1. Introduction

The injection of a viscoplastic fluid into another fluid occurs in many industrial applications, such as the plug and abandonment (P&A) of oil and gas wells (Nelson & Guillot Reference Nelson and Guillot2006; Khalifeh & Saasen Reference Khalifeh and Saasen2020; Akbari & Taghavi Reference Akbari and Taghavi2021), three-dimensional printing (Karyappa, Ohno & Hashimoto Reference Karyappa, Ohno and Hashimoto2019; Lawson et al. Reference Lawson, Li, Thakkar, Rownaghi and Rezaei2021), etc. From a fluid mechanics perspective, analysing viscoplastic fluid injection processes comes down to quantifying the interface evolution between the fluids, in particular in terms of the yielding behaviour of the viscoplastic fluid (Bonn et al. Reference Bonn, Denn, Berthier, Divoux and Manneville2017; Frigaard Reference Frigaard2019). However, the flow analysis may be complex, due to the presence of a large number of flow parameters, e.g. the density and viscosity ratios, the flow geometry characteristics and the yield stress, resulting in a variety of flow patterns, e.g. breakup, coiling, dripping and buckling of viscoplastic fluids (Balmforth, Frigaard & Ovarlez Reference Balmforth, Frigaard and Ovarlez2014).

Previous works have mainly considered the dynamics of a viscoplastic fluid injected/extruded under gravity into a dynamically passive exterior fluid, i.e. typically air. In this context, a dynamically passive fluid represents an exterior fluid that is assumed to remain stagnant or whose flow is assumed not to affect the injected fluid flow; in fact, only the exterior fluid's physical properties (e.g. the surface tension with the injected fluid) may affect the injected fluid flow dynamics. On the other hand, a dynamically active fluid, which is in direct contact with the injected fluid at the interface, describes a medium whose flow accompanied by its physical properties exerts significant forces on the injected fluid and, consequently, alters the flow dynamics. For example, Coussot & Gaulard (Reference Coussot and Gaulard2005) have experimentally and theoretically investigated the breakup of an extruded viscoplastic fluid into air, finding that an unyielded layer is developed until its weight becomes larger than the yield stress force; this leads to the yielding and breakup of the layer, forming a droplet, the volume of which increases with increasing flow rate. Similar results have been obtained by Al Khatib & Wilson (Reference Al Khatib and Wilson2005). Surface tension effects have been ignored in these studies, due to high viscosities of the viscoplastic materials considered. Similar observations have been made by Balmforth, Dubash & Slim (Reference Balmforth, Dubash and Slim2010a,Reference Balmforth, Dubash and Slimb) who have developed a rigorous asymptotic model for the extrusion of a viscoplastic fluid from a nozzle into air, while considering surface tension effects and focusing on the inertialess and inertial extensional dynamics of the resulting viscoplastic filament. They have demonstrated how the yielding of the viscoplastic fluid and the subsequent thinning and progression to pinch-off are governed by rheological, surface tension and gravitational forces. In a relevant work, German & Bertola (Reference German and Bertola2010) have experimentally looked into the slow dripping of a viscoplastic fluid from a thin capillary and qualitatively identified the yield stress effects on the viscoplastic drop stability and the subsequent breakup. Aytouna et al. (Reference Aytouna, Paredes, Shahidzadeh-Bonn, Moulinet, Wagner, Amarouchene, Eggers and Bonn2013) have analysed the breakup phenomenon in viscoplastic fluid droplets, finding that the pinch-off dynamics in their viscoplastic fluids is similar to that in Newtonian fluids. Zhang et al. (Reference Zhang, Fadoul, Lorenceau and Coussot2018) have experimentally investigated the yielding of soft-jammed viscoplastic fluids in elongation, suggesting that, to properly analyse the flow dynamics, appropriate constitutive models for yielding and slow-flow regimes need to be developed. Recently, Valette et al. (Reference Valette, Hachem, Khalloufi, Pereira, Mackley and Butler2019) have numerically studied the deformation and breakup dynamics of stretched yield stress filaments. They have observed the appearance of a conical meniscus prior to breakup (as a consequence of yield stress effects) and hemispherical end drops (as a result of capillary effects). The presence of these interface shapes in their observations is indicative of the competition between capillary and yield stress forces. There are, of course, numerous other works on the breakup phenomena in non-Newtonian fluids, but these have mainly considered elastic and viscoelastic fluids (see, for example, Anna & McKinley (Reference Anna and McKinley2001) as a classical work and Chan et al. (Reference Chan, van Berlo, Faizi, Matsumoto, Haward, Anderson and Shen2021) as a recent one); therefore, these fall out of the scope of our interest.

When an injected/extruded fluid filament front reaches a solid surface before breaking up, it lies on the surface and starts coiling; this is a well-known feature that has been most rigorously studied for Newtonian fluids by Ribe (Reference Ribe2004), e.g. via developing rod-type models considering the stretching, bending and twisting of the viscous filament. For a Newtonian fluid, four distinct coiling regimes (i.e. viscous, gravitational, inertio-gravitational and inertial) have been found, depending on the viscosity, the falling height and the flow rate (Habibi et al. Reference Habibi, Maleki, Golestanian, Ribe and Bonn2006; Ribe, Habibi & Bonn Reference Ribe, Habibi and Bonn2012; Habibi et al. Reference Habibi, Hosseini, Khatami and Ribe2014; Ribe Reference Ribe2017). In the absence of a yield stress, the coiling of power-law fluids has been examined by Pereira, Hachem & Valette (Reference Pereira, Hachem and Valette2020) using direct numerical simulations and providing scaling laws. They have observed that both the coil radius and the coiling frequency are a function of the Reynolds number and the power-law index, when viscous and inertial stresses are balanced in the coil. For a viscoplastic fluid, while the gravitational and viscous regimes have been found, the inertial regime has not been observed due to the breakup of the viscoplastic filaments at large falling heights or instabilities at high flow rates (Rahmani et al. Reference Rahmani, Habibi, Javadi and Bonn2011).

When the axial compression of a straight viscoplastic filament exceeds a critical value, its deformation from the straight configuration, called the buckling phenomenon, can be observed (Balmforth & Hewitt Reference Balmforth and Hewitt2013; O'Bryan et al. Reference O'Bryan, Brady-Miné, Tessmann, Spotz and Angelini2021). For example, Rasschaert et al. (Reference Rasschaert, Talansier, Blésès, Magnin and Lambert2018) have experimentally studied the filling of a container by a viscoplastic fluid and characterized dripping, buckling, mounding, planar filling and air entrainment regimes. However, they have found that, at high inertia, the transitions between these patterns are less dependent on the rheological properties of the viscoplastic fluid. There are also a few works on the buckling of pseudoplastic fluids under compression stresses (Pereira et al. Reference Pereira, Larcher, Hachem and Valette2019), identifying capillary and compressive viscous regimes. For such pseudoplastic (shear-thinning) fluids, the effective viscosity decreases with increasing shear rate, but these fluids do not possess a yield stress. In general, the literature of buckling of viscoplastic fluids is not well developed. In fact, despite substantial studies regarding various buckling-associated patterns in viscous or viscoelastic fluid flows, e.g. folding (Ribe Reference Ribe2003; Pan, Phani & Green Reference Pan, Phani and Green2020), bending (Ribe Reference Ribe2001; Teichman & Mahadevan Reference Teichman and Mahadevan2003; Tian et al. Reference Tian, Ribe, Wu and Shum2020), twisting (Charles, Gazzola & Mahadevan Reference Charles, Gazzola and Mahadevan2019; Wisinger, Maynard & Barone Reference Wisinger, Maynard and Barone2019), deflecting (Brun et al. Reference Brun, Audoly, Ribe, Eaves and Lister2015), etc., many aspects and patterns in the buckling problem of viscoplastic fluids remain obscure.

In order to better position our study with regard to the developed knowledge in previous works, it may be necessary to further clarify feature classifications for the case of a viscoplastic fluid injected vertically into air (i.e. a dynamically inactive fluid). For such a flow, the main parameters are the yield stress and gravity (and to a lesser extent the surface tension depending on the scale/configuration). For a continuous injection, while the latter (gravity) attempts to yield the viscoplastic fluid, the former (yield stress) resists the yielding. In a downward injection, as the length of the viscoplastic fluid increases, at some point, the gravity force (loosely speaking the material weight) starts to dominate the flow and overcome the yield stress force; therefore, the viscoplastic fluid filament (formed by the injection) can yield, thin and eventually break up, as carefully studied by several researchers (Coussot & Gaulard Reference Coussot and Gaulard2005; Balmforth et al. Reference Balmforth, Dubash and Slim2010a,Reference Balmforth, Dubash and Slimb; Geffrault et al. Reference Geffrault, Bessaies-Bey, Roussel and Coussot2021). If the flow domain is vertically bounded, e.g. by a solid surface positioned at some distance with the respect to the injection inlet, the filament front can reach the surface before the breakup occurs, in which case the filament can exhibit various coiling behaviours, as studied and classified by Rahmani et al. (Reference Rahmani, Habibi, Javadi and Bonn2011) in terms of gravitational, viscous and elastic-dominated dynamics. On the other hand, an upward injection creates an upright column of the viscoplastic fluid, which can eventually yield and bend (buckle) as its length exceeds some limit, e.g. as studied by Balmforth & Hewitt (Reference Balmforth and Hewitt2013). Although the yielding mechanism may be conceptually similar to that in the downward injection (i.e. the material weight overcoming the yield stress), the yielding in the upward direction is eventually manifested via a form of Euler buckling (Balmforth & Hewitt Reference Balmforth and Hewitt2013), as the initially vertical filament bends and finally falls sideway. To summarize, the downward injection of a viscoplastic fluid into air presents two main regimes (breakup and coiling) and no buckling regime, while the upward injection can typically exhibit a specific bending/buckling behaviour.

