1. Introduction

Turbulent combustion is an inherently complex flow problem, coupled with substantial heat release and inter-diffusion of a large number of species generated by a complex network of chemical reactions. A general classification of turbulent combustion is based on the ratio of the turbulent to chemical time scales. When the chemistry is slow, it occurs in a distributed manner throughout a large portion of the flow as in tubular reactors employed in the chemical processing industry. In applications associated with power generation, furnaces, boilers and propulsion, the chemistry is rapid, and occurs in relatively thin layers, or flames, embedded within a three-dimensional turbulent flow. The turbulent eddies advect and distort the flame, potentially altering its internal structure, whilst the gas expansion generated by the heat released by the chemical reactions affects the surrounding flow field. Studying these highly nonlinear coupled processes, forms a fundamental challenge in combustion theory. Progress has therefore relied primarily on numerical simulations guided by empiricism and physical reasoning. A regime of turbulent combustion that can be addressed more systematically is the fast chemistry limit, namely when the chemistry is assumed rapid compared with all of the turbulence.

In premixed systems, the burning may be characterized by the mean speed with which the flame propagates into the fresh turbulent mixture, or the turbulent flame speed. While its practical importance is evident, equally important is to understand the key mechanisms responsible for the topological changes of the flame surface that occur as a result of the turbulence, and identify pertinent parameters that characterize these changes. Additional complexities that affect the propagation of turbulent flames result from intrinsic combustion instabilities, which are known to distort the flame even under laminar conditions. The most prominent one is the hydrodynamic, or Darrieus–Landau (DL) instability, which arises by virtue of thermal-expansion-induced velocities and is thus ubiquitous to all premixed flames. The objective of this work is to explore fundamental aspects of premixed flames in homogeneous isotropic turbulent flows, examine the mechanisms governing flame–turbulence interactions, and identify the impact of the DL instability on the propagation.

Our study is based on the hydrodynamic theory of premixed flames, derived systematically using a multi-scale approach that assumes that the flame thickness is much smaller than all other fluidynamical length scales (Matalon & Matkowsky Reference Matalon and Matkowsky1982). The flame is thus confined to a surface that separates the fresh mixture from the combustion products, and propagates relative to the incoming flow at a speed determined by the thermo-chemical properties of the mixture, as well as the diffusion and reaction processes taking place within the thin flame zone. The entire formulation, which has been cast in coordinate-free form, lends itself to a hydrodynamic free-boundary problem (Matalon & Matkowsky Reference Matalon and Matkowsky1983), where the flow on either side of the flame front must be determined from the Navier–Stokes equations with different densities. The combustion processes are characterized by two lumped parameters: the unburned-to-burned density ratio or thermal expansion, which depends on the heat released by the chemical reactions, and the Markstein length, which is a parameter on the order of the flame thickness that depends on the state and physico-chemical properties of the combustible mixture. The present investigation is the first that addresses the propagation of turbulent flames in three-dimensional turbulent flows, within the context of the hydrodynamic theory. Previous investigations have been limited to two-dimensional flows, which evidently lack important features of turbulence (Creta & Matalon Reference Creta and Matalon2011a; Fogla, Creta & Matalon Reference Fogla, Creta and Matalon2015, Reference Fogla, Creta and Matalon2017). Despite this limitation, the acquired results from these studies captured complex topological configurations, including folding and pinching of surface elements, and creation of pockets of unburned gas, all of which are commonly observed in laboratory flames. These studies also instigated the development of a hybrid Navier–Stokes/level-set methodology to address the embedding of a curve (representing the flame) in a two-dimensional turbulent-like flow, which has been extended in the present work to the propagation of flame surfaces in three-dimensional turbulent flow fields.

Although direct numerical simulations (DNS) of the complete three-dimensional governing equations (albeit with simplified chemistry) have been used in recent years in turbulent combustion studies, the high computational cost involved limits the scope of such studies (Rutland & Cant Reference Rutland and Cant1994; Trouvé & Poinsot Reference Trouvé and Poinsot1994; Bell, Day & Grcar Reference Bell, Day and Grcar2002; Aspden Reference Aspden2008; Poludnenko & Oran Reference Poludnenko and Oran2010, Reference Poludnenko and Oran2011; Chen Reference Chen2011; Hamlington, Poludnenko & Oran Reference Hamlington, Poludnenko and Oran2011; Uranakara et al. Reference Uranakara, Chaudhuri, Dave, Arias and Im2016; Manias et al. Reference Manias, Tingas, Minamoto and Im2019; Klein et al. Reference Klein, Herbert, Kosaka, Böhm, Dreizler, Chakraborty, Papapostolou, Im and Hasslberger2020); the investigations are typically restricted to small domains and/or short time intervals, and focus on a particular set of conditions associated with a specific mixture. The approach proposed here is computationally affordable, and thus permits examining the morphological changes of the flame surface, the propagation speed of the turbulent flame, and the impact of the flame on the turbulent flow, while varying the level of turbulence from low to moderate values and adjusting the other parameters to represent mixtures of various properties. Moreover, the model makes transparent the physical interactions occurring between the flame and the fluid flow. Quantities related to the flame surface, such as speed, curvature, strain, degree of wrinkling and burning rates, are determined unambiguously. This marks a clear advantage over simulations that, similar to experiments, rely on an arbitrarily selected iso-surface of temperature or concentration to represent the flame surface, an approach that may introduce ambiguity in the reporting combustion characteristics. Finally, unlike other common strategies in turbulence modelling, the current approach is based on physical first principles, free of ad hoc closure assumptions and/or adjusting parameters.

In the simulations reported below, we address the complex dynamics that result from the interaction of a premixed flame with a turbulent flow, and examine the ramifications of the flow on the flame and the reciprocal effects on the flow, while segregating the influences of the DL instability on the propagation. In a laminar environment, the DL instability can be recognized visually or by tracing the distribution of the local flame curvature. Identifying the instability in a turbulent environment is not as straightforward, because fluctuations of the flame surface resulting from the turbulence are interlaced with disturbances caused by gas expansion, making the distinction difficult even at relatively low intensities. A number of experimental studies (Paul & Bray Reference Paul and Bray1996; Kobayashi, Kawabata & Maruta Reference Kobayashi, Kawabata and Maruta1998; Savarianandam & Lawn Reference Savarianandam and Lawn2006; Troiani, Creta & Matalon Reference Troiani, Creta and Matalon2015; Bauwens, Bergthorson & Dorofeev Reference Bauwens, Bergthorson and Dorofeev2017) and simulations (Akkerman & Bychkov Reference Akkerman and Bychkov2003; Creta, Fogla & Matalon Reference Creta, Fogla and Matalon2011; Creta et al. Reference Creta, Lamioni, Lapenna and Troiani2016; Fogla et al. Reference Fogla, Creta and Matalon2015, Reference Fogla, Creta and Matalon2017; Yu, Bai & Bychkov Reference Yu, Bai and Bychkov2015; Lapenna et al. Reference Lapenna, Lamioni, Troiani and Creta2019) have provided insight on the effect of the DL instability on turbulent flames. More recent studies including DNS for Bunsen flames (Klein, Alwazzan & Chakraborty Reference Klein, Alwazzan and Chakraborty2018; Lapenna et al. Reference Lapenna, Lamioni, Troiani and Creta2019, Reference Lapenna, Troiani, Lamioni and Creta2021; Zhang et al. Reference Zhang, Patyal, Huang and Matalon2019; Rasool, Chakraborty & Klein Reference Rasool, Chakraborty and Klein2021) have shown an interplay between the underlying turbulent field and the flame region under different pressures and Lewis number conditions, highlighting the role that DL instability plays in modifying flame topologies, surface curvature, impact on flame stretch and consumption speed. We extend this work with a systematic parametric investigation of the impact of the DL instability on freely propagating premixed flames in three-dimensional turbulent flows and the resulting modification of the induced flow. The effects of flow on the flame that will be addressed consist of the topological changes associated with flame displacement and curvature, the extent of surface wrinkling and folding of the flame surface, and the overall flame brush thickness. Aspects associated with the effect of the flame on the flow include enstrophy production/destruction by vortex stretching, dilatation and baroclinic torque, and scalar gradient creation/dissipation by gas expansion. Although these issues have been addressed previously in a number of simulations (Ashurst, Peters & Smooke Reference Ashurst, Peters and Smooke1987b; Swaminathan & Grout Reference Swaminathan and Grout2006; Hamlington et al. Reference Hamlington, Poludnenko and Oran2011; Chakraborty Reference Chakraborty2014), the present results examine the trend associated with increasing the turbulence level from low to moderate values, and the distinction in flame–turbulence interactions when the DL instability is effective or inoperative.

