1. Introduction

Gravity-driven flows of one fluid over another can involve complex interactions between the two fluids, which can lead to a rich dynamical behaviour. Such flows occur in a wide range of natural and human-made systems, as in lava flow over less viscous lava (Balmforth et al. Reference Balmforth, Burbidge, Craster, Salzig and Shen2000; Griffiths Reference Griffiths2000), spreading of the lithosphere over the mid-mantle boundary (Lister & Kerr Reference Lister and Kerr1989; Dauck et al. Reference Dauck, Box, Gell, Neufeld and Lister2019), ice flow over an ocean (Kivelson et al. Reference Kivelson, Khurana, Russell, Volwerk, Walker and Zimmer2000; DeConto & Pollard Reference DeConto and Pollard2016) and over bedrock consisting of sediments and water (Fowler Reference Fowler1987; Stokes et al. Reference Stokes, Clark, Lian and Tulaczyk2007), flows in permeable rocks (Woods & Mason Reference Woods and Mason2000), liquid drops deforming over lubricated surfaces (Daniel et al. Reference Daniel, Timonen, Li, Velling and Aizenberg2017), and droplets motion on liquid-infused surfaces (Keiser et al. Reference Keiser, Keiser, Clanet and Quéré2017).

The flow of gravity currents (GCs) in circular geometry has been studied with a range of boundary conditions. In the absence of a lubricating layer, a common boundary condition along the base of a sole GC is no-slip. Such GCs of Newtonian fluids that are discharged at a rate proportional to ![]() $t^{\alpha }$, where

$t^{\alpha }$, where ![]() $t$ is time and

$t$ is time and ![]() $\alpha$ is a non-negative scalar, admit similarity solutions in which the front evolves proportionally to

$\alpha$ is a non-negative scalar, admit similarity solutions in which the front evolves proportionally to ![]() $t^{(3\alpha + 1)/8}$ (Huppert Reference Huppert1982). Similar axisymmetric GCs of power-law fluids having exponent

$t^{(3\alpha + 1)/8}$ (Huppert Reference Huppert1982). Similar axisymmetric GCs of power-law fluids having exponent ![]() $n$, where

$n$, where ![]() $n=1$ represents a Newtonian fluid and

$n=1$ represents a Newtonian fluid and ![]() $n>1$ represents a strain-rate softening fluid, also admit similarity solutions in which the front propagation is proportional to

$n>1$ represents a strain-rate softening fluid, also admit similarity solutions in which the front propagation is proportional to ![]() $t^{[\alpha (2n+1) +1]/(5n+3)}$ (Sayag & Worster Reference Sayag and Worster2013).

$t^{[\alpha (2n+1) +1]/(5n+3)}$ (Sayag & Worster Reference Sayag and Worster2013).

On the other extreme, the presence of a lower fluid layer can significantly reduce friction at the base of the top fluid, resulting in extensionally dominated GCs. This is the case, for example, for ice shelves, which deform over the relatively inviscid oceans with weak friction along their interface. The late-time front evolution of such axisymmetric GCs of Newtonian fluids is proportional to ![]() $t$ and is believed to be stable (Pegler & Worster Reference Pegler and Worster2012). However, when the top fluid is strain-rate softening, an initially axisymmetric front can become unstable and develop fingering patterns consisting of tongues separated by rifts (Sayag & Worster Reference Sayag and Worster2019).

$t$ and is believed to be stable (Pegler & Worster Reference Pegler and Worster2012). However, when the top fluid is strain-rate softening, an initially axisymmetric front can become unstable and develop fingering patterns consisting of tongues separated by rifts (Sayag & Worster Reference Sayag and Worster2019).

In the more general case, friction along the base of GCs can vary spatiotemporally, as their stress field evolves. For example, the interface of an ice sheet with its underlying bedrock can consist of distributed melt water and sediments (e.g. Vogel et al. Reference Vogel, Tulaczyk, Kamb, Engelhardt, Carsey, Behar, Lane and Joughin2005). Subglacial sediments are believed to deform viscoplastically (Iverson, Hooyer & Baker Reference Iverson, Hooyer and Baker1998; Tulaczyk, Kamb & Engelhardt Reference Tulaczyk, Kamb and Engelhardt2000; Kamb Reference Kamb2001; Joughin, MacAyeal & Tulaczyk Reference Joughin, MacAyeal and Tulaczyk2004; Schoof Reference Schoof2004), and when saturated with water, the ice basal friction may be affected significantly by a complex subglacial hydrological network that can evolve in time (e.g. Nanni et al. Reference Nanni, Gimbert, Roux and Lecointre2021). Consequently, subglacial lubrication can collectively impose non-uniform and time-dependent friction along the ice base, and evolve spatiotemporally under the stresses imposed by the ice layer (Fowler Reference Fowler1981; Schoof & Hewitt Reference Schoof and Hewitt2013). This coupled ice–subglacial-water system may become unstable either over hard beds (Walder Reference Walder1982; Creyts & Schoof Reference Creyts and Schoof2009) or over sediment beds (Kyrke-Smith & Fowler Reference Kyrke-Smith and Fowler2014; Kasmalkar, Mantelli & Suckale Reference Kasmalkar, Mantelli and Suckale2019), and may contribute to the formation of complex flow patterns, such as ice streams and ice surges (Fowler Reference Fowler1987; Fowler & Johnson Reference Fowler and Johnson1995; Stokes et al. Reference Stokes, Clark, Lian and Tulaczyk2007; Sayag & Tziperman Reference Sayag and Tziperman2009; Kyrke-Smith, Katz & Fowler Reference Kyrke-Smith, Katz and Fowler2013). Such lubricated flows with spatiotemporally evolving friction were also modelled as two coupled GCs of Newtonian fluids spreading axisymmetrically one on top of the other (Kowal & Worster Reference Kowal and Worster2015). The early stage of these flows follows a similarity solution, in which the fronts of the two fluids evolve like ![]() $t^{1/2}$, as in non-lubricated (no-slip) GCs (Huppert Reference Huppert1982), but they can have a radially non-monotonic thickness. Furthermore, laboratory experiments were found to be consistent with the similarity solutions after an initial transient state, but became unstable at a later stage, developing fingering patterns (Kowal & Worster Reference Kowal and Worster2015). It has been suggested that such instabilities appear when the jump in hydrostatic pressure gradient across the lubrication front is negative (Kowal & Worster Reference Kowal and Worster2019a,Reference Kowal and Worsterb).

$t^{1/2}$, as in non-lubricated (no-slip) GCs (Huppert Reference Huppert1982), but they can have a radially non-monotonic thickness. Furthermore, laboratory experiments were found to be consistent with the similarity solutions after an initial transient state, but became unstable at a later stage, developing fingering patterns (Kowal & Worster Reference Kowal and Worster2015). It has been suggested that such instabilities appear when the jump in hydrostatic pressure gradient across the lubrication front is negative (Kowal & Worster Reference Kowal and Worster2019a,Reference Kowal and Worsterb).

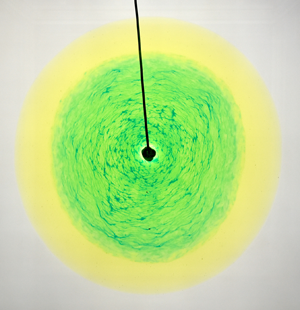

Despite the wide range of natural lubricated GCs that involve non-Newtonian fluids, the radial flow of a non-Newtonian fluid over a lubricated layer of Newtonian fluid has just recently been explored experimentally (Kumar et al. Reference Kumar, Zuri, Kogan, Gottlieb and Sayag2021). Motivated by glacier flow over lubricated bedrock, the experimental set-up consisted of a GC of a strain-rate softening fluid (xanthan gum solution) that has a power-law viscous deformation similar to ice (Glen Reference Glen1952), and a lubricating GC of a less viscous Newtonian fluid (diluted sugar solution). The pattern of both fluids in those constant flux ![]() $(\alpha =1)$ experiments remained axisymmetric throughout the flow (figure 1), in contrast to the fingering patterns that emerged in the purely Newtonian experiments (Kowal & Worster Reference Kowal and Worster2015), as long as the flux ratio of the lubricating fluid to the non-Newtonian fluid was lower than

$(\alpha =1)$ experiments remained axisymmetric throughout the flow (figure 1), in contrast to the fingering patterns that emerged in the purely Newtonian experiments (Kowal & Worster Reference Kowal and Worster2015), as long as the flux ratio of the lubricating fluid to the non-Newtonian fluid was lower than ![]() ${\sim }0.06$. The fronts of the two fluids appeared to have a power-law time evolution with different exponents. In particular, the front of the top non-Newtonian fluid evolved with the same exponent

${\sim }0.06$. The fronts of the two fluids appeared to have a power-law time evolution with different exponents. In particular, the front of the top non-Newtonian fluid evolved with the same exponent ![]() $(2n+2)/(5n+3)$ as a non-lubricated power-law fluid (Sayag & Worster Reference Sayag and Worster2013), whereas the front of the Newtonian lubricating fluid evolved with an exponent

$(2n+2)/(5n+3)$ as a non-lubricated power-law fluid (Sayag & Worster Reference Sayag and Worster2013), whereas the front of the Newtonian lubricating fluid evolved with an exponent ![]() $1/2$, similar to a Newtonian non-lubricated GC (Huppert Reference Huppert1982). Despite the similarity of the exponents with non-lubricated GCs, the fronts of those lubricated GCs evolved faster due to larger intercepts. In addition, in contrast with the monotonically declining thickness of non-lubricated GCs, the thickness of the lubricated, non-Newtonian fluid was found to be nearly uniform in the lubricated part of the flow, while that of the lubricating fluid was non-monotonic with localized spikes.

$1/2$, similar to a Newtonian non-lubricated GC (Huppert Reference Huppert1982). Despite the similarity of the exponents with non-lubricated GCs, the fronts of those lubricated GCs evolved faster due to larger intercepts. In addition, in contrast with the monotonically declining thickness of non-lubricated GCs, the thickness of the lubricated, non-Newtonian fluid was found to be nearly uniform in the lubricated part of the flow, while that of the lubricating fluid was non-monotonic with localized spikes.

Figure 1. Snapshots from a laboratory experiment (Kumar et al. Reference Kumar, Zuri, Kogan, Gottlieb and Sayag2021) of a lubricated GC that consists of a strain-rate softening fluid (yellow) lubricated by a sugar solution (blue, appears green). The marked time at each snapshot is relative to the discharge initiation time ![]() $t_L$ of the lubricating fluid.

