Introduction

Reporting on sustainability metrics and ‘achievements’ is becoming the norm for businesses, with the concept of reaching ‘net zero’ being an integral strategy within the global narrative around tackling climate change (Fankhauser et al., Reference Fankhauser, Smith, Allen, Axelsson, Hale and Hepburn2022). Net zero pledges have emerged in rapid succession from governments (UK Government 2021), companies (BP 2020) and across wider financial systems (NGFS 2021), becoming a vital component of the rhetoric concerning climate change, including across the agricultural sector, which contributes at least 8.5% of global greenhouse gas emissions (Shukla et al. Reference Shukla, Skea, Calvo Buendia, Masson-Delmotte, Pörtner and Roberts2019). Net zero involves the reduction of emissions to as close to zero as possible, with sinks (both natural and artificial) being used to offset the remainder. The process of moving towards net zero, whether at a country or company level, requires a number of vital steps, from commitment through to action, but critical is the stage of counting and analysing emissions.

With the transition from net zero as a policy to implementation, it has been increasingly realized that its implementation is challenging and that the guidance and methodologies for carbon accounting across all sectors are not equal. Hale et al. (Reference Hale, Smith, Black, Cullen, Fay, Lang and Mahmood2021) highlighted concerns over the credibility of the net zero targets currently being rapidly adopted globally; the concept of net zero ‘is still in its infancy’. While the simplicity of the concept makes it attractive as a policy, the reality of its implementation is much more complex. Most literature regarding net zero is focused on the creation of policies and much less on the actual logistics of implementation (Green & Reyes Reference Green and Reyes2023). Furthermore, the energy sector and net zero buildings have received the most attention, with few resources devoted to other sectors that are more difficult to measure and decarbonize (Green & Reyes Reference Green and Reyes2023). Agriculture is one such underrepresented, difficult-to-measure sector.

‘Scope 3 emissions’ – those that occur across the wider supply chain – are difficult to measure for those companies involved in complex supply chains, such as agriculture. Companies with agricultural supply chains, such as coffee traders, can measure their scope 3 emissions by ‘picking’ an off-the-shelf value for key inputs into production processes (e.g., emissions associated with exportable coffee production) or measuring and calculating these emissions at the farm level either by collecting the data themselves or via the producers. The former is easier, quicker and often less expensive but fails to capture the complexity of variation of emissions across suppliers and thus the opportunity to mitigate action through supplier choice or through action by those suppliers. The latter is more costly and also more complex, especially around questions of scope, underlying assumptions and emissions factors (EFs). This difference is particularly egregious in an industry such as coffee, for which over 80% of coffee is produced by smallholder farmers in over 50 countries (Fairtrade 2024). This results in substantial variabilities in farming practices and land-use management that have significant impacts on emissions.

Guidance for scope 3 emissions accounting in the agriculture sector is slowly emerging, with global frameworks currently being drafted. However, there is considerable uncertainty, with multiple methodologies emerging, such as the draft Greenhouse Gas (GHG) Protocol Land Sector and Removals Guidance (Greenhouse Gas Protocol 2023), and major scope for assumptions on issues such as boundaries and EFs (Noponen et al. Reference Noponen, Edwards-Jones, Haggar, Soto, Attarzadeh and Healey2012), which have huge impacts upon the final level and composition of emissions. For example, the GHG Protocol Corporate Standard ‘allows companies flexibility in choosing which, if any, scope 3 activities to include in the GHG inventory when the company defines its operational boundaries’ (Greenhouse Gas Protocol 2011). Therefore, even when following a singular standard, there may be considerable differences in the final mechanics of emissions calculations undertaken. This creates a particular challenge for businesses, who generally wish to find an efficient and easy solution to the measurement and subsequent reduction of their carbon footprint. The nature of this inherent uncertainty means that absolute accuracy is impossible, at least without significantly more resources and infrastructure than are currently available to most businesses in the agricultural sector. This is especially crucial for those businesses that view the exercise as more than a form-filling pursuit, but who want to understand the environmental, economic and social complexities in their supply chains.

These uncertainties in emissions calculations have been examined across different facets of the literature in countries such as Australia and the UK (Gibbons et al. Reference Gibbons, Ramsden and Blake2006, Thamo et al. Reference Thamo, Kingwell and Pannell2013), across various agricultural industries such as livestock (Lynch Reference Lynch2019) and in the context of particular greenhouse gases (Beusen et al. Reference Beusen, Bouwman, Heuberger, Van Drecht and Van Der Hoek2008, Reay et al. Reference Reay, Davidson, Smith, Smith, Melillo, Dentener and Crutzen2012, Xu et al. Reference Xu, Tian, Pan, Prior, Feng and Batchelor2019). A variety of methodologies and tools have emerged in recent years to aid the estimation of emissions from a variety of agricultural supply chains (e.g., Cool Farm Tool, 2024); however, these have understandably adopted particular approaches to boundaries, scope and EFs that impact the scale and composition of emissions from the relevant supply chains and thus focus attention and mitigation efforts on particular components of the supply chain. Understanding the impacts of these uncertainties (and decisions that are often subjective in nature) is vital to understanding the implications of these decisions and the types of action that may follow. It is the scale of these uncertainties involved in calculating farm-level emissions from the coffee supply chain that is investigated in this paper.

