Policy Significance Statement

In this document, we examine crucial issues that go beyond the adoption of technology but encompass the foundations to be acquired by young Africans. This study is strategic and central to encouraging future initiatives. In fact, it addresses the main transformations brought about by Fourth Industrial Revolution and their equivalents in skills trades. Given the low level of awareness around this subject and the lack of scientific production, this article provides a basis for researchers and practitioners. In addition, it highlights the academic aspects to be addressed in the future, the gaps to be filled by industry, and most importantly, a clear vision for policymakers and industry to promote the labor market, respond appropriately to new industrial requirements, and develop competitive national skills.

1. Introduction

Nobody can deny that today’s quality of life and development are a cumulative result of the industrial revolutions that began in the 1700s (Güleryüz and Duygulu, Reference Güleryüz and Duygulu2020). Each has contributed by weaving new trades. From heavy industry based on classical mechanics, water power, and steam, to the introduction of electric power and finally the rise of electronics and technology (Shan et al., Reference Shan, Wen, Wei, Wang and Chen2020). What all three industrial revolutions have in common is that they are based on human skill and capacity (Popkova et al., Reference Popkova, Ragulina and Bogoviz2019). Technological innovation moved at breakneck speed. Today, all industrial sectors are working hard to position themselves on the tracks of the Fourth Industrial Revolution (4IR) based on digital technology (Frank et al., Reference Frank, Dalenogare and Ayala2019; Prinsloo et al., Reference Prinsloo, Vosloo and Mathews2019). In this era of transmutation, technology and people are connected, and the boundaries between physical entities have been blurred (Dalmarco et al., Reference Dalmarco, Ramalho, Barros and Soares2019). Undoubtedly, Industrial Revolution 4.0 (IR 4.0) is not just about modern, digital techniques and simulation tools, but also a series of reflections on aspects of sustainability such as renewable energies and energy efficiency (Bai et al., Reference Bai, Dallasega, Orzes and Sarkis2020; Javaid et al., Reference Javaid, Haleem, Singh, Suman and Gonzalez2022). The aim of IR 4.0 is to create viable, sustainable, and integrated production systems that take into account of the three dimensions—social, economic, and environmental (Alaloul et al., Reference Alaloul, Liew, Zawawi and Mohammed2018; Gomes et al., Reference Gomes, da Silva, Pinto, Centoamore, Digiesi, Facchini and Neto2020).

Also, industrial change to meet the needs of economic development has led to changes in notions of learning, education, and the academic environment. Skills, defined as the knowledge and behaviors that enable one to succeed in a job, will have to be converted and oriented toward 4.0 (Bernabé-Moreno et al., Reference Bernabé-Moreno, Tejeda-Lorente, Herce-Zelaya, Porcel and Herrera-Viedma2019). To achieve this goal, education systems should be characterized by the integration of advanced technologies and innovative pedagogical approaches to meet the needs of the digital age (Dao et al., Reference Dao, Tran, Van Le, Nguyen and Trinh2023). Thus, the transformation of the University into a University4.0 that refers to an ideal environment for the integration of advanced technologies, innovative teaching, and learning methods is emphasized as indispensable (Jugembayeva and Murzagaliyeva, Reference Jugembayeva and Murzagaliyeva2023).

Industry 4.0 has been established as a term for the industrial development process consisting of automation and data exchange (Kagermann et al., Reference Kagermann, Helbig, Hellinger and Wahlster2013; Peres et al., Reference Peres, Parreira-Rocha, Rocha, Barbosa, Leitão and Barata2016). Its benefits are remarkable on all scales of industrial excellence and performance. It is expected to bring growth, improvement, and accelerated development to most industries shortly (Brozzi et al., Reference Brozzi, Forti, Rauch and Matt2020). Thanks to cutting-edge technologies such as paired digital simulation, robotization, the Internet of Things (IoT), Big Data, additive manufacturing, 3D printing, artificial intelligence (AI), and others. Due to modernization trends, this revolution was the only one active and simultaneously launched in most countries and regions of the world (Pereira and Romero, Reference Pereira and Romero2017; Chen et al., Reference Chen, Wan, Shu, Li, Mukherjee and Yin2018; Moraes et al., Reference Moraes, Kipper, Hackenhaar Kellermann, Austria, Leivas, Moraes and Witczak2022).

Previous literature and scientific studies reveal and explore several issues during the emergence of these technologies (Wichmann et al., Reference Wichmann, Eisenbart and Gericke2019; Cañas et al., Reference Cañas, Mula, Díaz-Madroñero and Campuzano-Bolarín2021). Despite the high added value, the innumerable advantages, and the opportunities offered by the technological package, many barriers hinder their deployment in the industry (Raj et al., Reference Raj, Dwivedi, Sharma, de Sousa Jabbour AB and Rajak2020; Kumar et al., Reference Kumar, Bhamu and Sangwan2021). In others, they have brought incredible spin-offs, but for other job creators and pillars of national economies, the conversion to Industry 4.0 is weak and slow (Idrissi Gartoumi et al., Reference Idrissi Gartoumi, Aboussaleh and Zaki2023c). A good example is the construction industry, with all sectors combined (heavy construction and civil engineering, construction of real estate, and specialized engineering activities [mechanical, electrical, air conditioning, and plumbing]) (Demirkesen and Tezel, Reference Demirkesen and Tezel2021).

Taking the case of the construction industry has become complex and fragmented. The development of countries is closely linked to the quality of infrastructure and the presence of mega-projects with large-scale developments. Even in this strategic direction for the economic reshaping of countries, the sector is hesitant to imbibe the concepts of IR 4.0 (Idrissi Gartoumi et al., Reference Idrissi Gartoumi, Aboussaleh and Zaki2023b). The construction industry is still struggling to embrace IR 4.0 concepts despite the obvious benefits it offers. A significant body of literature has been devoted to examining this paradoxical situation experienced by industrial sectors reluctant to embrace technological development (Osunsanmi et al., Reference Osunsanmi, Aigbavboa and Oke2018).

All continents are concerned by these challenges, including Africa. In several studies applied to certain African countries, IR 4.0 has proved to be an opportunity to overcome competition, create businesses, and develop new employment opportunities (Bongomin et al., Reference Bongomin, Nganyi, Abswaidi, Hitiyise and Tumusiime2020b). However, it is stressed that this is a revolution even on the scale of employment, with the disappearance of certain professions, the conversion of some, and the emergence of others. In the era of IR 4.0, skills, training, and increasing youth employment are less likely to be called into question and radically rethought (Pinzone et al., Reference Pinzone, Fantini, Perini, Garavaglia, Taisch and Miragliotta2017). At the time of 4IR, teaching and learning, particularly in South Africa, remained virtually static despite the use of (smart) mobile devices and social media (Ng’ambi et al., Reference Ng’ambi, Brown, Bozalek, Gachago and Wood2016). In Africa, although technology holds the potential to significantly enhance learner development, especially through collaborative learning, it is noteworthy that no academic institution from the continent is featured among the top 50 innovative companies globally. Furthermore, none of the organizations identified in this context hail from Africa (Warschauer, Reference Warschauer2007; Kreijns et al., Reference Kreijns, Van Acker, Vermeulen and Van Buuren2013).