$t_L$ of the lubricating fluid.

Following up the experimental study of Kumar et al. (Reference Kumar, Zuri, Kogan, Gottlieb and Sayag2021), here we develop a theory for lubricated axisymmetric GCs of power-law fluids, and explore its major consequences. Specifically, we develop a mathematical model for axisymmetric flow of a viscous GC of a power-law fluid lubricated by a Newtonian GC, considering a general input flux of the form ![]() $t^{\alpha }$, and show that in the general case, the flow has no global similarity solution of the first kind (§ 2). We then describe the numerical solver (§ 3), investigate several special cases that have similarity solutions (§ 4), and explore the possibility that the inner lubricating front outstrip the outer front (§ 5). Finally, we investigate the case of constant flux discharge (§ 6), compare our theoretical predictions with the laboratory experiments of Kumar et al. (Reference Kumar, Zuri, Kogan, Gottlieb and Sayag2021) (§ 7), and discuss caveats and implications (§ 8).

$t^{\alpha }$, and show that in the general case, the flow has no global similarity solution of the first kind (§ 2). We then describe the numerical solver (§ 3), investigate several special cases that have similarity solutions (§ 4), and explore the possibility that the inner lubricating front outstrip the outer front (§ 5). Finally, we investigate the case of constant flux discharge (§ 6), compare our theoretical predictions with the laboratory experiments of Kumar et al. (Reference Kumar, Zuri, Kogan, Gottlieb and Sayag2021) (§ 7), and discuss caveats and implications (§ 8).

2. Mathematical model

Consider a power-law fluid having viscosity ![]() $\mu$ and density

$\mu$ and density ![]() $\rho$ that spreads axisymmetrically under its own weight over a horizontal rigid surface. Simultaneously, a lubricating film of Newtonian immiscible fluid of viscosity

$\rho$ that spreads axisymmetrically under its own weight over a horizontal rigid surface. Simultaneously, a lubricating film of Newtonian immiscible fluid of viscosity ![]() $\mu _\ell$ and density

$\mu _\ell$ and density ![]() $\rho _\ell$ spreads axisymmetrically over the substrate and below the power-law fluid (figure 2). Both fluids are discharged at the origin of a cylindrical coordinate system in which

$\rho _\ell$ spreads axisymmetrically over the substrate and below the power-law fluid (figure 2). Both fluids are discharged at the origin of a cylindrical coordinate system in which ![]() $r$ is the radial coordinate and

$r$ is the radial coordinate and ![]() $z$ is the vertical coordinate. The upper and lower fluid fronts are denoted by

$z$ is the vertical coordinate. The upper and lower fluid fronts are denoted by ![]() $r_N(t)$ and

$r_N(t)$ and ![]() $r_L(t)$ respectively, and the corresponding fluid thicknesses are denoted by

$r_L(t)$ respectively, and the corresponding fluid thicknesses are denoted by ![]() $H(r,t)-h(r,t)$ and

$H(r,t)-h(r,t)$ and ![]() $h(r,t)$, respectively, where

$h(r,t)$, respectively, where ![]() $t$ is the time variable. Beginning the discharge of the lubricating fluid at a time delay

$t$ is the time variable. Beginning the discharge of the lubricating fluid at a time delay ![]() $t_L$, with respect to the upper fluid, creates two regions in the flow: an inner, lubricated region (

$t_L$, with respect to the upper fluid, creates two regions in the flow: an inner, lubricated region (![]() $r \leqslant r_L$) in which the power-law fluid flows at a finite velocity along the interface with the lubricating fluid, and an outer, non-lubricated region (

$r \leqslant r_L$) in which the power-law fluid flows at a finite velocity along the interface with the lubricating fluid, and an outer, non-lubricated region (![]() $r_L < r \leqslant r_N$) in which the power-law fluid meets the substrate and has zero velocity along it.

$r_L < r \leqslant r_N$) in which the power-law fluid meets the substrate and has zero velocity along it.

Figure 2. Diagram illustrating a GC of Newtonian fluid (blue) lubricating a GC of a power-law fluid (yellow). Exact solutions are singular at the origin, apart from the illustrated constant volume case ![]() $\alpha =0$.

$\alpha =0$.

We assume that the radial extent of the flow is much greater than its thickness in both fluid layers, and that the flow is primarily radial. Together with the no-slip boundary condition along the substrate, this implies that the flow is shear-dominated in the non-lubricated region and in the lower fluid layer in the lubricated region. We also assume that the flow in the upper fluid layer in the lubricated region is shear-dominated due to back pressure applied by the non-lubricated layer downstream, which inhibits the growth of extensional stresses. We elaborate further on this assumption in § 8. Consequently, we apply the lubrication approximation in each fluid layer ![]() $i$, with a dominant strain rate

$i$, with a dominant strain rate ![]() $\partial u_i / \partial z$, where

$\partial u_i / \partial z$, where ![]() $u_i(r,z,t)$ is the radial velocity component. Therefore, the axisymmetric Cauchy equations for each fluid layer, simplified for flows of low Reynolds numbers and lubrication approximations, are

$u_i(r,z,t)$ is the radial velocity component. Therefore, the axisymmetric Cauchy equations for each fluid layer, simplified for flows of low Reynolds numbers and lubrication approximations, are

to leading order, where ![]() $w_i$ is the vertical velocity component,

$w_i$ is the vertical velocity component, ![]() $p_i$ is the pressure field, and

$p_i$ is the pressure field, and ![]() $g$ is the gravitational acceleration. The pressure is determined hydrostatically in (2.1b) because we assume a large Bond number, implying that the effects of surface tension are negligible compared to gravity. Since (2.1) satisfy the lubrication approximation, this model does not describe accurately the problem at early times, before the fluid radial extent is sufficiently greater than its thickness. We estimate the instant when lubrication approximation is first satisfied in § 7, where we compare the theoretical predictions with the experimental data.

$g$ is the gravitational acceleration. The pressure is determined hydrostatically in (2.1b) because we assume a large Bond number, implying that the effects of surface tension are negligible compared to gravity. Since (2.1) satisfy the lubrication approximation, this model does not describe accurately the problem at early times, before the fluid radial extent is sufficiently greater than its thickness. We estimate the instant when lubrication approximation is first satisfied in § 7, where we compare the theoretical predictions with the experimental data.

The viscosity of the power-law fluid is determined by

where ![]() ${\boldsymbol{\mathsf{E}}}$ is the strain-rate tensor,

${\boldsymbol{\mathsf{E}}}$ is the strain-rate tensor, ![]() $k$ is the consistency coefficient, and

$k$ is the consistency coefficient, and ![]() $n$ is the power-law exponent, which determines the fluid's response to stress. Specifically,

$n$ is the power-law exponent, which determines the fluid's response to stress. Specifically, ![]() $n=1$ represents a Newtonian fluid with dynamical viscosity

$n=1$ represents a Newtonian fluid with dynamical viscosity ![]() $k$, with

$k$, with ![]() $n > 1$ a shear-thinning fluid, and

$n > 1$ a shear-thinning fluid, and ![]() $n < 1$ a shear-thickening fluid. In the lubrication limit,

$n < 1$ a shear-thickening fluid. In the lubrication limit, ![]() $\boldsymbol{\mathsf{E}}:\boldsymbol{\mathsf{E}} \approx (\partial u / \partial z)^{2}$ to leading order, so the viscosity of the power-law fluid simplifies to

$\boldsymbol{\mathsf{E}}:\boldsymbol{\mathsf{E}} \approx (\partial u / \partial z)^{2}$ to leading order, so the viscosity of the power-law fluid simplifies to

\begin{equation} \mu=k \left| \frac{1}{2}\,\frac{\partial u}{\partial z}\right|^{{{1}/{n}-1}}. \end{equation}

\begin{equation} \mu=k \left| \frac{1}{2}\,\frac{\partial u}{\partial z}\right|^{{{1}/{n}-1}}. \end{equation}We assume that the total volumes of the power-law fluid and the Newtonian fluid evolve following a power law in time given by

and for ![]() $t> t_L$,

$t> t_L$,

where ![]() $\alpha$ is a constant exponent, and

$\alpha$ is a constant exponent, and ![]() $Q$ and

$Q$ and ![]() $Q_\ell$ are constant coefficients representing, for instance, the discharge flux of each fluid when

$Q_\ell$ are constant coefficients representing, for instance, the discharge flux of each fluid when ![]() $\alpha =1$.

$\alpha =1$.

2.1. The non-lubricated region

In the non-lubricated region, the power-law fluid meets the substrate, and the lubricating fluid is absent. Integrating (2.1b), the pressure distribution is

where ![]() $p_0$ is the ambient pressure over the top free surface of the power-law fluid. Integration of the radial force balance (2.1a) across the depth of the fluid layer, together with no-slip boundary conditions along the substrate and no stress along the free surface

$p_0$ is the ambient pressure over the top free surface of the power-law fluid. Integration of the radial force balance (2.1a) across the depth of the fluid layer, together with no-slip boundary conditions along the substrate and no stress along the free surface

gives the radial velocity field

Similar integration of the continuity equation (2.1c), accounting for a free surface at the upper boundary ![]() $z=H(r,t)$, and assuming no normal flow through the substrate, gives the Reynolds equation

$z=H(r,t)$, and assuming no normal flow through the substrate, gives the Reynolds equation

which should satisfy the boundary conditions

where the local flux ![]() $q$ is determined using (2.7) to give

$q$ is determined using (2.7) to give

2.2. The lubricated region

As in the non-lubricated region and assuming continuity of pressure at the fluid–fluid interface ![]() $z=h$, the pressure in the lubricated region is determined hydrostatically by