Coffee is a global agricultural commodity, encompassing over 11 million ha of land worldwide (FAO 2021). Studies agree on the sources of emissions along the coffee supply chain, with the main contributors being fertilizer production and use, degradation of the coffee cherry pulp, wastewater from processing, fuel use for transport and electricity required for running the processing mills, roasters and cafes (Coltro et al. Reference Coltro, Mourad, Oliveira, Baddini and Kletecke2006, Hergoualc’h et al. Reference Hergoualc’h, Blanchart, Skiba, Hénault and Harmand2012). Although emissions are present throughout the supply chain (Killian et al. Reference Killian, Rivera, Soto and Navichoe2013), we have focused on one component of scope 3 emissions: the upstream emissions within coffee production, where the largest uncertainties lie. Wide variation exists in the scientific and grey literature regarding methodologies for determining boundaries, assumptions, metrics and scope for emissions accounting. These discrepancies drastically alter the resulting emissions reported (–19.5 to 18.5 kg CO2e per kg exportable coffee), leading to difficulties in understanding the actual magnitude of emissions. This makes it particularly challenging for organizations across the supply chain who are looking for simple numbers on the emissions of coffee production to make a suitable choice of what values to use.

For example, although fertilizer production is a significant source of emissions for coffee production, it is not always included in the system boundary, as it takes place off the farm. Additionally, some studies include carbon sinks from carbon sequestered in biomass of soil, coffee plants and/or shade trees, while others may include one or two of these sinks, or none at all (e.g., Killian et al. Reference Killian, Rivera, Soto and Navichoe2013, Van Rikxoort et al. Reference Van Rikxoort, Schroth, Läderach and Rodríguez-Sánchez2014, Maina et al. Reference Maina, Urbanus and Mutwiwa2015, Nab & Maslin Reference Nab and Maslin2020). Net emissions are decreased if sequestered carbon is included in the carbon calculations, and this can even result in a carbon-negative system. Furthermore, some studies consider the assessment boundary to be limited to the coffee production area, while others include trees and forested areas on the property but outside the area of production. Lastly, selected EFs used to calculate the kilogram carbon equivalent values for each of these measures differ, further compounding discrepancies and uncertainties in the resulting emissions for coffee.

In this article, we will evaluate the magnitude of the impacts that these choices have on emissions results by modelling several scenarios based on data collected on smallholder coffee farms in northern Peru. We examine the emissions of smallholder farmers in isolation from the wider supply chain and system in which they operate. We acknowledge that there may be feedback loops and interactions between wider factors that could impact emissions in the coffee supply chain and beyond, but in the spirit of over a century of partial equilibrium analysis in economics, we keep all other impacts beyond the sample being analysed as fixed.

The farms in our sample were mainly monocultures of coffee or had some shade trees planted within or around the coffee, most producers used a mix of both organic and inorganic fertilizers and the coffee was processed using a mix of washed and natural methods. We will explore the impacts of these decision points on farm-level emissions by calculating the net emissions for coffee production for varying process boundaries as follows: including/excluding emissions from fertilizer production; varying metrics by including/excluding carbon sequestration from coffee plants and shade trees within the production area; and varying EFs by selecting three ranges of EF values found in the literature (low, moderate and high). Each scenario modelled represents realistic calculations that are currently used for measuring emissions for coffee production.

Methods and protocols

Study area

The study was conducted in 146 coffee farms in the mountainous region of Jaén in the department of Cajamarca in Peru (5°42’29.31’ S, 78°48’33.09’ W). The farms surveyed had an average elevation (± SE) of 1785 ± 13 m above sea level. Average annual temperature and precipitation within the region ranged from 22°C to 32°C and from 700 to 1200 mm, respectively. The rainy season lasts from December to the beginning of April.

Coffee farms in northern Peru are representative of smallholder coffee-growing systems with a range of management practices (including organic and inorganic farms, sun and shaded coffee) as well as a diversity of on-farm processing methods (including natural and washed processing), which allows for a diverse dataset for examination that includes many of the features of smallholder coffee production found across many origins. Most farms in the survey were smaller than 3 ha, with an average size of 2.67 ± 0.2 ha, although there was a range in size from 0.5 to 19.6 ha. Agricultural production in the region consists of coffee along with rice and a variety of fruits, including banana and cacao. All of the selected farms grow arabica coffee (Coffea arabica). The average yield of the surveyed coffee farms was estimated as 2180 ± 170 kg exportable coffee per hectare for the 2022 season. Survey participants encompassed a range of elevations, processing types and vegetation management techniques.

We observed a variety of vegetation management systems within our study sites, from sun coffee (coffee monoculture with little to no other tree species present within the farm) to shade coffee or coffee agroforestry (coffee grown with a variety of other tree species interspersed within the coffee production area). The majority of farms in our sample were sun or sparsely shaded coffee.

Multiple brands and types of fertilizers are available for purchase in Jaén. In addition to inorganic fertilizers, the organic Guano de las Islas is available for purchase; it is derived from guano collected on islands off the coast of Peru and is sold by the Peruvian government.

