde{\boldsymbol{u}}\boldsymbol{u}_0 + \alpha_{\rho

0}'\boldsymbol{u}_0\boldsymbol{u}_0\tilde{\vartheta}

\right)\nonumber\\ ={-} \boldsymbol{\nabla}

\tilde{p}-\frac{{\textit{Bd}}}{\varepsilon}

\alpha_{\rho 0}'\tilde{\vartheta} \boldsymbol{e}_z

+\boldsymbol{\nabla}\boldsymbol{\cdot} (\alpha_{\mu 0}

\tilde{\boldsymbol{\mathsf{S}}} +\alpha_{\mu 0}'

\boldsymbol{\mathsf{S}}_0\tilde{\vartheta} ),

\end{gather}

\begin{gather} {[}\alpha_{\rho 0}

\alpha_{cp 0}+\vartheta_0 (\alpha_{\rho 0}' \alpha_{cp

0}+\alpha_{\rho 0} \alpha_{cp 0}')]\frac{\partial

\tilde{\vartheta}}{\partial

t}+{\textit{Re}}\boldsymbol{\nabla}\boldsymbol{\cdot}(

\alpha_{\rho 0} \alpha_{cp 0}

\boldsymbol{u}_0\tilde{\vartheta}+\alpha_{\rho 0}

\alpha_{cp

0}\vartheta_0\tilde{\boldsymbol{u}}\nonumber\\

+\alpha_{\rho 0}' \alpha_{cp 0}

\vartheta_0\boldsymbol{u}_0

\tilde{\vartheta}+

\alpha_{\rho 0} \alpha_{cp 0}'

\vartheta_0\boldsymbol{u}_0\tilde{\vartheta})=

\frac{1}{{\textit{Pr}}}\boldsymbol{\nabla}\boldsymbol{\cdot}(\alpha_{\lambda

0}' \tilde{\vartheta} \boldsymbol{\nabla} \vartheta_0+

\alpha_{\lambda 0} \boldsymbol{\nabla}\tilde{\vartheta}),

\end{gather}

\begin{gather} {[}\alpha_{\rho 0}

\alpha_{cp 0}+\vartheta_0 (\alpha_{\rho 0}' \alpha_{cp

0}+\alpha_{\rho 0} \alpha_{cp 0}')]\frac{\partial

\tilde{\vartheta}}{\partial

t}+{\textit{Re}}\boldsymbol{\nabla}\boldsymbol{\cdot}(

\alpha_{\rho 0} \alpha_{cp 0}

\boldsymbol{u}_0\tilde{\vartheta}+\alpha_{\rho 0}

\alpha_{cp

0}\vartheta_0\tilde{\boldsymbol{u}}\nonumber\\

+\alpha_{\rho 0}' \alpha_{cp 0}

\vartheta_0\boldsymbol{u}_0

\tilde{\vartheta}+

\alpha_{\rho 0} \alpha_{cp 0}'

\vartheta_0\boldsymbol{u}_0\tilde{\vartheta})=

\frac{1}{{\textit{Pr}}}\boldsymbol{\nabla}\boldsymbol{\cdot}(\alpha_{\lambda

0}' \tilde{\vartheta} \boldsymbol{\nabla} \vartheta_0+

\alpha_{\lambda 0} \boldsymbol{\nabla}\tilde{\vartheta}),

\end{gather}

where ![]() $\tilde {\boldsymbol{\mathsf{S}}} = \boldsymbol {\nabla }\tilde {\boldsymbol {u}} + (\boldsymbol {\nabla } \tilde {\boldsymbol {u}})^\mathrm {T} -(2/3)(\boldsymbol {\nabla }\boldsymbol {\cdot }\tilde {\boldsymbol {u}})\boldsymbol{\mathsf{I}}$ and

$\tilde {\boldsymbol{\mathsf{S}}} = \boldsymbol {\nabla }\tilde {\boldsymbol {u}} + (\boldsymbol {\nabla } \tilde {\boldsymbol {u}})^\mathrm {T} -(2/3)(\boldsymbol {\nabla }\boldsymbol {\cdot }\tilde {\boldsymbol {u}})\boldsymbol{\mathsf{I}}$ and ![]() $\boldsymbol{\mathsf{S}}_0 = \boldsymbol {\nabla }\boldsymbol {u}_0 + (\boldsymbol {\nabla }\boldsymbol {u}_0)^\mathrm {T} - (2/3)(\boldsymbol {\nabla }\boldsymbol {\cdot }\boldsymbol {u}_0 )\boldsymbol{\mathsf{I}}$. The basic state solution enters parametrically in the linear disturbance equations for

$\boldsymbol{\mathsf{S}}_0 = \boldsymbol {\nabla }\boldsymbol {u}_0 + (\boldsymbol {\nabla }\boldsymbol {u}_0)^\mathrm {T} - (2/3)(\boldsymbol {\nabla }\boldsymbol {\cdot }\boldsymbol {u}_0 )\boldsymbol{\mathsf{I}}$. The basic state solution enters parametrically in the linear disturbance equations for ![]() $\tilde {\boldsymbol {q}}$.

$\tilde {\boldsymbol {q}}$.

Since (2.11) is linear in ![]() $\tilde {\boldsymbol {q}}$ with coefficients that do not depend on

$\tilde {\boldsymbol {q}}$ with coefficients that do not depend on ![]() $\varphi$ and

$\varphi$ and ![]() $t$, the general solution

$t$, the general solution ![]() $\tilde {\boldsymbol {q}}$ of (2.11) can be constructed by a superposition of normal modes

$\tilde {\boldsymbol {q}}$ of (2.11) can be constructed by a superposition of normal modes

where the complex conjugates terms (c.c.) render the solution real. The normal modes are harmonic in ![]() $\varphi$ with wavenumber

$\varphi$ with wavenumber ![]() $m \in \mathbb {N}_0$. The time dependence of each mode is exponential with the complex growth

$m \in \mathbb {N}_0$. The time dependence of each mode is exponential with the complex growth ![]() $\psi _{j,m} \in \mathbb {C}$. The index

$\psi _{j,m} \in \mathbb {C}$. The index ![]() $j$ numbers the discrete set of solutions for fixed

$j$ numbers the discrete set of solutions for fixed ![]() $m$ that arise due to the finite domain in

$m$ that arise due to the finite domain in ![]() $r$ and

$r$ and ![]() $z$. Inserting the ansatz (2.12a,b) into (2.11) yields partial differential equations for the complex amplitudes

$z$. Inserting the ansatz (2.12a,b) into (2.11) yields partial differential equations for the complex amplitudes ![]() $\hat {\boldsymbol {q}}_{j,m}$ and