Maisiri and van Dyk (Reference Maisiri and van Dyk2019) examine the issue of skills for IR 4.0 in the context of manufacturing in South Africa. This study reveals that no action is being taken to align the skills of the workforce with the skills requirements of the industry. Mukwawaya et al. (Reference Mukwawaya, Emwanu, Za and Mdakane2018) highlight a lack of focus or motivation toward Industry 4.0, despite the anticipated arrival of Industry 5.0 by 2020 (Barata and Kayser, Reference Barata and Kayser2023). Current policies primarily address technological advancements within the framework of traditional Industry 3.0, with no incorporation of Industry 4.0 considerations. In a research study focused on Nigeria, the largest economy in Africa, Adepoju and Aigbavboa (Reference Adepoju and Aigbavboa2021) findings indicated a moderate level of familiarity with technologies incorporated in the construction industry and a limited level of training among professionals. Moreover, the results highlighted a notable deficiency in skills related to man–machine communication, data analysis, and cyber security. A study by Oke and Fernandes (Reference Oke and Fernandes2020) indicates that the education sector, particularly in Africa, is not adequately equipped for the 4IR. However, signs are pointing to opportunities to leverage the potential of the eagerly anticipated 4IR.

In this context, where Africa is a hub of skills, threatened by unemployment among young people, especially graduates, competition, the sustainability of companies, and the adequacy of training models to industrial needs, the following research questions oppose each other:

-

- In the era of Industry 4.0, what is the state of skill readiness?

-

- What are the new 4.0 educational trends?

-

- What changes need to be made to education policies to align them with the requirements of Industry 4.0?

Using a systematic literature review, this article aims to highlight the educational revolution that must accompany IR 4.0 and its requirements across Africa. By identifying the challenges linked to education systems, and the key factors for rebuilding a quality teaching policy and learning systems that fit in with the new industrial trends and needs.

This document is divided into five sections. Following the introduction, the research methodology is presented in Section 2. The results are presented in Section 3 and discussed in Section 4. At the end, Section 5 lists the main conclusions and recommendations raised.

2. Methods

This article is part of a worldwide effort to bridge the gap between the professional environment open to new technologies, trends, and the changes needed in education and training systems to train the skills required to succeed in the new jobs and professions requirement.

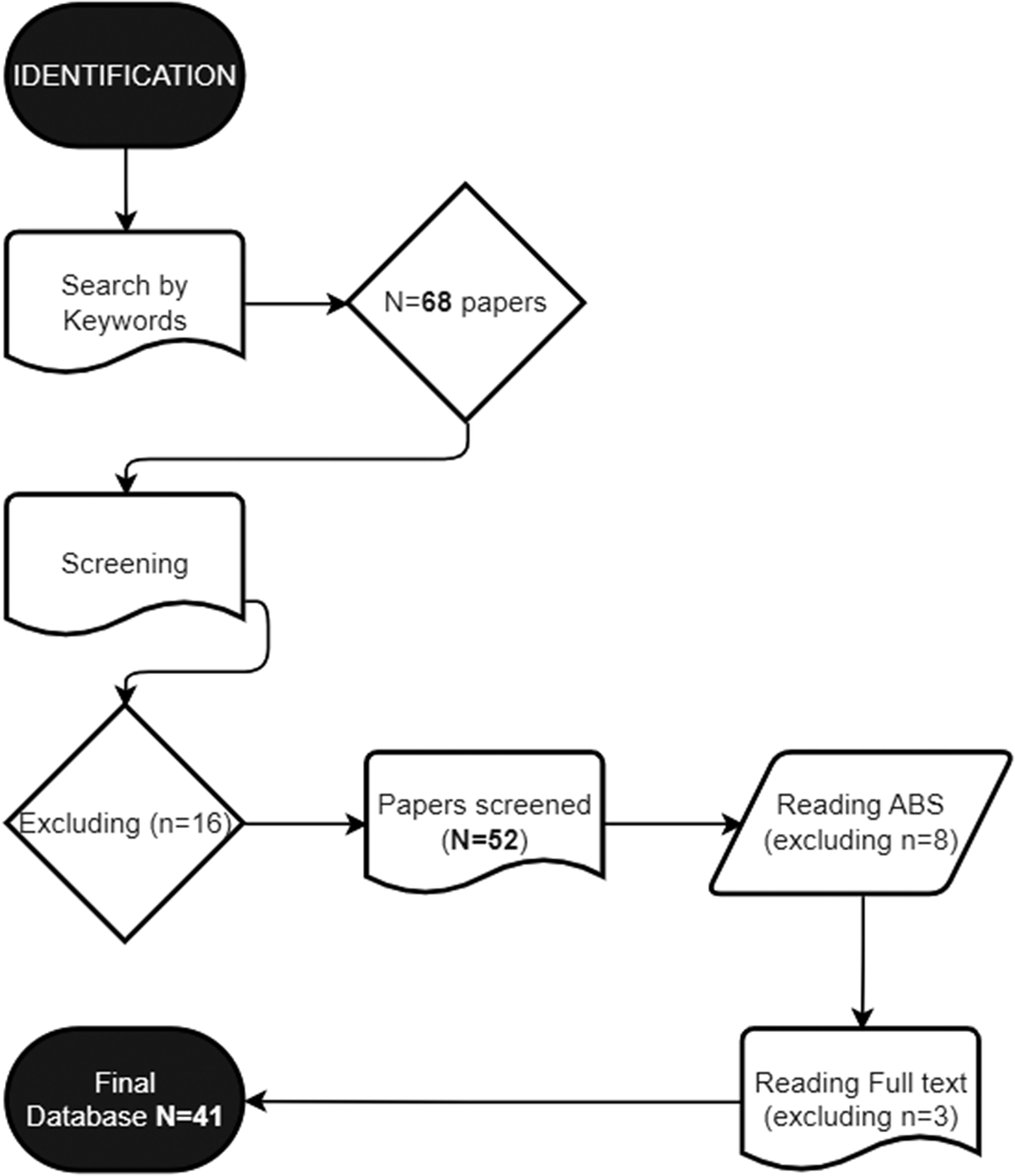

To do this, a systematic analysis of the literature was adopted as the research method. The content is extracted from relevant scientific articles and conference proceedings published in the Scopus and Web of Science databases. The systematic review was carried out using the PRISMA framework, which enables researchers to identify specific articles based on specified criteria. The inclusion and exclusion criteria encourage the selection of relevant and recent articles likely to provide specific answers to the research questions. The research implementation approach is conducted as mentioned in Figure 1. This article is structured into scrolling sections that analyze and examine the results. The challenges revealed will be discussed and the outcomes of the construction of new learning systems will be presented. The SLR as a relevant means of evaluation makes it possible to systematically assess a subject of specific interest (Koumetio Tekouabou et al., Reference Koumetio Tekouabou, Gherghina, Kameni, Filali and Idrissi Gartoumi2023). In our case, it is African education at the age of 4IR.