As mentioned above, several previous works have considered the extrusion of viscoplastic filaments under the force of gravity, for which the surface tension also plays an important role in governing the flow dynamics. In a more general context, a relevant body of work concerns the competition between the capillary stress and the yield stress in viscoplastic extrusions, via considering the spreading of viscoplastic droplets. For instance, Jalaal, Stoeber & Balmforth (Reference Jalaal, Stoeber and Balmforth2021) have found that, in contrast to a Newtonian droplet, the resulting viscoplastic droplet reaches a final shape when it is spread on a pre-wetted surface. This and a growing number of similar works find interest in design and manufacturing, e.g. in three-dimensional printing (Jalaal Reference Jalaal2016) and coatings processes (Zhang et al. Reference Zhang, Yin, Zhang, Chen, Chen and Hu2021).

When multiple and multilayer fluids are considered, a relevant research area to viscoplastic injection flows may include viscoplastic displacements. Significant contributions in this area are numerous, including a wide range of studies over the last two decades. Earlier works, such as those of Allouche, Frigaard & Sona (Reference Allouche, Frigaard and Sona2000), Dimakopoulos & Tsamopoulos (Reference Dimakopoulos and Tsamopoulos2007) and Freitas, Soares & Thompson (Reference Freitas, Soares and Thompson2011), have focused on residual and deposited layers of viscoplastic fluids and more recent works, such as those of Eslami, Frigaard & Taghavi (Reference Eslami, Frigaard and Taghavi2017), Taghavi (Reference Taghavi2018) and Amiri et al. (Reference Amiri, Eslami, Mollaabbasi, Larachi and Taghavi2019), have further analysed the viscoplastic displacement dynamics, e.g. front heights, shapes and speeds. These and many other similar works have used a variety of analytical, computational and experimental techniques, along with various flows geometries (e.g. narrow and wide channels, pipes, annuli, etc.), to throw light on the yield stress effects in the flow development of viscoplastic fluids, various flow patterns and flow regimes. Since it may not be possible to cite all the relevant viscoplastic displacement studies, to have a better perspective, the interested reader can refer to the appealing reviews by Balmforth et al. (Reference Balmforth, Frigaard and Ovarlez2014), Coussot (Reference Coussot2014) and Frigaard (Reference Frigaard2019).

In addition to developing a fundamental understanding, the motivation for the current study of buoyant viscoplastic injections comes from the P&A processes of oil and gas wells, which will be a highly active area over the next couple of decades (Trudel et al. Reference Trudel, Bizhani, Zare and Frigaard2019; Hassanzadeh, Eslami & Taghavi Reference Hassanzadeh, Eslami and Taghavi2021a,Reference Hassanzadeh, Eslami and Taghavib). These processes are carried out to preserve underground water aquifers and atmosphere from the oil and gas migration (Khalifeh & Saasen Reference Khalifeh and Saasen2020). For instance in the dump bailing method, which is a widely used P&A process, a heavy viscoplastic cement slurry is injected (via an eccentric inner pipe) into a long circular casing to remove in situ light Newtonian fluids (typically water) and seal the wellbore (Nelson & Guillot Reference Nelson and Guillot2006). We have recently studied in detail such injection flows, albeit for Newtonian fluids (Akbari & Taghavi Reference Akbari and Taghavi2020, Reference Akbari and Taghavi2021), finding highly dispersive flows. However, to realistically analyse industrially relevant flows, structured viscoplastic fluid flows must be considered. Thus, the study of the non-dispersive viscoplastic injection regime has substantial practical applications.

Most of the previous studies on the injection/extrusion of a viscoplastic fluid into another fluid have considered a dynamically passive in situ fluid, which in turn significantly limits the range of interesting phenomena that can be observed. In this work, motivated by P&A applications and inspired by our experiments, we develop a lubrication approximation model to study the downward injection of a heavy viscoplastic fluid into a dynamically active light Newtonian fluid filling a long closed-end pipe. Relying on the Herschel–Bulkley (HB) constitutive equation and a proper asymptotic scaling and reduction, our model will allow us to consider both extensional and compressional stresses affecting the viscoplastic fluid and its yielding condition. The model results will provide reasonable predictions to our novel experimental observations of three distinct flow regimes, i.e. the breakup, coiling and buckling (bulging) regimes, in terms of the viscoplastic fluid behaviour.

The paper is structured as follows. First, § 2 introduces the experimental materials, apparatus and procedure, and our general experimental observations. Then, § 3 provides the model derivation and § 4 presents our modelling results, their comparisons with the experiments and discussions. Finally, § 5 briefly summarizes the main findings.

2. Experiments

In this section, we first describe our experimental materials, apparatus and procedure, and then we briefly explain our general experimental observations of three distinct flow regimes. We use the latter to motivate the development of an appropriate model in the subsequent section.

2.1. Experimental materials, apparatus and procedure

The experiments involve the downward injection of a heavy viscoplastic fluid into a light in situ Newtonian one (see figure 1 and table 2 for the flow parameters). Motivated by P&A applications, in general, an eccentric configuration is considered by installing an eccentric inner pipe inside a vertical closed-end outer pipe (although a limited number of concentric experiments are also performed for comparison purposes). The inner pipe is connected to a gear pump (Ismatech 405A) through which the viscoplastic fluid is injected at a precise flow rate. For the Newtonian fluid filling the outer pipe, water–glycerol mixtures are used. For the injected viscoplastic fluid, water–glycerol mixtures with the addition of Carbopol (Carbomer 940, Making Cosmetics Co.) at various concentrations are employed. The preparation of our viscoplastic fluid follows the established methods in the field (Eslami & Taghavi Reference Eslami and Taghavi2017). For visualization purposes, the viscoplastic fluid is dyed with 800 (mg l![]() $^{-1}$) of ink (Fountain Pen India black ink). The densities are measured using a high-accuracy density meter (Anton Paar DMA 35).

$^{-1}$) of ink (Fountain Pen India black ink). The densities are measured using a high-accuracy density meter (Anton Paar DMA 35).

Figure 1. Schematic of the experimental apparatus, wherein a viscoplastic fluid is injected into a vertical closed-end pipe filled with a Newtonian fluid.

We perform the rheological measurements of our Carbopol solutions using a rheometer (DHR-3, TA Instruments) with a parallel-plate geometry, with a diameter of 40 (mm) and mean gap of 1 (mm). Fine sandpapers (as rough surfaces) are attached to the rheometer plates to eliminate any possible wall-slip effects in the measurements at low shear rates (Habibi et al. Reference Habibi, Dinkgreve, Paredes, Denn and Bonn2016; Roberts & Barnes Reference Roberts and Barnes2001). We obtain the steady-state flow curves of our Carbopol solutions in experiments with controlled shear rate (![]() $\hat {\dot {\gamma }}$), where the samples are sheared in an upward ramp of

$\hat {\dot {\gamma }}$), where the samples are sheared in an upward ramp of ![]() $10^{-2}<\hat {\dot {\gamma }}< 10^{3}$ (s

$10^{-2}<\hat {\dot {\gamma }}< 10^{3}$ (s![]() $^{-1}$), as shown in figure 2(a). The figure shows the rheometry data represented by the symbols. The flow curves (figure 2a) display the characteristics of the materials above the critical stress. At low shear rates, the shear stress plateaus to a finite value corresponding to the yield stress (

$^{-1}$), as shown in figure 2(a). The figure shows the rheometry data represented by the symbols. The flow curves (figure 2a) display the characteristics of the materials above the critical stress. At low shear rates, the shear stress plateaus to a finite value corresponding to the yield stress (![]() $\hat \tau _y$). In addition to the yield stress, the samples feature shear-thinning behaviours. As shown, the data points can be well fitted with the lines corresponding to the HB model parameters (Jaworski et al. Reference Jaworski, Spychaj, Story and Story2021). The model, fitted by the experimental data, has three parameters, i.e. the fluid consistency

$\hat \tau _y$). In addition to the yield stress, the samples feature shear-thinning behaviours. As shown, the data points can be well fitted with the lines corresponding to the HB model parameters (Jaworski et al. Reference Jaworski, Spychaj, Story and Story2021). The model, fitted by the experimental data, has three parameters, i.e. the fluid consistency ![]() $\hat {\kappa }$, the yield stress

$\hat {\kappa }$, the yield stress ![]() $\hat {\tau }_y$ and the power-law index

$\hat {\tau }_y$ and the power-law index ![]() $n$, defined as

$n$, defined as

Figure 2. (a) Flow curves of shear stress ![]() $\hat \tau$ versus shear rate

$\hat \tau$ versus shear rate ![]() $\hat {\dot {\gamma }}$ from the shear-rate-controlled tests. The symbols mark Sample I (

$\hat {\dot {\gamma }}$ from the shear-rate-controlled tests. The symbols mark Sample I (![]() ${\blacksquare }$), Sample II (

${\blacksquare }$), Sample II (![]() $\blacktriangleright$), Sample III (

$\blacktriangleright$), Sample III (![]() $\bullet$), Sample IV (

$\bullet$), Sample IV (![]() $\blacktriangle$), Sample V (

$\blacktriangle$), Sample V (![]() $\bigstar$) and Sample VI (

$\bigstar$) and Sample VI (![]() $\blacktriangleleft$). The green dashed lines correspond to the HB fits, (2.1), with the rheological parameters that are reported for each fluid in table 1. (b) The results of the oscillation amplitude sweep tests for Samples II, III, V and VI. The symbols and dotted lines correspond to the storage (

$\blacktriangleleft$). The green dashed lines correspond to the HB fits, (2.1), with the rheological parameters that are reported for each fluid in table 1. (b) The results of the oscillation amplitude sweep tests for Samples II, III, V and VI. The symbols and dotted lines correspond to the storage (![]() $\hat G^{\prime }$) and loss (

$\hat G^{\prime }$) and loss (![]() $\hat G^{\prime \prime }$) moduli, respectively. The vertical lines show the intersection of

