1. Introduction

When a granular medium is non-monodisperse, i.e. consisting of a mixture of particles of disparate size, grains tend to demix based on size during flow – a process referred to as size segregation. Predicting the dynamics of size segregation during flow is crucial in the design of various industrial processes where mixing is key and in understanding natural hazards, such as avalanches and landslides. The complex, spatially inhomogeneous distributions in particle size that can arise during the segregation process (e.g. Savage & Lun Reference Savage and Lun1988; Gray & Hutter Reference Gray and Hutter1997; Hill & Fan Reference Hill and Fan2008; Golick & Daniels Reference Golick and Daniels2009; Wiederseiner et al. Reference Wiederseiner, Andreini, Épely-Chauvin, Moser, Monnereau, Gray and Ancey2011; Schlick et al. Reference Schlick, Fan, Isner, Umbanhowar, Ottino and Lueptow2015; van der Vaart et al. Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015) pose a substantial challenge for modelling efforts, and significant effort over the last few decades has gone into developing continuum models for the evolution of particle-size distribution in a number of flow geometries (e.g. see the recent reviews of Gray Reference Gray2018; Umbanhowar, Lueptow & Ottino Reference Umbanhowar, Lueptow and Ottino2019).

Here, we highlight two specific challenges for dense, granular media that motivate the present work. First, as per current understanding, there are two important driving forces for size segregation in dense granular flows: (1) pressure gradients, typically arising due to gravity; and (2) shear-strain-rate gradients. In the presence of pressure gradients, the mechanisms of kinetic sieving and squeeze expulsion (Savage & Lun Reference Savage and Lun1988; Gray Reference Gray2018) result in a net flux of small particles to high-pressure regions and large particles to low-pressure regions, such as near a free surface. Pressure-gradient-driven segregation is widely recognized as a dominant driving force and is the focus of most size-segregation models in the literature (e.g. Gray & Thornton Reference Gray and Thornton2005; Gray & Chugunov Reference Gray and Chugunov2006; Gray & Ancey Reference Gray and Ancey2011; Marks, Rognon & Einav Reference Marks, Rognon and Einav2012; Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014; Gajjar & Gray Reference Gajjar and Gray2014; Schlick et al. Reference Schlick, Fan, Isner, Umbanhowar, Ottino and Lueptow2015; Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018; Liu, Gonzalez & Wassgren Reference Liu, Gonzalez and Wassgren2019; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021; Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2021; Trewhela, Ancey & Gray Reference Trewhela, Ancey and Gray2021). Apart from pressure gradients, gradients in shear-strain rate can also drive size segregation in dense flows, in which large particles segregate towards more rapidly shearing regions (Hill & Fan Reference Hill and Fan2008; Fan & Hill Reference Fan and Hill2010, Reference Fan and Hill2011a), and comparatively fewer continuum modelling works have been dedicated to capturing this driving force (Fan & Hill Reference Fan and Hill2011b; Hill & Tan Reference Hill and Tan2014; Liu, Singh & Henann Reference Liu, Singh and Henann2023). While it is reasonable to expect segregation phenomenology in shallow free-surface flows to be predominantly driven by pressure gradients, the comparative contributions of the two driving forces is not always clear (Staron & Phillips Reference Staron and Phillips2015), necessitating a model that accounts for both. The recent work of Jing et al. (Reference Jing, Ottino, Lueptow and Umbanhowar2021) developed a scaling law for the segregation force on a single intruder in a flowing dense granular medium that accounts for both mechanisms and tested the scaling law across different cases of pressure gradients and flow kinematics, but it remains to develop and test a continuum model that involves both mechanisms at finite particle concentrations across flow conditions.

The second challenge is coupling segregation modelling with rheology. The vast majority of the aforementioned segregation models do not involve rheological constitutive equations capable of predicting flow fields across different geometries. Instead, a certain flow field is assumed or measured from experiments or discrete element method (DEM) simulations and then prescribed as input to the segregation model. This is because modelling the rheological behaviour of dense granular materials across flow geometries is a substantial challenge itself. The inertial, or ![]() $\mu (I)$, rheology (MiDi Reference MiDi2004; da Cruz et al. Reference da Cruz, Emam, Prochnow, Roux and Chevoir2005; Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2005; Srivastava et al. Reference Srivastava, Silbert, Grest and Lechman2021), where

$\mu (I)$, rheology (MiDi Reference MiDi2004; da Cruz et al. Reference da Cruz, Emam, Prochnow, Roux and Chevoir2005; Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2005; Srivastava et al. Reference Srivastava, Silbert, Grest and Lechman2021), where ![]() $\mu$ is the stress ratio and

$\mu$ is the stress ratio and ![]() $I$ is the inertial number, is a common approach and uses dimensional arguments to relate the stress state to the state of strain rate at a point through a local constitutive equation. The

$I$ is the inertial number, is a common approach and uses dimensional arguments to relate the stress state to the state of strain rate at a point through a local constitutive equation. The ![]() $\mu (I)$ rheology works well in homogeneous shearing and certain other dense inertial flows, such as flow down an incline. However, the

$\mu (I)$ rheology works well in homogeneous shearing and certain other dense inertial flows, such as flow down an incline. However, the ![]() $\mu (I)$ rheology cannot capture a broad set of inhomogeneous flows spanning the quasi-static and dense inertial flow regimes, and a number of non-local continuum modelling approaches have been developed to capture the features of dense, inhomogeneous flows (Kamrin Reference Kamrin2019).

$\mu (I)$ rheology cannot capture a broad set of inhomogeneous flows spanning the quasi-static and dense inertial flow regimes, and a number of non-local continuum modelling approaches have been developed to capture the features of dense, inhomogeneous flows (Kamrin Reference Kamrin2019).

Only a few works have sought to couple segregation modelling with rheological constitutive equations for a dense, bidisperse granular medium. For example, Liu et al. (Reference Liu, Gonzalez and Wassgren2019) combined a rate-independent, Mohr–Coulomb-based, elasto-plasticity model with the pressure-gradient-driven segregation model of Fan et al. (Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014) and applied the coupled model to dense, bidisperse flows in rotating drums and hoppers. More recently, Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) combined a regularized version of the ![]() $\mu (I)$ rheology (Barker & Gray Reference Barker and Gray2017) with the pressure-gradient-driven segregation model of Trewhela et al. (Reference Trewhela, Ancey and Gray2021) and applied the coupled model to dense, bidisperse flows down an inclined plane and in a rotating drum. Finally, in our recent work (Liu et al. Reference Liu, Singh and Henann2023), we generalized the non-local granular fluidity (NGF) model for dense granular flow (Kamrin & Koval Reference Kamrin and Koval2012; Henann & Kamrin Reference Henann and Kamrin2013) from monodisperse to bidisperse granular systems and proposed a segregation model for the shear-strain-rate-gradient-driven flux. We showed that this coupled model could simultaneously capture segregation dynamics and flow fields in two different flow geometries in the absence of pressure gradients – vertical chute flow and annular shear flow. However, none of these models account for both pressure-gradient-driven and shear-strain-rate-gradient-driven segregation within a framework coupled to the rheological modelling of a dense granular medium.

$\mu (I)$ rheology (Barker & Gray Reference Barker and Gray2017) with the pressure-gradient-driven segregation model of Trewhela et al. (Reference Trewhela, Ancey and Gray2021) and applied the coupled model to dense, bidisperse flows down an inclined plane and in a rotating drum. Finally, in our recent work (Liu et al. Reference Liu, Singh and Henann2023), we generalized the non-local granular fluidity (NGF) model for dense granular flow (Kamrin & Koval Reference Kamrin and Koval2012; Henann & Kamrin Reference Henann and Kamrin2013) from monodisperse to bidisperse granular systems and proposed a segregation model for the shear-strain-rate-gradient-driven flux. We showed that this coupled model could simultaneously capture segregation dynamics and flow fields in two different flow geometries in the absence of pressure gradients – vertical chute flow and annular shear flow. However, none of these models account for both pressure-gradient-driven and shear-strain-rate-gradient-driven segregation within a framework coupled to the rheological modelling of a dense granular medium.

The purpose of this paper is to develop a model that integrates pressure-gradient-driven and shear-strain-rate-gradient-driven segregation, granular diffusion and non-local rheological behaviour spanning the quasi-static and dense inertial flow regimes ![]() $(I\lesssim 10^{-1})$ into one framework capable of predicting segregation dynamics and flow fields. The starting point is our recent work (Liu et al. Reference Liu, Singh and Henann2023), which accounts for all but the pressure-gradient-driven flux. To this end, we supplement this model with a phenomenological constitutive equation for the pressure-gradient-driven flux, based on the works of Gajjar & Gray (Reference Gajjar and Gray2014) and Trewhela et al. (Reference Trewhela, Ancey and Gray2021). To calibrate and test the coupled, continuum model, we perform DEM simulations using the open-source software LAMMPS (Plimpton Reference Plimpton1995). We return to the widely studied, inclined plane flow geometry to calibrate the model for dense, bidisperse systems of both frictional spheres and disks, focusing on a fixed grain-size ratio. Then, we perform validation tests, in which we compare continuum model predictions of the steady-state flow fields and the transient evolution of the segregation dynamics against DEM simulation results in both inclined plane flow and an additional flow geometry not used in model calibration – planar shear flow with gravity. Both of these flow geometries involve shear-strain-rate gradients and pressure gradients, so it is important to account for both driving forces of segregation to capture the segregation dynamics in both geometries with a single set of parameters.