Aside from weed whackers and chainsaws, mechanized equipment and vehicles are not used for farming in this region, which is typical of smallholder coffee farms globally. Vegetation maintenance and crop harvesting are done by hand.

The farms in this region process the harvested coffee on their farms using the washed method, the natural method or both (82%, 8% and 12% of farms in our study sites, respectively) before the coffee is brought to the dry mill in Jaén. The general process for the washed method (also called the ‘wet method’) on farms here involves washing the harvested coffee cherry, de-pulping the cherry, dry fermenting the de-pulped seeds, washing the seed to remove the mucilage layer and then drying the coffee on raised beds or patios. De-pulping equipment was manual or had an electric or gas-fuelled motor. The waste by-products of the washed process are coffee pulp, which is most often turned into compost and applied back on the farms, and wastewater from washing after fermentation, which is either piped into an unlined wastewater sedimentation tank or released directly to the ground. The dried coffee seeds or parchment are then brought to a dry mill for further off-farm processing.

The natural method (also called the ‘dry method’) involves washing the harvested coffee cherry, then laying the whole cherry out to dry on raised beds. The coffee is then brought to a dry mill for further processing off-farm. In contrast to the wet method, there are no waste by-products of the natural method at the farm level.

Data collection

Site visits and in-person surveys were conducted for 146 individual coffee producers in February 2023 by team members of Falcon Coffees Peru to gather information about the 2022 harvest year. Standardized survey questions were developed that pertained to the quantities of emissions sources and sinks at the farm level; these were focused on the categories of basic farm information, fertilizer use, crop residue management, shade tree management, processing and fuel use. Of the 146 producers surveyed, full usable responses were obtained from 142. Emissions data for the surveyed farms are available as supplementary material in Appendix S1.

Estimation of emissions

From reviews of the literature and of currently available guidance and carbon calculator methods, we selected the emissions sources and sinks most commonly measured for coffee (e.g., Noponen et al. Reference Noponen, Edwards-Jones, Haggar, Soto, Attarzadeh and Healey2012, Killian et al. Reference Killian, Rivera, Soto and Navichoe2013, Nab & Maslin Reference Nab and Maslin2020) based on factors that would be robust in scope and most illustrative in terms of differences documented in the emissions measurements for coffee. The literature contained a number of different units for coffee emissions measurements, including CO2e (i.e., carbon dioxide equivalent, which is the unit of measurement for GHG emissions) per hectare, per farm, per kilogram of coffee cherry, per kilogram of roasted coffee and per cup of coffee. However, in the coffee supply chain, CO2e per kilogram of exportable coffee (also called ‘green coffee’) is the unit of measurement used, and therefore this was adopted for the purposes of this study.

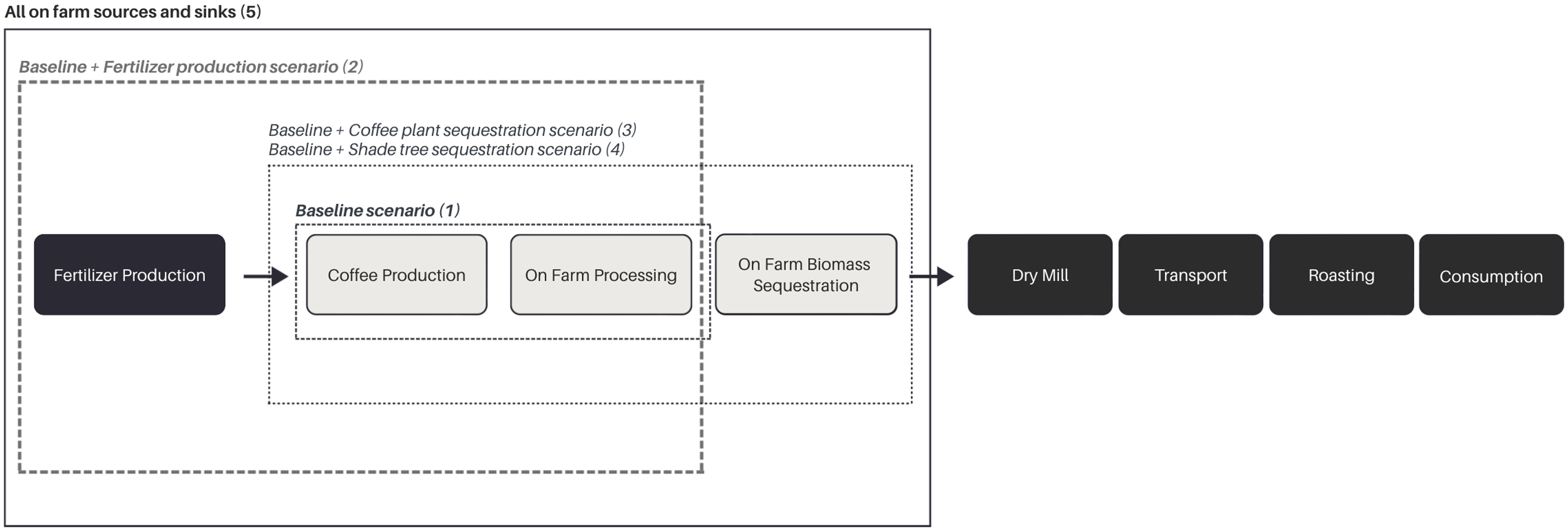

We calculated the emissions for coffee production and on-farm processing resulting from each of the major inputs and then subtracted the amount of carbon sequestered in the aboveground biomass. Each independent variable and its source are detailed in the following subsection. Although the majority of the input values were directly from the survey responses, estimations for some variables were required, and these were based on calculations from the primary data and literature. The conceptual model for the emissions and the scope boundary of the analysis are shown in Fig. 1.