$\hat G^{\prime \prime }$) moduli, respectively. The vertical lines show the intersection of ![]() $\hat G^{\prime }$ and

$\hat G^{\prime }$ and ![]() $\hat G^{\prime \prime }$ as an indication of

$\hat G^{\prime \prime }$ as an indication of ![]() $\hat \tau _y$. (c) Shear stress as a function of shear strain at constant shear rates for Sample II at

$\hat \tau _y$. (c) Shear stress as a function of shear strain at constant shear rates for Sample II at ![]() $\hat {\dot {\gamma }}= 0.0001$, 0.001, 0.01 and 0.1 s

$\hat {\dot {\gamma }}= 0.0001$, 0.001, 0.01 and 0.1 s![]() $^{-1}$ indicated by square, diamond, triangle and circle symbols, respectively. The scattered data at very low shear strains (

$^{-1}$ indicated by square, diamond, triangle and circle symbols, respectively. The scattered data at very low shear strains (![]() $\gamma <10^{-2}$) are due to instrument artifacts. (d) Creep tests showing shear rate as a function of time for Sample II at

$\gamma <10^{-2}$) are due to instrument artifacts. (d) Creep tests showing shear rate as a function of time for Sample II at ![]() $\hat \tau = 1$, 7, 13 and 19 Pa, marked by square, diamond, triangle and circle symbols, respectively. The shear rate variations at early times are due to instrument artifacts. Note that, to make the presented data visually distinguishable, the results for some samples are depicted, while the other sample data (not shown) exhibit similar trends. The size and the colour intensity of the symbols represent the following: in (a,b) the Carbopol concentration (i.e. larger and darker symbols represent higher Carbopol concentrations), in (c) the power of the applied shear rate and in (d) the intensity of the applied stress.

$\hat \tau = 1$, 7, 13 and 19 Pa, marked by square, diamond, triangle and circle symbols, respectively. The shear rate variations at early times are due to instrument artifacts. Note that, to make the presented data visually distinguishable, the results for some samples are depicted, while the other sample data (not shown) exhibit similar trends. The size and the colour intensity of the symbols represent the following: in (a,b) the Carbopol concentration (i.e. larger and darker symbols represent higher Carbopol concentrations), in (c) the power of the applied shear rate and in (d) the intensity of the applied stress.

The rheological parameters of our Carbopol solutions, obtained using the HB model, are given in table 1 for the fluids depicted in figure 2(a). As expected, at smaller (larger) Carbopol concentrations, the yield stress values are lower (higher), i.e. the solid-like behaviour of the material is less (more) pronounced, and the required stress to result in yielding is lower (higher).

Table 1. The rheological parameters of Carbopol solutions determined from fitting the shear stress–shear rate curves to the HB model: the yield stress (![]() $\hat \tau _y$), the consistency index (

$\hat \tau _y$), the consistency index (![]() $\hat \kappa$) and the power-law index (

$\hat \kappa$) and the power-law index (![]() $n$). The Carbopol concentration decreases from Sample I to Sample VI.

$n$). The Carbopol concentration decreases from Sample I to Sample VI.

Table 2. The dimensional parameters and their ranges in our experiments.

Although our rheological model choice is the classical HB model, there are also alternative procedures to fit viscoplastic flow curves, e.g. by taking the HB model as a base. An example is the three-component (TC) model (Caggioni, Trappe & Spicer Reference Caggioni, Trappe and Spicer2020), defined by ![]() $\hat \tau = {\hat \tau _y} + {\hat \tau _y}{( {\hat {\dot \gamma } /{{\hat {\dot \gamma }}_c}} )^{1/2}} + {\hat \eta _{bg}}\hat {\dot \gamma }$, where

$\hat \tau = {\hat \tau _y} + {\hat \tau _y}{( {\hat {\dot \gamma } /{{\hat {\dot \gamma }}_c}} )^{1/2}} + {\hat \eta _{bg}}\hat {\dot \gamma }$, where ![]() $\hat {\dot \gamma }_{c}$ and

$\hat {\dot \gamma }_{c}$ and ![]() $\hat {\eta }_{bg}$ are the critical shear rate and the viscosity of the continuous phase, respectively. The TC model represents three regimes of deformation, i.e. the elastic, plastic and viscous regimes. At low shear rates in this model, elastic straining determines the stress and, when the shear rate exceeds a critical value (

$\hat {\eta }_{bg}$ are the critical shear rate and the viscosity of the continuous phase, respectively. The TC model represents three regimes of deformation, i.e. the elastic, plastic and viscous regimes. At low shear rates in this model, elastic straining determines the stress and, when the shear rate exceeds a critical value (![]() $\hat {\dot \gamma }_{c}$), a transition takes place from elastic to plastic. Since the yield stress is an utmost important parameter in our study, we have also used the TC model to extract its value from the rheological data (results omitted for brevity), finding that the yield stresses obtained by the TC model are on average less than 10 % lower than those fitted by the HB model. Such closeness of yield stress values using these two models has been also reported by Caggioni et al. (Reference Caggioni, Trappe and Spicer2020). That said, in this study, we still use the classical HB model, as a simple, common, reliable and accurate model (Frigaard Reference Frigaard2019) for describing the rheological behaviours of our Carbopol solutions, in particular the yield stress values.

$\hat {\dot \gamma }_{c}$), a transition takes place from elastic to plastic. Since the yield stress is an utmost important parameter in our study, we have also used the TC model to extract its value from the rheological data (results omitted for brevity), finding that the yield stresses obtained by the TC model are on average less than 10 % lower than those fitted by the HB model. Such closeness of yield stress values using these two models has been also reported by Caggioni et al. (Reference Caggioni, Trappe and Spicer2020). That said, in this study, we still use the classical HB model, as a simple, common, reliable and accurate model (Frigaard Reference Frigaard2019) for describing the rheological behaviours of our Carbopol solutions, in particular the yield stress values.

For the sake of completeness of the rheological characterization, we also perform oscillatory rheometry tests, to characterize elastic and viscous behaviours of our samples at a fixed frequency of 1 (Hz), with applied shear stresses (![]() $\hat {\tau }$) ranging from 0.01 to 200 (Pa). This allows us to evaluate the storage modulus (

$\hat {\tau }$) ranging from 0.01 to 200 (Pa). This allows us to evaluate the storage modulus (![]() $\hat G^{\prime }$) and loss modulus (

$\hat G^{\prime }$) and loss modulus (![]() $\hat G^{\prime \prime }$), which represent the elastic and viscous characteristics, respectively. As shown in figure 2(b), initially (at small

$\hat G^{\prime \prime }$), which represent the elastic and viscous characteristics, respectively. As shown in figure 2(b), initially (at small ![]() $\hat {\tau }$)

$\hat {\tau }$) ![]() $\hat G^{\prime }$ is found to be higher than

$\hat G^{\prime }$ is found to be higher than ![]() $\hat G^{\prime \prime }$ for all the sample solutions. This indicates a solid-like behaviour before yielding. For each sample, when the stress exceeds a critical value, an increase in

$\hat G^{\prime \prime }$ for all the sample solutions. This indicates a solid-like behaviour before yielding. For each sample, when the stress exceeds a critical value, an increase in ![]() $\hat G^{\prime \prime }$ accompanied by a decrease in

$\hat G^{\prime \prime }$ accompanied by a decrease in ![]() $\hat G^{\prime }$ is observed. Such behaviour has been reported to occur in soft glassy materials (Hyun et al. Reference Hyun, Wilhelm, Klein, Cho, Nam, Ahn, Lee, Ewoldt and McKinley2011), such as Carbopol gels (Ovarlez, Barral & Coussot Reference Ovarlez, Barral and Coussot2010). Beyond this critical stress, the viscous response of the material overcomes the elastic one, and both

$\hat G^{\prime }$ is observed. Such behaviour has been reported to occur in soft glassy materials (Hyun et al. Reference Hyun, Wilhelm, Klein, Cho, Nam, Ahn, Lee, Ewoldt and McKinley2011), such as Carbopol gels (Ovarlez, Barral & Coussot Reference Ovarlez, Barral and Coussot2010). Beyond this critical stress, the viscous response of the material overcomes the elastic one, and both ![]() $\hat G^{\prime }$ and

$\hat G^{\prime }$ and ![]() $\hat G^{\prime \prime }$ vary with

$\hat G^{\prime \prime }$ vary with ![]() $\hat {\tau }$. Here,

$\hat {\tau }$. Here, ![]() $\hat G^{\prime }$ significantly and

$\hat G^{\prime }$ significantly and ![]() $\hat G^{\prime \prime }$ slightly decrease versus

$\hat G^{\prime \prime }$ slightly decrease versus ![]() $\hat {\tau }$, in such a way that

$\hat {\tau }$, in such a way that ![]() $\hat G^{\prime \prime }$ becomes greater than

$\hat G^{\prime \prime }$ becomes greater than ![]() $\hat G^{\prime }$, indicating that the material is indeed flowing and implying negligible elastic effects. Although the elastic effects of Carbopol solution may be important in certain situations, in this study, we neglect these effects on the flow patterns and dynamics.

$\hat G^{\prime }$, indicating that the material is indeed flowing and implying negligible elastic effects. Although the elastic effects of Carbopol solution may be important in certain situations, in this study, we neglect these effects on the flow patterns and dynamics.