2. Formulation

In this section, we present the mathematical formulation of the hydrodynamic model and briefly describe the numerical methodology used to simulate the flame propagation in a turbulent flow.

2.1. Hydrodynamic model

The hydrodynamic model is based on an analysis that exploits the difference of scales between the dimension characterizing the flame size, or the flow field ![]() $L$, and the representative flame thickness, or diffusion length

$L$, and the representative flame thickness, or diffusion length ![]() $l_{f}$ (Matalon & Matkowsky Reference Matalon and Matkowsky1982; Matalon, Cui & Bechtold Reference Matalon, Cui and Bechtold2003). The flame region consisting of the preheat and reaction zones is typically thin compared to the hydrodynamic length, such that

$l_{f}$ (Matalon & Matkowsky Reference Matalon and Matkowsky1982; Matalon, Cui & Bechtold Reference Matalon, Cui and Bechtold2003). The flame region consisting of the preheat and reaction zones is typically thin compared to the hydrodynamic length, such that ![]() $\delta \equiv l_f/L \ll 1$. Viewed on the hydrodynamical scale, the flame can therefore be treated as a surface separating the cold fresh mixture from hot burned products. Let the flame front be described by a function

$\delta \equiv l_f/L \ll 1$. Viewed on the hydrodynamical scale, the flame can therefore be treated as a surface separating the cold fresh mixture from hot burned products. Let the flame front be described by a function ![]() $\psi (\boldsymbol {x},t)=0$, where

$\psi (\boldsymbol {x},t)=0$, where ![]() $\psi <0$ identifies the unburned gas and

$\psi <0$ identifies the unburned gas and ![]() $\psi >0$ the burned gas regions. Each point on this surface propagates relative to the incoming unburned gas at a speed

$\psi >0$ the burned gas regions. Each point on this surface propagates relative to the incoming unburned gas at a speed ![]() $S_f \equiv - V_{f} + \boldsymbol {v^{*}} \boldsymbol {\cdot } \boldsymbol {n}$, where

$S_f \equiv - V_{f} + \boldsymbol {v^{*}} \boldsymbol {\cdot } \boldsymbol {n}$, where ![]() $\boldsymbol {v}$ is the gas velocity, with the superscript

$\boldsymbol {v}$ is the gas velocity, with the superscript ![]() $*$ indicating conditions on the unburned side of the flame surface,

$*$ indicating conditions on the unburned side of the flame surface, ![]() $\boldsymbol {n}$ is a unit normal to the surface pointing towards the burned gas, and

$\boldsymbol {n}$ is a unit normal to the surface pointing towards the burned gas, and ![]() $V_{f}$ is the propagation speed measured relative to a fixed coordinate system. Expressed as functions of the flame front,

$V_{f}$ is the propagation speed measured relative to a fixed coordinate system. Expressed as functions of the flame front,

where ![]() $t$ is the time.

$t$ is the time.

The flow on either side of the flame surface is governed by the Navier–Stokes equations, with the density given by

\begin{equation} \rho = \begin{cases} \rho_u, & \text{for} \ \psi(\boldsymbol{x},t) < 0 ,\\ \rho_b, & \text{for} \ \psi(\boldsymbol{x},t) > 0, \end{cases} \end{equation}

\begin{equation} \rho = \begin{cases} \rho_u, & \text{for} \ \psi(\boldsymbol{x},t) < 0 ,\\ \rho_b, & \text{for} \ \psi(\boldsymbol{x},t) > 0, \end{cases} \end{equation}

where the subscripts ![]() $u$ and

$u$ and ![]() $b$ denote unburned and burned values, respectively. Conservation of mass and momentum across the flame surface is enforced through the Rankine–Hugoniot jump relations

$b$ denote unburned and burned values, respectively. Conservation of mass and momentum across the flame surface is enforced through the Rankine–Hugoniot jump relations

\begin{equation} \left. \begin{gathered} {}[\![ \rho (\boldsymbol{v} \boldsymbol{\cdot} \boldsymbol{n} - V_{{f}}) ]\!] = 0, \\ [\![ \boldsymbol{n} \times (\boldsymbol{v} \times \boldsymbol{n}) ]\!] = 0, \\ [\![ p + \rho (\boldsymbol{v} \boldsymbol{\cdot} \boldsymbol{n}) (\boldsymbol{v}\boldsymbol{\cdot} \boldsymbol{n} - V_{{f}}) ]\!] = 0, \end{gathered} \right\} \end{equation}

\begin{equation} \left. \begin{gathered} {}[\![ \rho (\boldsymbol{v} \boldsymbol{\cdot} \boldsymbol{n} - V_{{f}}) ]\!] = 0, \\ [\![ \boldsymbol{n} \times (\boldsymbol{v} \times \boldsymbol{n}) ]\!] = 0, \\ [\![ p + \rho (\boldsymbol{v} \boldsymbol{\cdot} \boldsymbol{n}) (\boldsymbol{v}\boldsymbol{\cdot} \boldsymbol{n} - V_{{f}}) ]\!] = 0, \end{gathered} \right\} \end{equation}

where ![]() $[\![ \chi ]\!]$ denotes the jump in the quantity

$[\![ \chi ]\!]$ denotes the jump in the quantity ![]() $\chi$, namely the difference between its values at

$\chi$, namely the difference between its values at ![]() $\psi = 0^{+}$ and

$\psi = 0^{+}$ and ![]() $\psi = 0^{-}$.

$\psi = 0^{-}$.

An expression for the flame speed ![]() $S_{f}$ is obtained by resolving the internal flame structure on the diffusion length scale

$S_{f}$ is obtained by resolving the internal flame structure on the diffusion length scale ![]() $l_{f}$. For a two-reactant (fuel and oxidizer) mixture undergoing a chemical reaction modelled by an overall single step with a large activation energy, it is given by

$l_{f}$. For a two-reactant (fuel and oxidizer) mixture undergoing a chemical reaction modelled by an overall single step with a large activation energy, it is given by

where ![]() $S_L$ is the laminar flame speed and

$S_L$ is the laminar flame speed and ![]() $\mathbb {K}$ is the flame stretch rate, which measures the rate of distortion of the flame surface due to its motion and the non-uniform flow into which it propagates. Flame stretch is given by

$\mathbb {K}$ is the flame stretch rate, which measures the rate of distortion of the flame surface due to its motion and the non-uniform flow into which it propagates. Flame stretch is given by

where ![]() ${\boldsymbol v}_{s}$ is the component of the velocity vector tangent to the flame surface, and

${\boldsymbol v}_{s}$ is the component of the velocity vector tangent to the flame surface, and ![]() $\boldsymbol {\nabla }_{s}$ the surface gradient (Matalon Reference Matalon1983). The first term in these expressions corresponds to surface dilatation resulting from the motion of the flame whose local (mean) curvature is

$\boldsymbol {\nabla }_{s}$ the surface gradient (Matalon Reference Matalon1983). The first term in these expressions corresponds to surface dilatation resulting from the motion of the flame whose local (mean) curvature is ![]() $\kappa = - \boldsymbol {\nabla } \boldsymbol {\cdot } \boldsymbol {n}$, and the second term corresponds to surface extension due to the velocity gradient along the flame surface. Since

$\kappa = - \boldsymbol {\nabla } \boldsymbol {\cdot } \boldsymbol {n}$, and the second term corresponds to surface extension due to the velocity gradient along the flame surface. Since ![]() ${\boldsymbol v}_{s}$ is continuous across the flame, the stretch rate is defined uniquely and can be evaluated on either side of the flame surface. Flame stretch may also be expressed as a combination of curvature and hydrodynamic strain, namely in the form

${\boldsymbol v}_{s}$ is continuous across the flame, the stretch rate is defined uniquely and can be evaluated on either side of the flame surface. Flame stretch may also be expressed as a combination of curvature and hydrodynamic strain, namely in the form ![]() $\mathbb {K} = S_{L} \kappa + K_{S}$ where

$\mathbb {K} = S_{L} \kappa + K_{S}$ where ![]() $K_{S} = -\boldsymbol {n} \boldsymbol {\cdot } \boldsymbol {S} \boldsymbol {\cdot } \boldsymbol {n}$, with

$K_{S} = -\boldsymbol {n} \boldsymbol {\cdot } \boldsymbol {S} \boldsymbol {\cdot } \boldsymbol {n}$, with ![]() $\boldsymbol {S}$ the rate of strain tensor, provided that the constraint

$\boldsymbol {S}$ the rate of strain tensor, provided that the constraint ![]() $\boldsymbol {\nabla } \boldsymbol {\cdot } \boldsymbol {v} = 0$ is applied when evaluating

$\boldsymbol {\nabla } \boldsymbol {\cdot } \boldsymbol {v} = 0$ is applied when evaluating ![]() $\mathbb {K}$, as appropriate for the hydrodynamic model. Otherwise, the definition of stretch is ambiguous and depends on the location selected to represent the flame surface within the flow field. The dependence of the flame speed on the properties of the combustion mixture is captured by the Markstein length

$\mathbb {K}$, as appropriate for the hydrodynamic model. Otherwise, the definition of stretch is ambiguous and depends on the location selected to represent the flame surface within the flow field. The dependence of the flame speed on the properties of the combustion mixture is captured by the Markstein length ![]() $\mathcal {L}$, which is proportional to the flame thickness

$\mathcal {L}$, which is proportional to the flame thickness ![]() $l_f$ and depends on the composition and equivalence ratio of the mixture, the reaction orders of the chemical reaction rate, the diffusive properties of the reactants, and the overall heat release (Matalon et al. Reference Matalon, Cui and Bechtold2003).