Figure 1. SLR steeps using the PRISMA approach (Kitchenham, Reference Kitchenham2004; Fleming et al., Reference Fleming, Koletsi and Pandis2014).

2.1. Phase 01: keyword search

To conduct a systematic literature review, three types of inclusion criteria must be met: the databases to be included, the keywords to be chosen, and the nature of the publications to be included (Akinlolu et al., Reference Akinlolu, Haupt, Edwards and Simpeh2020). In the first instance, the Scopus and Web of Science databases were the sources of data and collection of corresponding articles (Idrissi Gartoumi and Koumetio Tékouabou, Reference Idrissi Gartoumi and Koumetio Tékouabou2023). These databases cover most scientific publications, known for the quality of their content, which undergoes meticulous evaluation by peers. As such, they are a source of data accepted by many academics.

The second decisive criterion is the keywords. Three sets of words were used to identify all the research:

-

- “Industrial revolution” AND (Training or Skills) AND Africa;

-

- “Industrial Revolution” AND (“Skills Development” OR University) AND Africa;

-

- “Industry 4.0” AND (Training OR Skills OR Education) AND Africa.

The keywords mentioned in the search were applied in the “Title/Abstract/Keyword” fields.

Given that the subject requires exhaustive coverage, all types of documents and forms of research were included, considering all publication periods to guarantee the integrity of the information. Using these databases and the search terms, 68 publications were compiled in the Mendeley bibliographic management software.

2.2. Phase 02: screening

The main exclusion criteria were applied in three stages. First, First, duplicate papers from multiple databases were removed. Then the search fields far from the subject were dropped. At this point, a total of 52 articles were obtained. Next, the titles, abstracts, and keywords were read. This stage resulted in the exclusion of eight articles. Finally, the third stage consisted of a complete reading of the retained articles. A total of three papers were excluded. At the end of the process, 41 articles were retained to form the basis of the analysis and the results that will be presented in the following sections.

2.3. Phase 03: data analysis

The base of articles obtained was examined using a systematic literature review to identify the key success factors for skills transformation in the era of IR 4.0. This review will be conducted in two main phases. The first will present an analysis of research indicators on this subject and the second will qualify the themes addressed.

3. Bibliometric results

In this section, several bibliometric properties of the database of articles collected will be analyzed, to highlight the requirements brought about by IR 4.0 in terms of skills teaching and training.

3.1 Number of publications

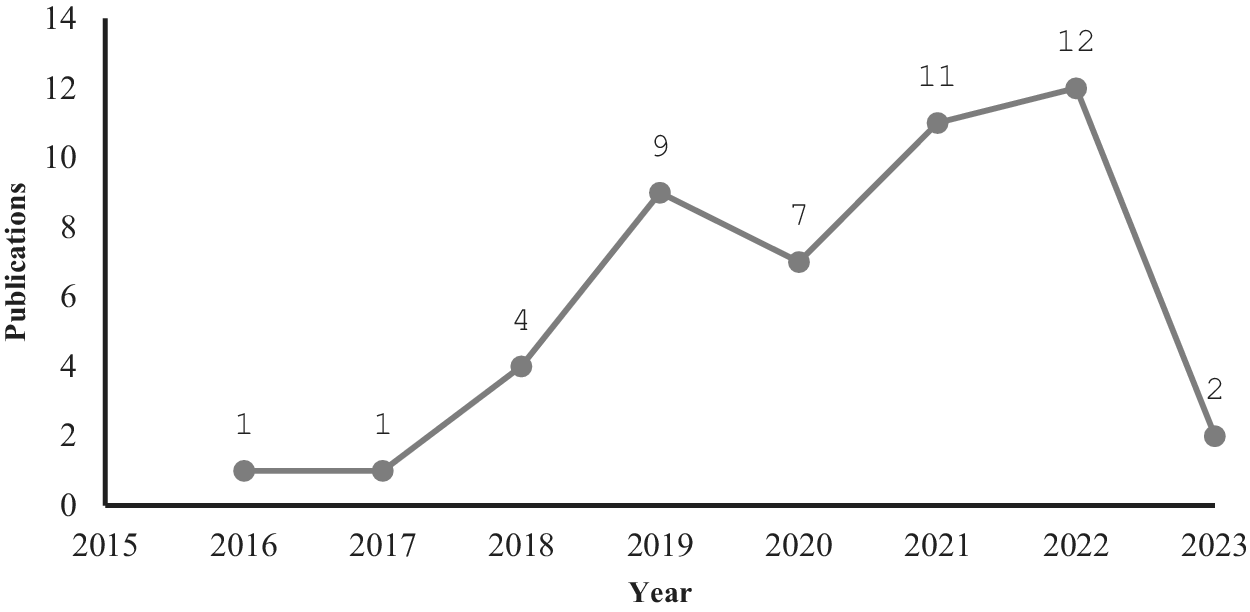

The link between the industrial revolution and the role of training systems has been forged since 2016 and will continue until September 2023. Figure 2 shows the annual breakdown of publications.

Figure 2. Annual publication trend.

In 2022, the highest number of publications is expected. Overall, there has been a remarkable increase in scientific output in this field.

3.2 Publications sources

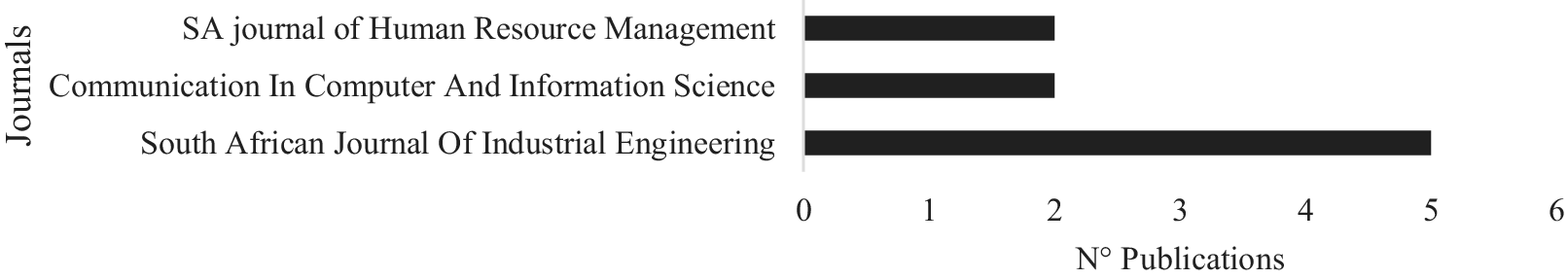

Examining the sources of publications, this topic has been addressed through various formats, including journal articles, conference papers, books, and book chapters. A total of 22 journals, 15 conference papers, 4 book chapters, and 15 book chapters were identified. Figure 3 includes journals with at least two articles to illustrate the top number of journals that have covered this subject.

