Article contents

Influence of dealloying solution on the microstructure of nanoporous copper through chemical dealloying of Al75Cu25 ribbons

Published online by Cambridge University Press: 20 April 2020

Abstract

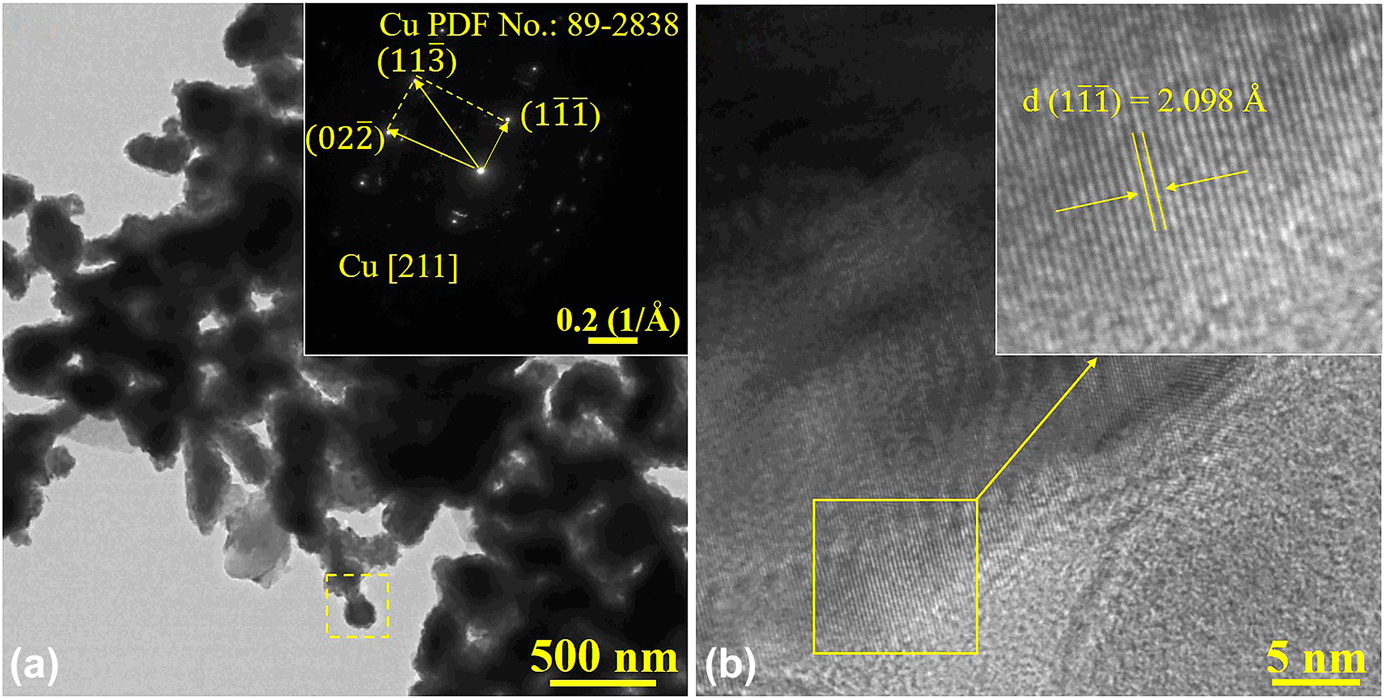

In this article, Al75Cu25 (at.%) ribbons were dealloyed by HCl, H2C2O4, H3PO4, and NaOH solutions, respectively, to prepare nanoporous copper (NPC). The dealloying behavior is varied with dealloying solutions, allowing modulating the microstructure and porosity of the NPC. Al75Cu25 ribbons are fully dealloyed in HCl, H2C2O4, and NaOH solutions, whereas they are partially dealloyed in H3PO4 solution. Except the NPC prepared in the NaOH solution, no obvious cracks are traced in other samples. The surface diffusivity (Ds) of Cu atoms along the alloy/solution interfaces is varied with solutions, producing the NPC with different microstructure. NPC with higher specific surface area can be obtained by dealloying the Al75Cu25 ribbons in the HCl solution. Compared with the dealloying in H2C2O4, H3PO4, and NaOH solutions, the dealloying in 10 wt% HCl solution for 25 min at 90 ± 1 °C facilitates the best NPC in this work.

- Type

- Article

- Information

- Journal of Materials Research , Volume 35 , Issue 19: Focus Issue: Porous Metals: From Nano to Macro , 14 October 2020 , pp. 2610 - 2619

- Copyright

- Copyright © Materials Research Society 2020

References

- 5

- Cited by