The vertical lines in figure 2(b) represent the stress values at which the ![]() $\hat G^{\prime }$ and

$\hat G^{\prime }$ and ![]() $\hat G^{\prime \prime }$ curves cross over, implying a rough estimation to the yield stress, as an alternative method (however, note that, as argued by Fernandes et al. (Reference Fernandes, Andrade, Franco and Negrão2017), estimating the yield point using the crossover must be made with caution). One can also compare these yield stress values with those reported in table 1. The values obtained from the HB model fitting in figure 2(a) are slightly different from the ones computed at the crossover of the

$\hat G^{\prime \prime }$ curves cross over, implying a rough estimation to the yield stress, as an alternative method (however, note that, as argued by Fernandes et al. (Reference Fernandes, Andrade, Franco and Negrão2017), estimating the yield point using the crossover must be made with caution). One can also compare these yield stress values with those reported in table 1. The values obtained from the HB model fitting in figure 2(a) are slightly different from the ones computed at the crossover of the ![]() $\hat G^{\prime }$ and

$\hat G^{\prime }$ and ![]() $\hat G^{\prime \prime }$ curves. This is in line with recent measurements of similar types of viscoplastic fluids (Dinkgreve et al. Reference Dinkgreve, Paredes, Denn and Bonn2016; Fernandes et al. Reference Fernandes, Andrade, Franco and Negrão2017; Jalaal, Kemper & Lohse Reference Jalaal, Kemper and Lohse2019).

$\hat G^{\prime \prime }$ curves. This is in line with recent measurements of similar types of viscoplastic fluids (Dinkgreve et al. Reference Dinkgreve, Paredes, Denn and Bonn2016; Fernandes et al. Reference Fernandes, Andrade, Franco and Negrão2017; Jalaal, Kemper & Lohse Reference Jalaal, Kemper and Lohse2019).

To further complete our rheological characterization, figure 2(c) presents an example of our results in terms of the shear stress as a function of the shear strain for different applied shear rates. Each curve presents the average of three rheological tests. At low shear strains, the stress curves are close to one another, implying nearly constant properties, regardless of the applied shear rate, hinting at a linear viscoelastic response (Fernandes et al. Reference Fernandes, Andrade, Franco and Negrão2017). At higher shear strains, however, the shear stress in each curve rises up as a function of the shear strain, and then deviates from the nearly linear viscoelastic region, to reach a maximum value associated with yielding and rupturing (Bonn et al. Reference Bonn, Denn, Berthier, Divoux and Manneville2017; Fernandes et al. Reference Fernandes, Andrade, Franco and Negrão2017). The maximum shear stress, however, increases with an increase in the applied shear rate value. On the other hand, the yield stress obtained from the shear stress–shear rate flow curve (figure 2a, table 1) is slightly lower than the maximum stress at the lowest shear rate in figure 2(c) (![]() $\hat {\dot {\gamma }}=10^{-4}$ (

$\hat {\dot {\gamma }}=10^{-4}$ (![]() $\textrm {s}^{-1}$)).

$\textrm {s}^{-1}$)).

As a final rheological characterization method, figure 2(d) presents the results of the creep tests for a given sample, by imposing a constant shear stress and recording the shear rate as a function of time. As seen, for ![]() $\hat \tau = 1$ (Pa) and

$\hat \tau = 1$ (Pa) and ![]() $\hat \tau = 7$ (Pa), the shear rate approaches zero at long time, implying that the applied stress is lower than the yield stress, i.e.

$\hat \tau = 7$ (Pa), the shear rate approaches zero at long time, implying that the applied stress is lower than the yield stress, i.e. ![]() $\hat \tau _y = 10.25$ (Pa) evaluated from the shear stress–shear rate flow curve (figure 2a, table 1). On the other hand, for

$\hat \tau _y = 10.25$ (Pa) evaluated from the shear stress–shear rate flow curve (figure 2a, table 1). On the other hand, for ![]() $\hat \tau = 13$ (Pa) and

$\hat \tau = 13$ (Pa) and ![]() $\hat \tau = 19$ (Pa), the shear rate tends to a constant non-zero value (Espinoza et al. Reference Espinoza, Varges, Rodrigues, Naccache and de Souza Mendes2022), implying that the applied stress is above the yield stress, i.e. an observation generally consistent with the previous measurements.

$\hat \tau = 19$ (Pa), the shear rate tends to a constant non-zero value (Espinoza et al. Reference Espinoza, Varges, Rodrigues, Naccache and de Souza Mendes2022), implying that the applied stress is above the yield stress, i.e. an observation generally consistent with the previous measurements.

Note that we consider our experimental pair of fluids (i.e. Carbopol solution and water) to be fully miscible, which means that there are no surface tension effects in our work. This consideration is in line with recent studies demonstrating that the difference between the surface tension of Carbopol solutions and pure water is very small (less than 10 %), and this difference does not vary significantly with the Carbopol concentration (Boujlel & Coussot Reference Boujlel and Coussot2013; Jørgensen et al. Reference Jørgensen, Le Merrer, Delanoë-Ayari and Barentin2015; Jalaal et al. Reference Jalaal, Kemper and Lohse2019).

Before running each experiment, a movable piston is used to adjust the falling height (![]() $\hat H$). Then, the inner and outer pipes are filled with the viscoplastic and Newtonian fluids, respectively, while a gate valve at the inlet initially separates the two fluids. Each experiment begins with opening the gate valve and injecting/extruding the viscoplastic fluid into the Newtonian fluid at a fixed flow rate; simultaneously, the flow images are obtained using a camera (Basler acA2040) at 20 frames per second and transmitted to a computer for subsequent post-processing (via MATLAB). As the injection flow behaviour is expected to be observed below the inlet area, our camera's field of view is focused on this region. A large number of experiments (

$\hat H$). Then, the inner and outer pipes are filled with the viscoplastic and Newtonian fluids, respectively, while a gate valve at the inlet initially separates the two fluids. Each experiment begins with opening the gate valve and injecting/extruding the viscoplastic fluid into the Newtonian fluid at a fixed flow rate; simultaneously, the flow images are obtained using a camera (Basler acA2040) at 20 frames per second and transmitted to a computer for subsequent post-processing (via MATLAB). As the injection flow behaviour is expected to be observed below the inlet area, our camera's field of view is focused on this region. A large number of experiments (![]() ${>}300$) are performed for different flow rates, falling heights, rheological parameters and density and viscosity ratios.

${>}300$) are performed for different flow rates, falling heights, rheological parameters and density and viscosity ratios.

2.2. Experimental observations of three distinct flow regimes

In this section, we describe the general observations made in our experiments. As mentioned before, our experiments are focused on analysing the viscoplastic fluid flow below the inlet area. For each experiment, the flow rate is chosen and the falling height is fixed. Upon opening the gate valve, which initially separates the fluids, the heavy fluid enters the flow domain below the gate valve and penetrates into the in situ light fluid.

Via our experiments, we have identified the following three distinct flow regimes during the injection of the heavy viscoplastic fluid into the light Newtonian fluid (as demonstrated in figure 3):

(i) Breakup regime. A flow example in this regime is illustrated in figure 3(a

$_1$). The breakup regime is typically observed at small injection rates (small

$_1$). The breakup regime is typically observed at small injection rates (small  $\hat {V}_0$), large buoyancy forces, small to moderate yield stresses of the viscoplastic fluid, small viscosities of the in situ fluid and large falling heights. In this regime, the viscoplastic core fluid is initially extruded as a stable cylinder from the inlet and it advances towards the pipe end. At short times and axial lengths of the core, the stress in the viscoplastic core fluid is below the yield stress, so that a long stable filament can advance downward, holding up against the gravitational forces that attempt to extend it more rapidly. While propagating downward, the core fluid axial length naturally increases and, at a certain point, the core fluid can no longer resist the progressively increasingly buoyancy, which overcomes the yield stress; the core fluid starts to yield and thin near the inlet and it is eventually broken/ruptured. Increasing the buoyancy force (e.g. by increasing the density difference) promotes this flow regime and eases the breakup of the core fluid. After the break of the filament, its upper part which is still connected to the injection inlet is restored fairly rapidly to form a new filament. If the injection continues for a long time in this regime, several filaments can be formed and subsequently break up; the broken parts fall down evenly and make a structure of broken filaments at the bottom end of the pipe.

$\hat {V}_0$), large buoyancy forces, small to moderate yield stresses of the viscoplastic fluid, small viscosities of the in situ fluid and large falling heights. In this regime, the viscoplastic core fluid is initially extruded as a stable cylinder from the inlet and it advances towards the pipe end. At short times and axial lengths of the core, the stress in the viscoplastic core fluid is below the yield stress, so that a long stable filament can advance downward, holding up against the gravitational forces that attempt to extend it more rapidly. While propagating downward, the core fluid axial length naturally increases and, at a certain point, the core fluid can no longer resist the progressively increasingly buoyancy, which overcomes the yield stress; the core fluid starts to yield and thin near the inlet and it is eventually broken/ruptured. Increasing the buoyancy force (e.g. by increasing the density difference) promotes this flow regime and eases the breakup of the core fluid. After the break of the filament, its upper part which is still connected to the injection inlet is restored fairly rapidly to form a new filament. If the injection continues for a long time in this regime, several filaments can be formed and subsequently break up; the broken parts fall down evenly and make a structure of broken filaments at the bottom end of the pipe.(ii) Coiling regime. A flow example in this regime is illustrated in figure 3(a

$_2$). The coiling regime is typically observed at moderate injection rates (moderate

$_2$). The coiling regime is typically observed at moderate injection rates (moderate  $\hat {V}_0$), moderate to large yield stresses of the viscoplastic fluid and relatively short falling heights. In typical situations in this regime, the viscoplastic core fluid is initially extruded, as a stable cylinder, with a diameter that remains typically unchanged as the filament front moves downward. In most cases, the core fluid front can reach the pipe end before the core fluid is broken; then, its front sits on the pipe end and starts coiling evenly, with a fixed centre and a constant coiling frequency (termed regular coiling). As the heavy viscoplastic fluid is injected continuously, the viscoplastic fluid layers are positioned on top of one another, with a thickness initially equal to the nozzle diameter and the coiling of the core fluid gradually continues up to the inlet area. At large velocities, secondary or irregular behaviour (termed irregular coiling) may be observed; at small buoyancy, in some cases the coiling may start to occur before the viscoplastic fluid front reaches the pipe end (termed free coiling). For simplicity, we collectively classify all these as the coiling regime. In general, the coiling behaviour observed in our experiments is reminiscent of the coiling of a viscous fluid filament or an elastic rope falling onto a solid surface, as studied by previous works (Habibi et al. Reference Habibi, Maleki, Golestanian, Ribe and Bonn2006; Ribe et al. Reference Ribe, Habibi and Bonn2012; Ribe Reference Ribe2017), explaining the coiling mechanism via a balance among viscous, gravitational, inertial and elastic stresses.