Figure 3. Publications per journal.

The South African Journal of Industrial Engineering is in first place with five publications, followed by the journal Communication in Computer and Information Science and SA Journal of Human Resource Management with publications each.

3.3 Origin of publications

To understand the position of this worrying subject in the focus of countries, the publications identified were linked to their countries and presented by the institution of the corresponding author. Table 1 shows the top African countries interested in this subject. South Africa leads the countries, producing 37 papers, followed by Ghana. On the university scale, South African universities rank first. The University of Johannesburg is the most productive, followed by North West University and Cape Peninsula University of Technology in third place.

Table 1. Number of publications by countries and African university

4. Thematic results

This section is devoted to identifying and bringing together the themes addressed in the literature on the changes and accompanying outcomes of IR 4.0 in education and training pathways. It is divided into four sections. The first analyses the state of readiness of African skills to be converted to meet the job requirements demanded in this era of industrial change. The second section focuses on market trends and Jobs 4.0. To keep pace with this wave of new jobs, the third section illustrates the main skills required for the successful emergence and deployment of IR 4.0 tools. Several identified articles analyze the new university model, which is further examined in the following sections. The ultimate theme revolves around the practical requirements of a University 4.0.

4.1. IR 4.0 versus training systems

IR 4.0 is imminent in the economies of several countries, including those in Africa (Ojubanire et al., Reference Ojubanire, Sebti and Berbain2023). The new industrial trends have disrupted all systems, calling into question the strategic orientations of the industrial world and education systems (Maria et al., Reference Maria, Shahbodin and Pee2018). Also, organizations can assess their preparedness for Industry 4.0 by employing tools designed for Industry 4.0 readiness assessment. To this end, new government innovation policies and initiatives have been launched (Nafea and Toplu, Reference Nafea and Toplu2021). Concurring with the assertion presented by Rajnai and Kocsis (Reference Rajnai and Kocsis2018), the conclusion is drawn that an Industry 4.0 readiness assessment aims to discern an organization’s position within the spectrum of digital transformation phases.

The recommendations of the 2016 World Economic Forum report reveal that Africa must invest more in improving productivity by creating technological readiness in the economy in the age of 4IR (Schwab et al., Reference Schwab, Xavier, Richard and Jennifer2016). In their work, Mukwawaya et al. (Reference Mukwawaya, Emwanu, Za and Mdakane2018) analyze South Africa’s readiness to implement the principles of Industry 4.0. The results show that the optimal deployment of this revolution is conditional on an overhaul of the education system and the draining of new skills required by Industry 4.0. IR 4.0 is known for its potential to bring about significant changes in the knowledge and skills required by all players, participants in a production chain, and especially those with higher education (Baygin et al., Reference Baygin, Yetis, Karakose and Akin2016). Before talking about an industrial transformation, it is necessary to reevaluate the place of current skills (Akyazi et al., Reference Akyazi, Goti, Oyarbide, Alberdi and Bayon2020), and the levels of knowledge and mastery of the tools that are essential if we are to avoid a failure such as that caused by the information technology identity crisis of the 1990s (Goti et al., Reference Goti, Akyazi, Alberdi, Oyarbide, Bayon and Galanakis2022; Sharma et al., Reference Sharma, Luthra, Joshi and Kumar2022).

The Sackey and Bester (Reference Sackey and Bester2016) case study focuses on the analysis of industrial engineering curricula in South Africa. The results indicate that several industrial engineering modules, professions, and functions will transform, generating gaps in compatibility with functions based on information technology, databases, and cyber-physical systems (Khaitan and McCalley, Reference Khaitan and McCalley2015). The adjustment of this gap must be corrected by promoting the learning of new skills from human–machine interfaces (Gorecky et al., Reference Gorecky, Schmitt, Loskyll and Zühlke2014).

As mentioned, South Africa is the country recording many articles on this subject. Just one university is making progress toward adopting an infrastructure that meets Industry 4.0 requirements (Deliwe, Reference Deliwe2021). On the road to adopting IR 4.0, several countries are in the preliminary stages (Siau et al., Reference Siau, Xi and Zou2019). These preparations would begin with a scaling up of ways of working and finding the best ways to adjust education systems. However, the road to implementation has encountered many obstacles, such as the emergence of COVID-19 (Idrissi Gartoumi et al., Reference Idrissi Gartoumi, Aboussaleh and Zaki2023a). The COVID-19 pandemic was a real opportunity to convert to digital mode and accept the changes brought about by innovative technologies (Aigbavboa et al., Reference Aigbavboa, Aghimien, Thwala and Ngozwana2022). Indeed, several universities in Africa and around the world have resorted to distance learning and e-learning, which are becoming increasingly important for maintaining levels of adaptation in the future (Tekin et al., Reference Tekin, Koyuncuoğlu, Geçkil and Baş2020). Thanks to this health crisis and the disruption to the organization, team management skills, and management, the subject of Industry 4.0 has become essential (Huba and Kozák, Reference Huba and Kozák2016).

Although significant progress has been made in the use of Industry 4.0 technologies, systems, and processes in developed countries, there is uncertainty about the readiness of businesses and industries in developing countries in Africa. In this context, previous studies do not reveal the state of readiness except (Maisiri and van Dyk, Reference Maisiri and van Dyk2019) which quantitatively revealed that a significant number of organizations do not have an existing strategy for Industry 4.0 readiness. However, there are a significant number of assessment tools available to measure Industry 4.0 readiness. These include micro and macro indices (Blanchet, Reference Blanchet2014).