$\hat {\boldsymbol {q}}_{j,m}$ and ![]() $\hat {\boldsymbol {q}}_{{g}j,m}$,

$\hat {\boldsymbol {q}}_{{g}j,m}$,

\begin{align}

&\psi\left(\boldsymbol{u}_0\alpha_{\rho 0}' \hat{\vartheta}

+\alpha_{\rho 0} \hat{\boldsymbol{u}}\right)+

{\textit{Re}}\boldsymbol{\nabla}\boldsymbol{\cdot}\left[\alpha_{\rho

0}'

\hat{\vartheta}\boldsymbol{u}_0\boldsymbol{u}_0+\alpha_{\rho

0}(\boldsymbol{u}_0\hat{\boldsymbol{u}}+\hat{\boldsymbol{u}}\boldsymbol{u}_0)\right]+{\textit{Re}}\frac{\alpha_{\rho

0}\mathrm{i} \hat{v}m\boldsymbol{u}_0}{r}\nonumber\\ &\quad

={-}\boldsymbol{\nabla}

\hat{p}-\frac{{\textit{Bd}}}{\varepsilon}\alpha_{\rho

0}'\hat{\vartheta}\boldsymbol{e}_z+\boldsymbol{\nabla}\boldsymbol{\cdot}\left(\alpha_{\mu

0}' \hat{\vartheta} \boldsymbol{\mathsf{S}}_0+\alpha_{\mu 0}

\hat{\boldsymbol{\mathsf{S}}}\right)+\left(\alpha_{\mu 0}'

\hat{\vartheta} \boldsymbol{\mathsf{S}}_0+\alpha_{\mu 0}

\hat{\boldsymbol{\mathsf{S}}}-\hat{p} \right)\frac{\mathrm{i} m

\boldsymbol{e}_\varphi}{r}

\end{align}

\begin{align}

&\psi\left(\boldsymbol{u}_0\alpha_{\rho 0}' \hat{\vartheta}

+\alpha_{\rho 0} \hat{\boldsymbol{u}}\right)+

{\textit{Re}}\boldsymbol{\nabla}\boldsymbol{\cdot}\left[\alpha_{\rho

0}'

\hat{\vartheta}\boldsymbol{u}_0\boldsymbol{u}_0+\alpha_{\rho

0}(\boldsymbol{u}_0\hat{\boldsymbol{u}}+\hat{\boldsymbol{u}}\boldsymbol{u}_0)\right]+{\textit{Re}}\frac{\alpha_{\rho

0}\mathrm{i} \hat{v}m\boldsymbol{u}_0}{r}\nonumber\\ &\quad

={-}\boldsymbol{\nabla}

\hat{p}-\frac{{\textit{Bd}}}{\varepsilon}\alpha_{\rho

0}'\hat{\vartheta}\boldsymbol{e}_z+\boldsymbol{\nabla}\boldsymbol{\cdot}\left(\alpha_{\mu

0}' \hat{\vartheta} \boldsymbol{\mathsf{S}}_0+\alpha_{\mu 0}

\hat{\boldsymbol{\mathsf{S}}}\right)+\left(\alpha_{\mu 0}'

\hat{\vartheta} \boldsymbol{\mathsf{S}}_0+\alpha_{\mu 0}

\hat{\boldsymbol{\mathsf{S}}}-\hat{p} \right)\frac{\mathrm{i} m

\boldsymbol{e}_\varphi}{r}

\end{align} \begin{align} &\psi\left[\vartheta_0 (\alpha_{\rho 0}' \alpha_{cp0}+\alpha_{\rho 0} \alpha_{cp0}')+\alpha_{\rho 0} \alpha_{cp0}\right] \hat{\vartheta}\nonumber\\ &\quad +{\textit{Re}}\boldsymbol{\nabla}\boldsymbol{\cdot} \left[(\alpha_{\rho 0}' \alpha_{cp0}+\alpha_{\rho 0} \alpha_{cp0}') \vartheta_0\boldsymbol{u}_0 \hat{\vartheta}+\alpha_{\rho 0} \alpha_{cp0} \hat{\vartheta}\boldsymbol{u}_0+\alpha_{\rho 0} \alpha_{cp0} \vartheta_0\hat{\boldsymbol{u}}\right]\nonumber\\ &\quad +{\textit{Re}}\frac{\alpha_{\rho 0} \alpha_{cp0}\mathrm{i} \hat{v} m}{r}=\frac{1}{{\textit{Pr}}}\boldsymbol{\nabla}\boldsymbol{\cdot}\left[ (\alpha_{\lambda 0}' \hat{\vartheta} \boldsymbol{\nabla} \vartheta_0+\alpha_{\lambda 0} \boldsymbol{\nabla} \hat{\vartheta})-\frac{\alpha_{\lambda 0} \hat{\vartheta} m^2}{r^2}\right]. \end{align}

\begin{align} &\psi\left[\vartheta_0 (\alpha_{\rho 0}' \alpha_{cp0}+\alpha_{\rho 0} \alpha_{cp0}')+\alpha_{\rho 0} \alpha_{cp0}\right] \hat{\vartheta}\nonumber\\ &\quad +{\textit{Re}}\boldsymbol{\nabla}\boldsymbol{\cdot} \left[(\alpha_{\rho 0}' \alpha_{cp0}+\alpha_{\rho 0} \alpha_{cp0}') \vartheta_0\boldsymbol{u}_0 \hat{\vartheta}+\alpha_{\rho 0} \alpha_{cp0} \hat{\vartheta}\boldsymbol{u}_0+\alpha_{\rho 0} \alpha_{cp0} \vartheta_0\hat{\boldsymbol{u}}\right]\nonumber\\ &\quad +{\textit{Re}}\frac{\alpha_{\rho 0} \alpha_{cp0}\mathrm{i} \hat{v} m}{r}=\frac{1}{{\textit{Pr}}}\boldsymbol{\nabla}\boldsymbol{\cdot}\left[ (\alpha_{\lambda 0}' \hat{\vartheta} \boldsymbol{\nabla} \vartheta_0+\alpha_{\lambda 0} \boldsymbol{\nabla} \hat{\vartheta})-\frac{\alpha_{\lambda 0} \hat{\vartheta} m^2}{r^2}\right]. \end{align}Discretisation of (2.13) leads to a large linear eigenvalue problem that must be solved to determine the stability boundary (§ 3).