$l_f$ and depends on the composition and equivalence ratio of the mixture, the reaction orders of the chemical reaction rate, the diffusive properties of the reactants, and the overall heat release (Matalon et al. Reference Matalon, Cui and Bechtold2003).

2.2. Numerical methodology

Numerical implementation of the hydrodynamic model is carried out using a hybrid Navier–Stokes/level-set methodology that generalizes the earlier approach implemented successfully in laminar and turbulent two-dimensional flows, where the flame is effectively a curve in the plane of motion (Creta & Matalon Reference Creta and Matalon2011a,Reference Creta and Matalonb; Fogla et al. Reference Fogla, Creta and Matalon2015). Its extension to three-dimensional flows, where the flame front is a two-dimensional surface, was initiated by Patyal & Matalon (Reference Patyal and Matalon2018) and used to simulate flame propagation in a laminar setting. It necessitated the development of new algorithms, focusing on the representation of the flame in intrinsic surface coordinates, and on accurate calculation of interfacial quantities such as curvature, strain, local gas velocity and stretch. A brief overview of the methodology and its application to turbulent flows is given below.

The piecewise-constant function (2.2) representing the density across the flame is smeared over a few computational cells and expressed in the form

where ![]() $h$ is a measure of the ‘numerical flame thickness’ and controls the number of cells needed to transition between either side of the flame, taken here as twice the cell size. Mass conservation across the flame is satisfied by introducing a source term in the continuity equation, namely

$h$ is a measure of the ‘numerical flame thickness’ and controls the number of cells needed to transition between either side of the flame, taken here as twice the cell size. Mass conservation across the flame is satisfied by introducing a source term in the continuity equation, namely

where ![]() ${\partial / \partial n}$ is the directional derivative along the coordinate

${\partial / \partial n}$ is the directional derivative along the coordinate ![]() $n$ normal to the flame surface (Rastigejev & Matalon Reference Rastigejev and Matalon2006b). Equation (2.7) confirms that the divergence-free condition is satisfied away from the flame surface, and its continuous representation across the flame allows for the flow field to be determined by solving the momentum equation

$n$ normal to the flame surface (Rastigejev & Matalon Reference Rastigejev and Matalon2006b). Equation (2.7) confirms that the divergence-free condition is satisfied away from the flame surface, and its continuous representation across the flame allows for the flow field to be determined by solving the momentum equation

over the entire computational domain; here, ![]() $\textrm {D}/ \textrm {D} t \equiv \partial /\partial t + \boldsymbol {v} \boldsymbol {\cdot } \boldsymbol {\nabla }$ is the convective derivative,

$\textrm {D}/ \textrm {D} t \equiv \partial /\partial t + \boldsymbol {v} \boldsymbol {\cdot } \boldsymbol {\nabla }$ is the convective derivative, ![]() $p$ is the pressure, and

$p$ is the pressure, and ![]() $\mu$ is the viscosity of the mixture, assumed constant. The instantaneous shape and location of the flame surface are described by the evolution equation

$\mu$ is the viscosity of the mixture, assumed constant. The instantaneous shape and location of the flame surface are described by the evolution equation

where ![]() $V_f$ is calculated from the definition of the flame speed and its dependence on flame stretch given by (2.4). As

$V_f$ is calculated from the definition of the flame speed and its dependence on flame stretch given by (2.4). As ![]() $h \to 0$, the distribution (2.6) approaches the piecewise density function (2.2), and when integrating (2.7) and (2.8) across the flame front, the Rankine–Hugoniot relations are recovered. Thus although the variations inside the thin numerical flame zone are not physically resolved, the variations outside the flame zone are accurate in an asymptotic sense.

$h \to 0$, the distribution (2.6) approaches the piecewise density function (2.2), and when integrating (2.7) and (2.8) across the flame front, the Rankine–Hugoniot relations are recovered. Thus although the variations inside the thin numerical flame zone are not physically resolved, the variations outside the flame zone are accurate in an asymptotic sense.

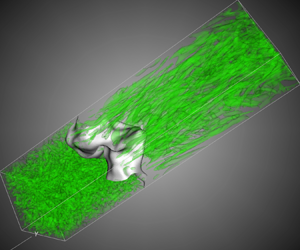

The nonlinear problem (2.6)–(2.9) involves a feedback between the Navier–Stokes solver and the level-set algorithm, with the source term in (2.7) representing the link between these two modules. The Navier–Stokes equations are solved using a parallel low-Mach-number variable-density solver. The algorithms that involve the embedding of the flame surface into the flow field and its evolution in time follow the methodology of Patyal & Matalon (Reference Patyal and Matalon2018). Since in a turbulent flow the flame has a tendency to fold and form pockets of unburned gas that get consumed separately, as observed in figure 1, the amalgamated surface can no longer be represented by a single-valued function, and a generic representation of the surfaces with disjointed interfaces is required. Details of the surface parametrization, its reconstruction at every time step, and the determination of the interfacial properties needed to describe accurately the evolution of the flame front, are discussed in Patyal & Matalon (Reference Patyal and Matalon2018). Finally, due to the limitation of the model that is valid strictly for weakly-stretched flames, the parametric space of turbulence intensities is restricted by the requirement that the local flame speed ![]() $S_f$ remains positive and above a threshold value during the entire simulation. For each case, any local instances of negative

$S_f$ remains positive and above a threshold value during the entire simulation. For each case, any local instances of negative ![]() $S_f$ are set to zero, with this cutoff operation tracked and limited to no more than 5 % of the total number of points on the flame surface. The limiting values of Markstein number and turbulence intensity are thus set when this threshold is crossed.

$S_f$ are set to zero, with this cutoff operation tracked and limited to no more than 5 % of the total number of points on the flame surface. The limiting values of Markstein number and turbulence intensity are thus set when this threshold is crossed.

Figure 1. Schematic of the proportional integral derivative (PID) control system used to control the mean flame position and the turbulence intensity and scale. The highly corrugated flame surface shown in grey consists, in addition to the main surface, of small disjoint pockets of unburned gas; the flow field illustrated by vorticity iso-contours is shown in green. The figure is based on a representative simulation with ![]() ${\mathcal {L}} = 0.018 l_f$, thermal expansion

${\mathcal {L}} = 0.018 l_f$, thermal expansion ![]() $\sigma = 5$, and turbulence intensity

$\sigma = 5$, and turbulence intensity ![]() $u'/S_L = 1.5$.

$u'/S_L = 1.5$.

2.3. Turbulent flow field

The primary objective of this work is to enhance understanding of flame propagation in a turbulent environment by performing a parametric study of intrinsic combustion properties and system operating conditions. To this end, it is essential to ensure that the computations first reach a statistical steady state before quantities of interest are approximated by averaging over a large number of realizations, or eddy turnover times. The relative simplicity of the hydrodynamic model, as opposed to DNS of the complete governing equations, allows for the estimation of combustion quantities, such as turbulent flame speed or probability distribution of flame properties, by performing an ensemble average over a large number of eddy turnover times to represent accurately the unsteady dynamics. In the present simulations, this was done by choosing a minimum averaging period of 40–60 eddy turnover times spread over at least 600–1000 realizations, after a statistical steady state was achieved.