$z=h$, the pressure in the lubricated region is determined hydrostatically by

The radial force balances simplify to

$$\begin{gather} \frac{k}{2^{{{1}/{n}-1}}}\,\frac{\partial}{\partial z}\left( \frac{\partial u}{\partial z}\left| \frac{\partial u}{\partial z}\right| ^{{{1}/{n}-1}} \right)= \frac{\partial p}{\partial r}, \quad \textrm{where} \ h \leqslant z \leqslant H, \end{gather}$$

$$\begin{gather} \frac{k}{2^{{{1}/{n}-1}}}\,\frac{\partial}{\partial z}\left( \frac{\partial u}{\partial z}\left| \frac{\partial u}{\partial z}\right| ^{{{1}/{n}-1}} \right)= \frac{\partial p}{\partial r}, \quad \textrm{where} \ h \leqslant z \leqslant H, \end{gather}$$together with the boundary conditions

$$\begin{gather}u_\ell=u, \quad k\left|\frac{1}{2}\,\frac{\partial { u}}{\partial { z}}\right| ^{{{1}/{n}-1}}\frac{\partial { u}}{\partial { z}}=\mu _\ell\, \frac{\partial u_\ell}{\partial z}, \quad \textrm{where} \ z=h, \end{gather}$$

$$\begin{gather}u_\ell=u, \quad k\left|\frac{1}{2}\,\frac{\partial { u}}{\partial { z}}\right| ^{{{1}/{n}-1}}\frac{\partial { u}}{\partial { z}}=\mu _\ell\, \frac{\partial u_\ell}{\partial z}, \quad \textrm{where} \ z=h, \end{gather}$$which represent, respectively, no-slip along the solid substrate, continuous flow velocity and shear stress at the fluid–fluid interface, and no shear stress along the free surface of the power-law fluid. Integrating the radial force balance (2.12) across the thickness of each fluid layer, and using the boundary conditions (2.13), we get the radial velocity fields in each fluid layer:

\begin{align} u(z,r,t)&= 2^{1-n}\left(\frac{\rho g}{k}\right)^{{n}}\frac{1}{1+n}\,\frac{\partial H}{\partial r} \left| \frac{\partial H}{\partial r}\right|^{n-1} \left[(H-z)^{{1+n}}-(H-h)^{{1+n}}\right]\nonumber\\ &\quad -\frac{\rho g}{\mu _\ell}\left[\frac{\partial H}{\partial r}\left(Hh-\frac{h^{2}}{2}\right)+\frac{h^{2}}{2}\,\frac{\rho _\ell -\rho}{\rho}\,\frac{\partial h}{\partial r}\right], \end{align}

\begin{align} u(z,r,t)&= 2^{1-n}\left(\frac{\rho g}{k}\right)^{{n}}\frac{1}{1+n}\,\frac{\partial H}{\partial r} \left| \frac{\partial H}{\partial r}\right|^{n-1} \left[(H-z)^{{1+n}}-(H-h)^{{1+n}}\right]\nonumber\\ &\quad -\frac{\rho g}{\mu _\ell}\left[\frac{\partial H}{\partial r}\left(Hh-\frac{h^{2}}{2}\right)+\frac{h^{2}}{2}\,\frac{\rho _\ell -\rho}{\rho}\,\frac{\partial h}{\partial r}\right], \end{align}The Reynolds equations corresponding to each fluid layer have forms similar to those of the non-lubricated region,

and should satisfy the boundary conditions

and

where (2.16b) signifies flux and height continuity across ![]() $r_L$. The local fluxes result from integrating (2.14) to get

$r_L$. The local fluxes result from integrating (2.14) to get

\begin{align} q=\int_h ^{H} u\,{\rm d}z &={-}2^{1-n}\left(\frac{\rho g}{k}\right)^{{n}} \frac{\partial H}{\partial r} \left| \frac{\partial H}{\partial r}\right|^{{n-1}}\frac{1}{n+2}\,(H-h)^{{n+2}}\nonumber\\ &\quad -(H-h)\,\frac{h \rho g}{\mu _\ell}\left[\frac{\partial H}{\partial r}\,(H-h)+\frac{h}{2}\left(\frac{\partial H}{\partial r}+\frac{\rho _\ell-\rho}{\rho}\,\frac{\partial h}{\partial r}\right)\right], \end{align}

\begin{align} q=\int_h ^{H} u\,{\rm d}z &={-}2^{1-n}\left(\frac{\rho g}{k}\right)^{{n}} \frac{\partial H}{\partial r} \left| \frac{\partial H}{\partial r}\right|^{{n-1}}\frac{1}{n+2}\,(H-h)^{{n+2}}\nonumber\\ &\quad -(H-h)\,\frac{h \rho g}{\mu _\ell}\left[\frac{\partial H}{\partial r}\,(H-h)+\frac{h}{2}\left(\frac{\partial H}{\partial r}+\frac{\rho _\ell-\rho}{\rho}\,\frac{\partial h}{\partial r}\right)\right], \end{align}

We note that without a lubricant, this set of partial differential equations (PDEs) is reduced to that of the non-lubricated region, which is consistent with the non-lubricated power-law GC model (Sayag & Worster Reference Sayag and Worster2013), and particularly with the Newtonian non-lubricated GC when ![]() $n=1$ (Huppert Reference Huppert1982). In addition, the full PDE set for the Newtonian case (

$n=1$ (Huppert Reference Huppert1982). In addition, the full PDE set for the Newtonian case (![]() $n=1$) and constant source fluxes (

$n=1$) and constant source fluxes (![]() $\alpha =1$) is consistent with the model for Newtonian lubricated GCs (Kowal & Worster Reference Kowal and Worster2015).

$\alpha =1$) is consistent with the model for Newtonian lubricated GCs (Kowal & Worster Reference Kowal and Worster2015).

2.3. Dimensionless equations

We non-dimensionalize equations (2.4), (2.8)–(2.10) and (2.15)–(2.17) with the following time, length and height scales:

$$\begin{gather}(H,h)\equiv \left( \left(\frac{\rho g}{k}\right)^{{-}2n} Q^{1+n} \mathcal{T}^{\alpha(1+n)-2} \right)^{{{1}/({5n+3})}} (\hat{H},\hat{h}), \end{gather}$$

$$\begin{gather}(H,h)\equiv \left( \left(\frac{\rho g}{k}\right)^{{-}2n} Q^{1+n} \mathcal{T}^{\alpha(1+n)-2} \right)^{{{1}/({5n+3})}} (\hat{H},\hat{h}), \end{gather}$$

where hats denote dimensionless quantities. The resulting dimensionless model, dropping hats, in the non-lubricated region ![]() $r_L \leqslant r \leqslant r_N$ is

$r_L \leqslant r \leqslant r_N$ is

where

and in the lubricated region ![]() $0 \leqslant r \leqslant r_L$ it is

$0 \leqslant r \leqslant r_L$ it is

where

\begin{align} q&={-} \mathscr{N}\,\frac{\partial H}{\partial r} \left| \frac{\partial H}{\partial r}\right|^{n-1}(H-h)^{2+n}\nonumber\\ &\quad - \mathscr{M} h(H-h) \left[\frac{\partial H}{\partial r}\,(H-h)+\left(\frac{\partial H}{\partial r}+\mathscr{D}\,\frac{\partial h}{\partial r}\right)\frac{h}{2}\right], \end{align}

\begin{align} q&={-} \mathscr{N}\,\frac{\partial H}{\partial r} \left| \frac{\partial H}{\partial r}\right|^{n-1}(H-h)^{2+n}\nonumber\\ &\quad - \mathscr{M} h(H-h) \left[\frac{\partial H}{\partial r}\,(H-h)+\left(\frac{\partial H}{\partial r}+\mathscr{D}\,\frac{\partial h}{\partial r}\right)\frac{h}{2}\right], \end{align}and where the boundary conditions are

and the total instantaneous volumes of the power-law and Newtonian fluids are

and for ![]() $t>t_L$

$t>t_L$

respectively. The resulting dimensionless quantities

\begin{equation} \left.\begin{gathered} \mathscr{Q}\equiv\frac{Q_\ell}{Q},\quad \mathscr{D}\equiv\frac{\rho _\ell-\rho}{\rho},\quad n,\quad \alpha,\\ \mathscr{M}\equiv\frac{\mu}{\mu_\ell}= \frac{\rho g}{\mu_\ell}\left(\frac{k}{\rho g}\right)^{{{8n}/({5n+3})}} \left(\frac{\mathcal{T}^{5-\alpha}}{Q}\right)^{{({n-1})/({5n+3})}}, \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \mathscr{Q}\equiv\frac{Q_\ell}{Q},\quad \mathscr{D}\equiv\frac{\rho _\ell-\rho}{\rho},\quad n,\quad \alpha,\\ \mathscr{M}\equiv\frac{\mu}{\mu_\ell}= \frac{\rho g}{\mu_\ell}\left(\frac{k}{\rho g}\right)^{{{8n}/({5n+3})}} \left(\frac{\mathcal{T}^{5-\alpha}}{Q}\right)^{{({n-1})/({5n+3})}}, \end{gathered}\right\} \end{equation}represent respectively the discharge flux ratio, the relative density difference of the lubricating and power-law fluids, the power-law fluid exponent, the volume growth exponent, and the dynamic viscosity ratio.

The scale for the non-Newtonian fluid viscosity is based on the leading-order viscosity (2.3) and the spatial scales in (2.18). Specifically, we evaluate the characteristic scale for the strain rate ![]() $\partial u/\partial z$ in (2.3) using (2.7) to get

$\partial u/\partial z$ in (2.3) using (2.7) to get ![]() $[\partial {u}/\partial {z}]\propto ({\rho g}/{k})^{n}{H^{2n}}/{R^{n}}$. Substituting the scales (2.18b,c) in the strain rate, we find that the characteristic viscosity scale is

$[\partial {u}/\partial {z}]\propto ({\rho g}/{k})^{n}{H^{2n}}/{R^{n}}$. Substituting the scales (2.18b,c) in the strain rate, we find that the characteristic viscosity scale is ![]() $[\mu ]\sim \rho g({k}/{\rho g})^{8n/(5n+3)}({\mathcal {T}^{5-\alpha }}/{Q})^{(n-1)/(5n+3)}$, which depends on the time scale

$[\mu ]\sim \rho g({k}/{\rho g})^{8n/(5n+3)}({\mathcal {T}^{5-\alpha }}/{Q})^{(n-1)/(5n+3)}$, which depends on the time scale ![]() $\mathcal {T}$. That time scale, which also enters the viscosity ratio

$\mathcal {T}$. That time scale, which also enters the viscosity ratio ![]() $\mathscr {M}$ (see (2.25e)), is scaled out of the equations in the two special cases

$\mathscr {M}$ (see (2.25e)), is scaled out of the equations in the two special cases ![]() $n=1$ and

$n=1$ and ![]() $\alpha =5$. Therefore, in the late-time limit (

$\alpha =5$. Therefore, in the late-time limit (![]() $t/t_L\gg 1$), the system no longer depends on the time scale

$t/t_L\gg 1$), the system no longer depends on the time scale ![]() $t_L$, and admits a global similarity solution of the first kind in these two special cases. For any other values of

$t_L$, and admits a global similarity solution of the first kind in these two special cases. For any other values of ![]() $n$ and

$n$ and ![]() $\alpha$, including the constant flux case (

$\alpha$, including the constant flux case (![]() $\alpha =1$), such global similarity solutions do not exist. Nevertheless, as we show in § 4, we find several additional asymptotic limits in which part of the flow evolves in a self-similar manner.