$(I\lesssim 10^{-1})$ into one framework capable of predicting segregation dynamics and flow fields. The starting point is our recent work (Liu et al. Reference Liu, Singh and Henann2023), which accounts for all but the pressure-gradient-driven flux. To this end, we supplement this model with a phenomenological constitutive equation for the pressure-gradient-driven flux, based on the works of Gajjar & Gray (Reference Gajjar and Gray2014) and Trewhela et al. (Reference Trewhela, Ancey and Gray2021). To calibrate and test the coupled, continuum model, we perform DEM simulations using the open-source software LAMMPS (Plimpton Reference Plimpton1995). We return to the widely studied, inclined plane flow geometry to calibrate the model for dense, bidisperse systems of both frictional spheres and disks, focusing on a fixed grain-size ratio. Then, we perform validation tests, in which we compare continuum model predictions of the steady-state flow fields and the transient evolution of the segregation dynamics against DEM simulation results in both inclined plane flow and an additional flow geometry not used in model calibration – planar shear flow with gravity. Both of these flow geometries involve shear-strain-rate gradients and pressure gradients, so it is important to account for both driving forces of segregation to capture the segregation dynamics in both geometries with a single set of parameters.

The remainder of this paper is organized as follows. First, we discuss the continuum framework for modelling coupled size segregation and flow in § 2. Specifically, we discuss the segregation model in § 2.5 wherein we append the constitutive equation for the pressure-gradient-driven flux (Gajjar & Gray Reference Gajjar and Gray2014; Trewhela et al. Reference Trewhela, Ancey and Gray2021) to the model of Liu et al. (Reference Liu, Singh and Henann2023). To determine the dimensionless material parameters that appear in the pressure-gradient-driven size-segregation model for both spheres and disks, we consider flows of bidisperse mixtures down an inclined plane in § 3 and fit the model to steady-state DEM simulation results. Then, we perform validation tests of the continuum model against DEM simulation results for the transient evolution of the segregation dynamics, first for inclined plane flow in § 4.1 and second for an additional flow configuration not used in model calibration – planar shear flow with gravity – in § 4.2 without parameter adjustment. In § 5 we examine the relative contributions of the two driving forces of segregation in both flow geometries and, finally, we close with some concluding remarks in § 6.

2. Continuum framework

In this section we discuss the continuum framework used to model dense, bidisperse granular mixtures. As in our prior work (Liu et al. Reference Liu, Singh and Henann2023), we utilize a mixture-theory-based approach (e.g. Gray Reference Gray2018; Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019). While the continuum model developed in this work is a coupled model for size segregation and flow, we primarily focus on the size-segregation aspect of the model in this section. The rheological constitutive equations that we utilize for bidisperse systems have been discussed in detail in our prior work (Liu et al. Reference Liu, Singh and Henann2023) and, for brevity, are only recapped in Appendix A. Regarding notation, we use component notation, in which the components of vectors, ![]() $\boldsymbol {v}$, and tensors,

$\boldsymbol {v}$, and tensors, ![]() $\boldsymbol {\sigma }$, relative to a set of Cartesian basis vectors

$\boldsymbol {\sigma }$, relative to a set of Cartesian basis vectors ![]() $\{\boldsymbol {e}_i|i=1,2,3\}$ are denoted by

$\{\boldsymbol {e}_i|i=1,2,3\}$ are denoted by ![]() $v_i$ and

$v_i$ and ![]() $\sigma _{ij}$, respectively. The Einstein summation convention is employed, and the Kronecker delta,

$\sigma _{ij}$, respectively. The Einstein summation convention is employed, and the Kronecker delta, ![]() $\delta _{ij}$, is utilized to denote the components of the identity tensor.

$\delta _{ij}$, is utilized to denote the components of the identity tensor.

2.1. Bidisperse systems

We consider bidisperse granular systems made up of grains of two different sizes: large grains with average diameter ![]() $d^{l}$ and small grains with average diameter

$d^{l}$ and small grains with average diameter ![]() $d^{s}$. As in Liu et al. (Reference Liu, Singh and Henann2023), our focus is size-based segregation, and to eliminate density-based segregation, all grains are taken to be made of the same material with mass density

$d^{s}$. As in Liu et al. (Reference Liu, Singh and Henann2023), our focus is size-based segregation, and to eliminate density-based segregation, all grains are taken to be made of the same material with mass density ![]() $\rho _{s}$. Both three-dimensional systems of bidisperse spheres and two-dimensional systems of bidisperse disks are considered in this work but, for brevity, in what follows, we describe the continuum framework for three-dimensional systems of spheres. In the mixture theory approach utilized here, several quantities are introduced for each species: the large grains and the small grains. Large-grain quantities are denoted with a superscript

$\rho _{s}$. Both three-dimensional systems of bidisperse spheres and two-dimensional systems of bidisperse disks are considered in this work but, for brevity, in what follows, we describe the continuum framework for three-dimensional systems of spheres. In the mixture theory approach utilized here, several quantities are introduced for each species: the large grains and the small grains. Large-grain quantities are denoted with a superscript ![]() ${l}$ and small-grain quantities with a superscript

${l}$ and small-grain quantities with a superscript ![]() ${s}$. The solid fractions, i.e. the volumes occupied by each species per unit total volume, are denoted as

${s}$. The solid fractions, i.e. the volumes occupied by each species per unit total volume, are denoted as ![]() $\phi ^{l}$ and

$\phi ^{l}$ and ![]() $\phi ^{s}$ for large and small grains, respectively, and the total solid fraction is

$\phi ^{s}$ for large and small grains, respectively, and the total solid fraction is ![]() $\phi = \phi ^{l} + \phi ^{s}$. The concentrations of each species are defined as

$\phi = \phi ^{l} + \phi ^{s}$. The concentrations of each species are defined as ![]() $c^{l} = \phi ^{l}/\phi$ and

$c^{l} = \phi ^{l}/\phi$ and ![]() $c^{s} = \phi ^{s}/\phi ^{s}$, so that

$c^{s} = \phi ^{s}/\phi ^{s}$, so that ![]() $c^{l} + c^{s} =1$. The average grain size is defined as

$c^{l} + c^{s} =1$. The average grain size is defined as ![]() $\bar {d} = c^{l} d^{l} + c^{s} d^{s}$.

$\bar {d} = c^{l} d^{l} + c^{s} d^{s}$.

2.2. Kinematics of flow

The velocity fields for each species are denoted as ![]() $v^{l}_i$ and

$v^{l}_i$ and ![]() $v^{s}_i$, and the mixture velocity field is defined as

$v^{s}_i$, and the mixture velocity field is defined as ![]() $v_i = c^{l} v^{l}_i + c^{s} v^{s}_i$. The strain-rate tensor for the mixture is defined as the symmetric part of the gradient of the mixture velocity:

$v_i = c^{l} v^{l}_i + c^{s} v^{s}_i$. The strain-rate tensor for the mixture is defined as the symmetric part of the gradient of the mixture velocity: ![]() ${\mathsf{D}}_{ij} = (1/2)(\partial v_i / \partial x_j + \partial v_j/ \partial x_i )$. In this work, we focus on dense flows spanning the quasi-static and dense inertial flow regimes

${\mathsf{D}}_{ij} = (1/2)(\partial v_i / \partial x_j + \partial v_j/ \partial x_i )$. In this work, we focus on dense flows spanning the quasi-static and dense inertial flow regimes ![]() $(I\lesssim 10^{-1})$. Across our DEM simulations, we observe that the total solid fraction remains approximately uniform both spatially and temporally, and any volume change at flow initiation occurs over a much shorter time scale than the process of segregation. Therefore, we make the common idealization that dense flow of the mixture proceeds at constant volume (e.g. Gray & Thornton Reference Gray and Thornton2005; Gray & Chugunov Reference Gray and Chugunov2006; Gray & Ancey Reference Gray and Ancey2011; Gajjar & Gray Reference Gajjar and Gray2014; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021; Liu et al. Reference Liu, Singh and Henann2023). (We note that this idealization is not appropriate for flows in the dilute, or collisional, flow regime (

$(I\lesssim 10^{-1})$. Across our DEM simulations, we observe that the total solid fraction remains approximately uniform both spatially and temporally, and any volume change at flow initiation occurs over a much shorter time scale than the process of segregation. Therefore, we make the common idealization that dense flow of the mixture proceeds at constant volume (e.g. Gray & Thornton Reference Gray and Thornton2005; Gray & Chugunov Reference Gray and Chugunov2006; Gray & Ancey Reference Gray and Ancey2011; Gajjar & Gray Reference Gajjar and Gray2014; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021; Liu et al. Reference Liu, Singh and Henann2023). (We note that this idealization is not appropriate for flows in the dilute, or collisional, flow regime (![]() $I\gtrsim 10^{-1}$), in which the total solid fraction can evolve both spatially and temporally.) Under the constant-volume idealization, the mixture velocity field is divergence free,

$I\gtrsim 10^{-1}$), in which the total solid fraction can evolve both spatially and temporally.) Under the constant-volume idealization, the mixture velocity field is divergence free, ![]() $\partial v_i/\partial x_i=0$; the strain-rate tensor is deviatoric,

$\partial v_i/\partial x_i=0$; the strain-rate tensor is deviatoric, ![]() ${\mathsf{D}}_{kk}=0$; and the total solid fraction

${\mathsf{D}}_{kk}=0$; and the total solid fraction ![]() $\phi$ remains constant. Based on our DEM simulations, throughout this study, we take

$\phi$ remains constant. Based on our DEM simulations, throughout this study, we take ![]() $\phi =0.6$ for spheres and

$\phi =0.6$ for spheres and ![]() $\phi =0.8$ for disks. The equivalent shear-strain rate is defined as

$\phi =0.8$ for disks. The equivalent shear-strain rate is defined as ![]() $\dot {\gamma } = (2 {\mathsf{D}}_{ij} {\mathsf{D}}_{ij})^{1/2}$.

$\dot {\gamma } = (2 {\mathsf{D}}_{ij} {\mathsf{D}}_{ij})^{1/2}$.