$\hat {V}_0$), moderate to large yield stresses of the viscoplastic fluid and relatively short falling heights. In typical situations in this regime, the viscoplastic core fluid is initially extruded, as a stable cylinder, with a diameter that remains typically unchanged as the filament front moves downward. In most cases, the core fluid front can reach the pipe end before the core fluid is broken; then, its front sits on the pipe end and starts coiling evenly, with a fixed centre and a constant coiling frequency (termed regular coiling). As the heavy viscoplastic fluid is injected continuously, the viscoplastic fluid layers are positioned on top of one another, with a thickness initially equal to the nozzle diameter and the coiling of the core fluid gradually continues up to the inlet area. At large velocities, secondary or irregular behaviour (termed irregular coiling) may be observed; at small buoyancy, in some cases the coiling may start to occur before the viscoplastic fluid front reaches the pipe end (termed free coiling). For simplicity, we collectively classify all these as the coiling regime. In general, the coiling behaviour observed in our experiments is reminiscent of the coiling of a viscous fluid filament or an elastic rope falling onto a solid surface, as studied by previous works (Habibi et al. Reference Habibi, Maleki, Golestanian, Ribe and Bonn2006; Ribe et al. Reference Ribe, Habibi and Bonn2012; Ribe Reference Ribe2017), explaining the coiling mechanism via a balance among viscous, gravitational, inertial and elastic stresses.(iii) Buckling regime. A flow example in this regime is illustrated in figure 3(a

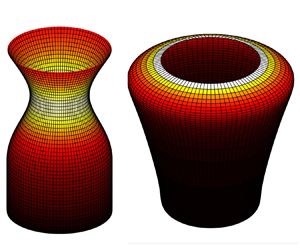

$_3$). The buckling (bulging) regime is typically observed at large injection rates (large

$_3$). The buckling (bulging) regime is typically observed at large injection rates (large  $\hat {V}_0$), small buoyancy forces, low yield stresses of the viscoplastic fluid and high viscosities of the in situ fluid. In this regime, as the heavy core fluid penetrates into the in situ light fluid, it undergoes axial compressions, due to the pressure gradient and shear stresses at the interface, applied by the resistive upward flow of the annular fluid, resulting in the yielding of the core fluid. As the yield stress is overcome, the core fluid buckles and it quickly expands radially. With time, the radial expansion continues until the injected fluid completely blocks the region near the inlet boundary, and impedes the removal of the light in situ fluid from the bottom of the pipe. Increasing the injection velocity and viscosifying the in situ fluid promote the viscous compressional stresses towards yielding and buckling of the core fluid. Note that, in the context of our results throughout the text, the buckling regime concerns a radial expansion and buckling of the viscoplastic core fluid and, therefore, can be also called the bulging regime.

$\hat {V}_0$), small buoyancy forces, low yield stresses of the viscoplastic fluid and high viscosities of the in situ fluid. In this regime, as the heavy core fluid penetrates into the in situ light fluid, it undergoes axial compressions, due to the pressure gradient and shear stresses at the interface, applied by the resistive upward flow of the annular fluid, resulting in the yielding of the core fluid. As the yield stress is overcome, the core fluid buckles and it quickly expands radially. With time, the radial expansion continues until the injected fluid completely blocks the region near the inlet boundary, and impedes the removal of the light in situ fluid from the bottom of the pipe. Increasing the injection velocity and viscosifying the in situ fluid promote the viscous compressional stresses towards yielding and buckling of the core fluid. Note that, in the context of our results throughout the text, the buckling regime concerns a radial expansion and buckling of the viscoplastic core fluid and, therefore, can be also called the bulging regime.

Figure 3. (a) Injection of viscoplastic fluid into closed-end pipe filled with Newtonian fluid through an eccentric inner pipe (![]() $\hat {E}=6.35$ mm): (

$\hat {E}=6.35$ mm): (![]() $a_1$) breakup regime for

$a_1$) breakup regime for ![]() $\hat V_0=5.3$ mm s

$\hat V_0=5.3$ mm s![]() $^{-1}$,

$^{-1}$, ![]() $\hat \rho _a= 998$ kg m

$\hat \rho _a= 998$ kg m![]() $^{-3}$ and

$^{-3}$ and ![]() $\hat {\mu }_a= 0.001$

$\hat {\mu }_a= 0.001$ ![]() $\textrm {Pa}\, \textrm {s}$; (

$\textrm {Pa}\, \textrm {s}$; (![]() $a_2$) coiling regime for

$a_2$) coiling regime for ![]() $\hat V_0=25.5$ mm s

$\hat V_0=25.5$ mm s![]() $^{-1}$,

$^{-1}$, ![]() $\hat \rho _a= 998$ kg m

$\hat \rho _a= 998$ kg m![]() $^{-3}$ and

$^{-3}$ and ![]() $\hat {\mu }_a= 0.001$

$\hat {\mu }_a= 0.001$ ![]() $\textrm {Pa}\,\textrm {s}$; (

$\textrm {Pa}\,\textrm {s}$; (![]() $a_3$) buckling (bulging) regime for

$a_3$) buckling (bulging) regime for ![]() $\hat V_0=87.5$ mm s

$\hat V_0=87.5$ mm s![]() $^{-1}$,

$^{-1}$, ![]() $\hat \rho _a=1007.5$ kg m

$\hat \rho _a=1007.5$ kg m![]() $^{-3}$ and

$^{-3}$ and ![]() $\hat \mu _a=0.025$

$\hat \mu _a=0.025$ ![]() $\textrm {Pa}\,\textrm {s}$. For all the snapshots,

$\textrm {Pa}\,\textrm {s}$. For all the snapshots, ![]() $\hat H=200$ mm and the field of view is

$\hat H=200$ mm and the field of view is ![]() $20\times 3.81$ cm

$20\times 3.81$ cm![]() $^{2}$. (b) Injection through a concentric inner pipe (

$^{2}$. (b) Injection through a concentric inner pipe (![]() $\hat {E}=0$ mm): (

$\hat {E}=0$ mm): (![]() $b_1$) breakup regime for

$b_1$) breakup regime for ![]() $\hat V_0=7.3$ mm s

$\hat V_0=7.3$ mm s![]() $^{-1}$; (

$^{-1}$; (![]() $b_2$) coiling regime for

$b_2$) coiling regime for ![]() $\hat V_0=40.4$ mm s

$\hat V_0=40.4$ mm s![]() $^{-1}$; (

$^{-1}$; (![]() $b_3$) buckling (bulging) regime for

$b_3$) buckling (bulging) regime for ![]() $\hat V_0=117.5$ mm s

$\hat V_0=117.5$ mm s![]() $^{-1}$. For all the snapshots,

$^{-1}$. For all the snapshots, ![]() $\hat H=100$ mm,

$\hat H=100$ mm, ![]() $\hat \rho _a= 997.5$ kg m

$\hat \rho _a= 997.5$ kg m![]() $^{-3}$ and

$^{-3}$ and ![]() $\hat {\mu }_a= 0.001$

$\hat {\mu }_a= 0.001$ ![]() $\textrm {Pa}\,\textrm {s}$ and the field of view is

$\textrm {Pa}\,\textrm {s}$ and the field of view is ![]() $10\times 3.81$ cm

$10\times 3.81$ cm![]() $^{2}$. In all panels, the injection fluid is Sample IV (see table 1),

$^{2}$. In all panels, the injection fluid is Sample IV (see table 1), ![]() ${\rm \Delta} \hat t$ is the time span between the snapshots, the injection inlet is indicated by an arrow and the outlet area of the flow domain is marked by a red surface.

${\rm \Delta} \hat t$ is the time span between the snapshots, the injection inlet is indicated by an arrow and the outlet area of the flow domain is marked by a red surface.

In general, the flow regimes observed and explained above can be also visualized in a concentric flow configuration. To illustrate this, we have conducted a number of experiments in a second apparatus, made of two concentric pipes, for which the results are shown in figure 3(b). As seen, the observed flow regimes in the injection of a viscoplastic fluid into the in situ fluid using the concentric inner pipe are similar to the regimes that occur in the eccentric case (compare top and bottom panel groups in figure 3).

Let us clarify the criterion for classifying our experimental observations into the three defined regimes. To be systematic, this is based on analysing the variation of the viscoplastic filament radius in the upper half of the domain, which renders consistent measurements. To do so, the variation of the ratio between the minimum and maximum radii of the filament, ![]() $\hat R_{min}/\hat R_{max}$, is quantified versus time, as exemplified in figure 4(a). If this ratio (

$\hat R_{min}/\hat R_{max}$, is quantified versus time, as exemplified in figure 4(a). If this ratio (![]() $\hat R_{min}/\hat R_{max}$) tends to zero at long time, implying that the core fluid is yielded towards breakup, we quantify the flow as the breakup regime. When the core buckles (bulges),

$\hat R_{min}/\hat R_{max}$) tends to zero at long time, implying that the core fluid is yielded towards breakup, we quantify the flow as the breakup regime. When the core buckles (bulges), ![]() $\hat R_{min}/\hat R_{max}$ tends to a constant value, i.e.