2.2.3. Boundary conditions

The equations for the steady two-dimensional basic flow ![]() $\boldsymbol {q}_0$ satisfying (2.4) and those for the perturbation amplitudes

$\boldsymbol {q}_0$ satisfying (2.4) and those for the perturbation amplitudes ![]() $\hat {\boldsymbol {q}}$ according to the linear stability equations (2.11) must be solved subject to boundary and coupling conditions.

$\hat {\boldsymbol {q}}$ according to the linear stability equations (2.11) must be solved subject to boundary and coupling conditions.

Solid walls: On all solid walls, the liquid and gas must satisfy the no-slip conditions

In contrast to the outer shield, which is thermally insulated in the radial direction, the cylindrical support discs are assumed to be perfect heat conductors, leading to

The amplitudes of the temperature perturbations vanish on the hot and cold walls since the imposed constant temperatures are taken care of by the basic state.

Axis of symmetry: On the axis ![]() $r=0$ the symmetry of the basic state requires

$r=0$ the symmetry of the basic state requires

The boundary conditions for the perturbation amplitudes depend on the azimuthal wavenumber ![]() $m$ and are given in table 1.

$m$ and are given in table 1.

Table 1. Boundary conditions for the perturbation flow on ![]() $r=0$.

$r=0$.

Liquid–gas interface: The liquid and gas flow are coupled via the interface at ![]() $r = h_0(z)$ that is assumed to be determined by the basic flow only. Therefore, we first consider the basic flow. The continuity of the basic temperature and the basic heat flux requires

$r = h_0(z)$ that is assumed to be determined by the basic flow only. Therefore, we first consider the basic flow. The continuity of the basic temperature and the basic heat flux requires

where

\begin{equation} \boldsymbol{n} = \frac{1}{N}\left(\boldsymbol{e}_r -\frac{\mathrm{d} h_0}{\mathrm{d} z}\boldsymbol{e}_z \right) \quad \text{with} \ N=\sqrt{1+\left(\frac{\mathrm{d} h_0}{\mathrm{d} z}\right)^2}, \end{equation}

\begin{equation} \boldsymbol{n} = \frac{1}{N}\left(\boldsymbol{e}_r -\frac{\mathrm{d} h_0}{\mathrm{d} z}\boldsymbol{e}_z \right) \quad \text{with} \ N=\sqrt{1+\left(\frac{\mathrm{d} h_0}{\mathrm{d} z}\right)^2}, \end{equation}is the outward-pointing unit normal vector to the interface. The kinematic coupling conditions

guarantee no slip on the interface and also enforce the basic streamlines to be parallel to the interface ![]() $h_0(z)$.

$h_0(z)$.

The dynamic coupling condition is represented by the stress balance on the interface. It is decomposed into a normal stress balance

\begin{align} &-(p_0-p_{g0}) +

\alpha_{\mu 0}\boldsymbol{n} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_0 \boldsymbol{\cdot} \boldsymbol{n} + \left(

\frac{1}{{\textit{Ca}}} -\vartheta_0\right)

\boldsymbol{\nabla}\boldsymbol{\cdot}\boldsymbol{n}

\nonumber\\ &\quad ={-}(\alpha_{\rho 0}-\alpha_{\rho

{g}0})\frac{{\textit{Bo}}}{{\textit{Ca}}}z+\alpha_{\mu

{g}0}\boldsymbol{n} \boldsymbol{\cdot} \boldsymbol{\mathsf{S}}_{g0}

\boldsymbol{\cdot} \boldsymbol{n},

\end{align}

\begin{align} &-(p_0-p_{g0}) +

\alpha_{\mu 0}\boldsymbol{n} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_0 \boldsymbol{\cdot} \boldsymbol{n} + \left(

\frac{1}{{\textit{Ca}}} -\vartheta_0\right)

\boldsymbol{\nabla}\boldsymbol{\cdot}\boldsymbol{n}

\nonumber\\ &\quad ={-}(\alpha_{\rho 0}-\alpha_{\rho

{g}0})\frac{{\textit{Bo}}}{{\textit{Ca}}}z+\alpha_{\mu

{g}0}\boldsymbol{n} \boldsymbol{\cdot} \boldsymbol{\mathsf{S}}_{g0}

\boldsymbol{\cdot} \boldsymbol{n},

\end{align}and a tangential stress balance

where ![]() $\boldsymbol {t}\perp \boldsymbol {n}$ is the unit tangent vector, and the basic state shape functions, like

$\boldsymbol {t}\perp \boldsymbol {n}$ is the unit tangent vector, and the basic state shape functions, like ![]() $\alpha _{\mu {g}0}(r,z)$, depend on

$\alpha _{\mu {g}0}(r,z)$, depend on ![]() $(r,z)$. In these non-dimensional equations

$(r,z)$. In these non-dimensional equations

denote the capillary number and the static Bond number, respectively. Since the term ![]() $(\alpha _{\rho 0}-\alpha _{\rho {g}0})$ in (2.20a) takes care of the static pressure distribution in the gas phase, the reference density of the gas

$(\alpha _{\rho 0}-\alpha _{\rho {g}0})$ in (2.20a) takes care of the static pressure distribution in the gas phase, the reference density of the gas ![]() $\rho _{g}^*$ does not enter

$\rho _{g}^*$ does not enter ![]() ${\textit {Bo}}$. This way, the non-dimensional material parameter

${\textit {Bo}}$. This way, the non-dimensional material parameter

serves as a proportionality factor between the dynamic and static Bond numbers and also between ![]() $\varepsilon$ and

$\varepsilon$ and ![]() ${\textit {Ca}}$.

${\textit {Ca}}$.

Since the location ![]() $h_0(z)$ is part of the basic flow solution, it is obtained iteratively by solving simultaneously the Navier–Stokes equations for both phases and imposing the coupling and boundary conditions. To that end, we assume the contact lines are pinned to the edges of the support discs,

$h_0(z)$ is part of the basic flow solution, it is obtained iteratively by solving simultaneously the Navier–Stokes equations for both phases and imposing the coupling and boundary conditions. To that end, we assume the contact lines are pinned to the edges of the support discs, ![]() $h_0(\pm 1/2)=1/\varGamma$, and impose the volume constraint

$h_0(\pm 1/2)=1/\varGamma$, and impose the volume constraint

\begin{equation} \varGamma^2\int_{{-}1/2}^{1/2} h_0(z)^2\,\mathrm{d} z=\mathcal{V}, \end{equation}

\begin{equation} \varGamma^2\int_{{-}1/2}^{1/2} h_0(z)^2\,\mathrm{d} z=\mathcal{V}, \end{equation}

where ![]() $\mathcal {V}=V/{\rm \pi} r_{i}^2d$ is the ratio between the volume

$\mathcal {V}=V/{\rm \pi} r_{i}^2d$ is the ratio between the volume ![]() $V$ occupied by the liquid and the upright cylindrical volume between the two support discs.