Many previous studies have reported radical changes in business operations due to the disruption and technological innovations brought about by IR 4.0. Regarding the education sector Oke and Fernandes (Reference Oke and Fernandes2020) explored the readiness and acceptability of the education sector for IR 4.0. The findings are that the African continent is not ready for this change although there are indications of opportunities to exploit its long-awaited potential (Nhamo et al., Reference Nhamo, Nhemachena and Nhamo2020). All the potential of IR 4.0 lies in facilitating the student learning experience and transforming the workplace, although there is a need to assess the learning environment and understand the enablers and barriers to diffusion (Sackey et al., Reference Sackey, Bester and Adams2017). The education sector could harness these innovations through research and teaching to enhance the learner experience (Wessels and van Wyk, Reference Wessels and van Wyk2022); however, this may require significant curriculum enhancement and investment (Brahma et al., Reference Brahma, Tripathi and Sahay2020).

4.2 Toward employment 4.0

Employment 4.0 refers to opportunities and roles that emerge in response to the advancements and transformations brought about by Industry 4.0. The alignment of industrial sectors with technological and organizational upheaval is strongly linked to socioeconomic policies, technical orientation, and academic needs in terms of basic skills, qualifications, and development. These imbalances have fostered the creation of new sustainable work opportunities, emerging markets, and a real opportunity to drive the restructuring of informal markets (Ahmad et al., Reference Ahmad, Shamsuddin and Seman2019; Saniuk et al., Reference Saniuk, Caganova and Saniuk2023).

Lambrechts et al. (Reference Lambrechts, Sinha and Marwala2020) examined the potential of IR 4.0 to create sustainable work opportunities in emerging markets that have not enjoyed the same advantages (compared to developed markets) in previous industrial revolutions. In fact, Industry 4.0 is unique in that it is ubiquitous thanks to the internet and enables remote participation in Industry 4.0 (Estrin and Prevezer, Reference Estrin and Prevezer2011). Emerging markets are invited to meet the challenges of adapting to Industry 4.0 early and preparing for its maturation (Beier et al., Reference Beier, Matthess, Guan, de Oliveira Pereira Grudzien, Xue, Lima and Chen2022). Despite the wide scope of occupations and jobs that could be generated by this transformation, there are barriers to the development of IR 4.0 in emerging markets and economies (Raj et al., Reference Raj, Dwivedi, Sharma, de Sousa Jabbour AB and Rajak2020). The first of these is skills development, followed by cultural barriers. In this respect, Brazil, Russia, India, China, and South Africa have been identified as important players in bridging the policy gaps that could hinder the development of Industry 4.0 in emerging markets (Menelau et al., Reference Menelau, Macedo, Carvalho, Nascimento and Carvalho Júnior2020).

The impact of technological and operational change in the industry has been observed at several scales, in several industrial sectors, and in several countries. Using a descriptive qualitative research design, Macpherson et al. (Reference Macpherson, Werner and Mey2022 analyzed the changes and new emerging job categories in the South African automotive industry. The results list new emerging jobs requiring skills related to automation and other hybrids. These Jobs 4.0 require the continuous realignment of employee skills with emerging job categories, which in turn forces organizations to reconfigure their talent management strategies (Pinzone et al., Reference Pinzone, Fantini, Perini, Garavaglia, Taisch and Miragliotta2017). Existing employees need to be upgraded and reskilled, while recruits need to meet the organization’s future needs (Rutkowska and Sulich, Reference Rutkowska and Sulich2020).

On an African scale, job creation is linked to public–private partnerships (3P; Dykes and Jones, Reference Dykes and Jones2016). To perpetuate the fabric of cooperation, generate more new jobs, and maintain the position of African skills at the heart of global change, the acquisition of an industrial skills package is essential (Marx, Reference Marx2019). Alba and Stucki (Reference Alba and Stucki2019) examined the 3P model in terms of inclusion, employability, and increased income in the context of the objectives of the 2030 sustainable development program.

Technological development is seen as a key driver of new growth and a means of developing and outperforming global competitors. Human capital, particularly young people, underpins inclusive and sustainable economic growth (Hajro et al., Reference Hajro, Gibson and Pudelko2017). The need to promote access to technology, particularly among young people in African society, has prompted a research question to determine whether technological tools can be developed and deployed in Africa to make life easier for young people and boost employability (Habyarimana and Opoku, Reference Habyarimana and Opoku2018). Offering young Africans diverse opportunities in the digital economy is possible through data collection and the creation of digital networks (Van Rensburg et al., Reference Van Rensburg, Telukdarie and Dhamija2019).

A South African-wide qualitative study reveals that rethinking the structure of basic education and learning content and improving the elements of interconnected systems are key factors for alignment with new modes of working (Mtotywa et al., Reference Mtotywa, Seabi, Manqele, Ngwenya and Moetsi2023). In turn, Borrageiro and Mennega (Reference Borrageiro and Mennega2023) prove that employability opportunities are opening for African youth through Europe-Africa cooperation and exchange and experience-sharing programs.

4.3 Competencies 4.0

The wave of industry is supported by technological advances that are leading to radical changes and adaptations. The education sector is also faced with the need to adapt (Oke and Fernandes, Reference Oke and Fernandes2020). In reality, national governments are having to adapt their curricula to meet skills needs (Dumitrescu et al., Reference Dumitrescu, Lima, Chattinnawat and Savu2019). Much previous work has tried to highlight the 4.0 skills needed to position oneself well in the challenges of IR 4.0 (Hernández-Muñoz et al., Reference Hernández-Muñoz, Habib-Mireles, García-Castillo and Montemayor-Ibarra2019). Overall, the emphasis is on the fact that advanced technologies are not intended to replace humans to improve productivity. However, human–machine collaboration is essential along with an academic focus on continuous lifelong learning to meet the challenge of rapidly evolving skill requirements (Krupitzer et al., Reference Krupitzer, Müller, Lesch, Züfle, Edinger, Lemken, Schäfer, Kounev and Becker2020). The latter concerns interdisciplinary and cross-disciplinary skills (Grzybowska and Anna, Reference Grzybowska and Anna2017).

With its significant growth and speed, Industry 4.0 has had the power to be implemented rapidly in a unique way to previous revolutions (Xu et al., Reference Xu, David and Kim2018). In terms of its scale and speed, its success depends on awareness of the changes it brings (Zervoudi, Reference Zervoudi2020). Even if the pace of adoption in Africa is slower than in European and American countries, it has to be said that the structuring of training programs and apprenticeship systems is a component undergoing major change (Radziwon et al., Reference Radziwon, Bilberg, Bogers and Madsen2014).

The attitude of aligning with Industry 4.0 requires skills and competencies in line with the main orientations of 4IR. Indeed, it is a matter of converting competence into the 4.0 mode through knowledge of the required dimensions. Bermúdez and Juárez (Reference Bermúdez and Juárez2017) conducted a test for the automotive sector, identifying four dimensions of skills required. These are Information and Communication Technologies (ICTs), Innovation Management, Organizational Learning, Environment, as well as the unavailability of soft skills and leadership. In an experiment conducted at a university in Romania reported by Cotet et al. (Reference Cotet, Balgiu and Zaleschi (Negrea)2017), a competency model comprises five dimensions, three technical, and two nontechnical. In Malaysia, the conversation of engineering education has been based on four core competencies, as reported by Mohd Kamaruzaman et al. (Reference Mohd Kamaruzaman, Hamid, Mutalib and Rasul2019). These competencies are technology design and programming, leadership, social influence, problem-solving, and ideation.