Figure 1. System boundaries for calculating emissions from farm-level coffee production and processing. Dashed lines show the boundaries for each of the five emissions models.

Emissions sources

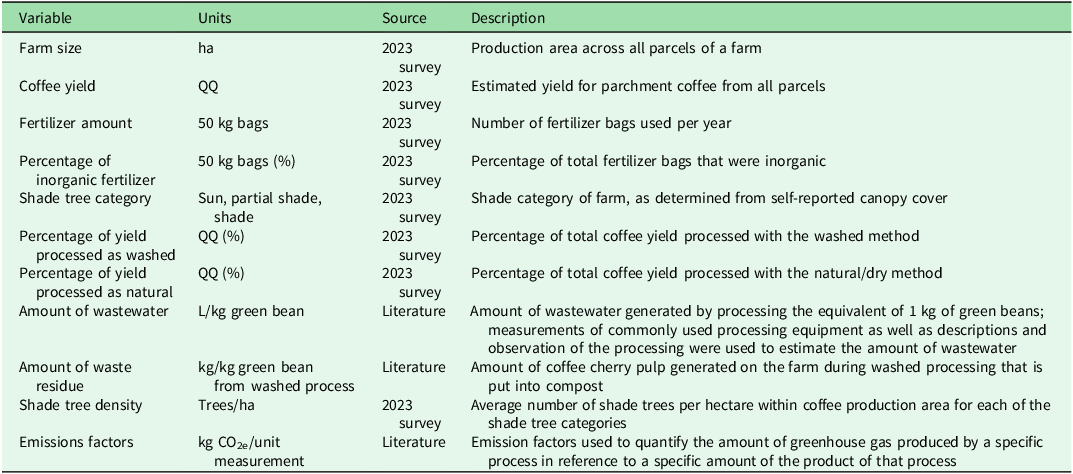

The sources of emissions included in this study were fertilizer production, fertilizer use, wastewater decomposition, waste residue decomposition and machinery use (Table 1).

Table 1. Key variables used in emissions models to calculate annual greenhouse emissions for on-farm coffee production and processing.

QQ = quintals.

Fertilizer production

Producers reported the amount of inorganic and organic fertilizers used per year. Nitrogen content for each fertilizer type was recorded in the field. The total mass of inorganic nitrogen applied per farm per year was calculated and multiplied by the EF (Yara 2023) to determine the emissions associated with the inorganic nitrogen production.

Fertilizer use

Producers reported the amounts of inorganic and organic fertilizers used per year. The nitrogen content of each fertilizer type was recorded in the field. The total mass of nitrogen applied per farm per year was calculated and multiplied by the EF to determine the amount of N2O-N emitted per year (Menegat et al. Reference Menegat, Ledo and Tirado2022).

Wastewater

The volume of wastewater resulting from the washed process was estimated based on the reported yield of washed-processed coffee (Van Rikxoort et al. Reference Van Rikxoort, Schroth, Läderach and Rodríguez-Sánchez2014). No wastewater is created through the natural/dry process. The chemical oxygen demand value of the wastewater was calculated based on Adams and Ghaly (Reference Adams and Ghaly2007) and was multiplied by an EF for wastewater disposal in a shallow lagoon (IPCC 2019) to determine the emissions associated with the wastewater. The shallow lagoon was selected as it was the closest to the shallow water sedimentation tanks that the producers in this study use for wastewater treatment on their farms.

Waste residue decomposition

Coffee pulp resulting from the de-pulped coffee cherry is generally composted on the farms themselves. The volume of waste residue (residual coffee pulp) was estimated based on the reported yield of washed-processed coffee (Rotta et al. Reference Rotta, Curry, Han, Reconco, Spang, Ristenpart and Donis-González2021). There is no waste residue created through the natural/dry process on the farm. The volume of waste residue was multiplied by an EF to determine the emissions of composting coffee pulp (San Martin Ruiz et al. Reference San Martin Ruiz, Reiser and Kranert2021).

Machinery use

Farms using the washed method de-pulp the coffee on the farm, often using fuel-powered de-pulpers. There is also fuel use from farm maintenance equipment such as weed whackers and chainsaws. Total fuel use was estimated based on values from Coltro et al. (Reference Coltro, Mourad, Oliveira, Baddini and Kletecke2006) and multiplied by EFs for diesel (US EPA 2022, UK Government 2022) to calculate the emissions from fuel use.

