1. Introduction

Technical and biological systems are often composed of connected elastic or rigid solid bodies. In the connecting joints of the bodies, the two adjacent components form a narrow gap. In order to reduce friction and wear or stick slip effects, the gap is usually filled with a lubricant, which is either gaseous, condensed or multi-phase.

The two main functions of the lubrication film are: (i) the reduction of the tangential drag force ![]() $\boldsymbol D$ of the two parts moving relative to each other with tangential speed

$\boldsymbol D$ of the two parts moving relative to each other with tangential speed ![]() $\boldsymbol U$ and (ii) the generation of a pressure field

$\boldsymbol U$ and (ii) the generation of a pressure field ![]() $p$ within the narrow gap, resulting in a normal force

$p$ within the narrow gap, resulting in a normal force ![]() $\boldsymbol N$ separating the two surfaces. Reduction of the drag force, e.g. by means of tailor-made fluids and interfaces, results in a reduction of the dissipated energy per unit time

$\boldsymbol N$ separating the two surfaces. Reduction of the drag force, e.g. by means of tailor-made fluids and interfaces, results in a reduction of the dissipated energy per unit time ![]() $|{\boldsymbol{U} \boldsymbol{\cdot} \boldsymbol{D}}|$ within the gap. This is of crucial importance with respect to sustainability considering that, in total,

$|{\boldsymbol{U} \boldsymbol{\cdot} \boldsymbol{D}}|$ within the gap. This is of crucial importance with respect to sustainability considering that, in total, ![]() $25\,\%$ of the world's energy consumption is dissipated within narrow gaps of tribological contacts, as sketched in figure 1 (Holmberg & Erdemir Reference Holmberg and Erdemir2017).

$25\,\%$ of the world's energy consumption is dissipated within narrow gaps of tribological contacts, as sketched in figure 1 (Holmberg & Erdemir Reference Holmberg and Erdemir2017).

Figure 1. Generic lubrication gap between two surfaces ![]() $S$ and

$S$ and ![]() $S_H$ moving relative to each other with the velocity

$S_H$ moving relative to each other with the velocity ![]() $\boldsymbol {U}+\dot {h}\boldsymbol {e}_z = U_i \boldsymbol {e}_i + \dot {h}\boldsymbol {e}_z$ (we use Einstein's summation convention for the index

$\boldsymbol {U}+\dot {h}\boldsymbol {e}_z = U_i \boldsymbol {e}_i + \dot {h}\boldsymbol {e}_z$ (we use Einstein's summation convention for the index ![]() $i=1,2$). The equation of motion for the incompressible Newtonian fluid with wall slip is a Poisson type partial differential equation for the velocity

$i=1,2$). The equation of motion for the incompressible Newtonian fluid with wall slip is a Poisson type partial differential equation for the velocity ![]() $\boldsymbol {u}(\boldsymbol x,\,t)=u_i\boldsymbol {e}_i$ and pressure field

$\boldsymbol {u}(\boldsymbol x,\,t)=u_i\boldsymbol {e}_i$ and pressure field ![]() $p(\boldsymbol x,\,t)$ for each point

$p(\boldsymbol x,\,t)$ for each point ![]() $\boldsymbol {x}=x_i\boldsymbol {e}_i+z\boldsymbol e_z$ in the gap. The fluid motion results in the force

$\boldsymbol {x}=x_i\boldsymbol {e}_i+z\boldsymbol e_z$ in the gap. The fluid motion results in the force ![]() $\boldsymbol {F}=\boldsymbol N +\boldsymbol D$ applied by the fluid to the lower wall, see Appendix A.

$\boldsymbol {F}=\boldsymbol N +\boldsymbol D$ applied by the fluid to the lower wall, see Appendix A.

For the gap sketched in figure 1, ![]() $\psi = |\boldsymbol {\nabla } h|$ is the angle of inclination between the upper and lower surfaces,

$\psi = |\boldsymbol {\nabla } h|$ is the angle of inclination between the upper and lower surfaces, ![]() $h$ and

$h$ and ![]() $\dot {h}$ are the gap height and its time derivative and

$\dot {h}$ are the gap height and its time derivative and ![]() $\varrho$ and

$\varrho$ and ![]() $\mu$ are the density and dynamic viscosity of the lubricant. For a journal bearing, the magnitude of the inclination angle and the relative bearing clearance, i.e. the ratio of the mean clearance

$\mu$ are the density and dynamic viscosity of the lubricant. For a journal bearing, the magnitude of the inclination angle and the relative bearing clearance, i.e. the ratio of the mean clearance ![]() $\bar h$ and the shaft radius

$\bar h$ and the shaft radius ![]() $R$, are of the same order (see Appendix A).

$R$, are of the same order (see Appendix A).

1.1. Focus of this paper

In technical systems the upper and lower surfaces of the adjacent solids are often metals being hardened and usually ground, honed or lapped, showing technical roughness ![]() $k$ with an order of magnitude of

$k$ with an order of magnitude of ![]() $10\, \mathrm {nm}\ \mathrm {to}\ 1\, \mathrm {\mu }\mathrm {m}$, cf. figure 2. In any case, the surfaces in technical applications are far from being atomically smooth (Klocke & König Reference Klocke and König2005). Furthermore, the lubricant is usually mineral oil or synthetic oil. It is therefore a mixture of non-polar molecules with different molecular weights. To positively influence friction by tailor-made fluids, polar molecules, i.e. additives, are added to the lubricant. These molecules adsorb on the metal surface and thus change the dynamic boundary condition, i.e. the slip length

$10\, \mathrm {nm}\ \mathrm {to}\ 1\, \mathrm {\mu }\mathrm {m}$, cf. figure 2. In any case, the surfaces in technical applications are far from being atomically smooth (Klocke & König Reference Klocke and König2005). Furthermore, the lubricant is usually mineral oil or synthetic oil. It is therefore a mixture of non-polar molecules with different molecular weights. To positively influence friction by tailor-made fluids, polar molecules, i.e. additives, are added to the lubricant. These molecules adsorb on the metal surface and thus change the dynamic boundary condition, i.e. the slip length ![]() $\lambda$ sketched in figures 1 and 5.

$\lambda$ sketched in figures 1 and 5.

Figure 2. Rough metal surfaces after surface treatment (Klocke & König Reference Klocke and König2005). The images were created by means of a scanning electron microscope. For the honed and lapped surfaces, the depths of the groves are of the order of 1 ![]() $\mathrm {\mu }$m and 10 nm, respectively. The lapped surface is isotropic, whereas the honed surface is not due to the obvious surface structure. In the experiments described in this paper, all surfaces are lapped.

$\mathrm {\mu }$m and 10 nm, respectively. The lapped surface is isotropic, whereas the honed surface is not due to the obvious surface structure. In the experiments described in this paper, all surfaces are lapped.

This work deals with the lubrication flow of Newtonian fluids (constant density ![]() $\varrho$, constant dynamic viscosity

$\varrho$, constant dynamic viscosity ![]() $\mu$) in narrow gaps where the mean gap clearance

$\mu$) in narrow gaps where the mean gap clearance ![]() $\bar {h}$ is so small in relation to the slip length

$\bar {h}$ is so small in relation to the slip length ![]() $\lambda$ that wall slip becomes relevant. As we will show: for the typical order of magnitude

$\lambda$ that wall slip becomes relevant. As we will show: for the typical order of magnitude ![]() $\lambda /\bar {h}\sim 10^{-2}$ that applies to hydrocarbon lubricated bearings, the wall slip indeed has a non-negligible influence on both the load carrying capacity of the bearing (see figures 13 and 15a) and the energy dissipation in the bearing (see figures 14 and 15b).

$\lambda /\bar {h}\sim 10^{-2}$ that applies to hydrocarbon lubricated bearings, the wall slip indeed has a non-negligible influence on both the load carrying capacity of the bearing (see figures 13 and 15a) and the energy dissipation in the bearing (see figures 14 and 15b).

Although the theory of hydrodynamic lubrication with Stokes’ no-slip dynamic boundary condition is well developed, there are three open needs or questions regarding Navier's dynamic boundary condition for Newtonian fluids with and without additives in technically relevant flows, cf. § 2: first, there is a particular need for new measurement principles for the robust, automated and reproducible determination of temperature-dependent wall slip on technically relevant rough surfaces. Existing measurement principles, which have been developed and used in nanofluidics in recent years, are either not suitable for the interface between a solid metal surface and a hydrocarbon fluid, or are only suitable to a certain degree for technically relevant systems since the measurement area is too small to average stochastic interface variations. Second, from an epistemological point of view as well as for tailor-made fluids and interfaces, the relation between volume shear and wall slip and its dependence on temperature and molecular structure of hydrocarbon fluids are of interest. Third, in an application, the influence of wall slip on the load-carrying capacity through the force–displacement curve of narrow gaps, i.e. the Sommerfeld number as a function of relative eccentricity in the case of a journal bearing, is of practical interest as well as the friction torque in terms of a sustainability point of view.

The aim of this paper is firstly to discuss the constitutive relationship between shear stress and slip velocity at the liquid–solid boundary from the point of view of rate theory, secondly to measure this constitutive relationship for hydrocarbon lubricants of different molecular structures and thirdly to evaluate the influence of the boundary condition on the energetic and functional characteristics of the gap of a journal bearing.