At the African level, the studies conducted (Table 2) remain somewhat limited given the size of the continent, which justifies the slow rate of adoption of the results of this industrial revolution. Based on thematic analysis, the data extracted localizes the key terms as formulated in the research questions. To contextualize this section, the following process has been established:

-

- The disciplines of the articles are listed.

-

- These disciplines are classified.

-

- For each discipline, the skills and technologies are extracted.

-

- In the end, these key technologies are then examined and ranked in order of importance.

Table 2. Required skills of industry 4.0

In this thematic study, skills 4.0 are a combination of know-how and interpersonal skills. It mainly involves acquiring new technological concepts, technical skills, and management and communication knowledge. Three main disciplines have been identified as the skills needed to meet the requirements of 4IR. The first is technical competence. Over time, each industrial period is characterized by contemporary trends. The 4IR is oriented toward innovation based on digital, visualization, and object-mode management in real time (Gray-Hawkins et al., Reference Gray-Hawkins, Michalkova, Suler and Zhuravleva2019). Consequently, new technical skills stem from this industrial orientation. As Table 2 shows, the first (technical) aspect of 4.0 competence is conditioned by learning innovative technology and programming techniques, namely building information modeling (BIM), virtual reality (VR), augmented reality (AR), and AI. Programming, 3D designs, and 3D printing are at the heart of the new techniques deemed necessary for the successful emergence of the construction industry in a 4.0 way. Given the enormous growth in human needs, the industry has missed the environmental dimension and has generated many failures in sustainability systems (Enrique et al., Reference Enrique, Druczkoski, Lima and Charrua-Santos2021). To this end, the transmission of green knowledge is characterized by the acquisition of skills in green design and simulation, certification, and energy efficiency (Haseeb et al., Reference Haseeb, Hussain, Kot, Androniceanu and Jermsittiparsert2019). The results reveal the need to acquire software for design and engineering, as well as for green production. Faced with the new challenges and constraints facing the industry, learning new technologies is essential. This is the case for IoT and blockchain.

In the other discipline (soft skills), previous studies have focused on new managerial and decision-making postures to meet industrial needs. The study reveals that this category covers management and other personal skills. Based on parallel research into improving production performance, the lean management philosophy has become a requirement for the new generation of apprentices (Gómez-Molina and Moyano-Fuentes, Reference Gómez-Molina and Moyano-Fuentes2021), especially its lean construction derivative for the construction industry (Al-Aomar, Reference Al-Aomar2012). This approach makes it possible to minimize waste and wastage and achieve the desired objectives in terms of quality, cost, and lead times (Amaro et al., Reference Amaro, Alves and Sousa2019). Furthermore, according to the results of the study, the success of an apprenticeship process cannot be achieved without acquiring skills in communication, adaptation, leadership, and decision-making.

By analyzing the three pillars of competence in the Industry 4.0 era, the technology component is counted as the most necessary and the most in demand. To gain a clearer understanding of the skills that fall under the technological component, we conducted a co-occurrence analysis using the tool most adopted by researchers in scientometric analyses. This is the VOSviewer (van Eck and Waltman, Reference van Eck and Waltman2010). Figure 4 shows the technologies, approaches, and skills that previous studies have shown to be necessary to achieve the objectives of 4IR in terms of training and teaching programs.

Figure 4. Competence identified by keyword occurrences.

In the context of this scientometric survey, Table 3 classifies the techniques according to the total link strength indicator.

Table 3. Top-ranked skills 4.0 cited by the literature

The progression of the industrial revolution has brought about transformations in all societal subsystems. As shown in the table, these changes have led to new concepts, new ways of thinking, and new ways of working, with the introduction of new concepts in social development, such as sustainability, human-centric approaches, and the reduction of carbon emissions. The manufacturing system or paradigm has faced challenges in adjusting to the demands of an innovative society (Leng et al., Reference Leng, Zhong, Lin, Xu, Mourtzis, Zhou, Zheng, Liu, Zhao and Shen2023). At this stage, the European Commission has articulated a vision for the future of European industry in its policy document, “Industry 5.0,” centered on three core principles: people-centricity, sustainability, and resilience (Breque et al., Reference Breque, De Nul and Petridis2021). In fact, Industry 5.0 stems from a forward-looking endeavor, serving as a framework to envision the coexistence of industry with emerging societal trends and needs. This concept provides an alternative perspective, highlighting the significance of research and innovation in supporting industry’s enduring service to humanity within planetary boundaries (Longo et al., Reference Longo, Padovano and Umbrello2020). Preceding the formal introduction of Industry 5.0, discussions revolved around the “age of augmentation,” envisioning a harmonious collaboration between humans and machines (Bednar and Welch, Reference Bednar and Welch2020).

4.4 University 4.0

Toward the end of the Middle Ages, University 1.0 democratized education, emphasizing personal excellence in various fields such as crafts, the military, diplomacy, and medicine. With the advent of University 2.0, education evolved beyond traditional scholastic pursuits, delving into the realm of technological design encompassing machines, structures, and innovations. This era marked the university’s pivotal role in driving the industrial revolutions (Boehm, Reference Boehm2018). University 3.0 embodies a paradigm shift, fostering the creation of novel practices. Its physical manifestation extends beyond traditional classrooms and libraries to include incubators, technology parks, design studios, and collaborative spaces for engagement with the broader community (Boehm and Boehm, Reference Boehm and Boehm2022).

University 4.0 is squarely focused on the burgeoning markets of emerging technologies, particularly in the realm of ICTs (Efimov and Lapteva, Reference Efimov and Lapteva2017). As an open and interconnected hub, the fourth-generation university serves as a nexus, facilitating the convergence of diverse networks—informational, social, and commercial (María et al., Reference María, Benavides, Alexander, Arias, Darío, Arango-Serna, William, Bedoya and Burgos2020). This advanced model provides a robust infrastructure for a myriad of research endeavors, spanning from fundamental research to practical projects and the development of innovative methodologies (Gueye and Exposito, Reference Gueye and Exposito2020).