2.3. Balance of mass

Using the mixture velocity field and the species-specific velocity fields, the relative volume fluxes for large and small grains are defined as ![]() $w^{l}_i = c^{l} (v^{l}_i - v_i)$ and

$w^{l}_i = c^{l} (v^{l}_i - v_i)$ and ![]() $w^{s}_i = c^{s} (v^{s}_i - v_i)$, respectively, so that

$w^{s}_i = c^{s} (v^{s}_i - v_i)$, respectively, so that ![]() $w^{l}_i + w^{s}_i = 0_i$. Conservation of mass applied to the large grains requires that

$w^{l}_i + w^{s}_i = 0_i$. Conservation of mass applied to the large grains requires that

where ![]() ${\rm D}(\bullet )/{\rm D}t$ is the material time derivative. In what follows, we utilize

${\rm D}(\bullet )/{\rm D}t$ is the material time derivative. In what follows, we utilize ![]() $c^{l}$ as the field variable that describes the dynamics of size segregation. A constitutive equation is then required for the relative volume flux

$c^{l}$ as the field variable that describes the dynamics of size segregation. A constitutive equation is then required for the relative volume flux ![]() $w^{l}_i$. In our previous work (Liu et al. Reference Liu, Singh and Henann2023), we proposed a constitutive equation for

$w^{l}_i$. In our previous work (Liu et al. Reference Liu, Singh and Henann2023), we proposed a constitutive equation for ![]() $w^{l}_i$ that accounts for diffusion and shear-strain-rate-gradient-driven segregation. In § 2.5 we review this model and extend it to account for pressure-gradient-driven segregation.

$w^{l}_i$ that accounts for diffusion and shear-strain-rate-gradient-driven segregation. In § 2.5 we review this model and extend it to account for pressure-gradient-driven segregation.

2.4. Stress and the equations of motion

The stress-related fields for the mixture are defined as follows: the symmetric Cauchy stress tensor ![]() $\sigma _{ij} = \sigma _{ji}$, the pressure

$\sigma _{ij} = \sigma _{ji}$, the pressure ![]() $P =- (1/3)\sigma _{kk}$, the stress deviator

$P =- (1/3)\sigma _{kk}$, the stress deviator ![]() $\sigma _{ij}' = \sigma _{ij} + P \delta _{ij}$, the equivalent shear stress

$\sigma _{ij}' = \sigma _{ij} + P \delta _{ij}$, the equivalent shear stress ![]() $\tau = (\sigma _{ij}'\sigma _{ij}'/2)^{1/2}$ and the stress ratio

$\tau = (\sigma _{ij}'\sigma _{ij}'/2)^{1/2}$ and the stress ratio ![]() $\mu =\tau /P$. The equations of motion are

$\mu =\tau /P$. The equations of motion are

where ![]() $\phi$ is the constant total solid fraction and

$\phi$ is the constant total solid fraction and ![]() $b_i$ is the non-inertial body force per unit volume (typically gravitational). Rheological constitutive equations are then required for the Cauchy stress

$b_i$ is the non-inertial body force per unit volume (typically gravitational). Rheological constitutive equations are then required for the Cauchy stress ![]() $\sigma _{ij}$. In our previous work (Liu et al. Reference Liu, Singh and Henann2023), we generalized the NGF model for dense granular flow from monodisperse to bidisperse systems. In this work, we continue to utilize the generalized NGF model to describe the rheological behaviour of dense, bidisperse granular flows, which, for brevity, is summarized in Appendix A.

$\sigma _{ij}$. In our previous work (Liu et al. Reference Liu, Singh and Henann2023), we generalized the NGF model for dense granular flow from monodisperse to bidisperse systems. In this work, we continue to utilize the generalized NGF model to describe the rheological behaviour of dense, bidisperse granular flows, which, for brevity, is summarized in Appendix A.

2.5. Segregation model

In this section we discuss the constitutive equation for the relative volume flux ![]() $w^{l}_i$. In dense granular flows a bidisperse mixture tends to segregate due to both shear-strain-rate gradients and pressure gradients. Moreover, diffusion acts counter to segregation and tends to mix the two species. Accordingly, we take the relative volume flux to be comprised of three contributions as follows:

$w^{l}_i$. In dense granular flows a bidisperse mixture tends to segregate due to both shear-strain-rate gradients and pressure gradients. Moreover, diffusion acts counter to segregation and tends to mix the two species. Accordingly, we take the relative volume flux to be comprised of three contributions as follows:

Here ![]() $w^{diff}_i$ is the diffusion flux,

$w^{diff}_i$ is the diffusion flux, ![]() $w^{S}_i$ is the shear-strain-rate-gradient-driven segregation flux and

$w^{S}_i$ is the shear-strain-rate-gradient-driven segregation flux and ![]() $w^{P}_i$ is the pressure-gradient-driven segregation flux.

$w^{P}_i$ is the pressure-gradient-driven segregation flux.

The first two contributions have been examined in detail in our prior work (Liu et al. Reference Liu, Singh and Henann2023) and are briefly recapped here. First, we take the diffusion flux to be driven by concentration gradients as ![]() $w^{diff}_i = -D (\partial c^{l} / \partial x_i )$, where

$w^{diff}_i = -D (\partial c^{l} / \partial x_i )$, where ![]() $D$ is the binary diffusion coefficient. In a dense, bidisperse granular mixture, the binary diffusion coefficient follows a well-established scaling (e.g. Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021; Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2021; Trewhela et al. Reference Trewhela, Ancey and Gray2021; Liu et al. Reference Liu, Singh and Henann2023) with the average grain size

$D$ is the binary diffusion coefficient. In a dense, bidisperse granular mixture, the binary diffusion coefficient follows a well-established scaling (e.g. Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021; Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2021; Trewhela et al. Reference Trewhela, Ancey and Gray2021; Liu et al. Reference Liu, Singh and Henann2023) with the average grain size ![]() $\bar {d}$ and the shear-strain rate

$\bar {d}$ and the shear-strain rate ![]() $\dot {\gamma }$ as

$\dot {\gamma }$ as ![]() $D = C_{diff} \bar {d}^2 \dot {\gamma }$, where

$D = C_{diff} \bar {d}^2 \dot {\gamma }$, where ![]() $C_{diff}$ is a dimensionless material parameter. Therefore, the diffusion flux is

$C_{diff}$ is a dimensionless material parameter. Therefore, the diffusion flux is

Second, in Liu et al. (Reference Liu, Singh and Henann2023) we isolated shear-strain-rate-gradient-driven segregation in two flow configurations with uniform pressure and proposed the following phenomenological constitutive equation for the flux ![]() $w^{S}_i$:

$w^{S}_i$:

Here ![]() $C^{S}_{seg}$ is another dimensionless material parameter. In (2.5) the pre-factor depends on the average grain size through

$C^{S}_{seg}$ is another dimensionless material parameter. In (2.5) the pre-factor depends on the average grain size through ![]() $\bar {d}^2$ for dimensional consistency and involves a symmetric dependence on

$\bar {d}^2$ for dimensional consistency and involves a symmetric dependence on ![]() $c^{l}$ through

$c^{l}$ through ![]() $c^{l}(1-c^{l})$, which ensures that segregation ceases when the bidisperse mixture becomes either all large (

$c^{l}(1-c^{l})$, which ensures that segregation ceases when the bidisperse mixture becomes either all large (![]() $c^{l}=1$) or all small (

$c^{l}=1$) or all small (![]() $c^{l}=0$) grains. While a symmetric dependence of the pre-factor on

$c^{l}=0$) grains. While a symmetric dependence of the pre-factor on ![]() $c^{l}$ was sufficient to capture the DEM data of Liu et al. (Reference Liu, Singh and Henann2023) in the absence of pressure gradients, it contrasts with the asymmetric dependence that has been invoked to model pressure-gradient-driven size segregation in the literature (e.g. Gajjar & Gray Reference Gajjar and Gray2014; Tunuguntla, Weinhart & Thornton Reference Tunuguntla, Weinhart and Thornton2017; Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021; Trewhela et al. Reference Trewhela, Ancey and Gray2021) and in the next paragraph of the present work.

$c^{l}$ was sufficient to capture the DEM data of Liu et al. (Reference Liu, Singh and Henann2023) in the absence of pressure gradients, it contrasts with the asymmetric dependence that has been invoked to model pressure-gradient-driven size segregation in the literature (e.g. Gajjar & Gray Reference Gajjar and Gray2014; Tunuguntla, Weinhart & Thornton Reference Tunuguntla, Weinhart and Thornton2017; Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021; Trewhela et al. Reference Trewhela, Ancey and Gray2021) and in the next paragraph of the present work.

Next, we consider the segregation flux associated with pressure gradients, ![]() $w^{P}_i$. We hypothesize that the segregation flux

$w^{P}_i$. We hypothesize that the segregation flux ![]() $w^{P}_i$ is driven by gradients in the pressure

$w^{P}_i$ is driven by gradients in the pressure ![]() $P$ and adopt the following phenomenological form for the constitutive equation for

$P$ and adopt the following phenomenological form for the constitutive equation for ![]() $w^{P}_i$:

$w^{P}_i$:

Here ![]() $C^{P}_{seg}$ and

$C^{P}_{seg}$ and ![]() $\alpha$ are dimensionless parameters dependent upon mixture properties (e.g. the grain-size ratio). The dependence of the pre-factor on

$\alpha$ are dimensionless parameters dependent upon mixture properties (e.g. the grain-size ratio). The dependence of the pre-factor on ![]() $\dot {\gamma }c^{l}(1-c^{l})$ ensures that (2.6) satisfies several minimal requirements – namely, that the pressure-gradient-driven segregation flux is zero when there is no flow (

$\dot {\gamma }c^{l}(1-c^{l})$ ensures that (2.6) satisfies several minimal requirements – namely, that the pressure-gradient-driven segregation flux is zero when there is no flow (![]() $\dot \gamma =0$) or when the mixture becomes either all large (

$\dot \gamma =0$) or when the mixture becomes either all large (![]() $c^{l}=1$) or all small (

$c^{l}=1$) or all small (![]() $c^{l}=0$) grains. Next, the dependence of the pre-factor on

$c^{l}=0$) grains. Next, the dependence of the pre-factor on ![]() $\bar {d}^2/P$ ensures dimensional consistency. Finally, in contrast to (2.5), the dependence of (2.6) on the factor

$\bar {d}^2/P$ ensures dimensional consistency. Finally, in contrast to (2.5), the dependence of (2.6) on the factor ![]() $(1 - \alpha + \alpha c^{l})$ introduces an asymmetric dependence on

$(1 - \alpha + \alpha c^{l})$ introduces an asymmetric dependence on ![]() $c^{l}$ into the flux constitutive equation.