$V$ occupied by the liquid and the upright cylindrical volume between the two support discs.

To assess the influence of the dynamic deformability of a dynamic interface (DI), we also consider a static interface (SI) whose shape ![]() $h_0(z)$, instead by the normal stress balance (2.20a), is determined by the solution of the Young–Laplace equation

$h_0(z)$, instead by the normal stress balance (2.20a), is determined by the solution of the Young–Laplace equation

where ![]() $\Delta p_h$ is a constant pressure jump across the interface. For more details, see Stojanović et al. (Reference Stojanović, Romanò and Kuhlmann2022).

$\Delta p_h$ is a constant pressure jump across the interface. For more details, see Stojanović et al. (Reference Stojanović, Romanò and Kuhlmann2022).

Once the interface shape ![]() $h_0(z)$ and the basic state are computed, the coupling conditions for the perturbation amplitudes

$h_0(z)$ and the basic state are computed, the coupling conditions for the perturbation amplitudes

and

can readily be imposed to solve the perturbation equations (2.13).

Inlet and outlet conditions: The boundary conditions at the ends of the shield tube, ![]() $z=\pm (1/2+\varGamma _{s}/\varGamma )$, depend on whether the tube is sealed or open. In the case of a sealed tube, we prescribe no-slip and adiabatic conditions on both plane end walls, i.e.

$z=\pm (1/2+\varGamma _{s}/\varGamma )$, depend on whether the tube is sealed or open. In the case of a sealed tube, we prescribe no-slip and adiabatic conditions on both plane end walls, i.e.

For an open tube, upflow in the positive ![]() $z$ direction and downflow in the negative

$z$ direction and downflow in the negative ![]() $z$ direction are distinguished by the sign of the Reynolds number

$z$ direction are distinguished by the sign of the Reynolds number ![]() ${Re}_{g} = \bar {W}_{g,in}\rho ^*d/\mu ^*$, defined as in Stojanovic, Romanò & Kuhlmann (Reference Stojanović, Romanò and Kuhlmann2023), which is taken positive for upflow and negative for downflow. The inlet

${Re}_{g} = \bar {W}_{g,in}\rho ^*d/\mu ^*$, defined as in Stojanovic, Romanò & Kuhlmann (Reference Stojanović, Romanò and Kuhlmann2023), which is taken positive for upflow and negative for downflow. The inlet ![]() $(z_{in})$ and outlet locations

$(z_{in})$ and outlet locations ![]() $(z_{out})$ are thus defined as

$(z_{out})$ are thus defined as

At the inlet, we prescribe a fully developed axial velocity profile

where the factor ![]() ${\textit {Re}}^{-1}$ arises due to the scaling. The unconventional gas Reynolds number

${\textit {Re}}^{-1}$ arises due to the scaling. The unconventional gas Reynolds number ![]() ${Re}_{g}$ is defined combining the mean inlet velocity of the gas and the kinematic viscosity of the liquid

${Re}_{g}$ is defined combining the mean inlet velocity of the gas and the kinematic viscosity of the liquid ![]() $\mu ^*/\rho ^*$. The usefulness of

$\mu ^*/\rho ^*$. The usefulness of ![]() ${Re}_{g}$ defined in this way is explained in Appendix A of Stojanovic et al. (Reference Stojanović, Romanò and Kuhlmann2023): it provides a better correlation of the critical Reynolds numbers, because the instability arises in the liquid and not in the gas.

${Re}_{g}$ defined in this way is explained in Appendix A of Stojanovic et al. (Reference Stojanović, Romanò and Kuhlmann2023): it provides a better correlation of the critical Reynolds numbers, because the instability arises in the liquid and not in the gas.

At the outlet, outflow conditions are used such that

Following Stojanović, Romanò & Kuhlmann (Reference Stojanović, Romanò and Kuhlmann2023a), constant temperatures are imposed at both ends of the tube

which are equal to the temperature of the respective adjacent support disc.

3. Numerical methods

All numerical calculations required to compute the basic flow and its linear stability are carried out using the code MaranStable (Stojanović, Romanò & Kuhlmann Reference Stojanović, Romanò and Kuhlmann2023b). It is written in Matlab and is available as open source from https://github.com/fromano88/MaranStable. The stability analysis implemented in MaranStable has been verified and validated extensively for statically and dynamically deformed liquid bridges, for single- and two-phase flows where the gas phase is confined to a cylindrical tube about the liquid bridge being either closed or subject to through flow (Stojanović et al. Reference Stojanović, Romanò and Kuhlmann2022; Stojanovic et al. Reference Stojanović, Romanò and Kuhlmann2023). Grid convergence of MaranStable has been proven for a Boussinesq fluid of ![]() ${\textit {Pr}}=28$ (Stojanović et al. Reference Stojanović, Romanò and Kuhlmann2022). Additional verifications and validations of MaranStable regarding the FTD properties are provided in Appendix B.

${\textit {Pr}}=28$ (Stojanović et al. Reference Stojanović, Romanò and Kuhlmann2022). Additional verifications and validations of MaranStable regarding the FTD properties are provided in Appendix B.

3.1. Basic flow

In MaranStable the governing equations (2.4) and the boundary and coupling conditions are discretised by finite volumes using body-fitted coordinates. The physical mesh fitted to the interface shape is mapped to an orthogonal computational mesh using the surface shape ![]() $h_0(z)$. It is computed together with the flow field updating the physical and computational meshes after every iteration step. The resulting set of nonlinear algebraic equations is linearised and solved iteratively using the Newton–Raphson method. At the

$h_0(z)$. It is computed together with the flow field updating the physical and computational meshes after every iteration step. The resulting set of nonlinear algebraic equations is linearised and solved iteratively using the Newton–Raphson method. At the ![]() $k$th iteration the known approximation

$k$th iteration the known approximation ![]() $\boldsymbol {q}_0^{(k)}$ is updated by the increment

$\boldsymbol {q}_0^{(k)}$ is updated by the increment ![]() $\delta \boldsymbol {q}$ to obtain the improved approximation