$\hat R_{min}/\hat R_{max}$ tends to a constant value, i.e. ![]() $\hat R_{min}/\hat R_{c}\approx 1/3$ at long times (marked by the dashed line in figure 4a). For the experiments in which

$\hat R_{min}/\hat R_{c}\approx 1/3$ at long times (marked by the dashed line in figure 4a). For the experiments in which ![]() $\hat R_{min}/\hat R_{max}$ does not reach zero or the constant value of

$\hat R_{min}/\hat R_{max}$ does not reach zero or the constant value of ![]() $\sim 1/3$ at long times (and in fact

$\sim 1/3$ at long times (and in fact ![]() $\hat R_{min}/\hat R_{max} \approx 1$), the type of flow regime is classified as the coiling regime. Our classification criterion/approach allows us to circumvent various flow complexities and secondary flow behaviours, e.g. in the coiling regime (which may exhibit regular, free and irregular coiling), providing a simple way to classify our complex flow in terms of the main behaviours.

$\hat R_{min}/\hat R_{max} \approx 1$), the type of flow regime is classified as the coiling regime. Our classification criterion/approach allows us to circumvent various flow complexities and secondary flow behaviours, e.g. in the coiling regime (which may exhibit regular, free and irregular coiling), providing a simple way to classify our complex flow in terms of the main behaviours.

Figure 4. Variation of the core fluid minimum radius identified by ![]() $\hat R_{min}/\hat R_{max}$ versus the dimensionless flow time (

$\hat R_{min}/\hat R_{max}$ versus the dimensionless flow time (![]() $t={\hat t \hat V_0}/{\hat R}$) for Sample V and

$t={\hat t \hat V_0}/{\hat R}$) for Sample V and ![]() $\hat {E}=6.35$ mm. (a) A typical breakup regime (

$\hat {E}=6.35$ mm. (a) A typical breakup regime (![]() $\square$) for

$\square$) for ![]() $\hat V_0= 8.2$ mm s

$\hat V_0= 8.2$ mm s![]() $^{-1}$,

$^{-1}$, ![]() $\hat \rho _a= 998$ kg m

$\hat \rho _a= 998$ kg m![]() $^{-3}$,

$^{-3}$, ![]() $\hat {\mu }_a= 0.001$

$\hat {\mu }_a= 0.001$ ![]() $\textrm {Pa}\,\textrm {s}$ and

$\textrm {Pa}\,\textrm {s}$ and ![]() $\hat H=400$ mm; a typical coiling regime (

$\hat H=400$ mm; a typical coiling regime (![]() $\circ$) for

$\circ$) for ![]() $\hat V_0= 34.0$ mm s

$\hat V_0= 34.0$ mm s![]() $^{-1}$,

$^{-1}$, ![]() $\hat \rho _a= 998$ kg m

$\hat \rho _a= 998$ kg m![]() $^{-3}$,

$^{-3}$, ![]() $\hat {\mu }_a= 0.001$

$\hat {\mu }_a= 0.001$ ![]() $\textrm {Pa}\,\textrm {s}$ and

$\textrm {Pa}\,\textrm {s}$ and ![]() $\hat H=400$ mm; a typical buckling regime (

$\hat H=400$ mm; a typical buckling regime (![]() $\vartriangle$) for

$\vartriangle$) for ![]() $\hat V_0=87.50$ mm s

$\hat V_0=87.50$ mm s![]() $^{-1}$,

$^{-1}$, ![]() $\hat \rho _a= 1007.5$ kg m

$\hat \rho _a= 1007.5$ kg m![]() $^{-3}$,

$^{-3}$, ![]() $\hat {\mu }_a= 0.0252$

$\hat {\mu }_a= 0.0252$ ![]() $\textrm {Pa}\,\textrm {s}$ and

$\textrm {Pa}\,\textrm {s}$ and ![]() $\hat H=260$ mm. (b) An example of coiling case where the viscoplastic core fluid starts to yield but, due to the finite-sized pipe length, its front reaches the pipe end and it is finally compressed; thus,

$\hat H=260$ mm. (b) An example of coiling case where the viscoplastic core fluid starts to yield but, due to the finite-sized pipe length, its front reaches the pipe end and it is finally compressed; thus, ![]() $\hat R_{min}/\hat R_{max}$ initially decreases but recovers. The results correspond to

$\hat R_{min}/\hat R_{max}$ initially decreases but recovers. The results correspond to ![]() $\hat V_0=34.0$ mm s

$\hat V_0=34.0$ mm s![]() $^{-1}$,

$^{-1}$, ![]() $\hat \rho _a= 998$ kg m

$\hat \rho _a= 998$ kg m![]() $^{-3}$,

$^{-3}$, ![]() $\hat {\mu }_a= 0.001$

$\hat {\mu }_a= 0.001$ ![]() $\textrm {Pa}\,\textrm {s}$,

$\textrm {Pa}\,\textrm {s}$, ![]() $\hat H=100$ mm and

$\hat H=100$ mm and ![]() $\hat {E}=6.35$ mm. The inset shows the initial yielding, the recovering and the eventual coiling of the core fluid, for

$\hat {E}=6.35$ mm. The inset shows the initial yielding, the recovering and the eventual coiling of the core fluid, for ![]() $t=[3.68~4.91~5.35~5.80~7.84]$ from left to right.

$t=[3.68~4.91~5.35~5.80~7.84]$ from left to right.

We have experimentally observed that, in some cases categorized within the coiling regime, as the flow develops the core fluid is actually yielded and starts thinning, while its radius decreases; however, the core fluid front eventually reaches the pipe end before any breakup can occur and starts coiling. A typical example of such a case is presented in figure 4(b). As can be seen, the value of the core radius recovers after the initial decrease. Note that increasing the falling height (![]() $H$) in such cases would lead to the breakup of the core. However, since the breakup does not actually occur for the used experimental falling height, we still classify these flows as the coiling regime (while highlighting the corresponding results in the results section).

$H$) in such cases would lead to the breakup of the core. However, since the breakup does not actually occur for the used experimental falling height, we still classify these flows as the coiling regime (while highlighting the corresponding results in the results section).

It may be worth mentioning that, in terms of the breakup regime, previous relevant studies (e.g. those considering the injection of a viscoplastic fluid into air) have reported a strong conical shape of the core at the breakup point, which also highly depends on the capillary effects and the core density (Balmforth et al. Reference Balmforth, Dubash and Slim2010b; Moschopoulos et al. Reference Moschopoulos, Syrakos, Dimakopoulos and Tsamopoulos2020; Geffrault et al. Reference Geffrault, Bessaies-Bey, Roussel and Coussot2021). However, in our miscible buoyant flow, the surface tension effects are neglected, the density differences are small and the core plasticity is more pronounced, resulting in a relatively more flat shape at the breakup point (e.g. figure 3a). This may be conceptually in line with the finding of Balmforth et al. (Reference Balmforth, Dubash and Slim2010b) who have shown that, when the yield stress effects dominate the surface tension ones, the breakup point shape changes to a flatter end cone.

Before we proceed, it may be worth mentioning that viscoplastic fluids are known to slip on smooth solid surfaces, for example glass plates (Jalaal, Balmforth & Stoeber Reference Jalaal, Balmforth and Stoeber2015) and hydrophobic surfaces (Rahmani & Taghavi Reference Rahmani and Taghavi2020). However, in this study, we do not expect the viscoplastic Carbopol flow in the pipe to be influenced by slippage on the surface of the outer pipe, since there is no direct contact between the injected viscoplastic fluid and the outer pipe wall. In fact, in the time scale of our interest, the in situ (Newtonian) fluid always exists and separates the injected viscoplastic fluid and the pipe wall. Considering this argument, we do not expect the pipe wall properties to significantly change the experimental observations, e.g. by causing slippage effects.

Based on the experimental observations, it is clear that the development of a multilayer viscoplastic model is appropriate to gain a deeper understanding of our results and provide predictions to the transition between the aforementioned flow regimes; this also allows an analysis of the effects of certain flow parameters (e.g. the eccentricity or the inner pipe radius) that cannot be easily changed in our experiments. Thus, in what follows, we develop such a model, which will include the key governing dimensionless parameters of table 3, to generalize our results.

Table 3. The key dimensionless parameters and their ranges in this study. Note that, expect for the Reynolds number, these flow dimensionless parameters also serve as inputs to the model developed in this study.

3. Model formulation

We consider an incompressible viscoplastic core fluid, which follows the HB constitutive model, and an annular fluid, which is Newtonian (see figure 5a for a schematic). Since our problem involves non-coaxial cylinders (eccentric annuli), we use the bipolar coordinates ![]() $( {\xi,\phi,z} )$, in which the

$( {\xi,\phi,z} )$, in which the ![]() $z$ axis points vertically downward, in the main direction of the viscoplastic fluid flow. We assume that the pure heavy viscoplastic fluid is injected from the inlet into the light Newtonian fluid, at a mean velocity

$z$ axis points vertically downward, in the main direction of the viscoplastic fluid flow. We assume that the pure heavy viscoplastic fluid is injected from the inlet into the light Newtonian fluid, at a mean velocity ![]() $\hat {V}_0$. To render the equations and parameters dimensionless, we use

$\hat {V}_0$. To render the equations and parameters dimensionless, we use ![]() $\hat {V}_0$ as the velocity scale,

$\hat {V}_0$ as the velocity scale, ![]() $\hat {R}$ as the length scale,

$\hat {R}$ as the length scale, ![]() $\hat {R}/\hat {V}_0$ as the time scale and

$\hat {R}/\hat {V}_0$ as the time scale and ![]() $\hat \mu _c {{\hat V}_0}/{{\hat R}}$ to scale pressure and stresses. Here,

$\hat \mu _c {{\hat V}_0}/{{\hat R}}$ to scale pressure and stresses. Here,

is a characteristic viscosity of the core fluid. Although the two fluids are miscible, we consider the limit in which the Péclet number is large, i.e.

where ![]() $\hat {D}_m\sim 10^{-9}$ (m

$\hat {D}_m\sim 10^{-9}$ (m![]() $^{2}$ s

$^{2}$ s![]() $^{-1}$) is the molecular diffusion. This implies that there is no significant mixing occurring over the time scales of our interest.