$c^{l}$ into the flux constitutive equation.

Several comments on the flux constitutive equation (2.6) are warranted.

(i) The dependence of (2.6) on

$c^{l}$ through the asymmetric flux function

$c^{l}$ through the asymmetric flux function  $f(c^{l}) = c^{l}(1-c^{l}) (1 - \alpha + \alpha c^{l})$ follows directly from the work of Gajjar & Gray (Reference Gajjar and Gray2014), where

$f(c^{l}) = c^{l}(1-c^{l}) (1 - \alpha + \alpha c^{l})$ follows directly from the work of Gajjar & Gray (Reference Gajjar and Gray2014), where  $\alpha \in [0,1]$ is a parameter that controls the amount of asymmetry (denoted as

$\alpha \in [0,1]$ is a parameter that controls the amount of asymmetry (denoted as  $\gamma$ in Gajjar & Gray Reference Gajjar and Gray2014). As discussed in Gajjar & Gray (Reference Gajjar and Gray2014), the flux function

$\gamma$ in Gajjar & Gray Reference Gajjar and Gray2014). As discussed in Gajjar & Gray (Reference Gajjar and Gray2014), the flux function  $f(c^{l})$ has the following properties: (1) for

$f(c^{l})$ has the following properties: (1) for  $\alpha =0$, the symmetric flux function is recovered; (2) for

$\alpha =0$, the symmetric flux function is recovered; (2) for  $\alpha \in (0,1]$, the function's maximum is skewed from

$\alpha \in (0,1]$, the function's maximum is skewed from  $c^{l}=0.5$ towards

$c^{l}=0.5$ towards  $c^{l}=1$; (3) for

$c^{l}=1$; (3) for  $\alpha \in (0, 0.5]$, it is convex; and (4) for

$\alpha \in (0, 0.5]$, it is convex; and (4) for  $\alpha \in (0.5, 1]$, it is non-convex with a single inflection point. Previously, a value of

$\alpha \in (0.5, 1]$, it is non-convex with a single inflection point. Previously, a value of  $\alpha =0.46$ was obtained in Gajjar & Gray (Reference Gajjar and Gray2014) by fitting to the experiments of Wiederseiner et al. (Reference Wiederseiner, Andreini, Épely-Chauvin, Moser, Monnereau, Gray and Ancey2011), and a value of

$\alpha =0.46$ was obtained in Gajjar & Gray (Reference Gajjar and Gray2014) by fitting to the experiments of Wiederseiner et al. (Reference Wiederseiner, Andreini, Épely-Chauvin, Moser, Monnereau, Gray and Ancey2011), and a value of  $\alpha =0.89$ was determined by fitting to experiments in van der Vaart et al. (Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015). In what follows, we estimate

$\alpha =0.89$ was determined by fitting to experiments in van der Vaart et al. (Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015). In what follows, we estimate  $\alpha$ along with

$\alpha$ along with  $C^{P}_{seg}$ for both simulated, frictional spheres and disks by fitting to DEM simulations.

$C^{P}_{seg}$ for both simulated, frictional spheres and disks by fitting to DEM simulations.(ii) We note that the scaling of the pressure-gradient-driven segregation flux (2.6) with

$\bar {d}^2\dot {\gamma }/P$ is quite similar to the scalings for the segregation velocity reported in Trewhela et al. (Reference Trewhela, Ancey and Gray2021) and Jing et al. (Reference Jing, Ottino, Umbanhowar and Lueptow2022) based on experiments and discrete simulations, respectively, of the dynamics of a single intruder in a flowing dense granular medium, and the scaling of Trewhela et al. (Reference Trewhela, Ancey and Gray2021) was utilized in the continuum simulations of Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021). As pointed out in these works, combining a segregation flux that is inversely proportional to the pressure with a pressure-independent diffusion flux enables a model to capture the attenuation of segregation with increasing pressure, which was observed in the discrete simulations of Fry et al. (Reference Fry, Umbanhowar, Ottino and Lueptow2018, Reference Fry, Umbanhowar, Ottino and Lueptow2019) in flows involving weak strain-rate gradients. However, one difference is that Trewhela et al. (Reference Trewhela, Ancey and Gray2021) introduces a second term in the denominator to prevent a singularity when the pressure is equal to zero, such as at a free surface. This additional term in the denominator depends on the product of the magnitude of the pressure gradient and the average grain size

$\bar {d}^2\dot {\gamma }/P$ is quite similar to the scalings for the segregation velocity reported in Trewhela et al. (Reference Trewhela, Ancey and Gray2021) and Jing et al. (Reference Jing, Ottino, Umbanhowar and Lueptow2022) based on experiments and discrete simulations, respectively, of the dynamics of a single intruder in a flowing dense granular medium, and the scaling of Trewhela et al. (Reference Trewhela, Ancey and Gray2021) was utilized in the continuum simulations of Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021). As pointed out in these works, combining a segregation flux that is inversely proportional to the pressure with a pressure-independent diffusion flux enables a model to capture the attenuation of segregation with increasing pressure, which was observed in the discrete simulations of Fry et al. (Reference Fry, Umbanhowar, Ottino and Lueptow2018, Reference Fry, Umbanhowar, Ottino and Lueptow2019) in flows involving weak strain-rate gradients. However, one difference is that Trewhela et al. (Reference Trewhela, Ancey and Gray2021) introduces a second term in the denominator to prevent a singularity when the pressure is equal to zero, such as at a free surface. This additional term in the denominator depends on the product of the magnitude of the pressure gradient and the average grain size  $\bar {d}$ and is multiplied by an additional (small) dimensionless constant. Here, we follow a similar approach but directly add a small constant to the pressure field when dealing with free-surface flows in § 4.1.

$\bar {d}$ and is multiplied by an additional (small) dimensionless constant. Here, we follow a similar approach but directly add a small constant to the pressure field when dealing with free-surface flows in § 4.1.(iii) Finally, it has been well established that the pressure-gradient-driven segregation flux should depend on the grain-size ratio

$d^{l}/d^{s}$ (e.g. Schlick et al. Reference Schlick, Fan, Isner, Umbanhowar, Ottino and Lueptow2015; Tunuguntla et al. Reference Tunuguntla, Weinhart and Thornton2017; Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021; Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2021; Trewhela et al. Reference Trewhela, Ancey and Gray2021). However, the aims of this paper are to combine pressure-gradient-driven and shear-strain-rate-gradient-driven segregation fluxes within a coupled model for size segregation and flow and then to use this model to examine the interplay between the mechanisms. Therefore, we consider a single grain-size ratio of

$d^{l}/d^{s}$ (e.g. Schlick et al. Reference Schlick, Fan, Isner, Umbanhowar, Ottino and Lueptow2015; Tunuguntla et al. Reference Tunuguntla, Weinhart and Thornton2017; Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021; Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2021; Trewhela et al. Reference Trewhela, Ancey and Gray2021). However, the aims of this paper are to combine pressure-gradient-driven and shear-strain-rate-gradient-driven segregation fluxes within a coupled model for size segregation and flow and then to use this model to examine the interplay between the mechanisms. Therefore, we consider a single grain-size ratio of  $d^{l}/d^{s}=1.5$ throughout, and considering the dependence of (2.6) on

$d^{l}/d^{s}=1.5$ throughout, and considering the dependence of (2.6) on  $d^{l}/d^{s}$ is beyond the scope of this paper. We expect that the substantial progress in the literature to characterize the role of the grain-size ratio (e.g. Trewhela et al. Reference Trewhela, Ancey and Gray2021) may be incorporated into (2.6).

$d^{l}/d^{s}$ is beyond the scope of this paper. We expect that the substantial progress in the literature to characterize the role of the grain-size ratio (e.g. Trewhela et al. Reference Trewhela, Ancey and Gray2021) may be incorporated into (2.6).

Combining (2.4), (2.5) and (2.6) with the balance of mass equation (2.1), we obtain the following differential relation governing the dynamics of ![]() $c^{l}$:

$c^{l}$:

$$\begin{gather} \dfrac{{\rm

D}{c}^{l}}{{\rm D}t} + \dfrac{\partial}{\partial x_i}

\left({-}C_{diff} \bar{d}^2 \dot{\gamma} \frac{\partial

c^l}{\partial x_i} + C^{S}_{seg} \bar{d}^2 c^{l}(1-c^{l})

\frac{\partial \dot{\gamma}}{\partial x_i}

\right.\nonumber\\ \left.- C^{P}_{seg}

\frac{\bar{d}^2 \dot{\gamma}}{P} c^{l}(1-c^{l}) (1- \alpha

+ \alpha c^{l}) \frac{\partial P}{\partial x_i} \right) =

0.

\end{gather}$$

$$\begin{gather} \dfrac{{\rm

D}{c}^{l}}{{\rm D}t} + \dfrac{\partial}{\partial x_i}

\left({-}C_{diff} \bar{d}^2 \dot{\gamma} \frac{\partial

c^l}{\partial x_i} + C^{S}_{seg} \bar{d}^2 c^{l}(1-c^{l})

\frac{\partial \dot{\gamma}}{\partial x_i}

\right.\nonumber\\ \left.- C^{P}_{seg}

\frac{\bar{d}^2 \dot{\gamma}}{P} c^{l}(1-c^{l}) (1- \alpha

+ \alpha c^{l}) \frac{\partial P}{\partial x_i} \right) =

0.