$\delta \boldsymbol {q}$ to obtain the improved approximation

Within the present FTD parameter approach, the nonlinear shape functions as well need to be linearised about their basic state value according to

\begin{equation} \alpha_j\left(\vartheta_0^{(k+1)}\right)=\alpha_j\left(\vartheta_0^{(k)}+\delta \vartheta\right)\approx\alpha_j\left(\vartheta_0^{(k)}\right)+\left. \frac{\partial\alpha_j}{\partial\vartheta}\right|_{\vartheta_0^{(k)}}\delta\vartheta:= \alpha_{j0}^{(k)}+\alpha_{j0}'^{(k)}\delta\vartheta, \end{equation}

\begin{equation} \alpha_j\left(\vartheta_0^{(k+1)}\right)=\alpha_j\left(\vartheta_0^{(k)}+\delta \vartheta\right)\approx\alpha_j\left(\vartheta_0^{(k)}\right)+\left. \frac{\partial\alpha_j}{\partial\vartheta}\right|_{\vartheta_0^{(k)}}\delta\vartheta:= \alpha_{j0}^{(k)}+\alpha_{j0}'^{(k)}\delta\vartheta, \end{equation}

where the increment ![]() $\delta \vartheta$ is contained in

$\delta \vartheta$ is contained in ![]() $\delta \boldsymbol {q}$. Inserting (3.1) and (3.2) into (2.4) yields the set of linear equations

$\delta \boldsymbol {q}$. Inserting (3.1) and (3.2) into (2.4) yields the set of linear equations

where ![]() $\boldsymbol {J}(\boldsymbol {q}_0^{(k)})$ and

$\boldsymbol {J}(\boldsymbol {q}_0^{(k)})$ and ![]() $\boldsymbol {f}(\boldsymbol {q}_0^{(k)})$ are the Jacobian operator and the nonlinear residual of the Navier–Stokes equations, respectively. This leads to the linearised momentum, continuity and energy equations

$\boldsymbol {f}(\boldsymbol {q}_0^{(k)})$ are the Jacobian operator and the nonlinear residual of the Navier–Stokes equations, respectively. This leads to the linearised momentum, continuity and energy equations

\begin{align} &{\textit{Re}}\boldsymbol{\nabla}\boldsymbol{\cdot}\left[\alpha_{\rho 0}^{(k)} \left(\boldsymbol{u}_0^{(k)}\delta\boldsymbol{u}+\delta\boldsymbol{u}\boldsymbol{u}_0^{(k)}\right) +\alpha_{\rho 0}'^{(k)}\boldsymbol{u}_0^{(k)}\boldsymbol{u}_0^{(k)}\delta\vartheta \right]\nonumber\\ &\qquad +\boldsymbol{\nabla} \delta p+\frac{{\textit{Bd}}}{\varepsilon} \alpha_{\rho 0}'^{(k)}\delta \vartheta-\boldsymbol{\nabla}\boldsymbol{\cdot}\left(\alpha_{\mu 0}^{(k)} \delta\boldsymbol{\mathsf{S}} -\alpha_{\mu 0}'^{(k)} \boldsymbol{\mathsf{S}}_0^{(k)}\delta\vartheta \right)\nonumber\\ &\quad ={-}{\textit{Re}}\boldsymbol{\nabla}\boldsymbol{\cdot}\left(\alpha_{\rho 0}^{(k)}\boldsymbol{u}_0^{(k)}\boldsymbol{u}_0^{(k)}\right) - \boldsymbol{\nabla} p_0^{(k)}-\frac{{\textit{Bd}}}{\varepsilon}\left( \alpha_{\rho 0}^{(k)} \boldsymbol{e}_z-\alpha_{\rho}^{*}\right) +\boldsymbol{\nabla}\boldsymbol{\cdot}\left(\alpha_{\mu 0}^{(k)} \boldsymbol{\mathsf{S}}_0^{(k)} \right), \end{align}

\begin{align} &{\textit{Re}}\boldsymbol{\nabla}\boldsymbol{\cdot}\left[\alpha_{\rho 0}^{(k)} \left(\boldsymbol{u}_0^{(k)}\delta\boldsymbol{u}+\delta\boldsymbol{u}\boldsymbol{u}_0^{(k)}\right) +\alpha_{\rho 0}'^{(k)}\boldsymbol{u}_0^{(k)}\boldsymbol{u}_0^{(k)}\delta\vartheta \right]\nonumber\\ &\qquad +\boldsymbol{\nabla} \delta p+\frac{{\textit{Bd}}}{\varepsilon} \alpha_{\rho 0}'^{(k)}\delta \vartheta-\boldsymbol{\nabla}\boldsymbol{\cdot}\left(\alpha_{\mu 0}^{(k)} \delta\boldsymbol{\mathsf{S}} -\alpha_{\mu 0}'^{(k)} \boldsymbol{\mathsf{S}}_0^{(k)}\delta\vartheta \right)\nonumber\\ &\quad ={-}{\textit{Re}}\boldsymbol{\nabla}\boldsymbol{\cdot}\left(\alpha_{\rho 0}^{(k)}\boldsymbol{u}_0^{(k)}\boldsymbol{u}_0^{(k)}\right) - \boldsymbol{\nabla} p_0^{(k)}-\frac{{\textit{Bd}}}{\varepsilon}\left( \alpha_{\rho 0}^{(k)} \boldsymbol{e}_z-\alpha_{\rho}^{*}\right) +\boldsymbol{\nabla}\boldsymbol{\cdot}\left(\alpha_{\mu 0}^{(k)} \boldsymbol{\mathsf{S}}_0^{(k)} \right), \end{align} \begin{align} & {\textit{Ma}} \boldsymbol{\nabla}\boldsymbol{\cdot}\left[\alpha_{\rho 0}^{(k)} \alpha_{cp 0}^{(k)}\left( \boldsymbol{u}_0^{(k)}\delta\vartheta + \vartheta_0^{(k)}\delta\boldsymbol{u}\right) + \left(\alpha_{\rho 0}'^{(k)} \alpha_{cp 0}^{(k)} + \alpha_{\rho 0}^{(k)} \alpha_{cp 0}'^{(k)} \right)\vartheta_0^{(k)}\boldsymbol{u}_0^{(k)} \delta\vartheta\right]\nonumber\\ &\quad -\boldsymbol{\nabla}\boldsymbol{\cdot}\left(\alpha_{\lambda 0}'^{(k)} \delta\vartheta \boldsymbol{\nabla} \vartheta_0^{(k)} +\alpha_{\lambda 0}^{(k)} \boldsymbol{\nabla} \delta\vartheta\right) =\boldsymbol{\nabla}\boldsymbol{\cdot}\left(\alpha_{\lambda 0}^{(k)} \boldsymbol{\nabla} \vartheta_0^{(k)}\right)-{\textit{Ma}}\boldsymbol{\nabla}\boldsymbol{\cdot} \left(\alpha_{\rho 0}^{(k)} \alpha_{cp 0}^{(k)}\boldsymbol{u}_0^{(k)}\vartheta_0^{(k)}\right), \end{align}