Carbon sinks

Carbon sequestration from plant biomass on coffee farms is often excluded from coffee emissions calculations. The Publicly Available Specification 2050 (PAS 2050), developed by the British Standard Institute (BSI 2012), excludes carbon stored in living organisms such as shade trees or perennial crops in its product carbon footprint method. Additionally, coffee plants often undergo extensive pruning practices, and through these carbon is released and must be accounted for. However, in this study, we have included sequestration to demonstrate its potential significance. The importance of carbon stocks sequestering carbon in agricultural lands is not to be underestimated. If coffee farms were converted to other land uses, such as development or pasture, there would be a loss of carbon stocks. However, carbon accounting takes into consideration the sources and sinks of emissions that are present on an annual basis (i.e., annual biomass growth), whereas carbon stocks take into account the total amount of carbon sequestered in biomass at any one time. The carbon sinks included in this study were sequestration in aboveground biomass in shade trees and coffee plants. Carbon stock – the existing carbon stored in biomass – was not accounted for here as it is not part of the annual carbon flux.

Shade tree sequestration

The amount of annual carbon sequestration for shade trees within the coffee farms was estimated by categorizing farms into sun, partial shade and shade based on the self-reported canopy cover. Sun coffee was designated as less than 10% canopy cover, partial shade at between 10% and 30% canopy cover and shade at greater than 30% canopy cover. Outliers were removed from the self-reported data, and an average tree density was assigned for each category. The average amount of carbon stored per farm was estimated based on the density of trees per hectare (Solis et al. Reference Solis, Vallejos-Torres, Arévalo, Marín-Díaz, Ñique-Alvarez, Engedal and Bruun2020), and the annual incremental increase in carbon sequestered per farm was calculated using an estimated compound annual growth rate of shade trees on a coffee farm (Goodall et al. Reference Goodall, Bacon and Mendez2015).

Coffee plant sequestration

The amount of annual carbon sequestration for coffee plants was calculated based on an assumed annual growth rate similar to that of tropical shade trees (Goodall et al. Reference Goodall, Bacon and Mendez2015), and coffee plant density per farm was based on field measurements of sample plots within coffee farms in the study. These values were used to calculate the annual increase in carbon stored in coffee plants per farm per year.

Models for the comparison of scenarios

Five scenarios were constructed covering different boundary conditions to explore the importance of these assumptions for emissions measurement in coffee. The best available EFs were used for emissions calculations in these scenarios and were held constant for each of the scope models.

Scope scenarios

-

(1) Baseline: emissions from the four sources that all occur directly on the farm, including fertilizer use, wastewater, waste residue and machinery use. No sequestration was included.

-

(2) Baseline plus fertilizer production: baseline plus emissions from fertilizer production added that takes place off the farm, including fertilizer production, fertilizer use, wastewater, waste residue and machinery use. No sequestration was included.

-

(3) Baseline plus coffee plant sequestration: baseline plus emission sink from annual carbon sequestration of coffee plants, including fertilizer use, wastewater, waste residue, machinery use and coffee plant sequestration.

-

(4) Baseline plus shade tree sequestration within farm: baseline plus emission sink from annual carbon sequestration of shade trees within coffee farm, including fertilizer use, wastewater, waste residue, machinery use and shade tree sequestration.

-

(5) All sources and sinks: baseline plus emissions from fertilizer production and sinks from annual carbon sequestration in shade trees within and outside of coffee farm, including fertilizer production, fertilizer use, wastewater, waste residue, machinery use and shade tree sequestration within and outside of coffee farm.

Emissions factors scenarios

Three levels of EFs were applied to each of the five scenarios listed earlier, resulting in 15 models, to illustrate the impact of EF selection on overall emissions results. We varied the EFs, selecting high, medium and low values used in the available literature on fertilizer production (Walling & Vaneeckhaute, Reference Walling and Vaneeckhaute2020, Yara 2023), fertilizer use (IPCC 2006, Hergoualc’h et al. Reference Hergoualc’h, Skiba, Harmand and Hénault2008, Menegat et al. Reference Menegat, Ledo and Tirado2022) and pulp waste residue (San Martin Ruiz et al. Reference San Martin Ruiz, Reiser and Kranert2021). Additionally, global warming potentials for these variables were calculated as needed (IPCC 2014).

Statistics and data analysis

We tested for differences between the calculated emissions among each of the scenarios using a non-parametric one-way Kruskal–Wallis rank sum test. Wilcoxon multiple comparison tests with Bonferroni correction was used for post-hoc comparisons between scenarios, in which the significance level of 0.05 was adjusted by dividing by the number of comparisons to maintain the overall error rate (ɑ = 0.05/4 = 0.0125). Non-parametric tests were used as the data did not comply with the assumption of normality (comparison of boundary scenarios: Shapiro–Wilk normality test W = 0.9774, p = 5.11e–9; comparison of EF scenarios: Shapiro–Wilk normality test W = 0.9467, p = 2.96e–11). We used R software version 4.3.2 (R Core Team 2024) for all statistical analyses.

Results

The carbon emissions from coffee production on the 142 Peruvian coffee farms were significantly altered solely based on the carbon accounting method selected, using different metrics, boundaries and EFs.