1.2. Structure of the paper

In order to provide answers to the three open questions, the paper is divided into seven main sections, with this introduction stating the motivation, focus and research questions. § 2 shows that the necessary bridging between the two research fields of nanofluidics and tribology to answer the open questions is not yet sufficiently formed. Wall slip is then discussed from the point of view of rate theory, (§ 3) and in particular from the point of view of the Eyring model (§ 3.1), leading to the conclusion that the activation energy for wall slip ![]() $E_{\lambda }$ in a mixture of non-polar hydrocarbon molecules is expected to be only approximately half of the activation energy for bulk shear,

$E_{\lambda }$ in a mixture of non-polar hydrocarbon molecules is expected to be only approximately half of the activation energy for bulk shear, ![]() $E_{\lambda }\approx 0.5E_\mu$. This theoretical result will be experimentally validated in the further course of the paper.

$E_{\lambda }\approx 0.5E_\mu$. This theoretical result will be experimentally validated in the further course of the paper.

For this purpose, § 4 presents a newly developed apparatus called the slip length tribometer (SLT). The SLT is used to simultaneously measure bulk shear and wall slip. This apparatus can be used over a wide and well-controlled temperature range, ![]() $-30\,^\circ \mathrm {C} \le \varTheta = T-273.15\,\mathrm {K} \le 100\,^\circ \mathrm {C}$ with a temperature uncertainty smaller than

$-30\,^\circ \mathrm {C} \le \varTheta = T-273.15\,\mathrm {K} \le 100\,^\circ \mathrm {C}$ with a temperature uncertainty smaller than ![]() $0.2\,^\circ \mathrm {C}$.

$0.2\,^\circ \mathrm {C}$.

Model-based estimation, i.e. the Eyring model and the activation energy for wall slip, is experimentally validated, cf. § 5, figure 11 and table 2. The addition of polar molecules to the oil and their influence on slip length is investigated, cf. § 5.3. The results reveal that the addition roughly halves the slip length at room temperature, while the influence on the activation energy is negligible, cf. table 2.

Subsequently, we discuss the impact of wall slip on Sommerfeld's similarity theory of tribology and in particular on the Stribeck curve resulting from this theory (§ 6.3). This is done by employing the SLT measured viscometric constants given by the parameter set [![]() $\mu _0,E_\mu,\lambda _0,E_{\lambda }$] with

$\mu _0,E_\mu,\lambda _0,E_{\lambda }$] with ![]() $\mu _0=\mu (T_0)$,

$\mu _0=\mu (T_0)$, ![]() $\lambda _0=\lambda (T_0)$ at reference temperature

$\lambda _0=\lambda (T_0)$ at reference temperature ![]() $T_0$, see table 2, to predict the load capacity and frictional force of a journal bearing at different temperatures

$T_0$, see table 2, to predict the load capacity and frictional force of a journal bearing at different temperatures ![]() $T$ (see § 6, figures 13–15). For this purpose, the Reynolds equation generalised for wall slip (see Appendix A) is solved both numerically and by means of an asymptotic expansion.

$T$ (see § 6, figures 13–15). For this purpose, the Reynolds equation generalised for wall slip (see Appendix A) is solved both numerically and by means of an asymptotic expansion.

Section 6 also shows that the asymptotic expansion gives a useful approximation of the numerical results, especially for small relative eccentricities and small Sommerfeld numbers. Hence, it provides a rule of thumb to estimate the influence of wall slip on the energy consumption due to tribological contacts. It is shown that the approximate solution is consistent with Petrov's equation (Petrov Reference Petrov1883) generalised for wall slip

To study the impact of wall slip in typical technical systems, § 7 presents two use cases, a typical camshaft journal bearing of a combustion engine and a journal bearing of an industrial compressor. The load-carrying capacity of the bearing as well as the drag force per unit length are compared for the presence and absence of wall slip within the bearing.

Appendix A gives a concise and strict derivation of the generalised Reynolds equation. In Appendix B a strict method to quantify the measurement uncertainty in the context of the SLT is derived. Appendix C finally reports slip lengths and activation energies for the most common lubricants, i.e. the mineral oils VG 46, VG 68. All values are gained with the SLT introduced here.

2. Literature review – wall slip in nanofluidics and tribology

In recent years, research on wall slip has been conducted in the two related research areas of nanofluidics and tribology. As § 2.2 shows, research to date in nanofluidics has focused primarily on the experimental determination of wall slip, often based on the atomic force microscope (AFM), while the focus in tribology (§ 2.3) has been on the theoretical determination of the load-bearing capacity and friction of technical components such as sliders and journal bearings. Previous work on tribology has mostly been of a purely theoretical nature, since experimentally determined input data for wall slip, e.g. in the form of measured slip lengths at technically relevant surfaces, are hardly available. On the one hand, existing experimental work in the field of nanofluidics is of limited value for tribology since stochastic interfacial variations due to interfacial roughness are not averaged and, on the other hand, the available experimental techniques are mostly not suitable for the technically relevant combination of metallic solids and hydrocarbon fluids. The following two subsections show that the two related research areas are not yet sufficiently connected.

An indication of this gap is that, in nanofluidics, the concept of Helmholtz’ slip length is commonly used as an interpretation of Navier's constitutive relation for wall slip, cf. (2.5) in the following subsection on the dynamic boundary condition. Thus, wall slip is interpreted from the perspective of kinematics or even geometry, whereas in tribology wall slip is usually interpreted from the Navier perspective, which relates shear stress to slip velocity or vice versa as in the constitutive relation (2.1), cf. the following subsection. One reason for this discrepancy could be the different length scales considered by the research groups. In nanofluidics, the length scales of interest range from 1 to 10 nm and are given by atomic scales and nano-surface roughness, while in tribology the typical length scales are given by engineering surface roughness and the typical size of a bearing or seal. The order of magnitude of the scales of interest in tribology therefore ranges from 10 nm to 100 mm (or even larger). In order to understand the influence of, for example, friction reducing additives on wall slip (i.e. slip length) but not on shear (i.e. viscosity), it is necessary to consider the scales and methods of nanofluidics holistically with the methods of tribology. This is attempted in this paper.

To provide a foundation for the paper and discussion, this literature review is introduced with a reminder of the boundary conditions at the solid–fluid interface for Newtonian lubricants and the distinction between Newtonian and non-Newtonian material behaviour.

2.1. Boundary conditions at the solid–fluid interface for Newtonian lubricants

As is well known, the kinematic boundary condition at the solid–fluid interface is given by Lagrange's theorem: ‘The interface is always made up of the same fluid particles’. This theorem is expressed in short by the scalar equation D![]() $H/$D

$H/$D![]() $t=0$ with

$t=0$ with ![]() $H=z-h(\boldsymbol x,\,t)=0$ for the upper wall of surface

$H=z-h(\boldsymbol x,\,t)=0$ for the upper wall of surface ![]() $S_H$ and

$S_H$ and ![]() $H=z=0$ for the lower wall of surface

$H=z=0$ for the lower wall of surface ![]() $S$, cf. (A5). Of greater interest than the kinematic boundary condition is the dynamic boundary condition, at least in the context of this paper. It is given by Newton's third law ‘actio est reactio’. This axiom demands the continuity of the stress vector

$S$, cf. (A5). Of greater interest than the kinematic boundary condition is the dynamic boundary condition, at least in the context of this paper. It is given by Newton's third law ‘actio est reactio’. This axiom demands the continuity of the stress vector ![]() $\boldsymbol{t} = {\rm d}\boldsymbol F/$d

$\boldsymbol{t} = {\rm d}\boldsymbol F/$d![]() $S$ across the wall. The force

$S$ across the wall. The force ![]() $\boldsymbol F$ is determined for given

$\boldsymbol F$ is determined for given ![]() $\boldsymbol t$ by integration over the wall surface

$\boldsymbol t$ by integration over the wall surface ![]() $S$.

$S$.

If the nonlinear convective terms and the linear transient term on the left-hand side of the equation of motion are negligibly small (for the necessary conditions see Appendix A), which is assumed here, the inductance of the fluid in the gap is negligibly small so that the left side of the equation of motion can be neglected. Hence, the tangential and normal forces ![]() $\boldsymbol D$ and

$\boldsymbol D$ and ![]() $\boldsymbol N$ on both walls are equal in magnitude and opposite in direction. It is therefore sufficient to consider the forces on the lower wall only. The stress vector at the lower wall

$\boldsymbol N$ on both walls are equal in magnitude and opposite in direction. It is therefore sufficient to consider the forces on the lower wall only. The stress vector at the lower wall ![]() $z=0$ with normal vector

$z=0$ with normal vector ![]() $\boldsymbol e_z$ is given by

$\boldsymbol e_z$ is given by ![]() $\boldsymbol t=(-p+\tau _{zz}) \boldsymbol e_z+\tau _{iz} \boldsymbol e_i$,

$\boldsymbol t=(-p+\tau _{zz}) \boldsymbol e_z+\tau _{iz} \boldsymbol e_i$, ![]() $i=1,2$ (we use Einstein's summation convention). With the nonlinear convective terms and the linear transient term being negligible, the normal viscous stress

$i=1,2$ (we use Einstein's summation convention). With the nonlinear convective terms and the linear transient term being negligible, the normal viscous stress ![]() $\tau _{zz}$ is much smaller than the static pressure

$\tau _{zz}$ is much smaller than the static pressure ![]() $p$ and the tangential stress components:

$p$ and the tangential stress components: ![]() $\tau _{zz}/\tau _{iz}\sim \tau _{zz}/p\sim \psi \ll 1$ (Spurk & Aksel Reference Spurk and Aksel2019). The continuity of the normal component

$\tau _{zz}/\tau _{iz}\sim \tau _{zz}/p\sim \psi \ll 1$ (Spurk & Aksel Reference Spurk and Aksel2019). The continuity of the normal component ![]() $\boldsymbol t\boldsymbol {\cdot } \boldsymbol e_z=-p$ demands the continuity of the static pressure

$\boldsymbol t\boldsymbol {\cdot } \boldsymbol e_z=-p$ demands the continuity of the static pressure ![]() $p$ across the interface, whereas the continuity of the tangential components

$p$ across the interface, whereas the continuity of the tangential components ![]() $\boldsymbol t\boldsymbol {\cdot } \boldsymbol e_i=\tau _{iz}$ requires a constitutive relation, which is the subject of this subsection. This constitutive relation relates the shear stress components

$\boldsymbol t\boldsymbol {\cdot } \boldsymbol e_i=\tau _{iz}$ requires a constitutive relation, which is the subject of this subsection. This constitutive relation relates the shear stress components ![]() $\tau _{iz}$ to the relative slip velocity

$\tau _{iz}$ to the relative slip velocity ![]() $w_i=U_i-u_i$ at the wall. Here,

$w_i=U_i-u_i$ at the wall. Here, ![]() $u_i$ is the component of the flow velocity within the gap in the

$u_i$ is the component of the flow velocity within the gap in the ![]() $i=1,2$ direction and

$i=1,2$ direction and ![]() $U_i$ is the lateral velocity of the walls, cf. figure 1.

$U_i$ is the lateral velocity of the walls, cf. figure 1.

Navier (Reference Navier1822) was the first to formulate a linear constitutive relationship between shear stress and slip velocity. The generalised tensor form of this relationship in Cartesian index notation is as follows:

Here, ![]() $\,f_{ij}$ is the component of wall friction tensor,

$\,f_{ij}$ is the component of wall friction tensor, ![]() $\tau _{iz}$ the components of the stress vector tangential to the wall and

$\tau _{iz}$ the components of the stress vector tangential to the wall and ![]() $w_i=U_i-u_i$ the slip velocity at the wall. Multiplying Navier's slip law by

$w_i=U_i-u_i$ the slip velocity at the wall. Multiplying Navier's slip law by ![]() $w_i$ yields the dissipation rate per unit wall surface area

$w_i$ yields the dissipation rate per unit wall surface area ![]() $w_i \tau _{iz}=w_i \,f_{ij} w_j$. From this, it follows that

$w_i \tau _{iz}=w_i \,f_{ij} w_j$. From this, it follows that ![]() $\,f_{ij} = \,f_{ji}$, i.e. the wall friction tensor is symmetric.

$\,f_{ij} = \,f_{ji}$, i.e. the wall friction tensor is symmetric.

The equivalent to Navier's constitutive law for wall slip is Newton's constitutive relation (Newton Reference Newton1687) for viscous friction at the wall for incompressible flow

Eliminating ![]() $\tau _{iz}$ from (2.1) and (2.2) yields

$\tau _{iz}$ from (2.1) and (2.2) yields

The relation of the slip length tensor ![]() $\lambda _{ij}$ to the wall friction tensor

$\lambda _{ij}$ to the wall friction tensor ![]() $\,f_{ij}$ is defined by the equation

$\,f_{ij}$ is defined by the equation

(here, and in the following, ‘:=’ means ‘is defined to be equal to’ and ![]() $\delta _{ij} = \boldsymbol {e}_i \boldsymbol {\cdot } \boldsymbol {e}_j$ is the Kronecker delta.) Combining (2.3) and (2.4) yields

$\delta _{ij} = \boldsymbol {e}_i \boldsymbol {\cdot } \boldsymbol {e}_j$ is the Kronecker delta.) Combining (2.3) and (2.4) yields

Even though this seems to be a kinematic boundary condition, the dynamic character becomes clear.

The technical lubrication gaps being addressed within this paper show isotropic surfaces properties, i.e. ![]() $\,f_{ij}=\,f\delta _{ij}$ and

$\,f_{ij}=\,f\delta _{ij}$ and ![]() $\lambda _{ij}=\lambda \delta _{ij}$. The slip length

$\lambda _{ij}=\lambda \delta _{ij}$. The slip length ![]() $\lambda$ for isotropic surfaces was first introduced by Helmholtz & von Piotrowski (Reference Helmholtz and von Piotrowski1860). Hence, we have

$\lambda$ for isotropic surfaces was first introduced by Helmholtz & von Piotrowski (Reference Helmholtz and von Piotrowski1860). Hence, we have ![]() $\mu =f\lambda$ for the relation of viscosity

$\mu =f\lambda$ for the relation of viscosity ![]() $\mu$, friction factor

$\mu$, friction factor ![]() $f$ and slip length

$f$ and slip length ![]() $\lambda$. Recent results from molecular dynamics (MD) simulations by Mehrnia & Pelz (Reference Mehrnia and Pelz2021) showed that the apparent viscosity for (non-polar) hydrocarbon alpha-olefin (PAO 6) is shear rate independent up to an apparent shear rate of

$\lambda$. Recent results from molecular dynamics (MD) simulations by Mehrnia & Pelz (Reference Mehrnia and Pelz2021) showed that the apparent viscosity for (non-polar) hydrocarbon alpha-olefin (PAO 6) is shear rate independent up to an apparent shear rate of ![]() $\dot {\gamma }_{c} = 10^8\,\mathrm {s}^{-1}$ (see figure 10). Hence, the relaxation time for those typical lubricant with mean molar mass

$\dot {\gamma }_{c} = 10^8\,\mathrm {s}^{-1}$ (see figure 10). Hence, the relaxation time for those typical lubricant with mean molar mass ![]() $\bar {M} = 600\, \mathrm {u}$ is approximately 10 ns (inverse of the critical shear rate) at ambient temperature. Furthermore, for the shear rates up to

$\bar {M} = 600\, \mathrm {u}$ is approximately 10 ns (inverse of the critical shear rate) at ambient temperature. Furthermore, for the shear rates up to ![]() $10^5\,{\rm s}^{-1}$ being realised in the experiments reported in this work and which are relevant in lubrication gaps, the fluid is, in fact, Newtonian with dynamic viscosity

$10^5\,{\rm s}^{-1}$ being realised in the experiments reported in this work and which are relevant in lubrication gaps, the fluid is, in fact, Newtonian with dynamic viscosity ![]() $\mu$ and slip length

$\mu$ and slip length ![]() $\lambda$, both being independent of shear rate. This is because apparent wall slip due to shear thinning, i.e. viscoelastic effects, are only expected at shear rates

$\lambda$, both being independent of shear rate. This is because apparent wall slip due to shear thinning, i.e. viscoelastic effects, are only expected at shear rates ![]() $\dot \gamma \sim \dot \gamma _c$ or larger.

$\dot \gamma \sim \dot \gamma _c$ or larger.

The slip length scales with the effective molecular length ![]() $a$ (Bocquet & Barrat Reference Bocquet and Barrat2007; Lauga, Brenner & Stone Reference Lauga, Brenner and Stone2007). This also results from the generalised Eyring model for wall slip developed in this paper, cf. § 3.1, (3.15). However, the statement

$a$ (Bocquet & Barrat Reference Bocquet and Barrat2007; Lauga, Brenner & Stone Reference Lauga, Brenner and Stone2007). This also results from the generalised Eyring model for wall slip developed in this paper, cf. § 3.1, (3.15). However, the statement ![]() $\lambda \sim a$ is only valid for

$\lambda \sim a$ is only valid for ![]() $h\gg a$, which is always assumed in this work. Mehrnia & Pelz (Reference Mehrnia and Pelz2021) considered also the complementary case

$h\gg a$, which is always assumed in this work. Mehrnia & Pelz (Reference Mehrnia and Pelz2021) considered also the complementary case ![]() $h \to a$ by analysing the Couette flow between two plates (gap height

$h \to a$ by analysing the Couette flow between two plates (gap height ![]() $h$, tangential speed

$h$, tangential speed ![]() $U$) using MD methods. The simulation results show

$U$) using MD methods. The simulation results show ![]() $\lambda \to \infty$ for

$\lambda \to \infty$ for ![]() $h \to a$. In fact, this singularity is easy to see: for

$h \to a$. In fact, this singularity is easy to see: for ![]() $h \to a$ the slip velocity approaches half the relative velocity,

$h \to a$ the slip velocity approaches half the relative velocity, ![]() $w \to U/2$, for symmetry reasons. As we will show in § 3.1, the adhesion forces between the molecules in the bulk are much larger than the adhesion forces between the non-polar molecules near the wall and the iron atoms of the wall. Therefore, for

$w \to U/2$, for symmetry reasons. As we will show in § 3.1, the adhesion forces between the molecules in the bulk are much larger than the adhesion forces between the non-polar molecules near the wall and the iron atoms of the wall. Therefore, for ![]() $h \to a$ the shear rate approaches zero. Equation (2.5) then gives

$h \to a$ the shear rate approaches zero. Equation (2.5) then gives ![]() $\lambda \to \infty$ for

$\lambda \to \infty$ for ![]() $h \to a$. We will come back to this when discussing the presented Stribeck curve, figure 15(b), in the asymptotic limit of very large Sommerfeld number and hence small gap height. In this limiting case, the assumption of a constant slip length no longer applies.