In this context, Education 4.0 will complement the needs of Industry 4.0 (Chaka, Reference Chaka2022). The changes and transformations in education systems associated with the industrial revolutions are taking place in four stages: Education 1.0, Education 2.0, Education 3.0, and Education 4.0 (Akturk et al., Reference Akturk, Talan and Cerasi2022). In fact, a standard definition of Education 4.0 has yet to emerge, but it can be expressed as a general approach or trend aimed at preparing the future workforce for Industry 4.0 (Moraes et al., Reference Moraes, Kipper, Hackenhaar Kellermann, Austria, Leivas, Moraes and Witczak2022). Education 4.0, which aims to transform the future of education using advanced technologies and automation, is an approach to learning that is compatible with the 4IR (Keser and Semerci, Reference Keser and Semerci2019). This concept can be briefly defined as the application of digital transformation in the world of education (Chaka, Reference Chaka2020). Education 5.0 is the next generation that precedes the previous four versions (Mustafa Kamal et al., Reference Mustafa Kamal, Adnan, Yusof, Ahmad and Mohd Kamal2019). It is defined as learner-related learning, learner-centered, learner-driven, and learner-driven (Diaz Lantada, Reference Diaz Lantada2020). Education 5.0 is based on the following pillars: A coherent and relevant curriculum, innovative teaching and evaluation methods, meaningful learning experience, and transformative learning (Alharbi, Reference Alharbi2023).

The concept of University 4.0 is expressed as an innovation/change in the university teaching system in the process of digitalization of university institutions (Telukdarie and Munsamy, Reference Telukdarie and Munsamy2019). This teaching system is seen as a transition from traditional teaching to continuous and uninterrupted teaching models in which various IT systems are used (Masdoki et al., Reference Masdoki, Din and Matore ME@2021). University 4.0 emphasizes that higher education institutions must see themselves as institutions that develop numerous projects and launch new applications based on the development of advanced technological systems that meet the needs of the digital age (Lapteva and Efimov, Reference Lapteva and Efimov2016).

5. Discussion

Being a natural part of any study, the discussion is presented in such a way as to answer the three research questions driving this study. These research questions underpin the objective of the study: to identify the necessary skills attributed to the 4IR at the scale of the African continent. In the 41 articles evaluated, the evolution of this research topic and other bibliometric parameters were deduced. The subject is new and of low scientific production. The subject has not yet been tackled in every country on every continent. Indeed, the educational revolution can only be achieved once the discussion of the IR 4.0 in Africa has reached maturity (Okam, Reference Okam2023). The skills model identified has three components. The first is technological competence. Singaram et al. (Reference Singaram, Mayer and Oosthuizen2023) confirm that the needs and demands of the 4IR must be met through learning in higher education, and this can only be achieved through awareness on the part of institutional leaders. Mtotywa et al. (Reference Mtotywa, Seabi, Manqele, Ngwenya and Moetsi2023) conclude from a South African-wide study that there is an urgent need to restructure higher education and even basic education systems. The study shows that technology is based on digital techniques and skills. In the same vein, Nasser and Ouerghi (Reference Nasser and Ouerghi2023) show that the digital infrastructure and skills have a positive and significant impact on the resilience of African countries at the age of 4IR. This industrial change is leading to the emergence of new job categories requiring hybrid skills. Through qualitative research with industrialists in South Africa, Macpherson et al. (Reference Macpherson, Werner and Mey2022) guide human resource practitioners and professionals to identify the new job categories emerging and the hybrid skills associated with them. This springboard has a positive and significant relationship with the unemployment rate. In fact, direct investment in the automation training cycle makes individuals more competitive and better suited to 4.0 jobs (Anakpo and Kollamparambil, Reference Anakpo and Kollamparambil2022b). In this sense, Anakpo and Kollamparambil (Reference Anakpo and Kollamparambil2022a) confirm that early learning and skills such as AI have a meaningful relationship with the competitiveness of young people.

As shown in this study, the creation of an adapted profile is linked to the acquisition of cross-disciplinary skills. Landsberg and van den Berg (Reference Landsberg and van den Berg2023), from a study evaluating training programs at South Africa’s top universities, conclude that the programs do not fully meet industrial needs, due to a lack of business, relational, and decision-making skills. A strong partnership between industry and educational establishments is needed to create learning factories that embrace Education 4.0, integrating interdisciplinary and multidisciplinary approaches to skills development (Sibiya, Reference Sibiya2023). This new competency framework generates the meta-competencies needed to consolidate the technical competencies of social and emotional intelligence, problem-solving, leadership, and team management (Rauch et al., Reference Rauch, Morandell and Matt2019).

Undoubtedly, there is a noticeable widening disparity between the skills currently possessed and those demanded. Without timely implementation of mandatory measures, this gap is bound to escalate. To cultivate vital skills, intelligence, and expertise, and to prepare the workforce for the challenges of Industry 4.0, the higher education system and universities must adjust and evolve (Bongomin et al., Reference Bongomin, Gilibrays Ocen, Oyondi Nganyi, Musinguzi and Omara2020a). Nevertheless, aligning higher education with the principles and demands of Industry 4.0 comes with both advantages and limitations (Maria et al., Reference Maria, Shahbodin and Pee2018). The main limitation is the need for state-of-the-art infrastructure, and universities also need staff specialized in University 4.0 to adapt students to Industry 4.0 concepts (Rocha et al., Reference Rocha, Gonçalves, da Silva, Teixeira and Silva2022).

In Malaysia, Mian et al. (Reference Mian, Salah, Ameen, Moiduddin and Alkhalefah2020) developed a model for transforming the university into a 4.0 university based on support innovation, administration willingness, allocation of dedicated funds, and internet accessibility. Faced with increased competition and the demands of modernization, it is essential to promote the transformation of university education. Giesenbauer and Müller-Christ (Reference Giesenbauer and Müller-Christ2020) propose a multidimensional organizational model based on the systemic acceleration of higher education institutions and participation in interorganizational networks to find inspiration for dealing with difficult trends.

The industrial revolution is strongly linked to the concept of the social revolution in which the last is the fifth generation. Society 5.0 is an intelligent society that is well integrated into the physical and digital worlds. This is a new form of society known as the data-driven open society (Mayarni et al., Reference Mayarni, Syahza, Siregar, Khoiri, Hariyani, Nasution and Sulistyani2023). It forms a bridge between Society 4.0 and the intelligent, people-centered Society 5.0 (Nikiforova et al., Reference Nikiforova, Flores and Lytras2023). In the era of this concept, University 4.0 is committed to emerging technological markets via ICTs (Gorina and Polyakova, Reference Gorina and Polyakova2021). Hawaii is an example of this dynamic fostering the growth of companies and talent that could be of the highest caliber and lead the growth of high-tech industries such as robots, AI, and machine learning. The University of Hawaii cluster, for example, is an important center for the creation, manufacture, and research of cutting-edge technologies and services, and shares characteristics with Hawaii Island, located on the island of Oahu (Kennedy, Reference Kennedy2021). Rosak-Szyrocka et al. (Reference Rosak-Szyrocka, Apostu, Ali Turi and Tanveer2022) demonstrate the characteristics of 4.0 universities, which are essentially their commitment to actions in favor of sustainable development. Their analysis shows a reciprocal contribution between 4.0 universities and the involvement of 5.0 society.