$^{-1}$) is the molecular diffusion. This implies that there is no significant mixing occurring over the time scales of our interest.

Figure 5. (a) Schematic and flow parameters in our experiments and model. Here, ![]() $\hat \ell$ denotes the viscoplastic core length. The

$\hat \ell$ denotes the viscoplastic core length. The ![]() $\hat z$ axis is aligned with the gravity vector. The subscripts

$\hat z$ axis is aligned with the gravity vector. The subscripts ![]() $c$ and

$c$ and ![]() $a$ refer to the core and annular fluids, respectively, and the hat symbol is used for dimensional quantities throughout the text. (b) Representation of the conformal mapping of the eccentric flow from Cartesian coordinates to bipolar coordinates.

$a$ refer to the core and annular fluids, respectively, and the hat symbol is used for dimensional quantities throughout the text. (b) Representation of the conformal mapping of the eccentric flow from Cartesian coordinates to bipolar coordinates.

The model equations are the motion and continuity equations:

where ![]() ${\boldsymbol {u}} = ( {{u_\xi },u_\phi,{u_{z}}} )$ denotes the velocity,

${\boldsymbol {u}} = ( {{u_\xi },u_\phi,{u_{z}}} )$ denotes the velocity, ![]() $\tau$ the deviatoric stress and

$\tau$ the deviatoric stress and ![]() $p$ the pressure. Note that we have already subtracted the static pressure gradient of the annular fluid from the pressure gradient term before scaling. Here,

$p$ the pressure. Note that we have already subtracted the static pressure gradient of the annular fluid from the pressure gradient term before scaling. Here, ![]() ${{\boldsymbol {e}}_g} = ( {0,0,1} )$ and

${{\boldsymbol {e}}_g} = ( {0,0,1} )$ and ![]() $\pm$ refers to the heavy and light fluid layers, respectively. In addition,

$\pm$ refers to the heavy and light fluid layers, respectively. In addition, ![]() $k = a, c$ refers to the core and annular layers, respectively; also

$k = a, c$ refers to the core and annular layers, respectively; also ![]() ${\chi _a} = 0$ and

${\chi _a} = 0$ and ![]() ${\chi _c} = \chi$ is the buoyancy number, defined as

${\chi _c} = \chi$ is the buoyancy number, defined as

\begin{equation} \chi = \frac{{( {{{\hat \rho }_c} - {{\hat \rho }_a}} )\hat g{{\hat R}^{2}}}}{{{{\hat \mu }_c}{{\hat V}_0}}}. \end{equation}

\begin{equation} \chi = \frac{{( {{{\hat \rho }_c} - {{\hat \rho }_a}} )\hat g{{\hat R}^{2}}}}{{{{\hat \mu }_c}{{\hat V}_0}}}. \end{equation}The two fluids are separated by a single interface, for which the surface is defined as

in which ![]() ${\xi _c}=\xi _c( {z,t} )$ is the core fluid interface position and

${\xi _c}=\xi _c( {z,t} )$ is the core fluid interface position and ![]() $t$ is time. For

$t$ is time. For ![]() $t>0$, the no-slip boundary conditions are satisfied at the pipe walls represented by

$t>0$, the no-slip boundary conditions are satisfied at the pipe walls represented by ![]() $\xi = \xi _w$ and, since the pipe end is closed, outflow conditions are imposed at the eccentric annular space surrounding the injection inlet.

$\xi = \xi _w$ and, since the pipe end is closed, outflow conditions are imposed at the eccentric annular space surrounding the injection inlet.

Regarding (3.3), we take the density difference to be small, i.e.

implying that ![]() $At$, i.e. the Atwood number, is not a governing dimensionless number of the flow.

$At$, i.e. the Atwood number, is not a governing dimensionless number of the flow.

Regarding the constitutive equations, for the Newtonian annular fluid we simply have

where ![]() $M$ is the viscosity ratio, i.e.

$M$ is the viscosity ratio, i.e.

in which ![]() $\hat {\mu }_a$ is the annular fluid's constant viscosity. The core viscoplastic fluid follows the constitutive laws for HB fluids, which includes also the simpler Bingham, power-law and Newtonian models. In dimensional form, the HB fluids are described by three parameters, i.e. the fluid consistency

$\hat {\mu }_a$ is the annular fluid's constant viscosity. The core viscoplastic fluid follows the constitutive laws for HB fluids, which includes also the simpler Bingham, power-law and Newtonian models. In dimensional form, the HB fluids are described by three parameters, i.e. the fluid consistency ![]() $\hat {\kappa }$, the yield stress

$\hat {\kappa }$, the yield stress ![]() $\hat {\tau }_y$ and the power-law index

$\hat {\tau }_y$ and the power-law index ![]() $n$. This model in dimensionless form can be written as

$n$. This model in dimensionless form can be written as

\begin{equation} \left.\begin{array}{c@{}} {\dot \gamma ({\boldsymbol{u}}) = 0 \Leftrightarrow \,\tau_c({\boldsymbol{u}}) \le B},\\ {{\tau _{c,ij}}({\boldsymbol{u}}) = \left[ {{{\dot \gamma }^{n - 1}}({\boldsymbol{u}}) + \dfrac{B}{{\dot \gamma ({\boldsymbol{u}})}}} \right]{{\dot \gamma }_{ij}}({\boldsymbol{u}}) \Leftrightarrow {\tau_c}({\boldsymbol{u}}) > B}, \end{array}\right\} \end{equation}

\begin{equation} \left.\begin{array}{c@{}} {\dot \gamma ({\boldsymbol{u}}) = 0 \Leftrightarrow \,\tau_c({\boldsymbol{u}}) \le B},\\ {{\tau _{c,ij}}({\boldsymbol{u}}) = \left[ {{{\dot \gamma }^{n - 1}}({\boldsymbol{u}}) + \dfrac{B}{{\dot \gamma ({\boldsymbol{u}})}}} \right]{{\dot \gamma }_{ij}}({\boldsymbol{u}}) \Leftrightarrow {\tau_c}({\boldsymbol{u}}) > B}, \end{array}\right\} \end{equation}where the strain rate tensor has the following components:

and the second invariants, ![]() $\dot {\gamma }(\boldsymbol {u})$ and

$\dot {\gamma }(\boldsymbol {u})$ and ![]() $\tau _c(\boldsymbol {u})$, are defined by

$\tau _c(\boldsymbol {u})$, are defined by

\begin{equation} \dot{\gamma}(\boldsymbol{u}) = \left[ \frac{1}{2} \sum_{i,j=1}^{3} [\dot{\gamma}_{ij}(\boldsymbol{u})]^{2} \right]^{1/2} ,\quad \tau_c(\boldsymbol{u}) = \left[ \frac{1}{2} \sum_{i,j=1}^{3} [\tau_{c,ij}(\boldsymbol{u})]^{2} \right]^{1/2}. \end{equation}

\begin{equation} \dot{\gamma}(\boldsymbol{u}) = \left[ \frac{1}{2} \sum_{i,j=1}^{3} [\dot{\gamma}_{ij}(\boldsymbol{u})]^{2} \right]^{1/2} ,\quad \tau_c(\boldsymbol{u}) = \left[ \frac{1}{2} \sum_{i,j=1}^{3} [\tau_{c,ij}(\boldsymbol{u})]^{2} \right]^{1/2}. \end{equation}

The Bingham number ![]() $B$ is defined as

$B$ is defined as

\begin{equation} B \equiv \frac{{{\hat\tau _y}\hat R}}{{{{\hat \mu }_c}{{\hat V}_0}}}. \end{equation}

\begin{equation} B \equiv \frac{{{\hat\tau _y}\hat R}}{{{{\hat \mu }_c}{{\hat V}_0}}}. \end{equation}

We focus on a flow that has a long, thin aspect ratio, i.e. after an initial time, the viscoplastic flow develops axially over a length scale ![]() $\delta ^{-1}\gg 1$ (in which

$\delta ^{-1}\gg 1$ (in which ![]() $\delta$ can be any arbitrary small aspect ratio). For simplicity, we define the aspect ratio as

$\delta$ can be any arbitrary small aspect ratio). For simplicity, we define the aspect ratio as

in which ![]() $H$ is the dimensionless pipe height. Relying on lubrication-type assumptions and following standard methods (Leal Reference Leal2007), we rescale the parameters as follows:

$H$ is the dimensionless pipe height. Relying on lubrication-type assumptions and following standard methods (Leal Reference Leal2007), we rescale the parameters as follows:

Considering the limit of ![]() $\delta \to 0$ (with

$\delta \to 0$ (with ![]() $Re$ fixed), in the leading order, the motion and continuity equations become

$Re$ fixed), in the leading order, the motion and continuity equations become

where ![]() $\hbar$ is the scale factor for the bipolar coordinates defined as

$\hbar$ is the scale factor for the bipolar coordinates defined as

Note that since our problem involves non-coaxial cylinders (forming an eccentric annulus), it is appropriate to use bipolar coordinates. The conformal mapping from Cartesian coordinates to bipolar coordinates is schematically shown in figure 5(b), which allows the eccentric flow to be mapped into a rectangular region. In this orthogonal coordinate system, the two cylindrical boundaries (i.e. the eccentric core interface and the wall) coincide with two coordinate surfaces having constant values of ![]() $\xi$. The other coordinate,

$\xi$. The other coordinate, ![]() $\phi$, represents a set of eccentric cylinders whose centres lie on the

$\phi$, represents a set of eccentric cylinders whose centres lie on the ![]() $x$ axis, which orthogonally intersect the boundaries. In this bipolar coordinate system representing our eccentric core annular flow, the pipe wall is represented by