$h \to a$. We will come back to this when discussing the presented Stribeck curve, figure 15(b), in the asymptotic limit of very large Sommerfeld number and hence small gap height. In this limiting case, the assumption of a constant slip length no longer applies.

2.2. Wall slip in nanofluidics

In nanofluidics, wall slip is usually measured by measuring the slip length tensor ![]() $\lambda _{ij}$ or the relative slip velocity

$\lambda _{ij}$ or the relative slip velocity ![]() $w_i=U_i-u_i= \lambda _{ij} \, \partial u_j / \partial z |_{z = 0,h}$ between a near-wall fluid particle of absolute velocity

$w_i=U_i-u_i= \lambda _{ij} \, \partial u_j / \partial z |_{z = 0,h}$ between a near-wall fluid particle of absolute velocity ![]() $u_i$ and the wall with the absolute velocity

$u_i$ and the wall with the absolute velocity ![]() $U_i$ (see figure 1). The experiments can be performed either in a controlled laboratory environment (cf. this paper) or ‘in silico’ using MD simulations (Mehrnia & Pelz Reference Mehrnia and Pelz2021). In either case, the determined viscometric constants for both shear, i.e. the dynamic viscosity

$U_i$ (see figure 1). The experiments can be performed either in a controlled laboratory environment (cf. this paper) or ‘in silico’ using MD simulations (Mehrnia & Pelz Reference Mehrnia and Pelz2021). In either case, the determined viscometric constants for both shear, i.e. the dynamic viscosity ![]() $\mu$, and wall slip, i.e. the slip length

$\mu$, and wall slip, i.e. the slip length ![]() $\lambda$, are both ensemble averaged. Therefore, any method must explicitly or implicitly average over many molecules and many (technical) interface roughness peaks.

$\lambda$, are both ensemble averaged. Therefore, any method must explicitly or implicitly average over many molecules and many (technical) interface roughness peaks.

2.2.1. Local measurement principles

Over the years, a variety of experimental set-ups and techniques to measure wall slip emerged. See Neto et al. (Reference Neto, Evans, Bonaccurso, Butt and Craig2005), Lauga et al. (Reference Lauga, Brenner and Stone2007), Maali & Bhushan (Reference Maali and Bhushan2012) and Garcia (Reference Garcia2016) just to mention some of the more recent ones. The methods can be divided into optical methods, interfacial resolving dynamic methods and interfacial averaging dynamic methods. Here, dynamic means that it is about force measurements, e.g. by means of the AFM or also wall shear stress integrated over larger surfaces. The last case concerns this paper, in which the dynamic quantity to be measured is torque.

The first two groups of measurement principles can be described as local, while the latter methods can be described as integral. Local methods are common in the research field of nanofluidics, while integral methods are found in the research field of tribology and rheology. Today, the eight most popular local methods applied in nanofluidics are:

(i) Fluorescence recovery after photobleaching, FRAP, (Durliat, Hervet & Léger Reference Durliat, Hervet and Léger1997; Pit, Hervet & Léger Reference Pit, Hervet and Léger1999, Reference Pit, Hervet and Léger2000).

(ii) Total internal reflection-fluorescence recovery after photobleaching, TIR-FRAP (Pit et al. Reference Pit, Hervet and Léger2000).

(iii) Particle image velocimetry, PIV (Restagno et al. Reference Restagno, Crassous, Charlaix, Cottin-Bizonne and Monchanin2002; Joseph & Tabeling Reference Joseph and Tabeling2005).

(iv) Fluorescence correlation spectroscopy, FCS (Joly, Ybert & Bocquet Reference Joly, Ybert and Bocquet2006).

(v) Double-focus fluorescence cross-correlation, DF-FCS (Vinogradova et al. Reference Vinogradova, Koynov, Best and Feuillebois2009).

(vi) Colloidal probe AFM (McBride & Law Reference McBride and Law2010).

(vii) Surface force apparatus, SFA (Horn et al. Reference Horn, Vinogradova, Mackay and Phan-Thien2000).

(viii) Dynamic surface force apparatus, DSFA (Restagno et al. Reference Restagno, Crassous, Charlaix, Cottin-Bizonne and Monchanin2002).

The optical methods (i) to (v) are not well suited for the technical systems we are focused on here. The interfacial resolving dynamic methods, (vi), (vii) and (viii), can be very accurate but are not suited for technically relevant substrates. Although they belong to the same class of experimental techniques, they are technically very different and have various strengths and limitations. The following is an overview of previous research on these methods.

Due to its simplicity and high resolution, of the order of magnitude of ![]() $0.5\,\mathrm {nm}$, the AFM is one of the most widely used methods for measuring wall slip. However, and besides its high resolution capabilities, many researchers have been confronted with significant noise during their measurements (Bonaccurso, Butt & Craig Reference Bonaccurso, Butt and Craig2003; Honig & Ducker Reference Honig and Ducker2007; McBride & Law Reference McBride and Law2010). To overcome the drawback of a noisy measurement signal, Zhu, Attard & Neto (Reference Zhu, Attard and Neto2011) developed an algorithm to reduce the impact of the experimental noise on the derived slip length, resulting in a reported overall systematic measurement uncertainty of only 2 nm (the typically reported measurement uncertainties of the different methods for measuring the slip length are given in table 1).

$0.5\,\mathrm {nm}$, the AFM is one of the most widely used methods for measuring wall slip. However, and besides its high resolution capabilities, many researchers have been confronted with significant noise during their measurements (Bonaccurso, Butt & Craig Reference Bonaccurso, Butt and Craig2003; Honig & Ducker Reference Honig and Ducker2007; McBride & Law Reference McBride and Law2010). To overcome the drawback of a noisy measurement signal, Zhu, Attard & Neto (Reference Zhu, Attard and Neto2011) developed an algorithm to reduce the impact of the experimental noise on the derived slip length, resulting in a reported overall systematic measurement uncertainty of only 2 nm (the typically reported measurement uncertainties of the different methods for measuring the slip length are given in table 1).

Table 1. Selection of typically reported measurement uncertainties of the different methods for measuring the slip length (![]() $^*$ no adequate or transparent uncertainty quantification reported).

$^*$ no adequate or transparent uncertainty quantification reported).

The SFA was initially developed to measure drainage forces between two transparent, half-cylindrical mica surfaces (Tabor & Winterton Reference Tabor and Winterton1969; Israelachvili & Adams Reference Israelachvili and Adams1976). Here, the force is obtained by measuring the deflection of a cantilever spring with known stiffness, supporting one of the two mica surfaces. The width, shape and optical index of the gap between the two solids is measured using the fringes of equal chromatic order (FECO) method, cf. Israelachvili et al. (Reference Israelachvili2010). Whereas for example Persson & Mugele (Reference Persson and Mugele2004) moved one surface at a constant speed, the SFA can also be used for oscillatory operation in which the two solids oscillate relative to each other either in the lateral direction (Israelachvili, Mcguiggan & Homla Reference Israelachvili, Mcguiggan and Homla1988) or in the normal direction (Zhu & Granick Reference Zhu and Granick2001; Baudry et al. Reference Baudry, Charlaix, Tonck and Mazuyer2001). For further details on the SFA see the thorough review articles of Neto et al. (Reference Neto, Evans, Bonaccurso, Butt and Craig2005) and Israelachvili et al. (Reference Israelachvili2010).

Zhu & Granick (Reference Zhu and Granick2001) employed a modified SFA with tetradecane liquid confined between solid mica surfaces coated with a methyl-terminated close-packed monolayer of condensed octadecyltriethoxysiloxane. The authors observed a rise in slip length above a critical shear rate and reported slip lengths of the order of magnitude of 1 ![]() $\mathrm {\mu }$m. Those high values are presumed to be caused by shear induced nucleation of gas or vapour bubbles on the surfaces. Therefore, they are not typical in terms of slip lengths in general.

$\mathrm {\mu }$m. Those high values are presumed to be caused by shear induced nucleation of gas or vapour bubbles on the surfaces. Therefore, they are not typical in terms of slip lengths in general.

The first DSFA was developed by Tonck, Georges & Loubet (Reference Tonck, Georges and Loubet1988). This method allows the measurement of intermolecular forces of a liquid confined between a solid sphere and a solid plane for transient operation. For the DSFA the gap width is measured using a combination of a high resolution interferometric sensor and a capacitive sensor (Restagno et al. Reference Restagno, Crassous, Charlaix, Cottin-Bizonne and Monchanin2002; Cottin-Bizonne et al. Reference Cottin-Bizonne, Steinberger, Cross, Raccurt and Charlaix2008). The wetted area for the used apparatus has an order of magnitude of ![]() $10^3\,\mathrm {\mu }{\rm m}^2$. The fluid is squeezed harmonically by a piezo actor and the inverse of the out of phase force component, i.e. the dissipative viscous force, is plotted vs the measured gap height. By means of linear regression and extrapolation, the slip length is derived.

$10^3\,\mathrm {\mu }{\rm m}^2$. The fluid is squeezed harmonically by a piezo actor and the inverse of the out of phase force component, i.e. the dissipative viscous force, is plotted vs the measured gap height. By means of linear regression and extrapolation, the slip length is derived.

Due to the deployment of the FECO method, the SFA is limited to transparent surfaces, whereas both the DSFA and the AFM are not limited to transparent substrates. However, the area to be examined (typical radius of the surfaces is of the order of magnitude of 10 ![]() $\mathrm {\mu }$m for the DSFA and smaller for the AFM) is too small compared with the area needed to handle technical roughnesses.