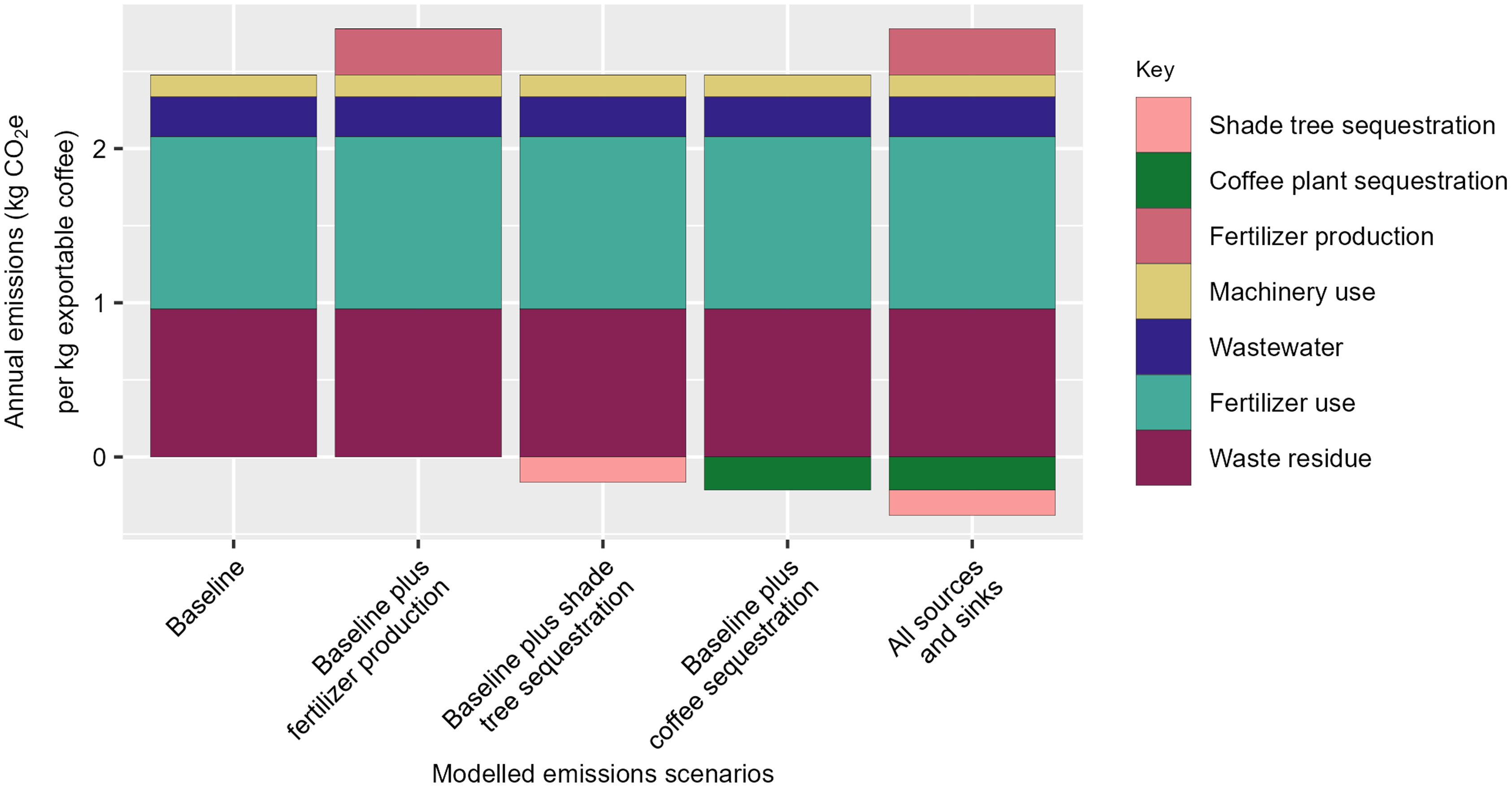

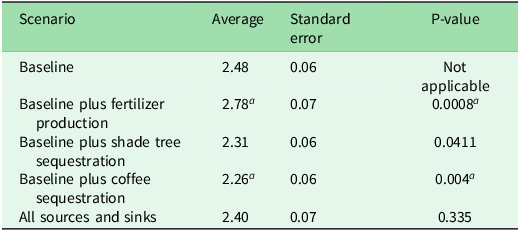

Scope scenarios modelled with varying boundaries and metrics

The modelled scenarios (baseline, baseline plus fertilizer production, baseline plus shade tree sequestration, baseline plus coffee plant sequestration, all sources and sinks) resulted in emissions that were different from the baseline scenario. The EF was held constant for all of the scope scenarios in this example to isolate the impact from only varying the metrics and scope boundaries. Significant differences were found between the baseline and scenarios with coffee plant sequestration and fertilizer production included (Fig. 2 & Table 2). For the scenarios that were not significantly different from the baseline, it should be noted that the carbon sequestration and fertilizer production emissions offset each other for the ‘all sources and sinks’ scenario (Fig. 2), and the farms surveyed were sparsely shaded with trees other than coffee, and therefore the shade tree sequestration scenario was not significantly different from the baseline.

Figure 2. Comparison of main sources and sinks among five emissions model scenarios for calculating the average greenhouse gas emissions from on-farm production and processing of coffee in smallholder coffee farms in Jaén (Peru) in 2022. All five scenarios were modelled with the emissions factors held constant.

Table 2. Average annual greenhouse gas emissions from on-farm production and processing of coffee in smallholder coffee farms (kg CO2e per kilogram of exportable coffee) in Jaén (Peru) in 2022. Each of the scope scenarios was modelled with the emissions factors held constant.

a Significantly different from the baseline per Wilcoxon multiple comparison tests with Bonferroni corrections.