$x$ axis, which orthogonally intersect the boundaries. In this bipolar coordinate system representing our eccentric core annular flow, the pipe wall is represented by ![]() $\xi = \xi _w$, while the interface between the two fluids is

$\xi = \xi _w$, while the interface between the two fluids is ![]() $\xi = \xi _c$. Therefore, the flow in the domain of

$\xi = \xi _c$. Therefore, the flow in the domain of ![]() $x$–

$x$–![]() $y$ (see figure 5b) is mapped into a semi-infinite strip in the domain of (

$y$ (see figure 5b) is mapped into a semi-infinite strip in the domain of (![]() $\phi$–

$\phi$–![]() $\xi$) given by

$\xi$) given by

\begin{equation} \left. \begin{array}{c@{}} \text{annular~phase:} {\xi _w} < \xi \le {\xi _c}; \quad 0 \le \phi \le 2{\rm \pi},\\ \text{core~phase:} {\xi _c} < \xi \le \infty ;\quad 0 \le \phi \le 2{\rm \pi}, \end{array} \right\} \end{equation}

\begin{equation} \left. \begin{array}{c@{}} \text{annular~phase:} {\xi _w} < \xi \le {\xi _c}; \quad 0 \le \phi \le 2{\rm \pi},\\ \text{core~phase:} {\xi _c} < \xi \le \infty ;\quad 0 \le \phi \le 2{\rm \pi}, \end{array} \right\} \end{equation}where

\begin{equation} \left. \begin{array}{c@{}} {\xi _c} = {\cosh ^{ - 1}}\left[ {\dfrac{{1 - R_i^{2} - {E^{2}}}}{{2{R_i}E}}} \right], \\ {\xi _w} = {\cosh ^{ - 1}}\left[ {\dfrac{{1 - R_i^{2} + {E^{2}}}}{{2E}}} \right], \end{array}\right\} \end{equation}

\begin{equation} \left. \begin{array}{c@{}} {\xi _c} = {\cosh ^{ - 1}}\left[ {\dfrac{{1 - R_i^{2} - {E^{2}}}}{{2{R_i}E}}} \right], \\ {\xi _w} = {\cosh ^{ - 1}}\left[ {\dfrac{{1 - R_i^{2} + {E^{2}}}}{{2E}}} \right], \end{array}\right\} \end{equation}

where ![]() $R_i$ is the dimensionless radius of the core fluid layer (i.e. the dimensionless interface radius) and

$R_i$ is the dimensionless radius of the core fluid layer (i.e. the dimensionless interface radius) and ![]() $E$ is the dimensionless eccentricity of the core fluid layer. Note that

$E$ is the dimensionless eccentricity of the core fluid layer. Note that ![]() $R_i=R_c$ at the inlet. Finally, providing the relation between the (

$R_i=R_c$ at the inlet. Finally, providing the relation between the (![]() $x$–

$x$–![]() $y$) Cartesian coordinates and the (

$y$) Cartesian coordinates and the (![]() $\phi$–

$\phi$–![]() $\xi$) bipolar coordinates can be useful for result presentation purposes:

$\xi$) bipolar coordinates can be useful for result presentation purposes:

\begin{equation} \left. \begin{array}{c@{}} x = \dfrac{{\sinh {\xi _w}\sinh \xi }}{{\cosh \xi - \cos \phi }} + 1 - \dfrac{{{{\sinh }^{2}}{\xi _w}}}{{\cosh {\xi _w}}}, \\ y =\dfrac{{\sinh {\xi _w}\sin \phi }}{{\cosh \xi - \cos \phi }}. \end{array}\right\} \end{equation}

\begin{equation} \left. \begin{array}{c@{}} x = \dfrac{{\sinh {\xi _w}\sinh \xi }}{{\cosh \xi - \cos \phi }} + 1 - \dfrac{{{{\sinh }^{2}}{\xi _w}}}{{\cosh {\xi _w}}}, \\ y =\dfrac{{\sinh {\xi _w}\sin \phi }}{{\cosh \xi - \cos \phi }}. \end{array}\right\} \end{equation}3.1. Analysis of the viscoplastic core fluid flow

Regarding the Newtonian annular fluid in (3.18) (![]() $k=a$), the term involving

$k=a$), the term involving ![]() ${{\tau _{a,ZZ}}}$ is of

${{\tau _{a,ZZ}}}$ is of ![]() ${O(\delta )}$ and can therefore be ignored. However, for the viscoplastic fluid (

${O(\delta )}$ and can therefore be ignored. However, for the viscoplastic fluid (![]() $k=c$ in (3.18)), the term involving

$k=c$ in (3.18)), the term involving ![]() ${{\tau _{c,ZZ}}}$ is large and cannot be ignored, as the flow is dominated by the extensional/compressional dynamics. Therefore, in the leading order, the main equation (axial momentum) for the viscoplastic fluid is

${{\tau _{c,ZZ}}}$ is large and cannot be ignored, as the flow is dominated by the extensional/compressional dynamics. Therefore, in the leading order, the main equation (axial momentum) for the viscoplastic fluid is

However, in general ![]() ${\tau }_{c,ZZ}$ (and accordingly the pressure) in the core phase is an unknown function. This situation results from the fact that the stress is indeterminate in the viscoplastic fluid below the yield stress and, therefore, the motion equations are not sufficient to uniquely determine all the stress components, i.e. a complexity that is frequently encountered in similar problems (Balmforth et al. Reference Balmforth, Dubash and Slim2010a). To overcome this problem, and in the interest of simplicity, we assume that

${\tau }_{c,ZZ}$ (and accordingly the pressure) in the core phase is an unknown function. This situation results from the fact that the stress is indeterminate in the viscoplastic fluid below the yield stress and, therefore, the motion equations are not sufficient to uniquely determine all the stress components, i.e. a complexity that is frequently encountered in similar problems (Balmforth et al. Reference Balmforth, Dubash and Slim2010a). To overcome this problem, and in the interest of simplicity, we assume that ![]() ${\tau }_{c,\xi \xi } = { \tau }_{c,\phi \phi }$, which, in the spirit of the regularization of the constitutive equation (Frigaard & Nouar Reference Frigaard and Nouar2005), allows us to use the continuity equation to find

${\tau }_{c,\xi \xi } = { \tau }_{c,\phi \phi }$, which, in the spirit of the regularization of the constitutive equation (Frigaard & Nouar Reference Frigaard and Nouar2005), allows us to use the continuity equation to find

Considering the dominance of ![]() ${\tau _{c,ZZ}}$ also implies that

${\tau _{c,ZZ}}$ also implies that

Let us for now assume that the solution to ![]() $\tau _{c,ZZ}$ may be found. The yield condition can be obtained in the leading order as

$\tau _{c,ZZ}$ may be found. The yield condition can be obtained in the leading order as

The simplified yield condition criterion above is consistent with some previous theoretical approaches for viscoplastic fluid flows downwardly injected in air, such as the work of Balmforth et al. (Reference Balmforth, Dubash and Slim2010b). However, there are more recent works in the literature, such as the works of Moschopoulos et al. (Reference Moschopoulos, Syrakos, Dimakopoulos and Tsamopoulos2020) and Geffrault et al. (Reference Geffrault, Bessaies-Bey, Roussel and Coussot2021), emphasizing the importance of including shear components in the analysis, particularly because, in certain cases, the flows of our consideration can lead to yielded conical shapes even in slender filaments. Nevertheless, for the simplicity of our analysis, we assume that such shear component terms are of higher order in ![]() $\delta$ and can be ignored. To simplify the analysis, it is straightforward to apply the normal stress balance at the interface (Leal Reference Leal2007):

$\delta$ and can be ignored. To simplify the analysis, it is straightforward to apply the normal stress balance at the interface (Leal Reference Leal2007):

in which ![]() $\sigma _a$ and

$\sigma _a$ and ![]() $\sigma _c$ are the stress tensors for the annular and core phases and

$\sigma _c$ are the stress tensors for the annular and core phases and ![]() $\boldsymbol n$ is the unit normal vector inward to the surface:

$\boldsymbol n$ is the unit normal vector inward to the surface:

\begin{equation} {\boldsymbol{n}} = \frac{{\boldsymbol{\nabla} F}}{{ | {\boldsymbol{\nabla} F} |}} = \frac{{ ( {1/\hbar ,0, - \delta \partial {\xi _c}/\partial Z} )}}{{\sqrt {{{ ( {1/\hbar } )}^{2}} + {{ ( {\delta \partial {\xi _c}/\partial Z} )}^{2}}} }}, \end{equation}

\begin{equation} {\boldsymbol{n}} = \frac{{\boldsymbol{\nabla} F}}{{ | {\boldsymbol{\nabla} F} |}} = \frac{{ ( {1/\hbar ,0, - \delta \partial {\xi _c}/\partial Z} )}}{{\sqrt {{{ ( {1/\hbar } )}^{2}} + {{ ( {\delta \partial {\xi _c}/\partial Z} )}^{2}}} }}, \end{equation}and, in the leading order, we eventually find

\begin{equation} \left. \begin{array}{c@{}} {P_c} = {P_a} - \dfrac{{\delta {\tau _{c,ZZ}}}}{2},\\ {\tau _{c,\xi Z}} = {\tau _{a,{\xi _c}Z}} + \dfrac{{3\hbar \delta {\tau _{c,ZZ}}}}{2}\dfrac{{\partial {\xi _c}}}{{\partial Z}}, \end{array} \right\} \end{equation}

\begin{equation} \left. \begin{array}{c@{}} {P_c} = {P_a} - \dfrac{{\delta {\tau _{c,ZZ}}}}{2},\\ {\tau _{c,\xi Z}} = {\tau _{a,{\xi _c}Z}} + \dfrac{{3\hbar \delta {\tau _{c,ZZ}}}}{2}\dfrac{{\partial {\xi _c}}}{{\partial Z}}, \end{array} \right\} \end{equation}