$\mathrm {\mu }$m for the DSFA and smaller for the AFM) is too small compared with the area needed to handle technical roughnesses.

Regarding the limitation due to the need for transparent surfaces, FRAP, TIR-FRAP and PIV form a compromise between the SFA and DSFA. These methods require only one transparent substrate, while the other can be opaque. The probed area for FRAP is of the order of ![]() $600\times 600\,\mathrm {\mu }{\rm m}$ (Hénot et al. Reference Hénot, Grzelka, Zhang, Mariot, Antoniuk, Drockenmuller, Léger and Restagno2018).

$600\times 600\,\mathrm {\mu }{\rm m}$ (Hénot et al. Reference Hénot, Grzelka, Zhang, Mariot, Antoniuk, Drockenmuller, Léger and Restagno2018).

In conclusion, the limited possibility of measuring technical rough metal surfaces combined with technical lubrication motivated us to think of an alternative measurement principle. The SLT has the advantage of an intrinsic averaging of the slip length over a high measurement area, which leads to the possibility of measuring technically relevant surfaces.

2.2.2. Surface roughness

As mentioned before, technical surfaces are far from being atomically smooth. Therefore, regarding surface roughness in the scope of the paper, a classification of firstly atomic and secondly technical roughness is required. Technically, rough surfaces are the focus of this paper. They are the result of mechanical surface treatment such as grinding, honing or lapping, where the latter is rarely used for cost reasons. When grinding, the technical surface roughness is of the order of 0.2 to 0.8 ![]() $\mathrm {\mu }$m. Honed surfaces achieve surface roughness of the order of 0.1 to 0.65

$\mathrm {\mu }$m. Honed surfaces achieve surface roughness of the order of 0.1 to 0.65 ![]() $\mathrm {\mu }$m. A surface roughness of up to 10 nm is achieved by lapping, cf. Gomeringer et al. (Reference Gomeringer, Kilgus, Menges, Oesterle, Rapp, Scholer, Stenzel, Stephan and Wieneke2019). Technical roughnesses are thus in the range 10 nm to 1

$\mathrm {\mu }$m. A surface roughness of up to 10 nm is achieved by lapping, cf. Gomeringer et al. (Reference Gomeringer, Kilgus, Menges, Oesterle, Rapp, Scholer, Stenzel, Stephan and Wieneke2019). Technical roughnesses are thus in the range 10 nm to 1 ![]() $\mathrm {\mu }$m. With the SLT the surfaces are lapped and the arithmetic mean roughness is below 10 nm, cf. § 4.

$\mathrm {\mu }$m. With the SLT the surfaces are lapped and the arithmetic mean roughness is below 10 nm, cf. § 4.

Atomically rough surfaces show roughness of the order of only 1 to 10 nm. This low roughness often requires a chemical surface treatment, which usually cannot be used in technical systems for environmental reasons (Zhu & Granick Reference Zhu and Granick2002; Bonaccurso et al. Reference Bonaccurso, Butt and Craig2003; Granick, Zhu & Lee Reference Granick, Zhu and Lee2003; Vinogradova & Yakubov Reference Vinogradova and Yakubov2006). The so far investigated surface roughnesses ranged from 0.2 to ![]() $6.0\, \mathrm {nm}$ (Zhu & Granick Reference Zhu and Granick2002), or 0.7 to

$6.0\, \mathrm {nm}$ (Zhu & Granick Reference Zhu and Granick2002), or 0.7 to ![]() $12.2\, \mathrm {nm}$ (Bonaccurso et al. Reference Bonaccurso, Butt and Craig2003). The results reported for those surfaces are somewhat contradictory, e.g. increasing or decreasing slip with or without surface roughness (Bonaccurso et al. Reference Bonaccurso, Butt and Craig2003; Granick et al. Reference Granick, Zhu and Lee2003; Zhu & Granick Reference Zhu and Granick2002). A detailed list of research on the influence of nano-scale surface roughness can be found in the review articles by Neto et al. (Reference Neto, Evans, Bonaccurso, Butt and Craig2005), Cao et al. (Reference Cao, Sun, Chen and Guo2009) and Vinogradova & Belyaev (Reference Vinogradova and Belyaev2011).

$12.2\, \mathrm {nm}$ (Bonaccurso et al. Reference Bonaccurso, Butt and Craig2003). The results reported for those surfaces are somewhat contradictory, e.g. increasing or decreasing slip with or without surface roughness (Bonaccurso et al. Reference Bonaccurso, Butt and Craig2003; Granick et al. Reference Granick, Zhu and Lee2003; Zhu & Granick Reference Zhu and Granick2002). A detailed list of research on the influence of nano-scale surface roughness can be found in the review articles by Neto et al. (Reference Neto, Evans, Bonaccurso, Butt and Craig2005), Cao et al. (Reference Cao, Sun, Chen and Guo2009) and Vinogradova & Belyaev (Reference Vinogradova and Belyaev2011).

Regarding the isotropic roughness of technically relevant surfaces being of the order of ![]() $10\, \mathrm {nm}$ to 1

$10\, \mathrm {nm}$ to 1 ![]() $\mathrm {\mu }$m (see figure 2), surface roughness and also wall slip will be characterised by averaging over a representative and sufficiently large distance or area. Following this paradigm, the measurement of slip length of technically rough surfaces will also be integrally averaged. This requires that the process-specific characteristic length for measuring slip length shall be at least as large as the demanded length or surface area for determining the surface roughness. Otherwise, the measured slip length would not be objective, i.e. independent of the sample and operator.

$\mathrm {\mu }$m (see figure 2), surface roughness and also wall slip will be characterised by averaging over a representative and sufficiently large distance or area. Following this paradigm, the measurement of slip length of technically rough surfaces will also be integrally averaged. This requires that the process-specific characteristic length for measuring slip length shall be at least as large as the demanded length or surface area for determining the surface roughness. Otherwise, the measured slip length would not be objective, i.e. independent of the sample and operator.

With regard to the most commonly used techniques, almost all of them measure slip length using small characteristic length scales of the order of 10 ![]() $\mathrm {\mu }$m. Therefore, all presented techniques are inadequate for the determination of slip length in technically relevant rough surfaces.

$\mathrm {\mu }$m. Therefore, all presented techniques are inadequate for the determination of slip length in technically relevant rough surfaces.

Non-isotropic, i.e. structured, surfaces, which are considered e.g. in the work of Steinberger et al. (Reference Steinberger, Cottin-Bizonne, Kleimann and Charlaix2007), are not the focus of this work.

2.2.3. Temperature dependence of wall slip

In the reviews by Bocquet & Barrat (Reference Bocquet and Barrat2007) and Lauga et al. (Reference Lauga, Brenner and Stone2007), the molecular scale for wall slip was highlighted. Indeed, one task of this paper is to discuss wall slip from a molecular point of view based on rate theory (§ 3.1). This will give us an insight into the relation between the activation energy for slip and shear and will help us to discuss the experimental results.

It appears that Tolstoi (Blake Reference Blake1990) was the first to quantify the effect of surface energies on wall slip at the molecular level. According to Blake (Reference Blake1990), Tolstoi evaluated the relation between molecular layers and surface energies and how it changes near a solid–fluid interface. The Tolstoi model quantifies the slip length as a function of contact angle. According to the Tolstoi model, the slip length would decrease with increasing temperature, which is consistent with the experimental and theoretical results of the present work. Andrienko, Dünweg & Vinogradova (Reference Andrienko, Dünweg and Vinogradova2003) presented an alternative perspective for the dependence of slip length on temperature in terms of a prewetting transition, which is not considered further here.

Pelz & Corneli (Reference Pelz and Corneli2021) based an argument on dimensional analysis combined with an Arrhenius rate equation to relate the activation energy for bulk shear ![]() $E_\mu$ and wall slip

$E_\mu$ and wall slip ![]() $E_{\lambda }$. The authors proposed to derive

$E_{\lambda }$. The authors proposed to derive ![]() $E_\mu$ and

$E_\mu$ and ![]() $E_{\lambda }$ and hence also the activation energy for the friction factor,

$E_{\lambda }$ and hence also the activation energy for the friction factor, ![]() $E_f=E_\mu -E_{\lambda }$ (cf. § 2.1 for the definition of the friction factor and § 3 for the relation of the different activation energies), by employing an Arrhenius plot for the dynamic viscosity

$E_f=E_\mu -E_{\lambda }$ (cf. § 2.1 for the definition of the friction factor and § 3 for the relation of the different activation energies), by employing an Arrhenius plot for the dynamic viscosity ![]() $\mu (T)$ and the slip length

$\mu (T)$ and the slip length ![]() $\lambda (T)$.

$\lambda (T)$.

Alternatively, and independently of arguments based on the Bridgman postulate, in this article we develop the Eyring model for wall slip to make a statement about the relation between the activation energies ![]() $E_\mu$,

$E_\mu$, ![]() $E_{\lambda }$,

$E_{\lambda }$, ![]() $E_f$, of which, from a phenomenological point of view, only two are independent due to the relationship

$E_f$, of which, from a phenomenological point of view, only two are independent due to the relationship ![]() $E_f=E_\mu -E_{\lambda }$. The Eyring model for wall slip for non-polar molecules leads to

$E_f=E_\mu -E_{\lambda }$. The Eyring model for wall slip for non-polar molecules leads to ![]() $E_{\lambda }\approx 0.5 E_\mu$. Hence, both viscosity and slip length decrease with increasing temperature, consistent with the experimental findings in this paper and the Tolstoi model. This decrease of slip length with increasing temperature is also a result of recent MD simulations by Mehrnia & Pelz (Reference Mehrnia and Pelz2021).