A realization of homogeneous isotropic turbulence was generated using TuGen (Gilling Reference Gilling2009a,Reference Gillingb), a turbulent field generator based on Mann's method for producing a divergence-free field of synthetic turbulence (Mann Reference Mann1998). To ensure a large number of independent realizations, the turbulent field was simulated on a sufficiently long domain, measuring ![]() $L \times 64 L \times L$. The turbulent fluctuations, which were created with a zero mean, were then superposed with a mean velocity

$L \times 64 L \times L$. The turbulent fluctuations, which were created with a zero mean, were then superposed with a mean velocity ![]() $v_{in}$ and provided as an inflow to the flame propagating towards the flow, in a domain of size

$v_{in}$ and provided as an inflow to the flame propagating towards the flow, in a domain of size ![]() $L \times 4 L \times L$ with periodic boundary conditions in the transverse directions and an outflow boundary condition at the top of the domain (see figure 1). The creation of the turbulent fluctuations on a much larger domain was done to ensure that each instantaneous realization of turbulence was not correlated in time such that there was no inherently imposed periodicity to the problem. The turbulent field was verified to be homogeneous, isotropic and divergence-free, with auto- and cross-correlation functions agreeing with theoretical predictions by von Kármán (Reference von Kármán1948). A sample calculation of the one-dimensional turbulent kinetic energy spectrum displayed in figure 2 for a range of integral scales shows that the turbulent field captures the behaviour characteristic of the inertial subrange in fully developed turbulent flows.

$L \times 4 L \times L$ with periodic boundary conditions in the transverse directions and an outflow boundary condition at the top of the domain (see figure 1). The creation of the turbulent fluctuations on a much larger domain was done to ensure that each instantaneous realization of turbulence was not correlated in time such that there was no inherently imposed periodicity to the problem. The turbulent field was verified to be homogeneous, isotropic and divergence-free, with auto- and cross-correlation functions agreeing with theoretical predictions by von Kármán (Reference von Kármán1948). A sample calculation of the one-dimensional turbulent kinetic energy spectrum displayed in figure 2 for a range of integral scales shows that the turbulent field captures the behaviour characteristic of the inertial subrange in fully developed turbulent flows.

Figure 2. Turbulence kinetic energy spectrum as a function of wavenumber ![]() $k$, of pre-generated fields of various turbulence integral scales

$k$, of pre-generated fields of various turbulence integral scales ![]() $\ell /L$, showing the

$\ell /L$, showing the ![]() $-5/3$ characteristic slope of the inertial subrange.

$-5/3$ characteristic slope of the inertial subrange.

To achieve a statistical steady state, two concurrent control systems using a PID-like closed loop control strategy are employed to monitor independently mean flame position and turbulence intensity close to the flame at a user-specified location. This target is set near the flame surface on its unburnt side and away from the inlet to avoid extremely large velocity gradients at the boundary. We avoid conditioning parameters directly on the flame surface as inputs for the PID controller to prevent its destabilization and get a faster convergence. As an example of one of the controllers, to statistically keep the flame at a fixed location along the direction of flow, the mean inflow velocity ![]() $v_{{in}}$ is modulated according to

$v_{{in}}$ is modulated according to

where ![]() $e(t)$ is the displacement of the instantaneous mean flame position from a user-specified value, with the temporal derivative of the error acting to minimize overshoot. For each controller, the constants

$e(t)$ is the displacement of the instantaneous mean flame position from a user-specified value, with the temporal derivative of the error acting to minimize overshoot. For each controller, the constants ![]() $K_p$ and

$K_p$ and ![]() $K_d$ were tuned appropriately, with the constant of the integral term set to zero based on numerical experimentation. For controlling the flame position, constant values

$K_d$ were tuned appropriately, with the constant of the integral term set to zero based on numerical experimentation. For controlling the flame position, constant values ![]() $K_p=100$,

$K_p=100$, ![]() $K_d=10$ were used, while for the turbulence intensity, these were set to

$K_d=10$ were used, while for the turbulence intensity, these were set to ![]() $K_p=2$,

$K_p=2$, ![]() $K_d=0.2$. The flow control system is of significant importance when investigating the dependence of flame speed on turbulence intensity and/or integral scale, allowing us to relate flame properties to the local turbulence conditions rather than conditions at the inflow boundary, which, due to decaying turbulence, are generally modified when reaching the flame. It also permits using a relatively smaller domain to study turbulent flame propagation, making a parametric study computationally affordable. A similar control system was used in the DNS study of Bell et al. (Reference Bell, Cheng, Day and Shepherd2007) to maintain and stabilize the flame within the integration domain, but other studies initialized the turbulence in the entire domain, and studied transient evolution of flames in decaying turbulence (Chen & Im Reference Chen and Im2000; Im & Chen Reference Im and Chen2002), or re-energized the system by injecting velocity perturbations at the largest scale of the flow to constantly maintain the mean turbulence intensity (Poludnenko & Oran Reference Poludnenko and Oran2011).

$K_d=0.2$. The flow control system is of significant importance when investigating the dependence of flame speed on turbulence intensity and/or integral scale, allowing us to relate flame properties to the local turbulence conditions rather than conditions at the inflow boundary, which, due to decaying turbulence, are generally modified when reaching the flame. It also permits using a relatively smaller domain to study turbulent flame propagation, making a parametric study computationally affordable. A similar control system was used in the DNS study of Bell et al. (Reference Bell, Cheng, Day and Shepherd2007) to maintain and stabilize the flame within the integration domain, but other studies initialized the turbulence in the entire domain, and studied transient evolution of flames in decaying turbulence (Chen & Im Reference Chen and Im2000; Im & Chen Reference Im and Chen2002), or re-energized the system by injecting velocity perturbations at the largest scale of the flow to constantly maintain the mean turbulence intensity (Poludnenko & Oran Reference Poludnenko and Oran2011).

A schematic of the control system is shown in figure 1, where the instantaneous turbulence intensity and mean flow speed were controlled using the strategy described above. The highly corrugated flame surface (in grey), which includes small pockets of unburned gas disjoint from the main surface, is clearly delineated from the background. The turbulent flow field is illustrated by coloured contours (in green) showing vorticity iso-surfaces based on the so-called Q-criterion (discussed below) that enables us to identify specifically regions of greater intensity. Figure 3 shows a test where the target flame position and turbulence intensity in the simulations were specified as ![]() $1.5$ and

$1.5$ and ![]() $1.0$ in units of

$1.0$ in units of ![]() $L$ and

$L$ and ![]() $S_L$, respectively. As observed, the control system is able to provide critical damping for mean flame position in figure 3(a) and turbulence intensity in figure 3(b), thereby allowing a statistical steady state to be reached. The corresponding mean inflow velocity (scaled by the laminar flame speed) shown in figure 3(c), may be referred to properly as the turbulent flame speed

$S_L$, respectively. As observed, the control system is able to provide critical damping for mean flame position in figure 3(a) and turbulence intensity in figure 3(b), thereby allowing a statistical steady state to be reached. The corresponding mean inflow velocity (scaled by the laminar flame speed) shown in figure 3(c), may be referred to properly as the turbulent flame speed ![]() $S_T$.

$S_T$.

Figure 3. Results of the closed-loop control system based on a representative simulation with ![]() $\sigma = 5$ and

$\sigma = 5$ and ![]() $\mathcal {M}^{-1} = 75$. Shown here is the approach in time of (a) the mean flame position to the target position

$\mathcal {M}^{-1} = 75$. Shown here is the approach in time of (a) the mean flame position to the target position ![]() $y = 1.5$, (b) the mean turbulence intensity to two target values

$y = 1.5$, (b) the mean turbulence intensity to two target values ![]() $u^{\prime }/S_L = 1.0, 2.0$, and (c) the resulting mean inflow velocity. The asymptote in (c) then corresponds to the turbulent flame speed.

$u^{\prime }/S_L = 1.0, 2.0$, and (c) the resulting mean inflow velocity. The asymptote in (c) then corresponds to the turbulent flame speed.

2.4. Dimensionless parameters

When recast in dimensionless form using ![]() $L$,

$L$, ![]() $S_L$,

$S_L$, ![]() $L/S_L$ and

$L/S_L$ and ![]() $\rho _u S_L^{2}$ as units of length, velocity, time and pressure, the hydrodynamic model involves three dimensionless parameters: the Markstein number

$\rho _u S_L^{2}$ as units of length, velocity, time and pressure, the hydrodynamic model involves three dimensionless parameters: the Markstein number ![]() ${\mathcal {M}} = {\mathcal {L}}/L$, the density contrast or thermal expansion parameter

${\mathcal {M}} = {\mathcal {L}}/L$, the density contrast or thermal expansion parameter ![]() $\sigma = \rho _u/\rho _b$, and the Reynolds number

$\sigma = \rho _u/\rho _b$, and the Reynolds number ![]() ${Re} = L \rho _u S_L / \mu$. The Markstein number

${Re} = L \rho _u S_L / \mu$. The Markstein number ![]() ${\mathcal {M}}$ differs from the conventional definition by the factor

${\mathcal {M}}$ differs from the conventional definition by the factor ![]() $l_f/L$ representing the nominal flame thickness, which can be estimated easily for different mixtures as discussed in Fogla et al. (Reference Fogla, Creta and Matalon2015). Typically, the pressure level, the fuel and oxidizer type, the composition of the mixture, the physico-chemical properties of the reactants, and the heat release determine the laminar flame speed

$l_f/L$ representing the nominal flame thickness, which can be estimated easily for different mixtures as discussed in Fogla et al. (Reference Fogla, Creta and Matalon2015). Typically, the pressure level, the fuel and oxidizer type, the composition of the mixture, the physico-chemical properties of the reactants, and the heat release determine the laminar flame speed ![]() $S_L$, the thermal expansion

$S_L$, the thermal expansion ![]() $\sigma$, and the Markstein number

$\sigma$, and the Markstein number ![]() $\mathcal {M}$. The pre-generated flow field is characterized by the turbulence intensity

$\mathcal {M}$. The pre-generated flow field is characterized by the turbulence intensity ![]() $u'/S_L$, defined as the r.m.s. of velocity fluctuation and expressed in units of the laminar flames speed, and the integral length scale

$u'/S_L$, defined as the r.m.s. of velocity fluctuation and expressed in units of the laminar flames speed, and the integral length scale ![]() $\ell /L$.