\end{gather}$$

The material parameters associated with the segregation model are the set ![]() $\{C_{diff}, C^{S}_{seg}, C^{P}_{seg}, \alpha \}$. As discussed in Liu et al. (Reference Liu, Singh and Henann2023), the parameter

$\{C_{diff}, C^{S}_{seg}, C^{P}_{seg}, \alpha \}$. As discussed in Liu et al. (Reference Liu, Singh and Henann2023), the parameter ![]() $C_{diff}$ may be determined from measurements of the mean square displacement during homogeneous simple shearing, and the parameter

$C_{diff}$ may be determined from measurements of the mean square displacement during homogeneous simple shearing, and the parameter ![]() $C^{S}_{seg}$ may be determined by examining size segregation in flows, in which the pressure field is spatially uniform. Based on the DEM simulations of Liu et al. (Reference Liu, Singh and Henann2023), these parameters are

$C^{S}_{seg}$ may be determined by examining size segregation in flows, in which the pressure field is spatially uniform. Based on the DEM simulations of Liu et al. (Reference Liu, Singh and Henann2023), these parameters are ![]() $\{C_{diff}=0.045, C^{S}_{seg}=0.08\}$ for frictional spheres and

$\{C_{diff}=0.045, C^{S}_{seg}=0.08\}$ for frictional spheres and ![]() $\{C_{diff}=0.20, C^{S}_{seg}=0.23\}$ for frictional disks over a range of modest grain-size ratios including

$\{C_{diff}=0.20, C^{S}_{seg}=0.23\}$ for frictional disks over a range of modest grain-size ratios including ![]() $d^{l}/d^{s}=1.5$. The remaining material parameters

$d^{l}/d^{s}=1.5$. The remaining material parameters ![]() $\{C^{P}_{seg}, \alpha \}$, which are associated with the pressure-gradient-driven segregation flux, will be determined for frictional spheres and disks in the following section.

$\{C^{P}_{seg}, \alpha \}$, which are associated with the pressure-gradient-driven segregation flux, will be determined for frictional spheres and disks in the following section.

3. Pressure-gradient-driven segregation flux

In this section we evaluate the constitutive equation for the pressure-gradient-driven segregation flux (2.6) and estimate the material parameters associated with this segregation flux ![]() $\{C^{P}_{seg}, \alpha \}$. To this end, we consider flows of both three-dimensional systems of dense, frictional spheres and two-dimensional systems of dense, frictional disks down an inclined plane, using DEM simulations. Details of the simulated granular systems, including the grain interaction properties that are maintained constant throughout, are given in Appendix B.1. We note that the inclined plane flow configuration has been widely utilized in the literature (e.g. Savage & Lun Reference Savage and Lun1988; Gray & Thornton Reference Gray and Thornton2005; Gray & Chugunov Reference Gray and Chugunov2006; Wiederseiner et al. Reference Wiederseiner, Andreini, Épely-Chauvin, Moser, Monnereau, Gray and Ancey2011; Marks et al. Reference Marks, Rognon and Einav2012; Gajjar & Gray Reference Gajjar and Gray2014; Staron & Phillips Reference Staron and Phillips2015; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021) to study size segregation in dense granular materials.

$\{C^{P}_{seg}, \alpha \}$. To this end, we consider flows of both three-dimensional systems of dense, frictional spheres and two-dimensional systems of dense, frictional disks down an inclined plane, using DEM simulations. Details of the simulated granular systems, including the grain interaction properties that are maintained constant throughout, are given in Appendix B.1. We note that the inclined plane flow configuration has been widely utilized in the literature (e.g. Savage & Lun Reference Savage and Lun1988; Gray & Thornton Reference Gray and Thornton2005; Gray & Chugunov Reference Gray and Chugunov2006; Wiederseiner et al. Reference Wiederseiner, Andreini, Épely-Chauvin, Moser, Monnereau, Gray and Ancey2011; Marks et al. Reference Marks, Rognon and Einav2012; Gajjar & Gray Reference Gajjar and Gray2014; Staron & Phillips Reference Staron and Phillips2015; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021) to study size segregation in dense granular materials.

Consider a semi-infinite layer of thickness ![]() $H$ of a dense, bidisperse granular mixture flowing down an inclined plane with surface inclination angle

$H$ of a dense, bidisperse granular mixture flowing down an inclined plane with surface inclination angle ![]() $\theta$ under the action of gravity

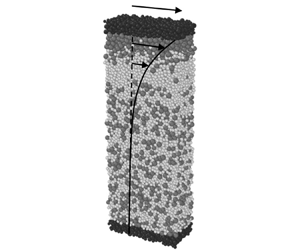

$\theta$ under the action of gravity ![]() $G$. For the case of bidisperse spheres, the DEM set-up is shown in figure 1(a) for

$G$. For the case of bidisperse spheres, the DEM set-up is shown in figure 1(a) for ![]() $H = 50\bar {d}_0$, where

$H = 50\bar {d}_0$, where ![]() $\bar {d}_0$ is the system-wide average grain size. The large particles are dark grey and the small particles are light grey. We employ periodic boundary conditions along both the direction of flow (i.e. the

$\bar {d}_0$ is the system-wide average grain size. The large particles are dark grey and the small particles are light grey. We employ periodic boundary conditions along both the direction of flow (i.e. the ![]() $x$ direction) and the lateral direction (i.e. the

$x$ direction) and the lateral direction (i.e. the ![]() $y$ direction), eliminating any lateral wall/boundary effects. In all DEM simulations of spheres, we take the length of the simulation domain along the

$y$ direction), eliminating any lateral wall/boundary effects. In all DEM simulations of spheres, we take the length of the simulation domain along the ![]() $x$ direction to be

$x$ direction to be ![]() $L=20 \bar {d}_0$ and the length along the

$L=20 \bar {d}_0$ and the length along the ![]() $y$ direction to be

$y$ direction to be ![]() $W=10 \bar {d}_0$, and we have verified that both of these length scales are sufficiently large, so that they do not affect the resulting flow and segregation fields. The rough bottom surface is comprised of touching, glued grains in our DEM simulations, which are denoted as black in figure 1(a). This is done to achieve a no-slip boundary condition along the bottom surface. In the resulting flow fields, the only non-zero component of the velocity field is

$W=10 \bar {d}_0$, and we have verified that both of these length scales are sufficiently large, so that they do not affect the resulting flow and segregation fields. The rough bottom surface is comprised of touching, glued grains in our DEM simulations, which are denoted as black in figure 1(a). This is done to achieve a no-slip boundary condition along the bottom surface. In the resulting flow fields, the only non-zero component of the velocity field is ![]() $v_x$, which only varies along the vertical coordinate

$v_x$, which only varies along the vertical coordinate ![]() $z$. A typical steady velocity field is qualitatively sketched in figure 1(a), which is consistent with the familiar ‘Bagnold profile’.

$z$. A typical steady velocity field is qualitatively sketched in figure 1(a), which is consistent with the familiar ‘Bagnold profile’.

Figure 1. (a) Initial well-mixed configuration for three-dimensional DEM simulation of bidisperse inclined plane flow with ![]() $\sim$15 000 flowing grains. The thickness of the flowing layer is

$\sim$15 000 flowing grains. The thickness of the flowing layer is ![]() $H=50 \bar {d}_0$. Black grains represent the rough fixed base. Dark grey grains indicate large flowing grains and light grey grains indicate small flowing grains. (b) Segregated configuration after flowing for a simulation time of

$H=50 \bar {d}_0$. Black grains represent the rough fixed base. Dark grey grains indicate large flowing grains and light grey grains indicate small flowing grains. (b) Segregated configuration after flowing for a simulation time of ![]() $\tilde {t} = t/\sqrt {\bar {d}_0/G} = 15\,000$. (c) Spatiotemporal evolution of the large-grain concentration field. Spatial profiles of (d) the concentration field

$\tilde {t} = t/\sqrt {\bar {d}_0/G} = 15\,000$. (c) Spatiotemporal evolution of the large-grain concentration field. Spatial profiles of (d) the concentration field ![]() $c^{l}$ and (e) the normalized velocity field

$c^{l}$ and (e) the normalized velocity field ![]() $v_x/\sqrt {G \bar {d}_0}$ at three time instants (

$v_x/\sqrt {G \bar {d}_0}$ at three time instants (![]() $\tilde {t} = 1000$,

$\tilde {t} = 1000$, ![]() $5000$ and

$5000$ and ![]() $15\,000$) as indicated by the vertical lines in (c).

$15\,000$) as indicated by the vertical lines in (c).

Regarding the stress field, due to the force balances along the ![]() $x$ and

$x$ and ![]() $z$ directions, we have

$z$ directions, we have ![]() $|\sigma _{xz}(z)| = |\sigma _{zx}(z)| = \phi \rho _{s} G z \sin \theta$ and

$|\sigma _{xz}(z)| = |\sigma _{zx}(z)| = \phi \rho _{s} G z \sin \theta$ and ![]() $\sigma _{zz}(z) = -\phi \rho _{s} G z\cos \theta$, respectively. For two-dimensional systems of disks, we observe in DEM simulations that the normal stresses are approximately equal, i.e.