$E_{\lambda }\approx 0.5 E_\mu$. Hence, both viscosity and slip length decrease with increasing temperature, consistent with the experimental findings in this paper and the Tolstoi model. This decrease of slip length with increasing temperature is also a result of recent MD simulations by Mehrnia & Pelz (Reference Mehrnia and Pelz2021).

Hénot et al. (Reference Hénot, Grzelka, Zhang, Mariot, Antoniuk, Drockenmuller, Léger and Restagno2018) measured slip length as a function of shear rate for three polymers of different molecular weights utilising a velocimetry technique based on photobleaching. The authors report an increasing slip length with increasing temperature for the non-Newtonian fluid considered. This contradicts the results obtained for Newtonian fluids in this paper. This might be due to the fact that Hénot et al. (Reference Hénot, Grzelka, Zhang, Mariot, Antoniuk, Drockenmuller, Léger and Restagno2018) analysed bulk shear and wall slip of polymer liquids of large molecular weight and not Newtonian fluids of rather small molecular weight, as is the case in this paper. For amorphous polymeric liquids near their glass transition temperature it is well known that the temperature dependence of the bulk viscosity is given by the Williams–Landel–Ferry (WLF) equation and not the Arrhenius equation and it is expected that the temperature dependence of wall slip would be described by a WLF equation as well. Besides this, it was concluded using the relation ![]() $E_f=E_\mu -E_{\lambda }$ that either an increase or a decrease in the slip length with respect to the temperature is to be expected (Pelz & Corneli Reference Pelz and Corneli2021; Hénot et al. Reference Hénot, Grzelka, Zhang, Mariot, Antoniuk, Drockenmuller, Léger and Restagno2018). The experiments presented in this paper, the Eyring model adapted for wall slip (§ 3.1), Tolstoi's model and the MD simulations all predict a decrease in slip length with increasing temperature for hydrocarbon lubricants in the Newtonian regime.

$E_f=E_\mu -E_{\lambda }$ that either an increase or a decrease in the slip length with respect to the temperature is to be expected (Pelz & Corneli Reference Pelz and Corneli2021; Hénot et al. Reference Hénot, Grzelka, Zhang, Mariot, Antoniuk, Drockenmuller, Léger and Restagno2018). The experiments presented in this paper, the Eyring model adapted for wall slip (§ 3.1), Tolstoi's model and the MD simulations all predict a decrease in slip length with increasing temperature for hydrocarbon lubricants in the Newtonian regime.

2.2.4. Non-Newtonian fluids

As with the paper of Hénot et al. (Reference Hénot, Grzelka, Zhang, Mariot, Antoniuk, Drockenmuller, Léger and Restagno2018) in terms of the temperature dependence of slip length, most of the research was carried out for non-Newtonian fluids (Yoshimura & Prud'homme Reference Yoshimura and Prud'homme1987; Hatzikiriakos & Dealy Reference Hatzikiriakos and Dealy1991). Hatzikiriakos & Dealy (Reference Hatzikiriakos and Dealy1992) investigated wall slip in a plate–plate tribometer with a non-Newtonian polymer flow to find the relationship between wall slip and shear stress. They stated that wall slip happens above a critical shear stress and it increases with increasing temperature. Andrienko et al. (Reference Andrienko, Dünweg and Vinogradova2003) measured the slip length as a function of temperature for a polymer mixture while the system was under a prewetting transition. Results revealed that the slip length reduces with the temperature rising after the prewetting transition.

2.3. Wall slip in tribology

The focus in tribology is mostly on the theoretical determination of the load capacity and friction of components such as slider and journal bearings under wall slip. In the research area of tribology, wall slip is sometimes regarded with altered shear stress at the wall (Shukla, Kumar & Chandra Reference Shukla, Kumar and Chandra1980; Ma, Wu & Zhou Reference Ma, Wu and Zhou2007; Xie et al. Reference Xie, Rao, Ta-Na, Liu and Chen2016; Xie, Ta & Rao Reference Xie, Ta and Rao2017). Here, Stokes’ no-slip boundary condition is the reference case. Spikes (Reference Spikes2003) used a concept of altered shear stress at the wall to describe a slider bearing with slip occurring at the upper but not the lower wall. By doing this, the author derives a form of Reynolds’ equation in which slip is considered at one of the surfaces. The concept of altered shear stress is not mis-matched with a yield stress of a Bingham medium.

Shukla et al. (Reference Shukla, Kumar and Chandra1980) derived a generalised form of Reynolds’ equation for liquid lubrication regarding an assumed viscosity variation in the gap and considering slip at the bearing surfaces. Cui et al. (Reference Cui, Le, Fillon and Zhang2021) studied the effect of coatings on the behaviour of plain journal bearings, considering wall slip occurring at the interface between oil and substrate, using a slip model introduced by Spikes & Granick (Reference Spikes and Granick2003).

Besides the theoretical work in the field of tribology, there is so far a lack of experimentally determined input data for wall slip, e.g. in the form of measured slip lengths at technically relevant interfaces. In the research area of tribology, integral measurement principles are employed mainly for non-Newtonian fluids.

2.3.1. Integral measurement principles

Cheikh & Koper (Reference Cheikh and Koper2003) employed a capillary to measure wall slip, similar to the historic work of Poiseuille. Since the pressure difference between the inlet and outlet of a capillary expresses the integral of the wall shear stress, it is, in fact, an integral measurement principle as well. Since it is hard to characterise the interface between solid and fluid insight the capillary with regard to surface roughness, a plate–plate topology is preferred in our work.

In tribology (and rheology) co-axial rotating plate–plate or plate–cone devices are common and were used to measure wall slip, especially for non-Newtonian fluids, cf. Henson & Mackay (Reference Henson and Mackay1995), Lee, Choi & Kim (Reference Lee, Choi and Kim2008) and Ming et al. (Reference Ming, Jian, Chunxia, Xiaokang and Lan2011). Henson & Mackay (Reference Henson and Mackay1995) used a plate–plate rheometer to investigate slip of monodisperse polystyrene melts. The discs, each of diameter 7.9 mm, were manufactured from titanium alloy and stainless steel. Lee et al. (Reference Lee, Choi and Kim2008) experimentally studied the effect of geometric parameters of a grooved and holed patterned hydrophobic surface on the liquid slip with a parallel plate geometry in a commercial torsional cone–plate rheometer. It should be noted that the measured slip length using a standard plate–plate or cone–plate rheometer is typically associated with high measurement uncertainty. For instance, Ming et al. (Reference Ming, Jian, Chunxia, Xiaokang and Lan2011) used a plate–plate rheometer to measure the slip length of glycerin solution moving relative to a superhydrophobic surface coated with carbon nanotube forests. From the diagrams shown by Ming et al. (Reference Ming, Jian, Chunxia, Xiaokang and Lan2011), the uncertainty of the slip length measured by them is approximately 2.8 ![]() $\mathrm {\mu }$m. This uncertainty is of the same order of magnitude as the gap height. It must therefore be concluded that standard and available plate–plate rheometers are not suitable for measuring wall slip in terms of uncertainty.

$\mathrm {\mu }$m. This uncertainty is of the same order of magnitude as the gap height. It must therefore be concluded that standard and available plate–plate rheometers are not suitable for measuring wall slip in terms of uncertainty.

Still, the advantage of the integral measurement principle is that averaging over the technical surface roughness is immanent. Therefore, the SLT presented in § 4.1 also uses this averaging, which is inherent in every classical rheometer. The SLT is to be understood as a sophisticated further development of a plate–plate rheometer. The further development offers five specific advantages: firstly, the SLT is robust against kinematic disturbances such as misalignment of the plates, due to the classical fixed and floating bearings of the drive side and the jewel bearing of the driven side. By this means, the two plates on the drive and driven side position themselves naturally parallel to each other due to the levelling effect of the pressure distribution within the gap. Secondly, the SLT is robust with regard to temperature disturbances, e.g. due to dissipation, due to the superimposition of the circumferential Couette flow needed for the measurement of wall slip and bulk shear and the radial Poiseuille flow needed for separating the plates and ensuring a constant temperature. Thirdly, wall slip and bulk shear are measured simultaneously with the SLT offering a convenient means to detect errors. Fourthly, the complete automation of the measurement process allows for a high number of measurement repetitions, making the stochastic measurement uncertainty negligible. Fifth, automation keeps the risk of operator error small. As a result, the formerly mentioned stochastic uncertainties, i.e. noise, are reduced significantly, cf. § 4.5.