$\alpha =1$), such global similarity solutions do not exist. Nevertheless, as we show in § 4, we find several additional asymptotic limits in which part of the flow evolves in a self-similar manner.

In the general case ![]() $n\ne 1$ and

$n\ne 1$ and ![]() $\alpha \ne 5$, there are enough relations to determine the time scale

$\alpha \ne 5$, there are enough relations to determine the time scale ![]() $\mathcal {T}$ (see (2.18)) independently of the height and radial scales. Specifically, requiring that the scales of the two contributions to the flux in the top fluid layer (2.22a) balance leads to the relation

$\mathcal {T}$ (see (2.18)) independently of the height and radial scales. Specifically, requiring that the scales of the two contributions to the flux in the top fluid layer (2.22a) balance leads to the relation ![]() $\mathscr {M}(\mathcal {T})=\mathscr {N}$ that can be solved for the time scale

$\mathscr {M}(\mathcal {T})=\mathscr {N}$ that can be solved for the time scale ![]() $\mathcal {T}$, which upon substitution in (2.18) leads to independent radial scale

$\mathcal {T}$, which upon substitution in (2.18) leads to independent radial scale ![]() $\mathcal {R}$ and thickness scale

$\mathcal {R}$ and thickness scale ![]() $\mathcal {H}$, given by

$\mathcal {H}$, given by

Therefore, in the more general case (![]() $n\ne 1$ and

$n\ne 1$ and ![]() $\alpha \ne 5$), which does not admit global similarity solution of the first kind, the above may represent the time, radius and thickness scales. The time scale

$\alpha \ne 5$), which does not admit global similarity solution of the first kind, the above may represent the time, radius and thickness scales. The time scale ![]() $\mathcal {T}$ can also be set by the lubricating fluid discharge time

$\mathcal {T}$ can also be set by the lubricating fluid discharge time ![]() $t_L$, as we do when comparing the theoretical predictions to the experimental measurements in § 7.

$t_L$, as we do when comparing the theoretical predictions to the experimental measurements in § 7.

3. Numerical solutions

We solve the dimensionless model (2.19)–(2.25a–e) numerically explicitly using the Matlab PDEPE solver, with an open-ended, non-uniform and time-dependent adaptive spatial mesh, and using the dimensional ![]() $t_L$ as the time scale

$t_L$ as the time scale ![]() $\mathcal {T}$, so that

$\mathcal {T}$, so that ![]() $\hat {t}_L=1$. We find that lower spatial resolution can be used in most of the domain if the mesh is spaced logarithmically, and is denser around the fluid fronts, where the fluid heights drop sharply and the slopes

$\hat {t}_L=1$. We find that lower spatial resolution can be used in most of the domain if the mesh is spaced logarithmically, and is denser around the fluid fronts, where the fluid heights drop sharply and the slopes ![]() $\partial { H}/\partial { r}$ and

$\partial { H}/\partial { r}$ and ![]() $\partial { h}/\partial { r}$ become singular. Therefore, we use a non-uniform spatial mesh that consists of two Gaussian distributions centred at the fronts

$\partial { h}/\partial { r}$ become singular. Therefore, we use a non-uniform spatial mesh that consists of two Gaussian distributions centred at the fronts ![]() $r_N$ and

$r_N$ and ![]() $r_L$, and uniform distributions between the origin and

$r_L$, and uniform distributions between the origin and ![]() $r_L$, the two fronts, and beyond

$r_L$, the two fronts, and beyond ![]() $r_N$ (figure 3). The instantaneous front positions

$r_N$ (figure 3). The instantaneous front positions ![]() $r_N(t)$ and

$r_N(t)$ and ![]() $r_L(t)$ are determined where

$r_L(t)$ are determined where ![]() $H(r,t) \leqslant 10^{-6}$ and

$H(r,t) \leqslant 10^{-6}$ and ![]() $h(r,t) \leqslant 10^{-6}$, respectively. Since the fronts evolve, we divide the simulation time into a set of intervals, and over each interval, we solve the PDE system and then adapt the spatial mesh. The mesh adaptation is done by predicting the front positions in the next time interval using the recent solution and the front evolution equations

$h(r,t) \leqslant 10^{-6}$, respectively. Since the fronts evolve, we divide the simulation time into a set of intervals, and over each interval, we solve the PDE system and then adapt the spatial mesh. The mesh adaptation is done by predicting the front positions in the next time interval using the recent solution and the front evolution equations

This technique allows us to keep higher mesh density centred at the front positions, where variations in the fields are larger, and lower density elsewhere, where variations are milder.

Figure 3. (a) Mesh density and (b) a solution at time ![]() $t/t_L=100$, showing the lubricated fluid (thick) and the lubricating fluid (thin) for

$t/t_L=100$, showing the lubricated fluid (thick) and the lubricating fluid (thin) for ![]() $n=1$,

$n=1$, ![]() $\alpha =1$,

$\alpha =1$, ![]() $\mathscr {M}=1$,

$\mathscr {M}=1$, ![]() $\mathscr {Q}=0.2$ and

$\mathscr {Q}=0.2$ and ![]() $\mathscr {D}=0.1$. Front positions (red circles) are determined where each fluid thickness drops below

$\mathscr {D}=0.1$. Front positions (red circles) are determined where each fluid thickness drops below ![]() $10^{-6}$. Substrate is not pre-wetted ahead of the intrusion, and each fluid thickness ahead of its front diminishes rapidly to zero.

$10^{-6}$. Substrate is not pre-wetted ahead of the intrusion, and each fluid thickness ahead of its front diminishes rapidly to zero.

We validated our numerical solver using several known asymptotic solutions. In the limit ![]() $\mathscr {Q}=0$ (no lubricating fluid), our model converges to a GC that propagates under a no-slip condition along the substrate, which has a similarity solution

$\mathscr {Q}=0$ (no lubricating fluid), our model converges to a GC that propagates under a no-slip condition along the substrate, which has a similarity solution ![]() $r_N(t) \propto t^{[\alpha (2n+1)+1]/{(5n+3)}}$ (Huppert Reference Huppert1982; Sayag & Worster Reference Sayag and Worster2013). We find that our numerical solutions for the fluid heights and for the leading front are consistent with those theoretical predictions (Appendix A). In particular, the discrepancy between the predicted and computed exponents is less than

$r_N(t) \propto t^{[\alpha (2n+1)+1]/{(5n+3)}}$ (Huppert Reference Huppert1982; Sayag & Worster Reference Sayag and Worster2013). We find that our numerical solutions for the fluid heights and for the leading front are consistent with those theoretical predictions (Appendix A). In particular, the discrepancy between the predicted and computed exponents is less than ![]() $5\times 10^{-3}$ and can be minimized further with a higher spatial resolution. In the limit

$5\times 10^{-3}$ and can be minimized further with a higher spatial resolution. In the limit ![]() $n=1$ and

$n=1$ and ![]() $\alpha =1$, our model converges to a purely Newtonian lubricated GC released at constant flux, which has a similarity solution

$\alpha =1$, our model converges to a purely Newtonian lubricated GC released at constant flux, which has a similarity solution ![]() $r_L,r_N\propto t^{1/2}$ (Kowal & Worster Reference Kowal and Worster2015). We find that our numerical solutions are consistent with both the front and thickness predictions for a wide range of

$r_L,r_N\propto t^{1/2}$ (Kowal & Worster Reference Kowal and Worster2015). We find that our numerical solutions are consistent with both the front and thickness predictions for a wide range of ![]() $\mathscr {M}$ and

$\mathscr {M}$ and ![]() $\mathscr {Q}$ values (Appendix A).

$\mathscr {Q}$ values (Appendix A).

4. Similarity solutions

The model described by (2.19)–(2.25) admits similarity solutions in several special cases. Specifically, global similarity solutions exist when the top fluid is also Newtonian (![]() $n=1$), or when the mass-discharge exponent is

$n=1$), or when the mass-discharge exponent is ![]() $\alpha =5$. In addition, part of the flow evolves in a self-similar manner in the asymptotic limits of the viscosity ratio

$\alpha =5$. In addition, part of the flow evolves in a self-similar manner in the asymptotic limits of the viscosity ratio ![]() $\mathscr {M}$. Finally, for any parameter combination, the solutions in the vicinity of each front evolve in a self-similar manner.

$\mathscr {M}$. Finally, for any parameter combination, the solutions in the vicinity of each front evolve in a self-similar manner.