$\sigma _{zz}(z) = -\phi \rho _{s} G z\cos \theta$, respectively. For two-dimensional systems of disks, we observe in DEM simulations that the normal stresses are approximately equal, i.e. ![]() $\sigma _{xx}(z) \approx \sigma _{zz}(z)$, so that

$\sigma _{xx}(z) \approx \sigma _{zz}(z)$, so that ![]() $\tau (z) = | \sigma _{xz}(z) | = \phi \rho _{s} G z \sin \theta$,

$\tau (z) = | \sigma _{xz}(z) | = \phi \rho _{s} G z \sin \theta$, ![]() $P(z) = - \sigma _{zz}(z) = \phi \rho _{s} G z \cos \theta$ and

$P(z) = - \sigma _{zz}(z) = \phi \rho _{s} G z \cos \theta$ and ![]() $\mu (z) = \tau (z)/P(z) = \tan \theta$. For three-dimensional systems of spheres, we observe normal stress differences in DEM simulations (e.g. Srivastava et al. Reference Srivastava, Silbert, Grest and Lechman2021), in which, in particular, the magnitude of the out-of-plane normal stress

$\mu (z) = \tau (z)/P(z) = \tan \theta$. For three-dimensional systems of spheres, we observe normal stress differences in DEM simulations (e.g. Srivastava et al. Reference Srivastava, Silbert, Grest and Lechman2021), in which, in particular, the magnitude of the out-of-plane normal stress ![]() $\sigma _{yy}(z)$ is slightly lower than the magnitude of

$\sigma _{yy}(z)$ is slightly lower than the magnitude of ![]() $\sigma _{zz}(z)$ at each

$\sigma _{zz}(z)$ at each ![]() $z$ position. For spheres, the stress ratio

$z$ position. For spheres, the stress ratio ![]() $\mu$ is still spatially uniform but slightly higher than

$\mu$ is still spatially uniform but slightly higher than ![]() $\tan \theta$, and the pressure field

$\tan \theta$, and the pressure field ![]() $P(z)$ still varies linearly in

$P(z)$ still varies linearly in ![]() $z$ but with a slope that is slightly lower than

$z$ but with a slope that is slightly lower than ![]() $\phi \rho _{s} G \cos \theta$.

$\phi \rho _{s} G \cos \theta$.

There are four important dimensionless parameters that specify a case of inclined plane flow: (1) ![]() $H/\bar {d}_0$, the dimensionless layer thickness; (2)

$H/\bar {d}_0$, the dimensionless layer thickness; (2) ![]() $\theta$, the inclination angle, which sets the stress field for a given case and controls the total flow rate down the incline; (3)

$\theta$, the inclination angle, which sets the stress field for a given case and controls the total flow rate down the incline; (3) ![]() $c^{l}_0(z)$, the initial large-grain concentration, which can be a spatially varying field; and (4)

$c^{l}_0(z)$, the initial large-grain concentration, which can be a spatially varying field; and (4) ![]() $d^{l}/d^{s}$, the bidisperse grain-size ratio. Thus, the parameter set

$d^{l}/d^{s}$, the bidisperse grain-size ratio. Thus, the parameter set ![]() $\{H/\bar {d}_0, \theta, c^{l}_0, d^{l}/d^{s}\}$ specifies the geometry, loads and initial conditions for a given case of inclined plane flow. We choose a representative base case for spheres corresponding to the parameter set

$\{H/\bar {d}_0, \theta, c^{l}_0, d^{l}/d^{s}\}$ specifies the geometry, loads and initial conditions for a given case of inclined plane flow. We choose a representative base case for spheres corresponding to the parameter set ![]() $\{H/\bar {d}_0=50, \theta =26^\circ, c^{l}_0 = 0.50, d^{l}/d^{s} = 1.5\}$, and the initially well-mixed DEM configuration for this case is shown in figure 1(a). We then run the DEM simulation from this initial configuration and observe the consequent segregation process. Due to the gravitationally induced pressure gradient, we expect the large grains (dark grey) to be driven towards the top of the layer where the pressure is the lowest. The segregated state after a simulation time of

$\{H/\bar {d}_0=50, \theta =26^\circ, c^{l}_0 = 0.50, d^{l}/d^{s} = 1.5\}$, and the initially well-mixed DEM configuration for this case is shown in figure 1(a). We then run the DEM simulation from this initial configuration and observe the consequent segregation process. Due to the gravitationally induced pressure gradient, we expect the large grains (dark grey) to be driven towards the top of the layer where the pressure is the lowest. The segregated state after a simulation time of ![]() $\tilde {t} = t/\sqrt {\bar {d}_0/G} = 15\,000$ is shown in figure 1(b), demonstrating that the large grains indeed segregate towards the top of the layer, leaving a layer of small grains (light grey) beneath. In order to obtain a more quantitative picture of the segregation dynamics, we coarse grain the concentration field

$\tilde {t} = t/\sqrt {\bar {d}_0/G} = 15\,000$ is shown in figure 1(b), demonstrating that the large grains indeed segregate towards the top of the layer, leaving a layer of small grains (light grey) beneath. In order to obtain a more quantitative picture of the segregation dynamics, we coarse grain the concentration field ![]() $c^{l}$ and plot contours of the spatiotemporal evolution of the

$c^{l}$ and plot contours of the spatiotemporal evolution of the ![]() $c^{l}$ field in figure 1(c). (The methods used for spatial coarse graining are described in Appendix B.2.) The growing width of the dark region indicates the temporal evolution of the large grains segregating to the top of the layer. Furthermore, snapshots of the concentration field

$c^{l}$ field in figure 1(c). (The methods used for spatial coarse graining are described in Appendix B.2.) The growing width of the dark region indicates the temporal evolution of the large grains segregating to the top of the layer. Furthermore, snapshots of the concentration field ![]() $c^{l}$ and the non-dimensionalized velocity field

$c^{l}$ and the non-dimensionalized velocity field ![]() $v_x/\sqrt {G \bar {d}_0}$ at different times –

$v_x/\sqrt {G \bar {d}_0}$ at different times – ![]() $\tilde {t} = 1000, 5000, 15\,000$ as indicated by the vertical lines in figure 1(c) – are shown in figures 1(d) and 1(e), respectively. It is evident from these plots that the velocity field reaches a steady state early in the simulation time window, while the concentration field continues to evolve and only reaches a steady state towards the end of the simulation time window, i.e.

$\tilde {t} = 1000, 5000, 15\,000$ as indicated by the vertical lines in figure 1(c) – are shown in figures 1(d) and 1(e), respectively. It is evident from these plots that the velocity field reaches a steady state early in the simulation time window, while the concentration field continues to evolve and only reaches a steady state towards the end of the simulation time window, i.e. ![]() $\tilde {t} \gtrsim 15\,000$. Lastly, the shape of the steady flow field

$\tilde {t} \gtrsim 15\,000$. Lastly, the shape of the steady flow field ![]() $v_x(z)$ in figure 1(e) is consistent with the scaling

$v_x(z)$ in figure 1(e) is consistent with the scaling ![]() $v_x(z) \propto H^{3/2} - z^{3/2}$, associated with the ‘Bagnold profile’ (e.g. Gray & Thornton Reference Gray and Thornton2005).

$v_x(z) \propto H^{3/2} - z^{3/2}$, associated with the ‘Bagnold profile’ (e.g. Gray & Thornton Reference Gray and Thornton2005).

In the inclined plane flow configuration, both pressure gradients and shear-strain-rate gradients are present. The shape of the steady flow field ![]() $v_x(z)$ in figure 1(e) indicates that the shear-strain rate is greatest at the bottom of the layer, decreasing with the distance from the bottom of the layer and approaching zero at the top of the layer. Therefore, the shear-strain-rate gradient drives the large grains towards the high-strain-rate region at the bottom of the layer, while the pressure gradient drives the large grains towards the low-pressure region at the top of the layer. As a result, the shear-strain-rate-gradient-driven and pressure-gradient-driven fluxes are in competition with one another, and the pressure-gradient-driven flux clearly wins out and drives the large grains towards the top of the layer. This characteristic of inclined plane flow makes it a suitable configuration for estimating the dimensionless material parameters

$v_x(z)$ in figure 1(e) indicates that the shear-strain rate is greatest at the bottom of the layer, decreasing with the distance from the bottom of the layer and approaching zero at the top of the layer. Therefore, the shear-strain-rate gradient drives the large grains towards the high-strain-rate region at the bottom of the layer, while the pressure gradient drives the large grains towards the low-pressure region at the top of the layer. As a result, the shear-strain-rate-gradient-driven and pressure-gradient-driven fluxes are in competition with one another, and the pressure-gradient-driven flux clearly wins out and drives the large grains towards the top of the layer. This characteristic of inclined plane flow makes it a suitable configuration for estimating the dimensionless material parameters ![]() $\{C^{P}_{seg},\alpha \}$. To achieve this, we first run the DEM simulation long enough so that all evolving fields reach the steady-state regime (

$\{C^{P}_{seg},\alpha \}$. To achieve this, we first run the DEM simulation long enough so that all evolving fields reach the steady-state regime (![]() $\tilde {t} \gtrsim 15\,000$). In this regime,

$\tilde {t} \gtrsim 15\,000$). In this regime, ![]() ${{\rm D} c^{l}}/{{\rm D} t} \approx 0$, and according to the balance of mass equation (2.1) and the no-flux boundary conditions at the top and bottom of the layer, the total flux is zero, i.e.