2.4. Conclusion of the literature review

As revealed by the literature review, the two disciplines, i.e. nanofluidics and tribology, focus on the same phenomenon from two different directions. Furthermore, it becomes clear that integral measurement principles such as plate–plate rheometers are well suited for measuring wall slip on technically rough surfaces. However, for relevant rough surfaces, there is no measurement device for objectively determining the slip length at different temperatures available at the moment. In fact, Cao et al. (Reference Cao, Sun, Chen and Guo2009) stated that there is a general need to develop new experimental techniques to overcome the uncertainty when measuring nano-scale effects near liquid–solid surfaces. To comply with this request, the SLT is introduced in § 4. Before the detailed description of the SLT, however, we discuss wall slip from the point of view of rate theory. This leads to the conclusion that the activation energy for wall slip ![]() $E_{\lambda }$ in a mixture of non-polar hydrocarbon molecules is expected to be only approximately half of the activation energy for bulk shear,

$E_{\lambda }$ in a mixture of non-polar hydrocarbon molecules is expected to be only approximately half of the activation energy for bulk shear, ![]() $E_{\lambda }\approx 0.5E_\mu$. This is, in fact, validated by our experiments, cf. § 5.

$E_{\lambda }\approx 0.5E_\mu$. This is, in fact, validated by our experiments, cf. § 5.

3. Generalised Eyring model for wall slip and activation energy for shear and slip

As shear takes place in the bulk and slip at the wall, the starting points are the two phenomenological constitutive relations, first Newton's law for the shearing motion of two fluid layers and second Navier's law for slip of a fluid layer relative to a wall. For a Newtonian flow, Newton (Reference Newton1687) described the response of a fluid to shear stress ![]() $\tau$ in the constitutive law

$\tau$ in the constitutive law

The response is a shear rate ![]() $\dot {\gamma }$ that is, for a Newtonian fluid, proportional to the shear stress

$\dot {\gamma }$ that is, for a Newtonian fluid, proportional to the shear stress ![]() $\tau$. The shear rate is a measure of the relative velocity

$\tau$. The shear rate is a measure of the relative velocity ![]() $\Delta u = a\dot {\gamma }$ of two adjacent fluid layers separated by the normal distance

$\Delta u = a\dot {\gamma }$ of two adjacent fluid layers separated by the normal distance ![]() $a$. The viscometric function, the dynamic viscosity

$a$. The viscometric function, the dynamic viscosity ![]() $\mu (T)$, is already needed on dimensional grounds. The viscosity is a function of the molecules’ activation, the inner energy measured by the absolute temperature

$\mu (T)$, is already needed on dimensional grounds. The viscosity is a function of the molecules’ activation, the inner energy measured by the absolute temperature ![]() $T$. On statistical grounds and heuristic arguments, Eyring derived the Arrhenius function,

$T$. On statistical grounds and heuristic arguments, Eyring derived the Arrhenius function, ![]() $\mu (T)\propto \exp (E_\mu /\mathcal {R}\,T)$, arguing that the activation energy for shear

$\mu (T)\propto \exp (E_\mu /\mathcal {R}\,T)$, arguing that the activation energy for shear ![]() $E_\mu$ is the difference of two Gibbs free energies in the context of transition state theory (Bird, Stewart & Lightfoot Reference Bird, Stewart and Lightfoot2007);

$E_\mu$ is the difference of two Gibbs free energies in the context of transition state theory (Bird, Stewart & Lightfoot Reference Bird, Stewart and Lightfoot2007); ![]() $\mathcal {R}$ is the universal gas constant.

$\mathcal {R}$ is the universal gas constant.

The second phenomenological constitutive relation is Navier's slip law (Navier Reference Navier1822), see § 2.1

The response of the fluid near the wall to a shear stress ![]() $\tau$ is a slip velocity

$\tau$ is a slip velocity ![]() $w$. The viscometric function is the friction factor

$w$. The viscometric function is the friction factor ![]() $f(T)$. Helmholtz & von Piotrowski (Reference Helmholtz and von Piotrowski1860) introduced the slip length

$f(T)$. Helmholtz & von Piotrowski (Reference Helmholtz and von Piotrowski1860) introduced the slip length

It is the task of this section to derive ![]() $f(T)\propto \exp (E_f/\mathcal {R}T)$ and

$f(T)\propto \exp (E_f/\mathcal {R}T)$ and ![]() $\lambda (T)\propto \exp (E_{\lambda }/\mathcal {R}T)$ and discuss the relation of activation energy for shear

$\lambda (T)\propto \exp (E_{\lambda }/\mathcal {R}T)$ and discuss the relation of activation energy for shear ![]() $E_\mu$ and slip

$E_\mu$ and slip ![]() $E_f$,

$E_f$, ![]() $E_{\lambda }$. Due to (3.3), the activation energies are related by

$E_{\lambda }$. Due to (3.3), the activation energies are related by

Here, ![]() $E_\mu$ is usually derived by viscosity measurements at different temperatures, or it may be estimated by the evaporation temperature

$E_\mu$ is usually derived by viscosity measurements at different temperatures, or it may be estimated by the evaporation temperature ![]() $T_v$ using the relation

$T_v$ using the relation

(Bird et al. Reference Bird, Stewart and Lightfoot2007).

The results of the following section are threefold:

(i) The slip length derives the concise result

$\lambda (T) = a \exp (E_{\lambda } / \mathcal {R}T)$.

$\lambda (T) = a \exp (E_{\lambda } / \mathcal {R}T)$.(ii) The slip length scales with the distance between two molecule layers

$a$, i.e. the effective molecular size.

$a$, i.e. the effective molecular size.(iii) For a weak interaction of the molecules with the solid wall, we derive

$E_{\lambda }\approx 0.5 \, E_\mu$. This will be validated by the experimental results shown in § 5 (see figure 11 and table 2).

$E_{\lambda }\approx 0.5 \, E_\mu$. This will be validated by the experimental results shown in § 5 (see figure 11 and table 2).

Table 2. The table gives the quadruple ![]() $[\mu (T_0),E_\mu,\lambda (T_0 ),E_{\lambda }]$ for each of the four investigated oils measured by the SLT. The reference temperature is

$[\mu (T_0),E_\mu,\lambda (T_0 ),E_{\lambda }]$ for each of the four investigated oils measured by the SLT. The reference temperature is ![]() $T_0 = 313.15\,\mathrm {K}$,

$T_0 = 313.15\,\mathrm {K}$, ![]() $\varTheta _0 = 40 \, ^\circ \mathrm {C}$. In addition, for verification purposes the dynamic viscosity

$\varTheta _0 = 40 \, ^\circ \mathrm {C}$. In addition, for verification purposes the dynamic viscosity ![]() $\mu _{ref}(T_0)$ as well as the activation energy for bulk shear

$\mu _{ref}(T_0)$ as well as the activation energy for bulk shear ![]() $E_{\mu,{ref}}$ of the four oils obtained by a capillary rheometer is given.

$E_{\mu,{ref}}$ of the four oils obtained by a capillary rheometer is given.

3.1. Eyring model for bulk shear and wall slip

Recapturing bulk shear, based on well-known literature, e.g. Bird et al. (Reference Bird, Stewart and Lightfoot2007), we discuss the similarity and difference of shear and slip. Eyring (Reference Eyring1935) developed an understanding of viscous friction based on the Eyring rate equation

The introduced rate may be seen as a generalisation (Pollak & Talkner Reference Pollak and Talkner2005) of the Arrhenius (Reference Arrhenius1889) rate

Often only relative rates are of interest. Therefore, the prefactor is often eliminated (Pollak & Talkner Reference Pollak and Talkner2005).

In the rate equation (3.6), ![]() $k_B$ is the Boltzmann and

$k_B$ is the Boltzmann and ![]() $\hslash$ the Planck constant, whereas

$\hslash$ the Planck constant, whereas ![]() $E$ is the molar free energy of activation. This is the Gibbs free energy at a transition state minus the minimal Gibbs free energy along the reaction path. In the context of the Arrhenius equation, this energy is often called the activation energy, a term we prefer due to its widespread usage, although it is somewhat less precise.

$E$ is the molar free energy of activation. This is the Gibbs free energy at a transition state minus the minimal Gibbs free energy along the reaction path. In the context of the Arrhenius equation, this energy is often called the activation energy, a term we prefer due to its widespread usage, although it is somewhat less precise.

Figure 3(a) shows the Eyring model of bulk shear. The effective molecular size is given by the distance ![]() $a$ of the cages and holes. The heuristic model reads as follows: a molecule is usually trapped in a cage. By thermal activation, it may escape through a bottleneck into a hole at a distance

$a$ of the cages and holes. The heuristic model reads as follows: a molecule is usually trapped in a cage. By thermal activation, it may escape through a bottleneck into a hole at a distance ![]() $a$. The bottleneck is due to the adjacent molecules in the upper or lower molecular layer. The jumps take place with a rate

$a$. The bottleneck is due to the adjacent molecules in the upper or lower molecular layer. The jumps take place with a rate ![]() $k$ being different for shear and slip. The shear stress

$k$ being different for shear and slip. The shear stress ![]() $\tau$ reasons the non-equilibrium and hence asymmetry of the process with regard to forward (index

$\tau$ reasons the non-equilibrium and hence asymmetry of the process with regard to forward (index ![]() $+$) and backward (index

$+$) and backward (index ![]() $-$) jumps. The kinematic response is the velocity difference between two molecule layers. It is the effective molecular size

$-$) jumps. The kinematic response is the velocity difference between two molecule layers. It is the effective molecular size ![]() $a$ multiplied with the net rate, i.e.

$a$ multiplied with the net rate, i.e.

Figure 3. (a) Eyring model for bulk shear. The sketch (a) is adapted from the figure shown in Bird et al. (Reference Bird, Stewart and Lightfoot2007); (b) wall slip near a solid wall.