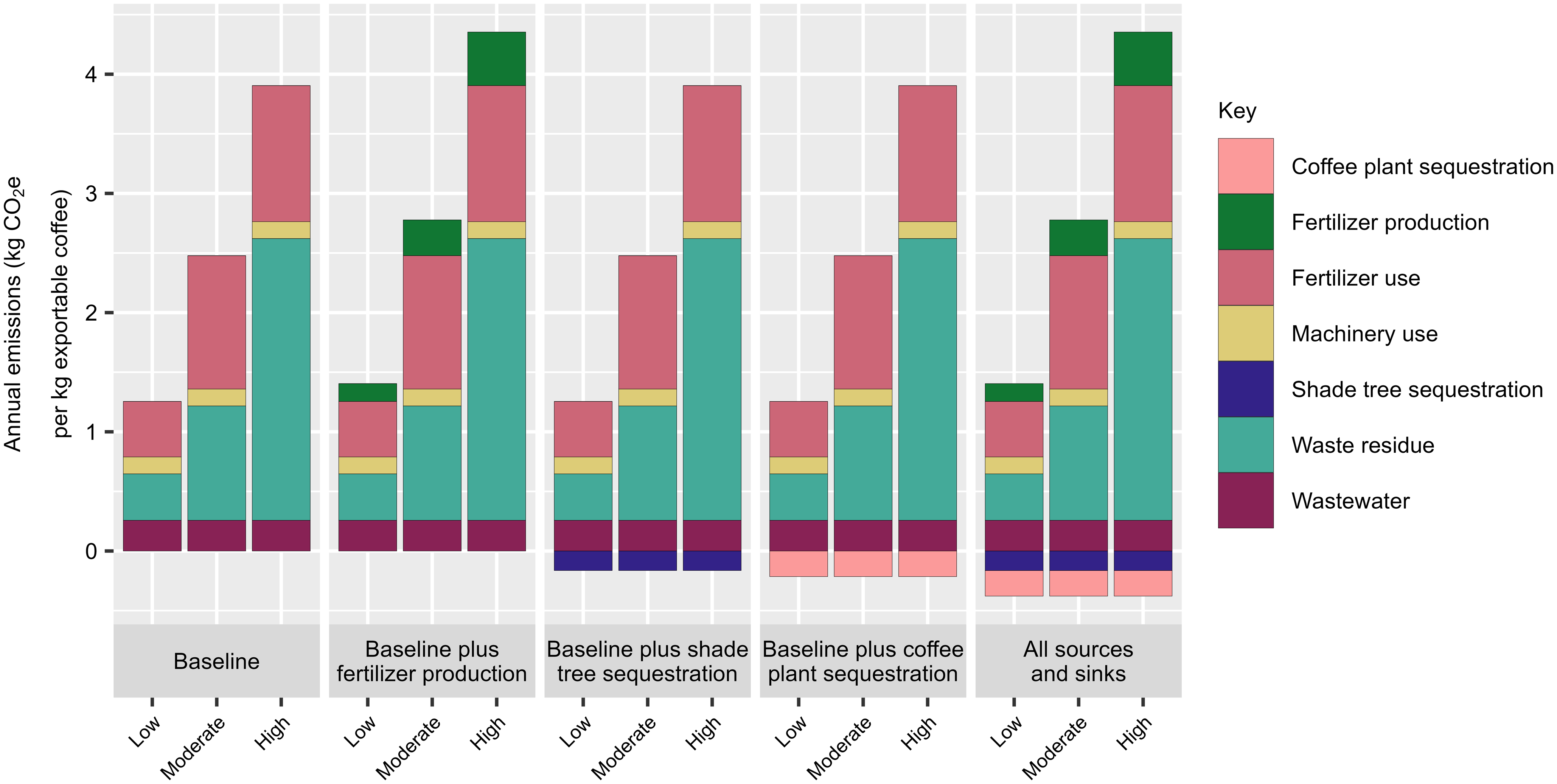

Scenarios modelled with varying emissions factors

The EFs selected for measuring farm-level coffee emissions significantly altered the resulting emissions for the farms in 2022, adding another layer of complexity and ambiguity to emission accounting methods. All EF scenarios were significantly different from each other (Fig. 3 & Table 3).

Figure 3. Comparison of main carbon sources and sinks, and average greenhouse gas emissions modelled with high, moderate and low levels of emissions factors across all scenarios.

Table 3. Comparison of average annual greenhouse gas emissions (kg CO2e per kilogram of exportable coffee) from on-farm production and processing of coffee in smallholder coffee farms in Jaén (Peru) in 2022 modelled in five scenarios, each with high, moderate and low emissions factors (EFs) from the literature.

a Significant difference from moderate EF according to Wilcoxon multiple comparison tests within each scenario.

When we varied the way in which the emissions were modelled within the different scenarios but kept the EF constant, the emissions varied by 8% on average. However, when we changed both the scenarios and the EFs within the scenarios, there was inflation or deflation in the resulting emissions by a factor of 3.4 on average within a single scenario, and among scenarios this was by a factor of 4.2 (overall lowest emissions versus overall highest emissions).