\begin{align} & {\textit{Ma}} \boldsymbol{\nabla}\boldsymbol{\cdot}\left[\alpha_{\rho 0}^{(k)} \alpha_{cp 0}^{(k)}\left( \boldsymbol{u}_0^{(k)}\delta\vartheta + \vartheta_0^{(k)}\delta\boldsymbol{u}\right) + \left(\alpha_{\rho 0}'^{(k)} \alpha_{cp 0}^{(k)} + \alpha_{\rho 0}^{(k)} \alpha_{cp 0}'^{(k)} \right)\vartheta_0^{(k)}\boldsymbol{u}_0^{(k)} \delta\vartheta\right]\nonumber\\ &\quad -\boldsymbol{\nabla}\boldsymbol{\cdot}\left(\alpha_{\lambda 0}'^{(k)} \delta\vartheta \boldsymbol{\nabla} \vartheta_0^{(k)} +\alpha_{\lambda 0}^{(k)} \boldsymbol{\nabla} \delta\vartheta\right) =\boldsymbol{\nabla}\boldsymbol{\cdot}\left(\alpha_{\lambda 0}^{(k)} \boldsymbol{\nabla} \vartheta_0^{(k)}\right)-{\textit{Ma}}\boldsymbol{\nabla}\boldsymbol{\cdot} \left(\alpha_{\rho 0}^{(k)} \alpha_{cp 0}^{(k)}\boldsymbol{u}_0^{(k)}\vartheta_0^{(k)}\right), \end{align}

where ![]() $\delta \boldsymbol{\mathsf{S}} = \boldsymbol {\nabla } \delta \boldsymbol {u} + (\boldsymbol {\nabla } \delta \boldsymbol {u})^\mathrm {T} - (2/3) (\boldsymbol {\nabla }\boldsymbol {\cdot }\delta \boldsymbol {u}) \boldsymbol{\mathsf{I}}$. An additional iteration loop arising from the normal stress balance (2.20a) is embedded in the Newton–Raphson iteration that updates the surface shape

$\delta \boldsymbol{\mathsf{S}} = \boldsymbol {\nabla } \delta \boldsymbol {u} + (\boldsymbol {\nabla } \delta \boldsymbol {u})^\mathrm {T} - (2/3) (\boldsymbol {\nabla }\boldsymbol {\cdot }\delta \boldsymbol {u}) \boldsymbol{\mathsf{I}}$. An additional iteration loop arising from the normal stress balance (2.20a) is embedded in the Newton–Raphson iteration that updates the surface shape ![]() $h_0(z)$ after each iteration step. Neglecting terms of order

$h_0(z)$ after each iteration step. Neglecting terms of order ![]() $O(\vartheta ^2)$ in

$O(\vartheta ^2)$ in ![]() $\sigma (\vartheta )$, the linearised normal stress balance becomes

$\sigma (\vartheta )$, the linearised normal stress balance becomes

\begin{align} &-(\delta p-\delta p_{g})

+ \alpha_{\mu 0}^{(k)}\boldsymbol{n}^{(k)}

\boldsymbol{\cdot} \delta\boldsymbol{\mathsf{S}} \boldsymbol{\cdot}

\boldsymbol{n}^{(k)} + \alpha_{\mu

0}^{(k)}\boldsymbol{n}^{(k)} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_0^{(k)} \boldsymbol{\cdot} \delta\boldsymbol{n}

+ \alpha_{\mu 0}^{(k)}\delta\boldsymbol{n}

\boldsymbol{\cdot} \boldsymbol{\mathsf{S}}_0^{(k)} \boldsymbol{\cdot}

\boldsymbol{n}^{(k)}\nonumber\\ &\quad+ \alpha_{\mu

0}'^{(k)}\boldsymbol{n}^{(k)} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_0^{(k)} \boldsymbol{\cdot}

\boldsymbol{n}^{(k)}\delta\vartheta+ \left(

\frac{1}{{\textit{Ca}}} -\vartheta_0^{(k)}\right)

\boldsymbol{\nabla}\boldsymbol{\cdot}\delta\boldsymbol{n}-\boldsymbol{\nabla}\boldsymbol{\cdot}

\boldsymbol{n}^{(k)}\delta\vartheta+\left(\alpha_{\rho

0}'^{(k)}-\alpha_{\rho

{g}0}'^{(k)}\right)\frac{{\textit{Bo}}}{{\textit{Ca}}}\delta\vartheta

z\nonumber\\ &\quad -\alpha_{\mu{g}

0}^{(k)}\boldsymbol{n}^{(k)} \boldsymbol{\cdot}

\delta\boldsymbol{\mathsf{S}}_{g} \boldsymbol{\cdot}

\boldsymbol{n}^{(k)} - \alpha_{\mu{g}

0}^{(k)}\boldsymbol{n}^{(k)} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_{{g}0}^{(k)} \boldsymbol{\cdot}

\delta\boldsymbol{n} - \alpha_{\mu{g}

0}^{(k)}\delta\boldsymbol{n} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_{{g}0}^{(k)} \boldsymbol{\cdot}

\boldsymbol{n}^{(k)} \nonumber\\ &\quad- \alpha_{\mu{g}

0}'^{(k)}\boldsymbol{n}^{(k)} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_{{g}0}^{(k)} \boldsymbol{\cdot}

\boldsymbol{n}^{(k)}\delta\vartheta=p_0^{(k)}-

p_{g0}^{(k)}-\left(\alpha_{\rho 0}^{(k)}-\alpha_{\rho

{g}0}^{(k)}\right)\frac{{\textit{Bo}}}{{\textit{Ca}}}z-\alpha_{\mu

0}^{(k)}\boldsymbol{n}^{(k)} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_0^{(k)} \boldsymbol{\cdot}

\boldsymbol{n}^{(k)}\nonumber\\ &\quad-\left(

\frac{1}{{\textit{Ca}}}

-\vartheta_0^{(k)}\right)\boldsymbol{\nabla}\boldsymbol{\cdot}\boldsymbol{n}^{(k)}+\alpha_{\mu

{g}0}^{(k)}\boldsymbol{n}^{(k)} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_{g0}^{(k)} \boldsymbol{\cdot}

\boldsymbol{n}^{(k)},

\end{align}

\begin{align} &-(\delta p-\delta p_{g})