The energy equation formulated for one mole of molecules (the number of molecules is given by the Avogadro constant ![]() $N_A$) occupying the molar volume

$N_A$) occupying the molar volume ![]() $V_m$ moving forward or backward reads

$V_m$ moving forward or backward reads

Here, ![]() $E_\mu$ is the activation energy for the fluid at rest. Hence, the constitutive relation between shear rate and shear stress is derived in the Eyring model as

$E_\mu$ is the activation energy for the fluid at rest. Hence, the constitutive relation between shear rate and shear stress is derived in the Eyring model as

For ![]() $\tau V_m \ll \mathcal {R}T$ the dynamic viscosity is given by

$\tau V_m \ll \mathcal {R}T$ the dynamic viscosity is given by

For practical application, (3.9) is used in the equivalent form, i.e. the time–temperature shift factor

As was mentioned earlier, due to the relative formulation the prefactor ![]() $\hslash N_A/V_m$ is eliminated. Here,

$\hslash N_A/V_m$ is eliminated. Here, ![]() $\mu _0=\mu (T_0)$ is the dynamic viscosity at a reference temperature. The activation energy is determined by an Arrhenius graph, i.e. a semilogarithmic plot of the viscosity ratio vs the inverse temperature (see figure 11).

$\mu _0=\mu (T_0)$ is the dynamic viscosity at a reference temperature. The activation energy is determined by an Arrhenius graph, i.e. a semilogarithmic plot of the viscosity ratio vs the inverse temperature (see figure 11).

With the schematic shown in figure 3(b) the transfer to wall slip is straightforward but new. From the heuristic model, it is made evident by replacing ![]() $\Delta u$ by the slip velocity

$\Delta u$ by the slip velocity ![]() $w$. Besides this, the interpretation and the complete derivation remains unchanged, yielding

$w$. Besides this, the interpretation and the complete derivation remains unchanged, yielding

For ![]() $\tau V_m \ll \mathcal {R}T$ the friction factor is derived as

$\tau V_m \ll \mathcal {R}T$ the friction factor is derived as

The result is more concise and easy to remember using the slip length. Since the slip length is a relative quantity, i.e. the ratio of two dynamic viscometric functions, the prefactor ![]() $\hslash N_A/V_m$ is eliminated, yielding with (3.3),

$\hslash N_A/V_m$ is eliminated, yielding with (3.3),

From this result and the model, we draw several conclusions: first, the slip length scales with the effective molecular length ![]() $a$. A result that is evident on dimensional grounds and in accordance with Bocquet & Barrat (Reference Bocquet and Barrat2007) and Lauga et al. (Reference Lauga, Brenner and Stone2007). Second, comparing the two schematic illustrations in figure 3(a,b) it is evident that the two bottlenecks for shear and slip differ, since for the latter there are only a few or even no molecules trapped in the near-wall holes. For an oil–metal interface, this is likely the case for a mixture of non-polar hydrocarbon molecules typically used in technical applications. We expect

$a$. A result that is evident on dimensional grounds and in accordance with Bocquet & Barrat (Reference Bocquet and Barrat2007) and Lauga et al. (Reference Lauga, Brenner and Stone2007). Second, comparing the two schematic illustrations in figure 3(a,b) it is evident that the two bottlenecks for shear and slip differ, since for the latter there are only a few or even no molecules trapped in the near-wall holes. For an oil–metal interface, this is likely the case for a mixture of non-polar hydrocarbon molecules typically used in technical applications. We expect ![]() $E_f$ to be smaller than

$E_f$ to be smaller than ![]() $E_\mu$. In fact,

$E_\mu$. In fact, ![]() $E_f\approx 0.5 E_\mu$ should hold for non-polar molecules, since only half of the molecules contribute to the bottleneck. Again, for experiments and applications typically the relative formulation

$E_f\approx 0.5 E_\mu$ should hold for non-polar molecules, since only half of the molecules contribute to the bottleneck. Again, for experiments and applications typically the relative formulation

with ![]() $\lambda _0 = \lambda (T_0)$ is used being the slip length at a reference temperature. The activation energy

$\lambda _0 = \lambda (T_0)$ is used being the slip length at a reference temperature. The activation energy ![]() $E_{\lambda }$ may be determined again by plotting the logarithm of the time–temperature shift factor for wall slip vs

$E_{\lambda }$ may be determined again by plotting the logarithm of the time–temperature shift factor for wall slip vs ![]() $1/T$ (see figure 11). With

$1/T$ (see figure 11). With ![]() $E_f \approx E_\lambda\approx 0.5 E_\mu$ and (3.5) a first guess for the activation energy of wall slip would be

$E_f \approx E_\lambda\approx 0.5 E_\mu$ and (3.5) a first guess for the activation energy of wall slip would be

for molecules with no affinity to the wall.

The result ![]() $E_{\lambda }=E_\mu -E_f\approx 0.5 \, E_\mu$ is indeed confirmed by the experimental results for the non-polar hydrocarbons presented in § 5 (see figure 11 and table 2). We will further show how the Eyring model for wall slip proposed here serves to determine the effective molecular size

$E_{\lambda }=E_\mu -E_f\approx 0.5 \, E_\mu$ is indeed confirmed by the experimental results for the non-polar hydrocarbons presented in § 5 (see figure 11 and table 2). We will further show how the Eyring model for wall slip proposed here serves to determine the effective molecular size ![]() $a$ as well as the molar volume

$a$ as well as the molar volume ![]() $V_m$ based on the SLT presented in the following section.

$V_m$ based on the SLT presented in the following section.

4. Slip length tribometer

In order to provide adequate viscometric functions ![]() $\lambda (T)$ and

$\lambda (T)$ and ![]() $\mu (T)$ at different absolute temperatures

$\mu (T)$ at different absolute temperatures ![]() $T$ (relative temperature

$T$ (relative temperature ![]() $\varTheta =T-273.15$ K), the present section presents and discusses a newly developed integral measurement apparatus, the SLT. Here, we use Helmholtz’ concept of slip length, which is consistent with Navier's constitutive relation between wall shear stress and relative slip velocity. Our preference originates from the fact that the slip length can be graphically interpreted as an effective increase in gap clearance, cf. figure 5. Subsequently and similar to the concept of the DSFA, the slip length is obtained via extrapolation. In addition, the SLT allows the synchronous measurement of wall slip and bulk shear in a technical relevant temperature range for relevant rough surfaces. Therefore, the introduced SLT is reliable and unique for measuring the temperature-dependent slip length of atomically smooth, atomically rough as well as of technically rough surfaces. Being an integral measurement method makes it valuable for gaining insight into technically relevant fluid–solid interfaces.

$\varTheta =T-273.15$ K), the present section presents and discusses a newly developed integral measurement apparatus, the SLT. Here, we use Helmholtz’ concept of slip length, which is consistent with Navier's constitutive relation between wall shear stress and relative slip velocity. Our preference originates from the fact that the slip length can be graphically interpreted as an effective increase in gap clearance, cf. figure 5. Subsequently and similar to the concept of the DSFA, the slip length is obtained via extrapolation. In addition, the SLT allows the synchronous measurement of wall slip and bulk shear in a technical relevant temperature range for relevant rough surfaces. Therefore, the introduced SLT is reliable and unique for measuring the temperature-dependent slip length of atomically smooth, atomically rough as well as of technically rough surfaces. Being an integral measurement method makes it valuable for gaining insight into technically relevant fluid–solid interfaces.

4.1. Measurement principle of the SLT

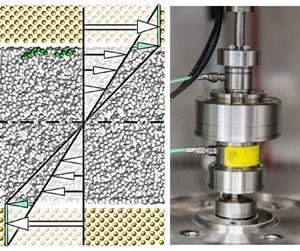

To overcome the drawbacks and end up with a robust apparatus that is applicable for quantifying viscosity and slip length simultaneously for technical lubrication gaps at relevant temperatures, the SLT was designed, cf. figure 4.

Figure 4. (a) Schematic sketch of the SLT; disk radius ![]() $R = 32\, \mathrm {mm}$). The temperature is controlled by tempering the rheometer as well as the fluid in a temperature test chamber. The volume flow

$R = 32\, \mathrm {mm}$). The temperature is controlled by tempering the rheometer as well as the fluid in a temperature test chamber. The volume flow ![]() $Q$ allows a constant temperature within the narrow gap. (b) Photograph of the SLT.

$Q$ allows a constant temperature within the narrow gap. (b) Photograph of the SLT.

Consisting of two circular plates, the SLT uses the fact that for a Couette flow the true gap height ![]() $h$ of a technical lubrication gap is effectively increased by twice the slip length (see figure 5a). To determine the slip length, the real gap height between the upper rotating disk and the lower stationary one as well as the transmitted frictional torque

$h$ of a technical lubrication gap is effectively increased by twice the slip length (see figure 5a). To determine the slip length, the real gap height between the upper rotating disk and the lower stationary one as well as the transmitted frictional torque ![]() $M$ by the flow from the upper to the lower plate is measured. By plotting the inverse torque

$M$ by the flow from the upper to the lower plate is measured. By plotting the inverse torque ![]() $M^{-1}$ vs the measured true gap height

$M^{-1}$ vs the measured true gap height ![]() $h$, originating at the lower disk surface, all measurement points

$h$, originating at the lower disk surface, all measurement points ![]() $x_i = h_i,y_i=M_i^{-1}$, with

$x_i = h_i,y_i=M_i^{-1}$, with ![]() $i$ being the index of the measurement point, fall on a straight line