4.1. The similarity solution for Newtonian fluids ( $n=1$)

$n=1$)

When the top fluid is Newtonian (![]() $n=1$), the viscosity ratio

$n=1$), the viscosity ratio ![]() $\mathscr {M}$ is independent of

$\mathscr {M}$ is independent of ![]() $\mathcal {T}$, and the resulting purely Newtonian coupled flow admits a global similarity solution. This case, restricted to a constant flux (

$\mathcal {T}$, and the resulting purely Newtonian coupled flow admits a global similarity solution. This case, restricted to a constant flux (![]() $\alpha =1$), has been explored thoroughly (Kowal & Worster Reference Kowal and Worster2015). For the general case of

$\alpha =1$), has been explored thoroughly (Kowal & Worster Reference Kowal and Worster2015). For the general case of ![]() $\alpha \geqslant 0$, the PDE set can be reduced to an ordinary differential equation set with similarity variable

$\alpha \geqslant 0$, the PDE set can be reduced to an ordinary differential equation set with similarity variable

and a solution of the form

\begin{equation} \left(H,h\right)=t^{({\alpha-1})/{4}}\left(Q\,\frac{k}{\rho g}\right)^{{1}/{4}}\left(F,f\right), \end{equation}

\begin{equation} \left(H,h\right)=t^{({\alpha-1})/{4}}\left(Q\,\frac{k}{\rho g}\right)^{{1}/{4}}\left(F,f\right), \end{equation}

where ![]() $F$ and

$F$ and ![]() $f$ are dimensionless functions of

$f$ are dimensionless functions of ![]() $\eta$. Therefore, the fronts of both the lubricated and lubricating fluids evolve like

$\eta$. Therefore, the fronts of both the lubricated and lubricating fluids evolve like

where ![]() $\eta _N\equiv \eta (r=r_N)$ and

$\eta _N\equiv \eta (r=r_N)$ and ![]() $\eta _L\equiv \eta (r=r_L)$ are numerical coefficients of order

$\eta _L\equiv \eta (r=r_L)$ are numerical coefficients of order ![]() $1$. These solutions have structure identical to that of the classical solution for Newtonian GCs (Huppert Reference Huppert1982). Upon substitution, the Reynolds equations (2.8) and (2.15) become, for the non-lubricated region (

$1$. These solutions have structure identical to that of the classical solution for Newtonian GCs (Huppert Reference Huppert1982). Upon substitution, the Reynolds equations (2.8) and (2.15) become, for the non-lubricated region (![]() $\eta _L\leqslant \eta \leqslant \eta _N$),

$\eta _L\leqslant \eta \leqslant \eta _N$),

where prime denotes a derivative with respect to ![]() $\eta$, and for the lubricated region (

$\eta$, and for the lubricated region (![]() $0\leqslant \eta \leqslant \eta _L$),

$0\leqslant \eta \leqslant \eta _L$),

where

The corresponding boundary conditions (2.23) become

where the last condition implies convergence to a similarity solution a long time after the initiation of the fluid discharge, ![]() $t \gg t_L$.

$t \gg t_L$.

For ![]() $\alpha =1$, the model converges to that of Kowal & Worster (Reference Kowal and Worster2015), and the similarity solutions that we predict for general

$\alpha =1$, the model converges to that of Kowal & Worster (Reference Kowal and Worster2015), and the similarity solutions that we predict for general ![]() $\alpha$ are consistent with our full numerical solution (figures 4 and 5).

$\alpha$ are consistent with our full numerical solution (figures 4 and 5).

Figure 4. (a) The numerical solutions for the evolution of the dimensionless fronts for ![]() $\alpha =1,2,3,4,5$,

$\alpha =1,2,3,4,5$, ![]() $n=1$ and for

$n=1$ and for ![]() $\alpha =5$,

$\alpha =5$, ![]() $n=1.25$ (coloured lines and dashed lines) for

$n=1.25$ (coloured lines and dashed lines) for ![]() $\mathscr {Q}=0.2$,

$\mathscr {Q}=0.2$, ![]() $\mathscr {D}=0.1$ and

$\mathscr {D}=0.1$ and ![]() $\mathscr {M}=100$. Regression to the late-time solutions (

$\mathscr {M}=100$. Regression to the late-time solutions (![]() $t/t_L>10$) to power-law evolution along one decade of time (dash, black) results in exponents (values in colour) consistent with the global similarity for the

$t/t_L>10$) to power-law evolution along one decade of time (dash, black) results in exponents (values in colour) consistent with the global similarity for the ![]() $n=1$ cases (

$n=1$ cases (![]() $t^{(3\alpha +1)/8}$, (4.2b)) and with the

$t^{(3\alpha +1)/8}$, (4.2b)) and with the ![]() $\alpha =5$ cases (

$\alpha =5$ cases (![]() $t^{2}$, (4.8b)). The inset shows the computed intercepts

$t^{2}$, (4.8b)). The inset shows the computed intercepts ![]() $\eta _N(\diamond ),\eta _L({\square })$ versus

$\eta _N(\diamond ),\eta _L({\square })$ versus ![]() $\alpha$. (b) The normalized thicknesses

$\alpha$. (b) The normalized thicknesses ![]() $H/t,h/t$ along the normalized radius

$H/t,h/t$ along the normalized radius ![]() $r/t^{2}$ at selected dimensionless time

$r/t^{2}$ at selected dimensionless time ![]() $t/t_L$ when

$t/t_L$ when ![]() $\alpha =5$ and

$\alpha =5$ and ![]() $n=1$. This shows the relatively rapid convergence of the numerical solution to an asymptotic similarity solution (4.8), where the front positions at the late-time instant

$n=1$. This shows the relatively rapid convergence of the numerical solution to an asymptotic similarity solution (4.8), where the front positions at the late-time instant ![]() $t/t_L=97.9$ are

$t/t_L=97.9$ are ![]() $\eta _N\approx 0.621$,

$\eta _N\approx 0.621$, ![]() $\eta _L\approx 0.473$, correspondingly with the computed values in the inset of (a).

$\eta _L\approx 0.473$, correspondingly with the computed values in the inset of (a).

Figure 5. The asymptotic solutions in the vicinity of the fronts ![]() $F(\eta ),f(\eta )$ (see (4.18a,b), (4.21)) given by the non-lubricated GC similarity solutions (blue dotted lines), compared with the full numerical solutions of lubricated GCs (solid lines) for

$F(\eta ),f(\eta )$ (see (4.18a,b), (4.21)) given by the non-lubricated GC similarity solutions (blue dotted lines), compared with the full numerical solutions of lubricated GCs (solid lines) for ![]() $\mathscr {M}=100$,

$\mathscr {M}=100$, ![]() $\mathscr {Q}=0.1$,

$\mathscr {Q}=0.1$, ![]() $\mathscr {D}=1$,

$\mathscr {D}=1$, ![]() $\alpha =1$ and

$\alpha =1$ and ![]() $n=0.5,1,2$ at

$n=0.5,1,2$ at ![]() $t/t_L\approx 20$. The positions of the fronts predicted by the non-lubricated GC solutions are cyan

$t/t_L\approx 20$. The positions of the fronts predicted by the non-lubricated GC solutions are cyan ![]() $\bigtriangledown$ (

$\bigtriangledown$ (![]() $\eta _N$) and cyan

$\eta _N$) and cyan ![]() $\Diamond$ (

$\Diamond$ (![]() $\eta _L$), but to have the shapes of the two solutions more clearly compared, we translated the asymptotic solutions so that their fronts coincide with those of the lubricated GC solution (

$\eta _L$), but to have the shapes of the two solutions more clearly compared, we translated the asymptotic solutions so that their fronts coincide with those of the lubricated GC solution (![]() ${\square }, \circ, {\triangle }$ markers). Each inset zooms into the region near the lubricating fluid front marked by a rectangle.

${\square }, \circ, {\triangle }$ markers). Each inset zooms into the region near the lubricating fluid front marked by a rectangle.

4.2. The similarity solution for mass-discharge exponent  $\alpha = 5$

$\alpha = 5$

When the top fluid is non-Newtonian, ![]() $n\neq 1$, the viscosity ratio

$n\neq 1$, the viscosity ratio ![]() $\mathscr {M}$ becomes independent of the time scale

$\mathscr {M}$ becomes independent of the time scale ![]() $\mathcal {T}$ for a discharge exponent

$\mathcal {T}$ for a discharge exponent ![]() $\alpha =5$, and the resulting flow also admits a similarity solution with similarity variable

$\alpha =5$, and the resulting flow also admits a similarity solution with similarity variable

and a solution of the form

\begin{equation} (H,h)= t\left[Q^{1+n} \left(\frac{k}{\rho g}\right)^{2n} \right]^{{1}/{(5n+3)}} (F,f), \end{equation}

\begin{equation} (H,h)= t\left[Q^{1+n} \left(\frac{k}{\rho g}\right)^{2n} \right]^{{1}/{(5n+3)}} (F,f), \end{equation}

where ![]() $F$ and

$F$ and ![]() $f$ are dimensionless functions of

$f$ are dimensionless functions of ![]() $\eta$. Therefore, the fronts of both the lubricated and lubricating fluids evolve like

$\eta$. Therefore, the fronts of both the lubricated and lubricating fluids evolve like

where ![]() $\eta _N$ and

$\eta _N$ and ![]() $\eta _L$ are numerical coefficients of order

$\eta _L$ are numerical coefficients of order ![]() $1$. Upon substitution, the Reynolds equations (2.8) and (2.15) become, for the non-lubricated region (

$1$. Upon substitution, the Reynolds equations (2.8) and (2.15) become, for the non-lubricated region (![]() $\eta _L\leqslant \eta \leqslant \eta _N$)

$\eta _L\leqslant \eta \leqslant \eta _N$)

and for the lubricated region (![]() $0\leqslant \eta \leqslant \eta _L$)

$0\leqslant \eta \leqslant \eta _L$)

where

The corresponding boundary conditions (2.23) become

Figure 4 shows the numerical solution of the full PDE set for ![]() $\alpha =5$ for varying power-law exponent values. We find that the numerical solutions are consistent with the predicted similarity solution (4.8). This consistency validates further the numerical simulation for the combination of lubricated GCs with lubricated power-law fluid.

$\alpha =5$ for varying power-law exponent values. We find that the numerical solutions are consistent with the predicted similarity solution (4.8). This consistency validates further the numerical simulation for the combination of lubricated GCs with lubricated power-law fluid.

We note that a similarity solution at ![]() $\alpha =5$ arises also in other GCs with radial symmetry, but of different settings. We elaborate on this aspect in § 8.

$\alpha =5$ arises also in other GCs with radial symmetry, but of different settings. We elaborate on this aspect in § 8.

4.3. Similarity solutions for the asymptotic limits in  $\mathscr {M}$: the upper fluid solid and liquid limits

$\mathscr {M}$: the upper fluid solid and liquid limits

In the general case of ![]() $\alpha \neq 5$ and

$\alpha \neq 5$ and ![]() $n \neq 1$, our model does not admit global similarity solutions of the first kind. However, a similarity solution arises in part of the flow domain in each of the asymptotic limits of the viscosity ratio, in which the upper fluid layer is either relatively more viscous (

$n \neq 1$, our model does not admit global similarity solutions of the first kind. However, a similarity solution arises in part of the flow domain in each of the asymptotic limits of the viscosity ratio, in which the upper fluid layer is either relatively more viscous (![]() $\mathscr {M} \gg 1$, the ‘solid’ limit) or relatively less viscous (

$\mathscr {M} \gg 1$, the ‘solid’ limit) or relatively less viscous (![]() $\mathscr {M} \ll 1$, the ‘liquid’ limit) compared with the lower fluid layer.