+ \alpha_{\mu 0}^{(k)}\boldsymbol{n}^{(k)}

\boldsymbol{\cdot} \delta\boldsymbol{\mathsf{S}} \boldsymbol{\cdot}

\boldsymbol{n}^{(k)} + \alpha_{\mu

0}^{(k)}\boldsymbol{n}^{(k)} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_0^{(k)} \boldsymbol{\cdot} \delta\boldsymbol{n}

+ \alpha_{\mu 0}^{(k)}\delta\boldsymbol{n}

\boldsymbol{\cdot} \boldsymbol{\mathsf{S}}_0^{(k)} \boldsymbol{\cdot}

\boldsymbol{n}^{(k)}\nonumber\\ &\quad+ \alpha_{\mu

0}'^{(k)}\boldsymbol{n}^{(k)} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_0^{(k)} \boldsymbol{\cdot}

\boldsymbol{n}^{(k)}\delta\vartheta+ \left(

\frac{1}{{\textit{Ca}}} -\vartheta_0^{(k)}\right)

\boldsymbol{\nabla}\boldsymbol{\cdot}\delta\boldsymbol{n}-\boldsymbol{\nabla}\boldsymbol{\cdot}

\boldsymbol{n}^{(k)}\delta\vartheta+\left(\alpha_{\rho

0}'^{(k)}-\alpha_{\rho

{g}0}'^{(k)}\right)\frac{{\textit{Bo}}}{{\textit{Ca}}}\delta\vartheta

z\nonumber\\ &\quad -\alpha_{\mu{g}

0}^{(k)}\boldsymbol{n}^{(k)} \boldsymbol{\cdot}

\delta\boldsymbol{\mathsf{S}}_{g} \boldsymbol{\cdot}

\boldsymbol{n}^{(k)} - \alpha_{\mu{g}

0}^{(k)}\boldsymbol{n}^{(k)} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_{{g}0}^{(k)} \boldsymbol{\cdot}

\delta\boldsymbol{n} - \alpha_{\mu{g}

0}^{(k)}\delta\boldsymbol{n} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_{{g}0}^{(k)} \boldsymbol{\cdot}

\boldsymbol{n}^{(k)} \nonumber\\ &\quad- \alpha_{\mu{g}

0}'^{(k)}\boldsymbol{n}^{(k)} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_{{g}0}^{(k)} \boldsymbol{\cdot}

\boldsymbol{n}^{(k)}\delta\vartheta=p_0^{(k)}-

p_{g0}^{(k)}-\left(\alpha_{\rho 0}^{(k)}-\alpha_{\rho

{g}0}^{(k)}\right)\frac{{\textit{Bo}}}{{\textit{Ca}}}z-\alpha_{\mu

0}^{(k)}\boldsymbol{n}^{(k)} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_0^{(k)} \boldsymbol{\cdot}

\boldsymbol{n}^{(k)}\nonumber\\ &\quad-\left(

\frac{1}{{\textit{Ca}}}

-\vartheta_0^{(k)}\right)\boldsymbol{\nabla}\boldsymbol{\cdot}\boldsymbol{n}^{(k)}+\alpha_{\mu

{g}0}^{(k)}\boldsymbol{n}^{(k)} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_{g0}^{(k)} \boldsymbol{\cdot}

\boldsymbol{n}^{(k)},

\end{align}where the surface increment

is contained implicitly in the increment of the surface normal vector

with

\begin{equation} \delta\boldsymbol{n}={-}\frac{1}{N^{(k)^3}}\frac{\mathrm{d} h_0^{(k)}}{\mathrm{d} z}\frac{\mathrm{d} \delta h_0}{\mathrm{d} z}\boldsymbol{e}_r - \frac{1}{N^{(k)}}\left[1- \frac{1}{N^{(k)^2}}\left(\frac{\mathrm{d} h_0^{(k)}}{\mathrm{d} z}\right)^2\right]\frac{\mathrm{d} \delta h_0}{\mathrm{d} z}\boldsymbol{e}_z \end{equation}

\begin{equation} \delta\boldsymbol{n}={-}\frac{1}{N^{(k)^3}}\frac{\mathrm{d} h_0^{(k)}}{\mathrm{d} z}\frac{\mathrm{d} \delta h_0}{\mathrm{d} z}\boldsymbol{e}_r - \frac{1}{N^{(k)}}\left[1- \frac{1}{N^{(k)^2}}\left(\frac{\mathrm{d} h_0^{(k)}}{\mathrm{d} z}\right)^2\right]\frac{\mathrm{d} \delta h_0}{\mathrm{d} z}\boldsymbol{e}_z \end{equation}and its divergence

\begin{align} &\boldsymbol{\nabla}\boldsymbol{\cdot}\delta \boldsymbol{n} \nonumber\\ &\quad = \frac{1}{h_0^{(k)^3} N^{(k)^3}} \left[{-}h_0^{(k)^3}\frac{\mathrm{d}^2 \delta h_0}{\mathrm{d} z^2} +\left(\frac{3h^{(k)^3}}{N^{(k)^2}}\frac{\mathrm{d}^2 h_0^{(k)}}{\mathrm{d} z^2} - h_0^{(k)^2} \right) \frac{\mathrm{d} h_0^{(k)}}{\mathrm{d} z} \frac{\mathrm{d} \delta h_0}{\mathrm{d} z} - h_0^{(k)} N^{(k)^2} \delta h_0 \right]. \end{align}

\begin{align} &\boldsymbol{\nabla}\boldsymbol{\cdot}\delta \boldsymbol{n} \nonumber\\ &\quad = \frac{1}{h_0^{(k)^3} N^{(k)^3}} \left[{-}h_0^{(k)^3}\frac{\mathrm{d}^2 \delta h_0}{\mathrm{d} z^2} +\left(\frac{3h^{(k)^3}}{N^{(k)^2}}\frac{\mathrm{d}^2 h_0^{(k)}}{\mathrm{d} z^2} - h_0^{(k)^2} \right) \frac{\mathrm{d} h_0^{(k)}}{\mathrm{d} z} \frac{\mathrm{d} \delta h_0}{\mathrm{d} z} - h_0^{(k)} N^{(k)^2} \delta h_0 \right]. \end{align}3.2. Linear stability analysis

MaranStable executes a linear stability analysis of the basic flow by discretising the linear perturbation equations (2.13) for the amplitudes ![]() $\hat {\boldsymbol {q}}_{j,m}$ and

$\hat {\boldsymbol {q}}_{j,m}$ and ![]() $\hat {\boldsymbol {q}}_{g;j,m}$ on the same grid and employing the same numerical scheme as used for the basic state. The resulting large system of algebraic equations represents a generalised eigenvalue problem for the spatial structure of the perturbation flow (eigenvector) and the complex growth rate