${{\rm D} c^{l}}/{{\rm D} t} \approx 0$, and according to the balance of mass equation (2.1) and the no-flux boundary conditions at the top and bottom of the layer, the total flux is zero, i.e. ![]() $w^{l}_z = w^{diff}_z + w^{S}_z + w^{P}_z = 0$, at each

$w^{l}_z = w^{diff}_z + w^{S}_z + w^{P}_z = 0$, at each ![]() $z$ position. Therefore, in the steady-state regime, using (2.4), (2.5) and (2.6), we have

$z$ position. Therefore, in the steady-state regime, using (2.4), (2.5) and (2.6), we have

Since the parameters ![]() $C_{diff}$ and

$C_{diff}$ and ![]() $C^{S}_{seg}$ have been previously determined, we use this steady-state flux balance to estimate the parameters

$C^{S}_{seg}$ have been previously determined, we use this steady-state flux balance to estimate the parameters ![]() $\{C^{P}_{seg},\alpha \}$. To do so, we spatially coarse grain the DEM data from

$\{C^{P}_{seg},\alpha \}$. To do so, we spatially coarse grain the DEM data from ![]() $1000$ evenly distributed snapshots in the steady-state regime to obtain the relevant field quantities in (3.1) – namely,

$1000$ evenly distributed snapshots in the steady-state regime to obtain the relevant field quantities in (3.1) – namely, ![]() $c^{l}$ (and, hence,

$c^{l}$ (and, hence, ![]() $\bar {d}$),

$\bar {d}$), ![]() $\partial c^{l}/\partial z$,

$\partial c^{l}/\partial z$, ![]() $v_x$,

$v_x$, ![]() $\dot {\gamma } = \partial v_x/\partial z$,

$\dot {\gamma } = \partial v_x/\partial z$, ![]() $\partial \dot {\gamma }/\partial z = \partial ^2 v_x/ \partial z^2$,

$\partial \dot {\gamma }/\partial z = \partial ^2 v_x/ \partial z^2$, ![]() $P$ and

$P$ and ![]() $\partial P/\partial z$. The fields are then arithmetically averaged in time so that the resultant fields only depend on the spatial coordinate

$\partial P/\partial z$. The fields are then arithmetically averaged in time so that the resultant fields only depend on the spatial coordinate ![]() $z$. Equation (3.1) suggests determining the parameter

$z$. Equation (3.1) suggests determining the parameter ![]() $C^{P}_{seg}$ from the slope of the

$C^{P}_{seg}$ from the slope of the ![]() $C^{S}_{seg} \bar {d}^2c^{l}(1-c^{l}) ({\partial \dot {\gamma }}/{\partial z}) - C_{diff} \bar {d}^2\dot {\gamma } ({\partial c^{l}}/{\partial z})$ vs

$C^{S}_{seg} \bar {d}^2c^{l}(1-c^{l}) ({\partial \dot {\gamma }}/{\partial z}) - C_{diff} \bar {d}^2\dot {\gamma } ({\partial c^{l}}/{\partial z})$ vs ![]() $({\bar {d}^2 \dot {\gamma }}/{P}) c^{l}(1-c^{l})(1 - \alpha + \alpha c^{l}) ({\partial P}/{\partial z})$ relation for a given choice of

$({\bar {d}^2 \dot {\gamma }}/{P}) c^{l}(1-c^{l})(1 - \alpha + \alpha c^{l}) ({\partial P}/{\partial z})$ relation for a given choice of ![]() $\alpha \in [0,1]$. Since

$\alpha \in [0,1]$. Since ![]() $\alpha$ is an adjustable parameter along with

$\alpha$ is an adjustable parameter along with ![]() $C^{P}_{seg}$, additional data are helpful to more precisely estimate the values of the parameters

$C^{P}_{seg}$, additional data are helpful to more precisely estimate the values of the parameters ![]() $\{C^{P}_{seg},\alpha \}$, and we consider three additional variants of the base case – namely, (1) a lower inclination angle case

$\{C^{P}_{seg},\alpha \}$, and we consider three additional variants of the base case – namely, (1) a lower inclination angle case ![]() $\{H/\bar {d}_0=50, \theta =24^\circ, c^{l}_0 = 0.50, d^{l}/d^{s} = 1.5\}$; (2) a more large grains case

$\{H/\bar {d}_0=50, \theta =24^\circ, c^{l}_0 = 0.50, d^{l}/d^{s} = 1.5\}$; (2) a more large grains case ![]() $\{H/\bar {d}_0=50, \theta =26^\circ, c^{l}_0 = 0.75, d^{l}/d^{s} = 1.5\}$; and (3) a thicker layer case

$\{H/\bar {d}_0=50, \theta =26^\circ, c^{l}_0 = 0.75, d^{l}/d^{s} = 1.5\}$; and (3) a thicker layer case ![]() $\{H/\bar {d}_0=60, \theta =26^\circ, c^{l}_0 = 0.50, d^{l}/d^{s} = 1.5\}$. We coarse grain the steady-state DEM field data for all four cases and iterate over values of

$\{H/\bar {d}_0=60, \theta =26^\circ, c^{l}_0 = 0.50, d^{l}/d^{s} = 1.5\}$. We coarse grain the steady-state DEM field data for all four cases and iterate over values of ![]() $\alpha$, seeking the strongest linear collapse in

$\alpha$, seeking the strongest linear collapse in ![]() $C^{S}_{seg} \bar {d}^2c^{l}(1-c^{l})({\partial \dot {\gamma }}/{\partial z}) - C_{diff} \bar {d}^2\dot {\gamma } ({\partial c^{l}}/{\partial z})$ vs

$C^{S}_{seg} \bar {d}^2c^{l}(1-c^{l})({\partial \dot {\gamma }}/{\partial z}) - C_{diff} \bar {d}^2\dot {\gamma } ({\partial c^{l}}/{\partial z})$ vs ![]() $({\bar {d}^2 \dot {\gamma }}/{P}) c^{l}(1-c^{l})(1 - \alpha + \alpha c^{l}) ({\partial P}/{\partial z})$. The DEM data for the best-fit case of

$({\bar {d}^2 \dot {\gamma }}/{P}) c^{l}(1-c^{l})(1 - \alpha + \alpha c^{l}) ({\partial P}/{\partial z})$. The DEM data for the best-fit case of ![]() $\alpha =0.4$ is shown in figure 2(a), where each data point represents a unique

$\alpha =0.4$ is shown in figure 2(a), where each data point represents a unique ![]() $z$ position. The data collapses quite well across the different cases and a linear dependence is evident. For

$z$ position. The data collapses quite well across the different cases and a linear dependence is evident. For ![]() $\alpha =0.4$, the coefficient of determination (i.e. the R-squared value) is

$\alpha =0.4$, the coefficient of determination (i.e. the R-squared value) is ![]() $0.92$. Finally, the dimensionless material parameter

$0.92$. Finally, the dimensionless material parameter ![]() $C^{P}_{seg}$ may be obtained from the slope of the linear relation in figure 2(a) (indicated by the solid line), which we determine to be

$C^{P}_{seg}$ may be obtained from the slope of the linear relation in figure 2(a) (indicated by the solid line), which we determine to be ![]() $C^{P}_{seg} = 0.34$ for frictional spheres with a size ratio of

$C^{P}_{seg} = 0.34$ for frictional spheres with a size ratio of ![]() $d^{l}/d^{s}=1.5$.

$d^{l}/d^{s}=1.5$.

Figure 2. Collapse of ![]() $C^{S}_{seg} \bar {d}^2c^{l}(1-c^{l})({\partial \dot {\gamma }}/{\partial z}) - C_{diff} \bar {d}^2\dot {\gamma } ({\partial c^{l}}/{\partial z})$ vs

$C^{S}_{seg} \bar {d}^2c^{l}(1-c^{l})({\partial \dot {\gamma }}/{\partial z}) - C_{diff} \bar {d}^2\dot {\gamma } ({\partial c^{l}}/{\partial z})$ vs ![]() $({\bar {d}^2 \dot {\gamma }}/{P}) c^{l}(1-c^{l})(1 - \alpha + \alpha c^{l}) ({\partial P}/{\partial z})$ for several cases of inclined plane flow of (a) bidisperse spheres and (b) bidispserse disks with a size ratio of

$({\bar {d}^2 \dot {\gamma }}/{P}) c^{l}(1-c^{l})(1 - \alpha + \alpha c^{l}) ({\partial P}/{\partial z})$ for several cases of inclined plane flow of (a) bidisperse spheres and (b) bidispserse disks with a size ratio of ![]() $d^{l}/d^{s}=1.5$. Symbols represent coarse-grained, steady-state DEM field data, and the solid lines are the best linear fits using (a)

$d^{l}/d^{s}=1.5$. Symbols represent coarse-grained, steady-state DEM field data, and the solid lines are the best linear fits using (a) ![]() $C^{P}_{seg} = 0.34$ for spheres and (b)

$C^{P}_{seg} = 0.34$ for spheres and (b) ![]() $C^{P}_{seg} = 0.51$ for disks.

$C^{P}_{seg} = 0.51$ for disks.