$\mathscr {M} \ll 1$, the ‘liquid’ limit) compared with the lower fluid layer.

4.3.1. The top layer solid limit,  $\mathscr {M} \gg 1$

$\mathscr {M} \gg 1$

The limit ![]() $\mathscr {M} \gg 1$ represents the case where the top fluid is much more viscous than the lubricating fluid. One motivation to study this limit is the geophysical setting of ice sheets creeping over less viscous lubricated beds. In this case, the leading-order scaling of the power-law fluid local flux in the lubricated region (2.22a) is

$\mathscr {M} \gg 1$ represents the case where the top fluid is much more viscous than the lubricating fluid. One motivation to study this limit is the geophysical setting of ice sheets creeping over less viscous lubricated beds. In this case, the leading-order scaling of the power-law fluid local flux in the lubricated region (2.22a) is

which is identical to the scaling of the Newtonian lubricating fluid flux (2.22b). In such a case, the three scales ![]() $\mathcal {H}$,

$\mathcal {H}$, ![]() $\mathcal {R}$ and

$\mathcal {R}$ and ![]() $\mathcal {T}$ in the lubricated region cannot be determined independently despite the fact that the upper fluid is a power-law fluid. Therefore, both fluids in the lubricated region have a similarity solution in which the dimensionless front in the lubricated region evolves with an

$\mathcal {T}$ in the lubricated region cannot be determined independently despite the fact that the upper fluid is a power-law fluid. Therefore, both fluids in the lubricated region have a similarity solution in which the dimensionless front in the lubricated region evolves with an ![]() $n$-independent exponent

$n$-independent exponent

where the intercept ![]() $\eta _L$ may depend on the system dimensionless numbers. The exponent in (4.14) is consistent with the predictions made for the special cases discussed above. Specifically, for

$\eta _L$ may depend on the system dimensionless numbers. The exponent in (4.14) is consistent with the predictions made for the special cases discussed above. Specifically, for ![]() $n=1$ it is

$n=1$ it is ![]() $(3\alpha +1)/8$ as we predict in (4.2b), and for

$(3\alpha +1)/8$ as we predict in (4.2b), and for ![]() $\alpha =5$ it is

$\alpha =5$ it is ![]() $2$ independently of

$2$ independently of ![]() $n$ as we predict in (4.8b). This similarity solution does not reveal the evolution of the fluid front

$n$ as we predict in (4.8b). This similarity solution does not reveal the evolution of the fluid front ![]() $r_N$ in the non-lubricated region, which depends on the fluid exponent

$r_N$ in the non-lubricated region, which depends on the fluid exponent ![]() $n$.

$n$.

4.3.2. The top layer ‘liquid’ limit,  $\mathscr {M} \ll 1$

$\mathscr {M} \ll 1$

The second asymptotic limit, ![]() $\mathscr {M} \ll 1$, in which the top fluid is much less viscous than the underlying fluid, also admits a similarity solution, but of a different subset of the model. In this case, the leading-order scaling of the power-law fluid local flux in the lubricated region (2.22a) is

$\mathscr {M} \ll 1$, in which the top fluid is much less viscous than the underlying fluid, also admits a similarity solution, but of a different subset of the model. In this case, the leading-order scaling of the power-law fluid local flux in the lubricated region (2.22a) is

which is identical to the scaling of the power-law fluid in the non-lubricated region (2.20a,b). Therefore, the evolution of the power-law fluid in the entire domain converges when ![]() $h\ll H$ to the similarity solution of a non-lubricated power-law GC, in which case the upper fluid front evolves with an

$h\ll H$ to the similarity solution of a non-lubricated power-law GC, in which case the upper fluid front evolves with an ![]() $n$-dependent exponent

$n$-dependent exponent

(Sayag & Worster Reference Sayag and Worster2013), where the intercept ![]() $\eta _N$ may depend on the system dimensionless numbers. This similarity solution does not hold for the underlying fluid layer since the local flux of the Newtonian underlying fluid sets a different scaling. Therefore, it does not predict the evolution of the underlying fluid front

$\eta _N$ may depend on the system dimensionless numbers. This similarity solution does not hold for the underlying fluid layer since the local flux of the Newtonian underlying fluid sets a different scaling. Therefore, it does not predict the evolution of the underlying fluid front ![]() $r_L$. For

$r_L$. For ![]() $H-h>1$, the coupling between the upper fluid layer and the lower one grows stronger the more shear-thinning the fluid is (

$H-h>1$, the coupling between the upper fluid layer and the lower one grows stronger the more shear-thinning the fluid is (![]() $n\rightarrow \infty$), as the exponent in (4.15) grows like

$n\rightarrow \infty$), as the exponent in (4.15) grows like ![]() $n$. Therefore, (4.16) is expected to be less accurate the more shear-thinning the upper fluid is when

$n$. Therefore, (4.16) is expected to be less accurate the more shear-thinning the upper fluid is when ![]() $H-h>1$, and more accurate when

$H-h>1$, and more accurate when ![]() $H-h<1$.

$H-h<1$.

4.4. Asymptotic solutions in the vicinity of the fluid fronts

The thicknesses of the two fluid layers in the vicinity of the fronts also have self-similar forms in the absence of a global similarity solution. These self-similar forms arise because the dynamics in the vicinity of both fronts is dominated by the same dynamics that governs non-lubricated GCs, which are known to have self-similar solutions for any ![]() $\alpha$ and

$\alpha$ and ![]() $n$ (Huppert Reference Huppert1982; Sayag & Worster Reference Sayag and Worster2013).

$n$ (Huppert Reference Huppert1982; Sayag & Worster Reference Sayag and Worster2013).

The dominance of a non-lubricated GC dynamics is naturally expected in the vicinity of the front ![]() $r_N$, which is the edge of the non-lubricated region in the flow. In this case, we expect consistency of the fluid thickness with Sayag & Worster (Reference Sayag and Worster2013), which implies a similarity solution of the form

$r_N$, which is the edge of the non-lubricated region in the flow. In this case, we expect consistency of the fluid thickness with Sayag & Worster (Reference Sayag and Worster2013), which implies a similarity solution of the form

for the model described by (2.19) and (2.20a,b). Therefore, the asymptotic solution for the function ![]() $F$ near the front

$F$ near the front ![]() $\eta _N$ in the similarity space is (Sayag & Worster Reference Sayag and Worster2013)

$\eta _N$ in the similarity space is (Sayag & Worster Reference Sayag and Worster2013)

\begin{equation} F=\left[N\eta_N^{n+1}\left(1-\frac{\eta}{\eta_N}\right)^{n}\right]^{{1}/{(2n+1)}},\quad N=\left(\frac{1}{\mathscr{N}}\,\frac{\alpha(2n+1)+1}{5n+3}\right)^{1/n}\frac{2n+1}{n}. \end{equation}

\begin{equation} F=\left[N\eta_N^{n+1}\left(1-\frac{\eta}{\eta_N}\right)^{n}\right]^{{1}/{(2n+1)}},\quad N=\left(\frac{1}{\mathscr{N}}\,\frac{\alpha(2n+1)+1}{5n+3}\right)^{1/n}\frac{2n+1}{n}. \end{equation}

Near the front ![]() $r_L$, the dominance of non-lubricated GC dynamics is also valid, but requires a more careful supporting argument. Specifically, we assert that the free surface slope

$r_L$, the dominance of non-lubricated GC dynamics is also valid, but requires a more careful supporting argument. Specifically, we assert that the free surface slope ![]() $\partial H/\partial r$ is finite at

$\partial H/\partial r$ is finite at ![]() $r_L$, whereas the slope of the lubricating fluid is singular. Therefore, provided that the density difference is non zero, the leading-order flux

$r_L$, whereas the slope of the lubricating fluid is singular. Therefore, provided that the density difference is non zero, the leading-order flux ![]() $q_\ell$ (2.22b) becomes

$q_\ell$ (2.22b) becomes

Consequently, the model (2.21a) for the lubricating fluid near ![]() $r_L$ is decoupled from

$r_L$ is decoupled from ![]() $H$, and describes a modified non-lubricated GC of a Newtonian fluid (Huppert Reference Huppert1982). In this case, the thickness

$H$, and describes a modified non-lubricated GC of a Newtonian fluid (Huppert Reference Huppert1982). In this case, the thickness ![]() $h$ has a similarity solution of the form

$h$ has a similarity solution of the form

Therefore, the asymptotic solution for the function ![]() $f$ near the front

$f$ near the front ![]() $\eta _L$ in the similarity space is (Huppert Reference Huppert1982)

$\eta _L$ in the similarity space is (Huppert Reference Huppert1982)

\begin{equation} f=\left[ \frac{9(3\alpha+1)}{8}\,\frac{\eta _L^{2}}{\mathscr{M}\mathscr{D}} \left( 1 - \frac{\eta}{\eta_L} \right) \right]^{1/3}. \end{equation}

\begin{equation} f=\left[ \frac{9(3\alpha+1)}{8}\,\frac{\eta _L^{2}}{\mathscr{M}\mathscr{D}} \left( 1 - \frac{\eta}{\eta_L} \right) \right]^{1/3}. \end{equation}Plugging the similarity solutions for the power-law fluid (4.17a) and for the Newtonian fluid (4.20a) into the dimensionless form of the global mass conservation equations (2.24), we get

in the late-time limit ![]() $t/t_L\gg 1$, where we note that the time exponents in the first equation vanish even though the exponents in the non-Newtonian case have

$t/t_L\gg 1$, where we note that the time exponents in the first equation vanish even though the exponents in the non-Newtonian case have ![]() $n$ dependence. Plugging the similarity solutions for

$n$ dependence. Plugging the similarity solutions for ![]() $F$ and

$F$ and ![]() $f$ and solving, we obtain the closed-form solutions for the intercepts of the fronts:

$f$ and solving, we obtain the closed-form solutions for the intercepts of the fronts:

$$\begin{gather} \eta_N=\left[\frac{2{\rm \pi}}{1+\mathscr{Q}}\,\frac{(2n+1)^{2}}{(5n+2)(3n+1)}\,N^{{{n}/({2n+1})}} \right]^{{-({2n+1})/({5n+3})}}, \end{gather}$$

$$\begin{gather} \eta_N=\left[\frac{2{\rm \pi}}{1+\mathscr{Q}}\,\frac{(2n+1)^{2}}{(5n+2)(3n+1)}\,N^{{{n}/({2n+1})}} \right]^{{-({2n+1})/({5n+3})}}, \end{gather}$$ $$\begin{gather}\eta_L=\left[\frac{2{\rm \pi}}{\mathscr{Q}}\,\frac{9}{28} \left(\frac{9(3\alpha+1)}{8\mathscr{M}\mathscr{D}} \right)^{{1}/{3}} \right]^{-{3}/{8}}. \end{gather}$$

$$\begin{gather}\eta_L=\left[\frac{2{\rm \pi}}{\mathscr{Q}}\,\frac{9}{28} \left(\frac{9(3\alpha+1)}{8\mathscr{M}\mathscr{D}} \right)^{{1}/{3}} \right]^{-{3}/{8}}. \end{gather}$$

The asymptotic solutions (4.18a,b) and (4.21) that we obtain based on the asymptotic limit in which the two layers are decoupled appear to provide a precise prediction for the fluid thicknesses of the lubricated GC in the vicinity of the fronts when using the numerically calculated values for ![]() $\eta _L,\eta _N$ of the lubricated GC (figure 5). The values for

$\eta _L,\eta _N$ of the lubricated GC (figure 5). The values for ![]() $\eta _L$ and

$\eta _L$ and ![]() $\eta _N$ in (4.23), based on the non-lubricated GC solution, provide a rough estimate for those of the lubricated GC. Discrepancies between the two seem to decline the more shear-thickening (

$\eta _N$ in (4.23), based on the non-lubricated GC solution, provide a rough estimate for those of the lubricated GC. Discrepancies between the two seem to decline the more shear-thickening (![]() $n<1$) and the less lubricated the upper layer (

$n<1$) and the less lubricated the upper layer (![]() $\mathscr {M}\ll 1$) is (figure 6a). These discrepancies could be due to differences in the predicted thickness structure near the fluid fronts. Specifically, the more shear-thinning the fluid, the sharper the fluid front region, as implied by the thickness structure

$\mathscr {M}\ll 1$) is (figure 6a). These discrepancies could be due to differences in the predicted thickness structure near the fluid fronts. Specifically, the more shear-thinning the fluid, the sharper the fluid front region, as implied by the thickness structure ![]() $F\sim (1- \eta /\eta _N)^{n/(2n+1)}$ (see (4.18a,b)). Consequently, the more shear-thinning the fluid, the more the predicted thickness

$F\sim (1- \eta /\eta _N)^{n/(2n+1)}$ (see (4.18a,b)). Consequently, the more shear-thinning the fluid, the more the predicted thickness ![]() $F$ in the lubricated region overestimates the numerical solution (compare figures 5a,c), and by global mass conservation (see (4.22)), the smaller the predicted

$F$ in the lubricated region overestimates the numerical solution (compare figures 5a,c), and by global mass conservation (see (4.22)), the smaller the predicted ![]() $\eta _N$ compared to the numerical value.

$\eta _N$ compared to the numerical value.

Figure 6. (a) The coefficients ![]() $\eta _N,\eta _L$ of the lubricated GC solutions compared with those of the asymptotic solution near the fronts given by the non-lubricated GC similarity solutions, where

$\eta _N,\eta _L$ of the lubricated GC solutions compared with those of the asymptotic solution near the fronts given by the non-lubricated GC similarity solutions, where ![]() $\mathscr {Q}=0.2$,

$\mathscr {Q}=0.2$, ![]() $\mathscr {D}=0.1$,

$\mathscr {D}=0.1$, ![]() $\alpha =1$,

$\alpha =1$, ![]() $10^{-2}\leqslant \mathscr {M}\leqslant 10^{4}$, and

$10^{-2}\leqslant \mathscr {M}\leqslant 10^{4}$, and ![]() $n=10,1,0.5$. The

$n=10,1,0.5$. The ![]() $\eta _N$ of the asymptotic solutions (solid lines) are independent of

$\eta _N$ of the asymptotic solutions (solid lines) are independent of ![]() $\mathscr {M}$ and diminish with

$\mathscr {M}$ and diminish with ![]() $n$, whereas those of the lubricated GC (solid markers at corresponding colours) are nearly equal in the liquid limit (

$n$, whereas those of the lubricated GC (solid markers at corresponding colours) are nearly equal in the liquid limit (![]() $\mathscr {M}\ll 1$) and grow monotonically with

$\mathscr {M}\ll 1$) and grow monotonically with ![]() $\mathscr {M}$. The corresponding

$\mathscr {M}$. The corresponding ![]() $\eta _L$ of the asymptotic solution (dashed cyan line) are independent of

$\eta _L$ of the asymptotic solution (dashed cyan line) are independent of ![]() $n$, unlike those of the lubricated GC solution (hollow markers), but both grow monotonically with

$n$, unlike those of the lubricated GC solution (hollow markers), but both grow monotonically with ![]() $\mathscr {M}$. Vertical grid lines mark the threshold viscosity ratio

$\mathscr {M}$. Vertical grid lines mark the threshold viscosity ratio ![]() $\mathscr {M}_c$ based on the non-lubricated GC solutions. (b) The difference

$\mathscr {M}_c$ based on the non-lubricated GC solutions. (b) The difference ![]() $\Delta \eta \equiv \eta _N-\eta _L$ of the lubricated and non-lubricated values in (a).

$\Delta \eta \equiv \eta _N-\eta _L$ of the lubricated and non-lubricated values in (a).

5. Front outstripping

In the absence of global similarity solutions, the fronts propagate at different rates, implying that under certain conditions, the inner lubricating front ![]() $r_L$ may outstrip the outer front

$r_L$ may outstrip the outer front ![]() $r_N$. We identify two outstripping mechanisms, one driven by the solution intercepts at early time, and the other by the exponents at late time.

$r_N$. We identify two outstripping mechanisms, one driven by the solution intercepts at early time, and the other by the exponents at late time.

5.1. Intercept outstripping

When the lubricating fluid emerges, ![]() $t-t_L\gtrsim 0$, the growth of its front is dominated by the intercept

$t-t_L\gtrsim 0$, the growth of its front is dominated by the intercept ![]() $\eta _L$, whereas the contribution of the power-law growth

$\eta _L$, whereas the contribution of the power-law growth ![]() $(t-t_L)^{\beta _L}$ is relatively small. Therefore, the outstripping of

$(t-t_L)^{\beta _L}$ is relatively small. Therefore, the outstripping of ![]() $r_N(t)$ by

$r_N(t)$ by ![]() $r_L(t)$ can occur faster the larger

$r_L(t)$ can occur faster the larger ![]() $\eta _L$ is compared to

$\eta _L$ is compared to ![]() $\eta _N$. The intercept difference

$\eta _N$. The intercept difference ![]() $\Delta \eta \equiv \eta _N-\eta _L$ predicted by the asymptotic, non-lubricated GC solution (4.23) diminishes with

$\Delta \eta \equiv \eta _N-\eta _L$ predicted by the asymptotic, non-lubricated GC solution (4.23) diminishes with ![]() $\mathscr {M}$ and becomes negative when

$\mathscr {M}$ and becomes negative when ![]() $\mathscr {M}$ grows beyond a threshold value that we denote by

$\mathscr {M}$ grows beyond a threshold value that we denote by ![]() $\mathscr {M}_c$ (figure 6b). This implies that across that threshold in the viscosity ratio,

$\mathscr {M}_c$ (figure 6b). This implies that across that threshold in the viscosity ratio, ![]() $\eta _L>\eta _N$ and the lubricating front can outstrip the upper fluid front. The threshold viscosity ratio

$\eta _L>\eta _N$ and the lubricating front can outstrip the upper fluid front. The threshold viscosity ratio ![]() $\mathscr {M}_c$ is found by setting

$\mathscr {M}_c$ is found by setting ![]() $\Delta \eta =0$ and solving for

$\Delta \eta =0$ and solving for ![]() $\mathscr {M}$, to get

$\mathscr {M}$, to get

\begin{equation} \mathscr{M}_c\equiv\left(\frac{2{\rm \pi}}{\mathscr{Q}}\,\frac{9}{28}\right)^{3} \left(\frac{9(3\alpha+1)}{8\mathscr{D}} \right)\left[\frac{1+\mathscr{Q}}{2{\rm \pi}}\,\frac{(5n+2)(3n+1)}{(2n+1)^{2}}\,N^{{-{n}/({2n+1})}} \right]^{{{8(2n+1)}/({5n+3})}}. \end{equation}

\begin{equation} \mathscr{M}_c\equiv\left(\frac{2{\rm \pi}}{\mathscr{Q}}\,\frac{9}{28}\right)^{3} \left(\frac{9(3\alpha+1)}{8\mathscr{D}} \right)\left[\frac{1+\mathscr{Q}}{2{\rm \pi}}\,\frac{(5n+2)(3n+1)}{(2n+1)^{2}}\,N^{{-{n}/({2n+1})}} \right]^{{{8(2n+1)}/({5n+3})}}. \end{equation}Therefore, in the purely Newtonian case, the threshold viscosity ratio is

which is independent of ![]() $\alpha$. In the case of constant flux

$\alpha$. In the case of constant flux ![]() $\alpha =1$, the threshold is

$\alpha =1$, the threshold is

\begin{align} \mathscr{M}_c(\alpha=1)= \left(\frac{2{\rm \pi}}{\mathscr{Q}}\,\frac{9}{28}\right)^{3} \frac{9}{2\mathscr{D}} \left[\frac{1+\mathscr{Q}}{2{\rm \pi}}\,\frac{(5n+2)(3n+1)}{(2n+1)^{2}}\,N^{{-{n}/({2n+1})}} \right]^{{{8(2n+1)}/({5n+3})}}. \end{align}

\begin{align} \mathscr{M}_c(\alpha=1)= \left(\frac{2{\rm \pi}}{\mathscr{Q}}\,\frac{9}{28}\right)^{3} \frac{9}{2\mathscr{D}} \left[\frac{1+\mathscr{Q}}{2{\rm \pi}}\,\frac{(5n+2)(3n+1)}{(2n+1)^{2}}\,N^{{-{n}/({2n+1})}} \right]^{{{8(2n+1)}/({5n+3})}}. \end{align}

This behaviour, which is reasoned based on the asymptotic, non-lubricated GC solution, is consistent with the trend of the full lubricated GC solution (figure 6b). We note that we do not explicitly observe an outstripping of the outer front by the inner one since the simulation involves the constraint ![]() $r_L< r_N$.