$\hat {\boldsymbol {q}}_{g;j,m}$ on the same grid and employing the same numerical scheme as used for the basic state. The resulting large system of algebraic equations represents a generalised eigenvalue problem for the spatial structure of the perturbation flow (eigenvector) and the complex growth rate ![]() $\psi _{j,m}$ (eigenvalue) for a given wavenumber

$\psi _{j,m}$ (eigenvalue) for a given wavenumber ![]() $m$. The real growth rate

$m$. The real growth rate ![]() ${\rm Re}(\psi _{j,m})$ determines the stability of the respective mode, whereas its imaginary part

${\rm Re}(\psi _{j,m})$ determines the stability of the respective mode, whereas its imaginary part ![]() $\omega _c = {\rm Im} [\psi _{j,m} ({\textit {Re}}_c)]$ represents the angular frequency. The mode whose real growth rate vanishes at a particular Reynolds number is called the neutral mode and the corresponding Reynolds number is identified as the neutral Reynolds number

$\omega _c = {\rm Im} [\psi _{j,m} ({\textit {Re}}_c)]$ represents the angular frequency. The mode whose real growth rate vanishes at a particular Reynolds number is called the neutral mode and the corresponding Reynolds number is identified as the neutral Reynolds number ![]() ${\textit {Re}}_n^{j,m}$. The minimum value

${\textit {Re}}_n^{j,m}$. The minimum value ![]() ${\textit {Re}}_c = \min _{j,m\geq 0}{\textit {Re}}_n^{j,m}$ defines the critical Reynolds number

${\textit {Re}}_c = \min _{j,m\geq 0}{\textit {Re}}_n^{j,m}$ defines the critical Reynolds number ![]() ${\textit {Re}}_c$. To identify the eigenvalues with the largest real part, we follow Stojanović et al. (Reference Stojanović, Romanò and Kuhlmann2022) and use an implicitly restarted Arnoldi method provided by ARPACK (Lehoucq, Sorensen & Yang Reference Lehoucq, Sorensen and Yang1998). The neutral curves are obtained by arclength continuation (Keller Reference Keller1977) for moderate step sizes of the dependent (

${\textit {Re}}_c$. To identify the eigenvalues with the largest real part, we follow Stojanović et al. (Reference Stojanović, Romanò and Kuhlmann2022) and use an implicitly restarted Arnoldi method provided by ARPACK (Lehoucq, Sorensen & Yang Reference Lehoucq, Sorensen and Yang1998). The neutral curves are obtained by arclength continuation (Keller Reference Keller1977) for moderate step sizes of the dependent (![]() ${\textit {Re}}$) and independent parameters (

${\textit {Re}}$) and independent parameters (![]() $\mathcal {V}$,

$\mathcal {V}$, ![]() $\varGamma$,

$\varGamma$, ![]() $d$ or

$d$ or ![]() ${Re}_{g}$).

${Re}_{g}$).

3.3. Postprocessing: energetics

The Reynolds–Orr type of equations for the kinetic and thermal energies of the perturbation flow can be obtained in the usual way. For variable material properties, Stojanović et al. (Reference Stojanović, Romanò and Kuhlmann2023a) have derived the rates of change of the total kinetic ![]() $(\mathrm {d} E_{kin}/\mathrm {d} t)$ and the total thermal energy

$(\mathrm {d} E_{kin}/\mathrm {d} t)$ and the total thermal energy ![]() $(\mathrm {d} E_{th}/\mathrm {d} t)$ in the form

$(\mathrm {d} E_{th}/\mathrm {d} t)$ in the form

$$\begin{gather} \frac{\mathrm{d} E_{kin}}{\mathrm{d} t} ={-}1+ M_r + M_\varphi + M_z + \sum_{j=1}^5 I_j + B+K_{g}\, \underbrace{+\,\varLambda_\rho + \varLambda_\mu + \varLambda_{\rho\mu}} , \end{gather}$$

$$\begin{gather} \frac{\mathrm{d} E_{kin}}{\mathrm{d} t} ={-}1+ M_r + M_\varphi + M_z + \sum_{j=1}^5 I_j + B+K_{g}\, \underbrace{+\,\varLambda_\rho + \varLambda_\mu + \varLambda_{\rho\mu}} , \end{gather}$$ $$\begin{gather}\frac{\mathrm{d} E_{th}}{\mathrm{d} t} ={-}1 + \sum_{j=1}^2 J_j + H_{fs}+ K_{g,th}\, \underbrace{-\, \frac{\mathrm{d} E_{th}'}{\mathrm{d} t} + \varPi_\rho +\varPi_{cp}+\varPi_\lambda}, \end{gather}$$

$$\begin{gather}\frac{\mathrm{d} E_{th}}{\mathrm{d} t} ={-}1 + \sum_{j=1}^2 J_j + H_{fs}+ K_{g,th}\, \underbrace{-\, \frac{\mathrm{d} E_{th}'}{\mathrm{d} t} + \varPi_\rho +\varPi_{cp}+\varPi_\lambda}, \end{gather}$$providing explicit expressions in dimensional from for all terms appearing on the right-hand sides. Since the non-dimensionalisation of the energy budgets is straightforward, we refrain from reproducing all expression here. Most terms in (3.10) also arise in the OB approximation. They have the usual meaning (see, e.g. Nienhüser & Kuhlmann Reference Nienhüser and Kuhlmann2002; Stojanović et al. Reference Stojanović, Romanò and Kuhlmann2022). The additional terms arising in the FTD model are indicated by the underbraces in (3.10).

All terms in (3.10) are volume integrals over the space occupied by the liquid or gas, or surface integrals over the interface or the inlet for the gas. The integrands represent local production/dissipation rates of kinetic or thermal energy of the perturbation flow that are often useful to understand the local physical mechanisms by which energy is exchanged between the basic state and the perturbation. The spatial distribution of the integrands thus serve a better understanding of the overall instability mechanism (see, e.g. Wanschura et al. Reference Wanschura, Shevtsova, Kuhlmann and Rath1995; Nienhüser & Kuhlmann Reference Nienhüser and Kuhlmann2002). Stojanović et al. (Reference Stojanović, Romanò and Kuhlmann2023a) have shown that the instability mechanism for ![]() ${\textit {Pr}}=28.8$ is that of a hydrothermal wave and that the mechanism as such is hardly influenced by the temperature dependence of the material parameters. However, the critical Reynolds numbers can be significantly affected. We shall make use of (3.10) to identify the regions of largest perturbation energy production and for the analysis of a new instability in the gas phase in § 5.1.2.