We also apply this process to dense, bidisperse mixtures of frictional disks to determine the parameters ![]() $\{C^{P}_{seg},\alpha \}$. We consider a base case for disks corresponding to the parameter set

$\{C^{P}_{seg},\alpha \}$. We consider a base case for disks corresponding to the parameter set ![]() $\{H/\bar {d}_0=60, \theta =20^\circ, c^{l}_0 = 0.50, d^{l}/d^{s} = 1.5\}$ as well as three variants – (1) a lower inclination angle case

$\{H/\bar {d}_0=60, \theta =20^\circ, c^{l}_0 = 0.50, d^{l}/d^{s} = 1.5\}$ as well as three variants – (1) a lower inclination angle case ![]() $\{H/\bar {d}_0=60,\, \theta =18^\circ, c^{l}_0 = 0.50, d^{l}/d^{s} = 1.5\}$; (2) a more large grains case

$\{H/\bar {d}_0=60,\, \theta =18^\circ, c^{l}_0 = 0.50, d^{l}/d^{s} = 1.5\}$; (2) a more large grains case ![]() $\{H/\bar {d}_0=60,\, \theta =20^\circ,\, c^{l}_0 = 0.75, d^{l}/d^{s} = 1.5\}$; and (3) a thinner layer case

$\{H/\bar {d}_0=60,\, \theta =20^\circ,\, c^{l}_0 = 0.75, d^{l}/d^{s} = 1.5\}$; and (3) a thinner layer case ![]() $\{H/\bar {d}_0=40, \theta =20^\circ, c^{l}_0 = 0.50, d^{l}/d^{s} = 1.5\}$. In the DEM simulations for disks, the length of the simulation domain along the

$\{H/\bar {d}_0=40, \theta =20^\circ, c^{l}_0 = 0.50, d^{l}/d^{s} = 1.5\}$. In the DEM simulations for disks, the length of the simulation domain along the ![]() $x$ direction is taken to be

$x$ direction is taken to be ![]() $L=60\bar {d}_0$ in all cases, and each case involves

$L=60\bar {d}_0$ in all cases, and each case involves ![]() $\sim$5000 flowing grains. Each DEM simulation is run to steady state; the steady-state DEM data are coarse grained; and the flux balance (3.1) is applied. The DEM data for all four cases is plotted in figure 2(b) for

$\sim$5000 flowing grains. Each DEM simulation is run to steady state; the steady-state DEM data are coarse grained; and the flux balance (3.1) is applied. The DEM data for all four cases is plotted in figure 2(b) for ![]() $\alpha =0.4$ and the data again collapses quite well. A linear relation is observed (with an R-squared value of

$\alpha =0.4$ and the data again collapses quite well. A linear relation is observed (with an R-squared value of ![]() $0.82$), and the parameter

$0.82$), and the parameter ![]() $C^{P}_{seg}$ for frictional disks with a size ratio of

$C^{P}_{seg}$ for frictional disks with a size ratio of ![]() $d^{l}/d^{s}=1.5$ is determined from the slope of the linear relation to be

$d^{l}/d^{s}=1.5$ is determined from the slope of the linear relation to be ![]() $C^{P}_{seg} = 0.51$. We note that we have utilized the same value of

$C^{P}_{seg} = 0.51$. We note that we have utilized the same value of ![]() $\alpha =0.4$ for both spheres and disks. Of course, the parameter

$\alpha =0.4$ for both spheres and disks. Of course, the parameter ![]() $\alpha$ may be fitted separately to steady-state DEM data for spheres and disks, respectively, but we observed that the separately fitted values of

$\alpha$ may be fitted separately to steady-state DEM data for spheres and disks, respectively, but we observed that the separately fitted values of ![]() $\alpha$ turn out to be quite similar, so for simplicity, the value of

$\alpha$ turn out to be quite similar, so for simplicity, the value of ![]() $\alpha =0.4$ represents the collective best fit that yields the strongest linear collapses of the steady-state DEM data for both spheres and disks simultaneously.

$\alpha =0.4$ represents the collective best fit that yields the strongest linear collapses of the steady-state DEM data for both spheres and disks simultaneously.

4. Validation of the continuum model in the transient regime

In § 2.5 we extended the coupled model for segregation and flow in the absence of pressure gradients proposed in our prior work (Liu et al. Reference Liu, Singh and Henann2023) to account for pressure-gradient-driven segregation, and in § 3 we estimated the dimensionless material parameters ![]() $\{C^{P}_{seg},\alpha \}$ associated with the pressure-gradient-driven segregation flux using steady-state DEM data in inclined plane flow. In this section we test the continuum model by comparing predictions of the transient evolution of the large-grain concentration fields and the steady-state flow fields against DEM simulation results for spheres. To this end, we consider both inclined plane flow as described in § 3 and an additional flow geometry – planar shear flow with gravity. The coupled continuum model consists of the segregation dynamics equation (2.7) and the NGF model, (A2) and (A3), and throughout, we utilize a fixed set of parameters for spheres,

$\{C^{P}_{seg},\alpha \}$ associated with the pressure-gradient-driven segregation flux using steady-state DEM data in inclined plane flow. In this section we test the continuum model by comparing predictions of the transient evolution of the large-grain concentration fields and the steady-state flow fields against DEM simulation results for spheres. To this end, we consider both inclined plane flow as described in § 3 and an additional flow geometry – planar shear flow with gravity. The coupled continuum model consists of the segregation dynamics equation (2.7) and the NGF model, (A2) and (A3), and throughout, we utilize a fixed set of parameters for spheres,

$$\begin{gather} \left\{\vphantom{C^{P}_{seg}} \mu_{s}=0.37, \mu_2=0.95, I_0=0.58, A=0.43, \right. \nonumber\\ \left. C_{diff}=0.045, C^{S}_{seg}=0.08, C^{P}_{seg}=0.34, \alpha=0.4 \right\}, \end{gather}$$

$$\begin{gather} \left\{\vphantom{C^{P}_{seg}} \mu_{s}=0.37, \mu_2=0.95, I_0=0.58, A=0.43, \right. \nonumber\\ \left. C_{diff}=0.045, C^{S}_{seg}=0.08, C^{P}_{seg}=0.34, \alpha=0.4 \right\}, \end{gather}$$

where ![]() $\{\mu _{s},\mu _2,I_0,A\}$ are rheological parameters.

$\{\mu _{s},\mu _2,I_0,A\}$ are rheological parameters.

4.1. Inclined plane flow

We first consider inclined plane flow to test predictions of the coupled continuum model against corresponding DEM results. As discussed above, when there are no normal stress differences, the stress field may be obtained from a static force balance, which implies that the stress ratio field is uniform and given by ![]() $\mu (z) = \tan \theta$ and that the pressure field is linear in

$\mu (z) = \tan \theta$ and that the pressure field is linear in ![]() $z$ and given by

$z$ and given by ![]() $P(z) = \phi \rho _{s} G z \cos \theta$. However, the normal stress differences that arise in dense flows of spheres induce a slightly higher, uniform value of

$P(z) = \phi \rho _{s} G z \cos \theta$. However, the normal stress differences that arise in dense flows of spheres induce a slightly higher, uniform value of ![]() $\mu$ and a slightly lower slope in the pressure field

$\mu$ and a slightly lower slope in the pressure field ![]() $P(z)$. Accordingly, to control for this effect when working with dense flows of spheres, in our continuum simulations, we utilize the values of the uniform stress ratio and the slope of the pressure field obtained from the coarse-grained stress fields in the DEM data for each case, rather than the nominal values of

$P(z)$. Accordingly, to control for this effect when working with dense flows of spheres, in our continuum simulations, we utilize the values of the uniform stress ratio and the slope of the pressure field obtained from the coarse-grained stress fields in the DEM data for each case, rather than the nominal values of ![]() $\tan \theta$ and

$\tan \theta$ and ![]() $\phi \rho _{s} G \cos \theta$, respectively. Moreover, to avoid a singularity in the pressure-gradient-driven segregation flux (2.6) at the free surface where

$\phi \rho _{s} G \cos \theta$, respectively. Moreover, to avoid a singularity in the pressure-gradient-driven segregation flux (2.6) at the free surface where ![]() $z=0$, we add a small constant to the pressure field corresponding to the weight of a layer of

$z=0$, we add a small constant to the pressure field corresponding to the weight of a layer of ![]() $(1/4)\bar {d}_0$ thickness, i.e.

$(1/4)\bar {d}_0$ thickness, i.e. ![]() $(1/4)\phi \rho _{s} G \bar {d}_0 \cos \theta$. This approach is quite similar to that of Trewhela et al. (Reference Trewhela, Ancey and Gray2021), who directly incorporate this small constant into the denominator of their pressure-gradient-driven flux equation. We have verified that the subsequently presented results are insensitive to the exact choice of this constant, so long as it is sufficiently small. With the relevant stress-related fields determined in this way, the balance of linear momentum (2.2) is satisfied and does not further enter the solution procedure.

$(1/4)\phi \rho _{s} G \bar {d}_0 \cos \theta$. This approach is quite similar to that of Trewhela et al. (Reference Trewhela, Ancey and Gray2021), who directly incorporate this small constant into the denominator of their pressure-gradient-driven flux equation. We have verified that the subsequently presented results are insensitive to the exact choice of this constant, so long as it is sufficiently small. With the relevant stress-related fields determined in this way, the balance of linear momentum (2.2) is satisfied and does not further enter the solution procedure.

Continuum model predictions are obtained by numerically solving the remaining governing equations using finite differences. The remaining unknown fields in inclined plane flow are the velocity field ![]() $v_x(z,t)$ with the associated strain-rate field

$v_x(z,t)$ with the associated strain-rate field ![]() $\dot {\gamma }(z,t) = \partial v_x/\partial z$, the granular fluidity field

$\dot {\gamma }(z,t) = \partial v_x/\partial z$, the granular fluidity field ![]() $g(z,t)$ and the concentration field

$g(z,t)$ and the concentration field ![]() $c^{l}(z,t)$. The governing equations are (1) the flow rule (A2),

$c^{l}(z,t)$. The governing equations are (1) the flow rule (A2),

(2) the non-local rheology (A3),

where ![]() $g_{loc} (\mu, P)$ and

$g_{loc} (\mu, P)$ and ![]() $\xi (\mu )$ are stress-dependent functions given through (A4) and (A5)

$\xi (\mu )$ are stress-dependent functions given through (A4) and (A5)![]() $_1$, respectively; and finally (3) the segregation dynamics equation (2.7),

$_1$, respectively; and finally (3) the segregation dynamics equation (2.7),

$$\begin{gather} \dfrac{\partial c^{l}}{\partial t} + \frac{\partial}{\partial z} \left(- C_{diff} \bar{d}^2\dot{\gamma} \frac{\partial c^{l}}{\partial z} + C^{S}_{seg}\bar{d}^2c^{l}(1-c^{l})\frac{\partial \dot{\gamma}}{\partial z} \right.\nonumber\\ \left. - C^{P}_{seg} \frac{\bar{d}^2 \dot{\gamma}}{P} c^{l}(1-c^{l})(1 - \alpha + \alpha c^{l}) \frac{\partial P}{\partial z} \right) = 0, \end{gather}$$