$\ell /L$.

In the simulations reported below, the thermal expansion coefficient was chosen as ![]() $\sigma =5$, the turbulence integral scale was chosen as

$\sigma =5$, the turbulence integral scale was chosen as ![]() $\ell /L = 0.1$, and a range of flow and mixture conditions were examined, as summarized in table 1. Only mixtures with

$\ell /L = 0.1$, and a range of flow and mixture conditions were examined, as summarized in table 1. Only mixtures with ![]() ${\mathcal {M}} > 0$ were studied, representing those deficient in their heavier component, such as lean hydrocarbon–air or rich hydrogen–air mixtures. The

${\mathcal {M}} > 0$ were studied, representing those deficient in their heavier component, such as lean hydrocarbon–air or rich hydrogen–air mixtures. The ![]() ${{O}}(\delta ^{-1})$ Reynolds number was assumed as

${{O}}(\delta ^{-1})$ Reynolds number was assumed as ![]() ${Re} = 10^{6}$ such that, consistent with the hydrodynamic model, viscous effects add only a small degree of dissipation to an otherwise inviscid flow. All studies were run with a grid resolution of 64 points per unit length

${Re} = 10^{6}$ such that, consistent with the hydrodynamic model, viscous effects add only a small degree of dissipation to an otherwise inviscid flow. All studies were run with a grid resolution of 64 points per unit length ![]() $L$. Select cases were also tested for grid independence at 128 and 256 points per unit length, with a noted maximum variation in flame speeds at 3 % and 7 % respectively. Though the range of parameters considered in this work are modest due to a limitation on computational resources, the numerical methodology is easily extendable to large domains over long time intervals with parameters that can be associated with a variety of fuels and/or mixture conditions.

$L$. Select cases were also tested for grid independence at 128 and 256 points per unit length, with a noted maximum variation in flame speeds at 3 % and 7 % respectively. Though the range of parameters considered in this work are modest due to a limitation on computational resources, the numerical methodology is easily extendable to large domains over long time intervals with parameters that can be associated with a variety of fuels and/or mixture conditions.

Table 1. Parametric space spanned by the simulations.

3. Influences of the Darrieus–Landau instability

One of the prominent instabilities in premixed combustion is the hydrodynamic, or Darrieus–Landau (DL) instability. It results from gas expansion caused by the heat released by the chemical reactions, which induces hydrodynamic disturbances that enhance perturbations of the flame front. The DL is a long-wave instability, which can be suppressed in relatively narrow domains when diffusion effects act to stabilize the short wavelength disturbances – namely, in mixtures of sufficiently large positive Markstein number. Accordingly, planar flames are stable when ![]() ${\mathcal {M}} > {\mathcal {M}}_c$, with the critical Markstein number given by

${\mathcal {M}} > {\mathcal {M}}_c$, with the critical Markstein number given by

For ![]() ${\mathcal {M}} < {\mathcal {M}}_c$, the nonlinear evolution of nominally planar flames leads to cusp-like structures, i.e. conformations with pointed crests intruding into the burned gas, that propagate at a constant speed

${\mathcal {M}} < {\mathcal {M}}_c$, the nonlinear evolution of nominally planar flames leads to cusp-like structures, i.e. conformations with pointed crests intruding into the burned gas, that propagate at a constant speed ![]() $U_L > S_L$. With decreasing

$U_L > S_L$. With decreasing ![]() ${\mathcal {M}}$, i.e. moving away from criticality into the unstable domain, the crests become sharper, pointing further into the burned gas region, and the flames propagate faster. The nonlinear development under laminar conditions has been studied for realistic gas expansion in two- and three-dimensional flows (Rastigejev & Matalon Reference Rastigejev and Matalon2006a; Creta & Matalon Reference Creta and Matalon2011b; Patyal & Matalon Reference Patyal and Matalon2018).

${\mathcal {M}}$, i.e. moving away from criticality into the unstable domain, the crests become sharper, pointing further into the burned gas region, and the flames propagate faster. The nonlinear development under laminar conditions has been studied for realistic gas expansion in two- and three-dimensional flows (Rastigejev & Matalon Reference Rastigejev and Matalon2006a; Creta & Matalon Reference Creta and Matalon2011b; Patyal & Matalon Reference Patyal and Matalon2018).

In analogy to this characterization, Creta & Matalon (Reference Creta and Matalon2011a) identified two distinct regimes of flame propagation in turbulent flows; a sub-critical regime, where the DL instability has minimal to no effect on the flame, and its fluctuating surface remains planar on average, and a super-critical regime, where the turbulent flame is affected strongly by the instability and develops frequent cusp-like structures on its surface, reminiscent of the unstable flames under laminar conditions. The sub- and super-critical regimes depend on whether ![]() $\mathcal {M}$ is above/below a critical value, approximately equal to (3.1). Unlike

$\mathcal {M}$ is above/below a critical value, approximately equal to (3.1). Unlike ![]() ${\mathcal {M}}_c$, which is obtained from a linear stability analysis that treats the flame as a surface of density discontinuity, the characterization in a turbulent flow is based on simulations with a small non-zero value of the numerical flame thickness, known to slightly underestimate the critical value of

${\mathcal {M}}_c$, which is obtained from a linear stability analysis that treats the flame as a surface of density discontinuity, the characterization in a turbulent flow is based on simulations with a small non-zero value of the numerical flame thickness, known to slightly underestimate the critical value of ![]() $\mathcal {M}$ (Patyal & Matalon Reference Patyal and Matalon2018). Note that the critical Markstein number at which a fluctuating turbulent flame becomes highly corrugated, or unstable, can be different from its laminar counterpart.

$\mathcal {M}$ (Patyal & Matalon Reference Patyal and Matalon2018). Note that the critical Markstein number at which a fluctuating turbulent flame becomes highly corrugated, or unstable, can be different from its laminar counterpart.

In the following, we examine the effects of a turbulent flow field on the flame topology, surface conformation and surface wrinkling. Since the DL instability is primarily a consequence of thermal expansion, the simulations are performed under three different conditions: a non-reacting interface, which is not subjected to the instability; a sub-critical flame, which is inherently stable; and a super-critical flame, where the influence of the instability is notable. The non-reacting interface is simulated by propagating a passive interface in a constant-density turbulent flow with the interface exerting no feedback on the flow field – i.e. with ![]() $\rho = \rho _u$ and the source term in (2.7) set to zero. The simulations of sub- and super-critical flames account fully for gas expansion, and are distinguished primarily by the specified Markstein number. The non-reacting (NR) interface serves to establish a baseline to differentiate between the presence/absence of thermal expansion and the influence, or lack, of the instability.

$\rho = \rho _u$ and the source term in (2.7) set to zero. The simulations of sub- and super-critical flames account fully for gas expansion, and are distinguished primarily by the specified Markstein number. The non-reacting (NR) interface serves to establish a baseline to differentiate between the presence/absence of thermal expansion and the influence, or lack, of the instability.

For convenience, the results reported below are presented in terms of the reciprocal of the Markstein number, such that sub- and super-critical conditions correspond to ![]() ${\mathcal {M}}^{-1}$ below/above criticality; for

${\mathcal {M}}^{-1}$ below/above criticality; for ![]() $\sigma = 5$, the critical value is approximately

$\sigma = 5$, the critical value is approximately ![]() $25$, slightly larger than

$25$, slightly larger than ![]() ${\mathcal {M}}_c^{-1} = 22$. In the remainder of the paper, the values

${\mathcal {M}}_c^{-1} = 22$. In the remainder of the paper, the values ![]() $\mathcal {M}^{-1} = 22.5$ and

$\mathcal {M}^{-1} = 22.5$ and ![]() $\mathcal {M}^{-1} =75$ were selected to represent sub- and super-critical conditions, respectively.