In the current landscape, a profound interconnection emerges among three pivotal concepts, such as Industry 4.0, University 4.0, and Society 5.0. With the industry’s overarching goals shifting toward resilience, sustainability, human-centric methodologies, and values-based strategies, the trajectory of Industry 5.0 is broadening (Huang et al., Reference Huang, Wang, Li, Zheng, Mourtzis and Wang2022). It is evolving to intricately intertwine with the ongoing social revolution 5.0, fostering a dynamic ecosystem where technological advancements, educational paradigms, and societal aspirations converge harmoniously (Xu et al., Reference Xu, Lu, Vogel-Heuser and Wang2021; Maddikunta et al., Reference Maddikunta, Pham, Prabadevi, Deepa, Dev, Gadekallu, Ruby and Liyanage2022). This convergence not only drives innovation but also shapes a future where human welfare and societal progress are central pillars of development (Nikiforova, Reference Nikiforova2021; Sołtysik-Piorunkiewicz and Zdonek, Reference Sołtysik-Piorunkiewicz and Zdonek2021).

At this stage of development, we need to start converting the university into a University 4.0, with teaching methodologies and innovation programs that include technical and managerial skills. The University 4.0 model must be designed in close collaboration between academics and industry. University programs must be adapted to each country and each continent, because of the social and economic failures facing some continents and the need to build educational units and applications from the cultural context of the country. The essential barrier to overcome, as reported by several countries, is funding (Roodt and Koen, Reference Roodt and Koen2020; Vuksanović Herceg et al., Reference Vuksanović Herceg, Kuč, Mijušković and Herceg2020). In this respect, funding mechanisms and support programs within the framework of 3Ps should be encouraged. These initiatives can be cost-effective by creating new institutes that train qualified academic staff to meet digital challenges. The hindsight of professors and the network can help universities develop partnerships with private companies to offer a platform for application and practical training. Toward action-based learning, University 4.0 should focus its transformation on three main areas. The first is to open to the industrial world and understand the new perceptions and concerns. The second is to include and introduce practical learning based on the delivery of technical and managerial training units. Finally, higher education must be aware of its role in accelerating industrial transformation 4.0 by training managers and relevant skills capable of promoting industrial trends. Despite the barriers that confront these transformations, local adaptation tailored to each country remains a promising solution toward a University 4.0 compatible with 4IR.

An analysis of the state of readiness of education systems in Africa reveals significant shortcomings, despite the investments that have been made, particularly in South Africa and Nigeria. These initial initiatives, while admirable, are hampered by a series of obstacles, including the vulnerability of the technological infrastructures that play a central role. To overcome these challenges, decision-makers must draw inspiration from the successes seen in Asia and Europe, particularly in terms of conceptualizing the University 4.0 paradigm.

The transition to University 4.0 requires major adjustments, ranging from the adoption of innovative and sustainable teaching strategies to an overhaul of managerial and government policies. It is crucial to promote a collective will and strong leadership to guide these changes. Indeed, the move toward an education aligned with Industry 4.0 requires a profound transformation of the educational landscape, integrating technology-based pedagogical approaches, partnerships with the private sector, and increased awareness of the needs of the labor market.

However, this development cannot be isolated from the wider reality of Industry 5.0 and Society 5.0. Africa must become aware of the new industrial and societal centralization that this transition brings. This implies a proactive adaptation of education systems to ensure their relevance and competitiveness in the face of current technological and societal developments. By investing in digital infrastructures, promoting research and innovation, and developing flexible educational programs, Africa can play a leading role in achieving an education aligned with the needs of industry and society in the 21st century.

6. Conclusion

Africa is a continent that fosters skills development for the entire world. The transformation of industrial activity remains a challenge that needs to be studied to find the right mechanisms for intelligent and sustainable transformation. The guidelines of the IR 4.0 encourage the development of training and skills that are appropriate and suitable for a job 4.0.

This study has highlighted the different views of previous researchers on the key skills disciplines for Industry 4.0 across Africa. The study concludes that the topic is in a developmental phase and the pace of processing in Africa remains slow compared to other countries and continents. From a sample of 41 papers addressing the main research question, the study shows and concludes that the emergence of Skills 4.0 must be achieved by implementing training programs and teaching based on three components. The first is technological, consisting of new information technologies. The second is digital, with skills in engineering, design, and 3D programming. The last component aims to equip young people with cross-disciplinary, personal, and managerial skills. Nevertheless, 4.0 learning is influenced by the maturity of Industry 4.0 implementation. As the results show, few countries in Africa are approaching this adjustment of Education 4.0 with Operator. Despite research efforts in previous studies, African countries do not seem to be aware of this disruptive transformation.

The study illustrates some of the technologies and skills that are strongly required to build these skills 4.0 models. These mainly involve generating knowledge on information technologies such as BIM, VR, AR, and IoT, acquiring managerial philosophies such as lean, leadership, and emotional intelligence, and creating sustainable know-how based on a green culture, green design, and sustainable development.

As the continent should continue to make efforts and catch up on the lost years in terms of industrial/skills transformation, it is essential to take into consideration the implications of this preliminary, exploratory study and draw up future studies on models, strategies, and roadmaps for the African continent on its way to a valid Skills 4.0 to Industry 4.0.

The study does not lack limitations. First, the data acquisition process is limited to online search engines, so it is biased against offline publications. Thus, only the Scopus and Web of Science databases are considered. Second, the keyword combinations are not exhaustive because this is a vast disciplinary field containing several subfields. The authors suggest using this data platform and the results to carry out specific studies for each industry and generate strategic models for the continent or more customized models for specific countries. Future work can focus on developing a roadmap to adjust education curricula to meet Industry 4.0 and 5.0 requirements.

Data availability statement

The authors state that all data used for production are declared in this article.

Author contribution

Khalil Idrissi Gartoumi: Conceptualization (Lead), formal analysis (Lead), methodology (Equal), project administration (Lead), supervision (Lead), visualization (Equal), writing—original draft (Lead), wrinting-review and editing. Cédric Stéphane Koumetio Tekouabou: Conceptualization (Supporting), formal analysis (Supporting), methodology (Equal), project administration (Supporting), supervision (Supporting), visualization (Supporting), writing—original draft (Supporting), writing—review and editing (Supporting). All authors approved the final submitted draft.

Funding statement

This work received no specific grant from any funding agency, commercial, or not-for-profit sectors.

Competing interest

The authors declare none.

Comments

No Comments have been published for this article.