Discussion

Our analysis highlights the challenges involved at the organizational level in calculating, comparing and understanding emissions in complex agricultural supply chains. We do so by focusing on components within the control of smallholder farmers in the coffee supply chain whilst acknowledging that the decisions of these farmers have impacts (both direct and indirect) beyond their direct scope; however, modelling these impacts is beyond the scope of this analysis.

As discussed in the ‘Introduction’ section, there is currently no established carbon accounting method for coffee; therefore, comparing reported emissions is difficult and often misleading. Here the method of emissions measurement had a potentially large impact on the estimated emissions of coffee beans, farms and companies interested in understanding and reducing their scope 3 emissions. The scenarios that we modelled are for illustrative purposes, and for the coffee industry there are critical decision points regarding the subjective choices of whether items such as emissions from fertilizer production and carbon sequestration in coffee plants and shade trees should be included. This analysis has shown that these decisions are critical to defining emissions levels. Furthermore, when scaled up to the level of organizations in the middle of supply chains, these variations in results can produce potentially significant changes in overall emissions and therefore define how successful (or not) efforts to reduce emissions have been. We have demonstrated that many of these choices create statistically significant differences in mean emissions across groups, thus having important implications for efforts to compare emissions across parties and to assess mitigation efforts. Where there were no differences between scenarios, there are logical reasons to believe that this might not hold true for other coffee-producing origins where, for example, the prevalence of densely shaded coffee production is higher.

Although the difference in resulting emissions between the highest and lowest values for scope scenarios appears slight for kilograms of exportable coffee at 0.5 kg CO2e, the impact is apparent when scaling the emissions to relevant quantities such as annual yield per farm, resulting in a difference of 750 kg CO2e per kilogram of exportable coffee, a c. 125 000 kg CO2e difference per harvest season for the Jaén supply chain or a discrepancy of c. 22 350 000 kg CO2e per annual coffee purchased for a small to medium-size coffee trader such as Falcon Coffees. To compound these discrepancies, the average change in emission values per EF baseline scenario was 1.77 kg CO2e per kilogram of exportable coffee, which would result in a difference of c. 440 000 kg CO2e for the Jaén supply chain or c. 77 000 000 kg CO2e for a small to medium-size coffee trader.

There is a further critical factor in determining emissions levels, even once the scope of the analysis has been agreed: for many of the inputs required to calculate emissions of agricultural supply chains, there are considerable uncertainties regarding the levels of emissions that arise from certain activities. A wide range of EFs exist in the available literature, and the choice as to which of these EFs are most accurate is subjective to the organization involved. For example, the EFs associated with fertilizer use can vary by a factor of up to 2.5, with resulting implications on GHG emissions levels.

The twin uncertainties around scope and EFs demonstrate the importance of clear guidance and sector-wide agreement on such critical factors to curtail individual organizations making their own subjective decisions. Although current guidance provides a framework for emissions calculations, we have shown that there is a pressing need for a greater set of micro-level agreements between organizations, companies and individuals calculating the emissions of commodities across agricultural supply chains, without which results may vary substantially even when working within similar methodologies. This raises challenges both inside and outside organizations regarding comparability with competitors and also regarding the identification of how mitigation efforts may best and most effectively be deployed. Efforts to reduce emissions may be overstated or understated depending on the type of EFs applied. Changes in scope might mean that easy options to reduce emissions are missed or underestimated.

While communicating commitments to sustainability and emissions goals is important, these efforts are meaningless if the measurements of these goals are inaccurate. We advocate for emissions reductions throughout the supply chain; however, our strategies to tackle climate change are compromised when a sustainability status is claimed that is built on uncertainties. Clear guidance is required at a macro level regarding processes for calculating emissions. In addition, more micro-level agreements are also needed between companies and organizations involved in particular agricultural sectors to come to agreements on potentially subjective decisions regarding emissions scope and EFs. Such agreement are needed in order to ensure that emissions calculations are comparable across the sector and provide clear learning points and signals to both internal and external stakeholders regarding performance and how best to focus efforts to reduce emissions. Mobilizing finance to help industry associations, organizations and interested parties to collaborate and reach agreements on decision points should therefore be a key task of those looking to assist in emissions reductions across agricultural supply chains. Fostering a culture of collaboration and of placing value on scientific insights can improve knowledge along supply chains that not only will improve the sustainability of those supply chains and business performance, but also provide wider economic and social benefits.

Supplementary materials

For supplementary material accompanying this paper, visit https://doi.org/10.1017/S0376892924000286.

Acknowledgements

We thank the coffee producers in Jaén who participated in the survey and all who facilitated the data collection process. We also thank Jacqueline Mocek, Kate Monteiro, Liz Johnson and Emmy Sales for their support and assistance with the project. We are grateful to the anonymous reviewers whose comments strengthened and improved this manuscript.

Financial support

This research has received funding through the Falcon Coffees/University of Brighton Knowledge Transfer Partnership (KTP), a scheme funded by UK Research and Innovation, KTP grant 10002382 (KTP no. 12919).

Competing interests

Although some of the authors are employed by Falcon Coffees, there is no direct financial interest in the study.

Ethical standards

Not applicable.