$\mathcal {M}^{-1} =75$ were selected to represent sub- and super-critical conditions, respectively.

3.1. Flame topology

Under laminar conditions, the DL instability can be recognized by visual inspection, but this becomes more complicated in a turbulent environment. Since it is easier to visualize these convoluted structures in two dimensions, when the flame surface degenerates to a curve in the plane of motion, we show in figure 4 results of sub- and super-critical flames for varying turbulence intensities ![]() $u^{\prime }/S_L$. Each panel shows a flame brush, which consists of instantaneous snapshots of the flame front superimposed on each other about a mean position that has been modulated by the control system. For low turbulence intensities, the sub-critical flame brush in figure 4(a) remains nearly planar with no preferred orientation towards the unburned or burned gas regions. As the turbulence intensity increases, the flame brush thickens; the flames experience larger fluctuations but remain equally distributed between the unburned and burned sides. For

$u^{\prime }/S_L$. Each panel shows a flame brush, which consists of instantaneous snapshots of the flame front superimposed on each other about a mean position that has been modulated by the control system. For low turbulence intensities, the sub-critical flame brush in figure 4(a) remains nearly planar with no preferred orientation towards the unburned or burned gas regions. As the turbulence intensity increases, the flame brush thickens; the flames experience larger fluctuations but remain equally distributed between the unburned and burned sides. For ![]() $u'/S_L = 1.8$, the flames no longer bear resemblance to the nearly planar conformations observed at lower values of turbulence intensity, and appear to be controlled by the turbulence. In contrast, the super-critical flame brush in figure 4(b) shows that the flames at low turbulence intensities develop distinct cusp-like structures pointing towards the burned gas region, reminiscent of the DL unstable flames in laminar conditions. These structures appear at first resilient to turbulent fluctuations and preserve their general shape while translating back and forth in the transverse direction. At higher turbulence intensities, the flames lose their characteristic shape and, similar to the sub-critical flames, develop into a flame brush that is dominated primarily by the turbulence with no visible effect of the instability. The distinction between sub- and super-critical flames becomes invisible at higher intensity values. The fluctuating surface gets tangled up by the turbulence and develops folds that often pinch off, forming pockets of unburned gas that burn instantaneously once detached from the main flame surface. The existence of a regime where the DL instability has limited-to-no influence on the turbulent flame has been observed experimentally (Al-Shahrany et al. Reference Al-Shahrany, Bradley, Lawes, Liu and Woolley2006; Bradley et al. Reference Bradley, Lawes, Liu and Mansour2013; Troiani et al. Reference Troiani, Creta and Matalon2015) and in simulations (Boughanem & Trouvé Reference Boughanem and Trouvé1998; Chaudhuri, Akkerman & Law Reference Chaudhuri, Akkerman and Law2011), and will be examined further below. The two-dimensional results shown in figure 4 were presented for ease of illustration; the remainder of the paper pertains to the topology and propagation of flame surfaces in three-dimensional flows.

$u'/S_L = 1.8$, the flames no longer bear resemblance to the nearly planar conformations observed at lower values of turbulence intensity, and appear to be controlled by the turbulence. In contrast, the super-critical flame brush in figure 4(b) shows that the flames at low turbulence intensities develop distinct cusp-like structures pointing towards the burned gas region, reminiscent of the DL unstable flames in laminar conditions. These structures appear at first resilient to turbulent fluctuations and preserve their general shape while translating back and forth in the transverse direction. At higher turbulence intensities, the flames lose their characteristic shape and, similar to the sub-critical flames, develop into a flame brush that is dominated primarily by the turbulence with no visible effect of the instability. The distinction between sub- and super-critical flames becomes invisible at higher intensity values. The fluctuating surface gets tangled up by the turbulence and develops folds that often pinch off, forming pockets of unburned gas that burn instantaneously once detached from the main flame surface. The existence of a regime where the DL instability has limited-to-no influence on the turbulent flame has been observed experimentally (Al-Shahrany et al. Reference Al-Shahrany, Bradley, Lawes, Liu and Woolley2006; Bradley et al. Reference Bradley, Lawes, Liu and Mansour2013; Troiani et al. Reference Troiani, Creta and Matalon2015) and in simulations (Boughanem & Trouvé Reference Boughanem and Trouvé1998; Chaudhuri, Akkerman & Law Reference Chaudhuri, Akkerman and Law2011), and will be examined further below. The two-dimensional results shown in figure 4 were presented for ease of illustration; the remainder of the paper pertains to the topology and propagation of flame surfaces in three-dimensional flows.

Figure 4. Instantaneous snapshots of fluctuating flames in a two-dimensional turbulent flow under increasing values of turbulence intensity ![]() $u'/S_L$. The region between the dashed red lines denoted by

$u'/S_L$. The region between the dashed red lines denoted by ![]() $\delta _T$, which marks the region where the p.d.f. of the flame position is above a minimal threshold, is a measure of the flame brush thickness. (a) Flame brush for sub-critical conditions (

$\delta _T$, which marks the region where the p.d.f. of the flame position is above a minimal threshold, is a measure of the flame brush thickness. (a) Flame brush for sub-critical conditions (![]() $\mathcal {M}^{-1} = 22.5$). (b) Flame brush for super-critical conditions (

$\mathcal {M}^{-1} = 22.5$). (b) Flame brush for super-critical conditions (![]() $\mathcal {M}^{-1} = 75$).

$\mathcal {M}^{-1} = 75$).

To quantify differences in flame topology, we present in figure 5 the probability distribution function (p.d.f.) of the position of an NR interface and of sub- and super-critical flames, for increasing values of ![]() $u'/S_L$. The mean position

$u'/S_L$. The mean position ![]() $y=1.5$, as determined by the PID controller, is marked by the vertical dashed line; it was selected sufficiently far from the lower boundary of the domain to allow for the induced flow resulting from gas expansion to develop and interact with the flame. The length of the domain was chosen long enough to ensure that the fluctuating flames remain within the domain of integration at all times, and to allow for complete consumption of the pockets of unburned gas that get randomly detached from the flame surface. The p.d.f.s of the NR interface in figure 5(a) are distributed symmetrically about the mean and show no affinity towards one of the two sides. This is to be expected because a passive interface does not have a feedback effect on the surrounding flow field. As the turbulence intensity increases, the p.d.f.s widen, due to larger fluctuations of the interface, while retaining their symmetrical nature. The p.d.f.s of the sub-critical flames, shown in figure 5(b), also display a symmetric distribution about the mean despite the large variation in density across the interface that affects the surrounding flow field. In this regime, the perturbations induced by thermal expansion are damped by diffusion and therefore have no overall effect on the flame topology. Here too, the distribution widens when increasing the turbulence intensity due to enhanced turbulent fluctuations. This behaviour changes drastically for super-critical flames, as seen in figure 5(c), because, despite the stabilizing influences of diffusion, hydrodynamic effects tend to amplify velocity perturbations induced by gas expansion. The asymmetric bimodal p.d.f. with its extended tail towards the burned gas region is a direct consequence of the sharp crests intruding into the burned gas, which is a reminiscent of the DL instability in laminar flames (Patyal & Matalon Reference Patyal and Matalon2018). As the turbulence intensity increases and the flame surface becomes increasingly controlled by the turbulence, the p.d.f.s lose their distinct distribution; they tend towards a symmetric distribution and widen due to the thickening of the flame brush.

$y=1.5$, as determined by the PID controller, is marked by the vertical dashed line; it was selected sufficiently far from the lower boundary of the domain to allow for the induced flow resulting from gas expansion to develop and interact with the flame. The length of the domain was chosen long enough to ensure that the fluctuating flames remain within the domain of integration at all times, and to allow for complete consumption of the pockets of unburned gas that get randomly detached from the flame surface. The p.d.f.s of the NR interface in figure 5(a) are distributed symmetrically about the mean and show no affinity towards one of the two sides. This is to be expected because a passive interface does not have a feedback effect on the surrounding flow field. As the turbulence intensity increases, the p.d.f.s widen, due to larger fluctuations of the interface, while retaining their symmetrical nature. The p.d.f.s of the sub-critical flames, shown in figure 5(b), also display a symmetric distribution about the mean despite the large variation in density across the interface that affects the surrounding flow field. In this regime, the perturbations induced by thermal expansion are damped by diffusion and therefore have no overall effect on the flame topology. Here too, the distribution widens when increasing the turbulence intensity due to enhanced turbulent fluctuations. This behaviour changes drastically for super-critical flames, as seen in figure 5(c), because, despite the stabilizing influences of diffusion, hydrodynamic effects tend to amplify velocity perturbations induced by gas expansion. The asymmetric bimodal p.d.f. with its extended tail towards the burned gas region is a direct consequence of the sharp crests intruding into the burned gas, which is a reminiscent of the DL instability in laminar flames (Patyal & Matalon Reference Patyal and Matalon2018). As the turbulence intensity increases and the flame surface becomes increasingly controlled by the turbulence, the p.d.f.s lose their distinct distribution; they tend towards a symmetric distribution and widen due to the thickening of the flame brush.