$r_L< r_N$.

5.2. Exponent outstripping

Another mechanism of outstripping can arise due to the different time exponents of the two fronts. This difference can be evaluated by the similarity solutions in the vicinity of the fronts. Specifically, denoting the front exponents by ![]() $\beta _N\equiv [\alpha (1+2n)+1]/(5n+3)$ (see (4.17a)) and

$\beta _N\equiv [\alpha (1+2n)+1]/(5n+3)$ (see (4.17a)) and ![]() $\beta _L\equiv (3\alpha +1)/8$ (see (4.20a)), we have

$\beta _L\equiv (3\alpha +1)/8$ (see (4.20a)), we have

When the flow has a global similarity solution (![]() $\alpha =5$ or

$\alpha =5$ or ![]() $n=1$), the exponents of the two fluid fronts are identical,

$n=1$), the exponents of the two fluid fronts are identical, ![]() $\Delta \beta =0$, implying that asymptotically in time, the gap between the two fronts evolves with the same exponent, and the ratio of their positions

$\Delta \beta =0$, implying that asymptotically in time, the gap between the two fronts evolves with the same exponent, and the ratio of their positions ![]() $r_L/r_N$ is constant. When

$r_L/r_N$ is constant. When ![]() $n\ne 1$ and

$n\ne 1$ and ![]() $\alpha \ne 5$, there is no global similarity solution, implying that

$\alpha \ne 5$, there is no global similarity solution, implying that ![]() $\beta _L\ne \beta _N$ and that the fronts ratio evolves proportionally to

$\beta _L\ne \beta _N$ and that the fronts ratio evolves proportionally to ![]() $t^{\Delta \beta }$. Consequently, the gap between the fronts closes down in time, and front outstripping occurs when

$t^{\Delta \beta }$. Consequently, the gap between the fronts closes down in time, and front outstripping occurs when ![]() $\Delta \beta >0$, which is when

$\Delta \beta >0$, which is when ![]() $\alpha <5$ and

$\alpha <5$ and ![]() $n >1$, or when

$n >1$, or when ![]() $\alpha >5$ and

$\alpha >5$ and ![]() $n <1$ (figure 7). When

$n <1$ (figure 7). When ![]() $\varDelta \beta <0$, intercept outstripping does not occur through exponent outstripping, but can still occur through intercept outstripping at early time (

$\varDelta \beta <0$, intercept outstripping does not occur through exponent outstripping, but can still occur through intercept outstripping at early time (![]() $t/t_L\gtrsim 1$) when

$t/t_L\gtrsim 1$) when ![]() $\mathscr {M}>\mathscr {M}_c$.

$\mathscr {M}>\mathscr {M}_c$.

Figure 7. The exponent difference ![]() $\Delta \beta$ as a function of the fluid discharge exponent

$\Delta \beta$ as a function of the fluid discharge exponent ![]() $\alpha$ and the viscosity exponent

$\alpha$ and the viscosity exponent ![]() $n$. Dark lines are the

$n$. Dark lines are the ![]() $\Delta \beta =0$ contours, where global similarity solutions exist. When

$\Delta \beta =0$ contours, where global similarity solutions exist. When ![]() $\Delta \beta >0$ (hot colours), the lubricating fluid front

$\Delta \beta >0$ (hot colours), the lubricating fluid front ![]() $r_L$ outstrips the non-Newtonian fluid front

$r_L$ outstrips the non-Newtonian fluid front ![]() $r_N$.

$r_N$.

6. Solutions for constant flux discharge  $\alpha =1$

$\alpha =1$

The case of constant flux (![]() $\alpha =1$) was explored theoretically in several asymptotic limits, including the case of no lubrication (Huppert Reference Huppert1982; Sayag & Worster Reference Sayag and Worster2013) and the case where both fluids are Newtonian (Kowal & Worster Reference Kowal and Worster2015). These cases are useful to validate our general solutions in several asymptotic limits and to elucidate the impact of lubrication when the upper fluid is non-Newtonian.

$\alpha =1$) was explored theoretically in several asymptotic limits, including the case of no lubrication (Huppert Reference Huppert1982; Sayag & Worster Reference Sayag and Worster2013) and the case where both fluids are Newtonian (Kowal & Worster Reference Kowal and Worster2015). These cases are useful to validate our general solutions in several asymptotic limits and to elucidate the impact of lubrication when the upper fluid is non-Newtonian.

When the upper fluid is Newtonian (![]() $n=1$), the flow is self-similar and can be classified into four different flow regimes in the

$n=1$), the flow is self-similar and can be classified into four different flow regimes in the ![]() $\mathscr {M}\unicode{x2013} \mathscr {Q}$ state space (Kowal & Worster Reference Kowal and Worster2015), in which the radial distribution of the fluid thickness and the evolution of the fronts have unique qualitative characteristics (figures 8 and 9). When the upper fluid is non-Newtonian (

$\mathscr {M}\unicode{x2013} \mathscr {Q}$ state space (Kowal & Worster Reference Kowal and Worster2015), in which the radial distribution of the fluid thickness and the evolution of the fronts have unique qualitative characteristics (figures 8 and 9). When the upper fluid is non-Newtonian (![]() $n \neq 1$), no global similarity solution arises for a constant flux discharge (§ 2.3). Nevertheless, we find numerically that the characteristic distributions of the fluid thickness in each of the four regimes are preserved qualitatively (figure 9). Moreover, the thickness of the lubricating fluid in the non-Newtonian case varies very weakly from that in the purely Newtonian case, and the fronts

$n \neq 1$), no global similarity solution arises for a constant flux discharge (§ 2.3). Nevertheless, we find numerically that the characteristic distributions of the fluid thickness in each of the four regimes are preserved qualitatively (figure 9). Moreover, the thickness of the lubricating fluid in the non-Newtonian case varies very weakly from that in the purely Newtonian case, and the fronts ![]() $r_L$ in both cases appear to follow a similar evolution pattern (figure 9). In contrast, the propagation rate of the front

$r_L$ in both cases appear to follow a similar evolution pattern (figure 9). In contrast, the propagation rate of the front ![]() $r_N$ varies strongly with the non-Newtonian properties of the upper fluid, becoming faster than the purely Newtonian case for shear-thickening fluids, and slower than the purely Newtonian case for shear-thinning fluids (figure 9). This pattern in all of the four regimes can be rationalized physically through a dimension-based argument: the radial velocity at constant flux

$r_N$ varies strongly with the non-Newtonian properties of the upper fluid, becoming faster than the purely Newtonian case for shear-thickening fluids, and slower than the purely Newtonian case for shear-thinning fluids (figure 9). This pattern in all of the four regimes can be rationalized physically through a dimension-based argument: the radial velocity at constant flux ![]() $[u]\sim Q/(2{\rm \pi} R H)$ combined with the thickness scale

$[u]\sim Q/(2{\rm \pi} R H)$ combined with the thickness scale ![]() $[H]\sim (Q\mu _\ell /\rho g)^{1/4}$ (see (2.26c)) implies that the dominant strain rate

$[H]\sim (Q\mu _\ell /\rho g)^{1/4}$ (see (2.26c)) implies that the dominant strain rate ![]() $[\partial u/\partial z]\sim Q/(2{\rm \pi} R H^{2})\sim (\rho g Q/\mu _\ell )^{1/2}/(2{\rm \pi} R)$ declines radially. Consequently, a shear-thinning fluid (

$[\partial u/\partial z]\sim Q/(2{\rm \pi} R H^{2})\sim (\rho g Q/\mu _\ell )^{1/2}/(2{\rm \pi} R)$ declines radially. Consequently, a shear-thinning fluid (![]() $n > 1$) becomes increasingly more viscous with radius than a shear-thickening fluid, leading to its relatively slower propagation.

$n > 1$) becomes increasingly more viscous with radius than a shear-thickening fluid, leading to its relatively slower propagation.

Figure 8. The ![]() $\mathscr {M}\unicode{x2013} \mathscr {Q}$ state map for

$\mathscr {M}\unicode{x2013} \mathscr {Q}$ state map for ![]() $\alpha =1$,

$\alpha =1$, ![]() $n=1$ and

$n=1$ and ![]() $\mathscr {D}=1$ is divided into four characteristic flow regimes, I–IV. The dashed curves mark the critical viscosity ratios

$\mathscr {D}=1$ is divided into four characteristic flow regimes, I–IV. The dashed curves mark the critical viscosity ratios ![]() $\mathscr {M}_c(\mathscr {Q},n)$ from (5.3), beyond which we expect the front of the lubricating fluid to outstrip the front of the top fluid. The characteristic solution of the

$\mathscr {M}_c(\mathscr {Q},n)$ from (5.3), beyond which we expect the front of the lubricating fluid to outstrip the front of the top fluid. The characteristic solution of the ![]() $\mathscr {M}\unicode{x2013} \mathscr {Q}$ states marked by diamonds are shown in figure 9.

$\mathscr {M}\unicode{x2013} \mathscr {Q}$ states marked by diamonds are shown in figure 9.

Figure 9. Characteristic solutions of each of the four states in the different regimes marked by diamonds in figure 8 for a range of power-law exponents (yellow ![]() $n=2$, black

$n=2$, black ![]() $n=1$, and red

$n=1$, and red ![]() $n=0.5$), at constant flux (

$n=0.5$), at constant flux (![]() $\alpha =1$), showing the position of the free surface of the lubricated power-law fluid (solid lines), and the lubricating Newtonian fluid (dashed lines), at constant dimensionless time

$\alpha =1$), showing the position of the free surface of the lubricated power-law fluid (solid lines), and the lubricating Newtonian fluid (dashed lines), at constant dimensionless time ![]() $t=20$, and

$t=20$, and ![]() $\mathscr {D}=1$.

$\mathscr {D}=1$.

The slower front speed of a shear-thinning fluid compared to a Newtonian fluid implies that outstripping by the front of the Newtonian lubricating fluid may occur after some time (§ 5). We investigate this more carefully by considering the evolution of the two fronts within a range of viscosity ratios ![]() $10^{-2}\leqslant \mathscr {M}\leqslant 10^{4}$, a range of fluid exponent