Figure 5. Distribution function of the position of a passive (NR) interface and sub- and super-critical flames relative to the mean value ![]() $y=1.5$, at various intensities

$y=1.5$, at various intensities ![]() $u'/S_L$. (a) Non-reacting (NR) interface. (b) Sub-critical flame. (c) Super-critical flame.

$u'/S_L$. (a) Non-reacting (NR) interface. (b) Sub-critical flame. (c) Super-critical flame.

The p.d.f. of the local curvature of the flame front can also be used to quantify differences in flame topology, as shown in figure 6 for increasing values of the turbulence intensity. The sub-critical flame exhibits a symmetric distribution about ![]() $\kappa = 0$, indicating that the flame is equally as convex as it is concave, which verifies that it remains planar on average. In contrast, the super-critical flame, which is strongly affected by the DL instability, shows a bias in its p.d.f. It displays a preferential distribution towards larger negative curvatures, corresponding to the sharp crests and creases pointing into the burned gases, and a smaller distribution of positive curvatures, corresponding to the smoother troughs of the flame surface. As the turbulence intensity increases, the distribution begins to widen, encompassing a much larger range of positive and negative curvatures than for a sub-critical flame, and it loses gradually its asymmetric behaviour. Skewed distributions of flame surface curvature towards negative values have been reported previously in numerical simulations (Echekki & Chen Reference Echekki and Chen1996; Treurniet, Nieuwstadt & Boersma Reference Treurniet, Nieuwstadt and Boersma2006), for values

$\kappa = 0$, indicating that the flame is equally as convex as it is concave, which verifies that it remains planar on average. In contrast, the super-critical flame, which is strongly affected by the DL instability, shows a bias in its p.d.f. It displays a preferential distribution towards larger negative curvatures, corresponding to the sharp crests and creases pointing into the burned gases, and a smaller distribution of positive curvatures, corresponding to the smoother troughs of the flame surface. As the turbulence intensity increases, the distribution begins to widen, encompassing a much larger range of positive and negative curvatures than for a sub-critical flame, and it loses gradually its asymmetric behaviour. Skewed distributions of flame surface curvature towards negative values have been reported previously in numerical simulations (Echekki & Chen Reference Echekki and Chen1996; Treurniet, Nieuwstadt & Boersma Reference Treurniet, Nieuwstadt and Boersma2006), for values ![]() $u'/S_L = 2.35- 4.2$. The distinct features of the results displayed in figure 6 are the tendency of the p.d.f. towards a symmetric distribution, as the turbulence intensity increases, and the characterization of the DL influence in terms of a physically measurable Markstein number.

$u'/S_L = 2.35- 4.2$. The distinct features of the results displayed in figure 6 are the tendency of the p.d.f. towards a symmetric distribution, as the turbulence intensity increases, and the characterization of the DL influence in terms of a physically measurable Markstein number.

Figure 6. Distribution function of the local curvature of the flame surface for sub- and super-critical conditions at various turbulence intensities ![]() $u'/S_L$. (a) Sub-critical flame. (b) Super-critical flame.

$u'/S_L$. (a) Sub-critical flame. (b) Super-critical flame.

In summary, the distribution of key characteristics of the flame surface, such as local flame displacement and curvature, serves as useful markers to enhance understanding of the interplay between turbulence and the DL instability, particularly at high intensities where it may not be possible to identify visually the topological changes.

3.2. Flame brush thickness

A useful measure quantifying the extent of flame fluctuations is the flame brush thickness ![]() $\delta _T$, defined as the width of the p.d.f. of the flame position, shown schematically in figure 4. The dependence of

$\delta _T$, defined as the width of the p.d.f. of the flame position, shown schematically in figure 4. The dependence of ![]() $\delta _T$ on turbulence intensity for different values of the Markstein number is shown in figure 7. Remarkable differences are observed between sub- and super-critical flames. For sub-critical conditions, the flame brush thickness

$\delta _T$ on turbulence intensity for different values of the Markstein number is shown in figure 7. Remarkable differences are observed between sub- and super-critical flames. For sub-critical conditions, the flame brush thickness ![]() $\delta _T \rightarrow 0$ when

$\delta _T \rightarrow 0$ when ![]() $u'/S_L \to 0$, corresponding to a stable planar flame propagating in a quiescent mixture. For super-critical conditions, the flame brush thickness

$u'/S_L \to 0$, corresponding to a stable planar flame propagating in a quiescent mixture. For super-critical conditions, the flame brush thickness ![]() $\delta _T$ tends to a constant when

$\delta _T$ tends to a constant when ![]() $u'/S_L \to 0$, corresponding to the amplitude of the DL cusp-like structure, which is the only stable state under such conditions. For given turbulence conditions, the flame brush thickens with increasing

$u'/S_L \to 0$, corresponding to the amplitude of the DL cusp-like structure, which is the only stable state under such conditions. For given turbulence conditions, the flame brush thickens with increasing ![]() ${\mathcal {M}}^{-1}$, because of the deeper intrusion of the cusp-like conformations into the burned gas, consistent with the nonlinear stability results of Patyal & Matalon (Reference Patyal and Matalon2018). In both cases, the flame brush thickness increases monotonically with increasing turbulence level due to the growing fluctuations. Although for low intensities the thickness

${\mathcal {M}}^{-1}$, because of the deeper intrusion of the cusp-like conformations into the burned gas, consistent with the nonlinear stability results of Patyal & Matalon (Reference Patyal and Matalon2018). In both cases, the flame brush thickness increases monotonically with increasing turbulence level due to the growing fluctuations. Although for low intensities the thickness ![]() $\delta _T$ of the super-critical flames is significantly larger than the thickness of a sub-critical flame, the difference diminishes when increasing the turbulence intensity. It may therefore be anticipated that at sufficiently large values of

$\delta _T$ of the super-critical flames is significantly larger than the thickness of a sub-critical flame, the difference diminishes when increasing the turbulence intensity. It may therefore be anticipated that at sufficiently large values of ![]() $u'/S_L$, both flames will be controlled by the turbulence, and

$u'/S_L$, both flames will be controlled by the turbulence, and ![]() $\delta _T$ will approach a common value asymptotically, independent of the Markstein number.

$\delta _T$ will approach a common value asymptotically, independent of the Markstein number.

Figure 7. The dependence of the flame brush thickness ![]() $\delta _T$ on turbulence intensity

$\delta _T$ on turbulence intensity ![]() $u'/S_L$ for various values of the Markstein number; the value

$u'/S_L$ for various values of the Markstein number; the value ![]() ${\mathcal {M}}^{-1} = 22.5$ corresponds to sub-critical conditions, and all the larger values correspond to super-critical conditions.

${\mathcal {M}}^{-1} = 22.5$ corresponds to sub-critical conditions, and all the larger values correspond to super-critical conditions.

3.3. Surface wrinkling

The extent of wrinkling of a flame surface may also be used to differentiate sub- and super-critical conditions, and to understand the changes in the surface morphology resulting from the underlying turbulent flow. It may be measured by plotting the p.d.f. of the components of the unit normal vector ![]() ${\boldsymbol n} = (n_x, n_y, n_z)$, conditioned on the flame surface. Based on the adopted convention,

${\boldsymbol n} = (n_x, n_y, n_z)$, conditioned on the flame surface. Based on the adopted convention, ![]() $\boldsymbol n$ points towards the burned gas region, with the flame propagating along the negative

$\boldsymbol n$ points towards the burned gas region, with the flame propagating along the negative ![]() $y$-direction. Since periodic boundary conditions have been assumed in the transverse

$y$-direction. Since periodic boundary conditions have been assumed in the transverse ![]() $x$- and

$x$- and ![]() $z$-directions, it is sufficient to focus on only one of the transverse components, say

$z$-directions, it is sufficient to focus on only one of the transverse components, say ![]() $n_x$, with the observations extended easily to

$n_x$, with the observations extended easily to ![]() $n_z$. Figures 8(a,b) show that both the passive interface and the sub-critical flame exhibit symmetric distributions of

$n_z$. Figures 8(a,b) show that both the passive interface and the sub-critical flame exhibit symmetric distributions of ![]() $n_x$ with a zero mean, suggestive of a nearly planar surface. With increasing turbulence intensity, the p.d.f. widens due to more frequent fluctuations, but retains its symmetric nature. The similarity between the two confirms that the wrinkling of a sub-critical flame is affected minimally by gas expansion. In contrast, the distribution of

$n_x$ with a zero mean, suggestive of a nearly planar surface. With increasing turbulence intensity, the p.d.f. widens due to more frequent fluctuations, but retains its symmetric nature. The similarity between the two confirms that the wrinkling of a sub-critical flame is affected minimally by gas expansion. In contrast, the distribution of ![]() $n_x$ for a super-critical flame in figure 8(c) shows a starkly different behaviour, with peaks in both

$n_x$ for a super-critical flame in figure 8(c) shows a starkly different behaviour, with peaks in both ![]() $n_x = {\pm }1$. This distinctive distribution, which results from frequent formation of cusps and creases along the flame surface, weakens at higher turbulence levels.

$n_x = {\pm }1$. This distinctive distribution, which results from frequent formation of cusps and creases along the flame surface, weakens at higher turbulence levels.

Figure 8. Distribution of the transverse component ![]() $n_x$ of the unit normal vector, conditioned on the flame surface, for a passive interface and for sub- and super-critical flames at various turbulence intensities

$n_x$ of the unit normal vector, conditioned on the flame surface, for a passive interface and for sub- and super-critical flames at various turbulence intensities ![]() $u'/S_L$. (a) Non-reacting interface. (b) Sub-critical. (c) Super-critical.

$u'/S_L$. (a) Non-reacting interface. (b) Sub-critical. (c) Super-critical.

A more useful measure of the extent of wrinkling is the conditional p.d.f. of the axial component ![]() ${n}_y$ of the normal vector, which is directed along the mean flow direction. Since the cusp-like structure of a super-critical flame has a direct impact on the distribution of

${n}_y$ of the normal vector, which is directed along the mean flow direction. Since the cusp-like structure of a super-critical flame has a direct impact on the distribution of ![]() $n_y$, we begin by examining the nature of the p.d.f. under laminar conditions. The flame structure resulting from the DL instability, as shown in figure 9(a), has a tent-like conformation, consisting of a narrow rounded crest and wider troughs with ridges or creases formed along its surface. Key components of the flame surface are shown in figures 9(c–e); these include the rounded crest, the surface with the creases removed, and the troughs surfaces where both the crest and creases are removed. Evidently, the p.d.f. of

$n_y$, we begin by examining the nature of the p.d.f. under laminar conditions. The flame structure resulting from the DL instability, as shown in figure 9(a), has a tent-like conformation, consisting of a narrow rounded crest and wider troughs with ridges or creases formed along its surface. Key components of the flame surface are shown in figures 9(c–e); these include the rounded crest, the surface with the creases removed, and the troughs surfaces where both the crest and creases are removed. Evidently, the p.d.f. of ![]() $n_y$ in this case is strictly positive, as seen in figure 9(b). It has a bimodal distribution with peaks resulting from the negatively stretched regions of the flame (the crest and the sharp creases); in their absence, the troughs areas exhibit a distribution with a single peak near

$n_y$ in this case is strictly positive, as seen in figure 9(b). It has a bimodal distribution with peaks resulting from the negatively stretched regions of the flame (the crest and the sharp creases); in their absence, the troughs areas exhibit a distribution with a single peak near ![]() $n_y = 1$.

$n_y = 1$.

Figure 9. Characterization of the p.d.f. of the axial component of the normal vector ![]() ${n}_y$ conditioned on the flame surface of the super-critical flame (under laminar conditions) shown in (a), with key components of the flame surface shown in (c–e). (a) Flame surface of a supercritical flame under laminar conditions. (b) Probability density function of

${n}_y$ conditioned on the flame surface of the super-critical flame (under laminar conditions) shown in (a), with key components of the flame surface shown in (c–e). (a) Flame surface of a supercritical flame under laminar conditions. (b) Probability density function of ![]() ${n}_y$. (c) Only crest. (d) No creases. (e) Only troughs.

${n}_y$. (c) Only crest. (d) No creases. (e) Only troughs.

In figure 10, we show the conditional p.d.f. of ![]() $n_y$ for a super-critical flame under turbulent conditions and contrast it with the corresponding p.d.f.s of a sub-critical flame and an NR interface. Since the tendency of the flame is to propagate into the unburned gas in a direction normal to its surface, a value of

$n_y$ for a super-critical flame under turbulent conditions and contrast it with the corresponding p.d.f.s of a sub-critical flame and an NR interface. Since the tendency of the flame is to propagate into the unburned gas in a direction normal to its surface, a value of ![]() ${n}_y < 0$ indicates a scenario in which the flame surface is multi-valued – namely, it has formed folds and/or detached pockets of unburned gas. At low intensities, the p.d.f. of

${n}_y < 0$ indicates a scenario in which the flame surface is multi-valued – namely, it has formed folds and/or detached pockets of unburned gas. At low intensities, the p.d.f. of ![]() $n_y$ for a passive interface is strictly positive; the peak near one confirms earlier observations that the tendency of the NR interface is to remain nearly planar. Negative values may occur at much higher intensities, due to the intensified turbulence. The p.d.f. of

$n_y$ for a passive interface is strictly positive; the peak near one confirms earlier observations that the tendency of the NR interface is to remain nearly planar. Negative values may occur at much higher intensities, due to the intensified turbulence. The p.d.f. of ![]() ${n}_y$ for a sub-critical flame shown in figure 10(b) has similar characteristics; despite developing perturbations on its surface due to gas expansion, the flame surface remains nearly planar. As the turbulence intensity increases, the p.d.f. begins to widen and assumes negative values only for intensities larger than

${n}_y$ for a sub-critical flame shown in figure 10(b) has similar characteristics; despite developing perturbations on its surface due to gas expansion, the flame surface remains nearly planar. As the turbulence intensity increases, the p.d.f. begins to widen and assumes negative values only for intensities larger than ![]() $u^{\prime }/S_{L} \approx 1.5$. The situation is markedly different for a super-critical flame, as shown in figure 10(c). For very low intensities,

$u^{\prime }/S_{L} \approx 1.5$. The situation is markedly different for a super-critical flame, as shown in figure 10(c). For very low intensities, ![]() $u^{\prime }/S_{L} = 0.1$ say, the conditional p.d.f. has a bimodal distribution similar to the laminar flame in figure 9(b). As the turbulence intensity increases, multi-valued positions characterized by negative values of

$u^{\prime }/S_{L} = 0.1$ say, the conditional p.d.f. has a bimodal distribution similar to the laminar flame in figure 9(b). As the turbulence intensity increases, multi-valued positions characterized by negative values of ![]() $n_y$ become more frequent, which implies that the super-critical flame is more likely to fold and form pockets. This observation is linked directly to the increase in flame surface area and the corresponding increase in propagation speed discussed in the next section. While the current results are limited to

$n_y$ become more frequent, which implies that the super-critical flame is more likely to fold and form pockets. This observation is linked directly to the increase in flame surface area and the corresponding increase in propagation speed discussed in the next section. While the current results are limited to ![]() $u'/S_L \le 2$, it is anticipated that at higher intensities, the turbulence will overshadow the characteristic structures resulting from the instability, leading to surface topologies that do not differentiate between sub- and super-critical conditions, similar to the one shown in figure 4 for two-dimensional flows.

$u'/S_L \le 2$, it is anticipated that at higher intensities, the turbulence will overshadow the characteristic structures resulting from the instability, leading to surface topologies that do not differentiate between sub- and super-critical conditions, similar to the one shown in figure 4 for two-dimensional flows.

Figure 10. The distribution of the axial component of the normal vector ![]() ${n}_y$, conditioned on the flame surface, for (a) a passive interface (NR), (b) sub-critical flames, and (c) super-critical flames, at various turbulence intensities

${n}_y$, conditioned on the flame surface, for (a) a passive interface (NR), (b) sub-critical flames, and (c) super-critical flames, at various turbulence intensities ![]() $u'/S_L$.

$u'/S_L$.

In addition to quantifying the extent of wrinkling, it is useful to examine the nature of the local corrugations using the shape parameter, defined as the ratio of the smallest-to-largest principal curvatures at a given point on the flame surface (Pope Reference Pope1988; Pope, Yeung & Girimaji Reference Pope, Yeung and Girimaji1989). The shape parameter is constrained to values between ![]() $-1$ and

$-1$ and ![]() $+1$. For values equal to

$+1$. For values equal to ![]() $+1$, both principal curvatures are identical, and the flame surface is curved spherically. When the shape parameter is

$+1$, both principal curvatures are identical, and the flame surface is curved spherically. When the shape parameter is ![]() $0$, one of the principal curvatures is zero, and the flame surface is curved cylindrically. As the shape parameter nears