Article contents

Relaminarization effects in hypersonic flow on a three-dimensional expansion–compression geometry

Published online by Cambridge University Press: 22 April 2024

Abstract

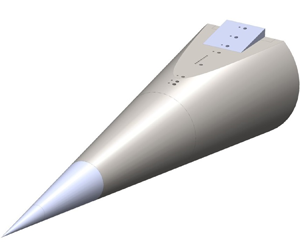

This experimental work explores the flow field around a three-dimensional expansion–compression geometry on a slender cone at Mach 8 using high-frequency pressure sensors, high-frame-rate schlieren, temperature-sensitive paint, shear-stress measurements and oil-flow visualizations. The  $7^\circ$ cone geometry has a hyperbolic slice which acts as an expansion corner and suppresses the disturbances present in the upstream boundary layer. Downstream of the cone-slice corner, high-frequency boundary-layer disturbances attenuate in all cases. Under laminar conditions, second-mode instabilities from the cone diminish and lower-frequency second-mode waves develop on the slice at a frequency commensurate with the increased boundary layer thickness. For fully turbulent cases, the boundary layer over the slice shows evidence of a two-layered nature with a turbulent outer region and a near-wall region with strong attenuation of high-frequency disturbances and reappearance of lower-frequency instability waves. When a downstream compression ramp is added to the slice, the expanded boundary layer shows enhanced susceptibility to separation such that separation is observed at a

$7^\circ$ cone geometry has a hyperbolic slice which acts as an expansion corner and suppresses the disturbances present in the upstream boundary layer. Downstream of the cone-slice corner, high-frequency boundary-layer disturbances attenuate in all cases. Under laminar conditions, second-mode instabilities from the cone diminish and lower-frequency second-mode waves develop on the slice at a frequency commensurate with the increased boundary layer thickness. For fully turbulent cases, the boundary layer over the slice shows evidence of a two-layered nature with a turbulent outer region and a near-wall region with strong attenuation of high-frequency disturbances and reappearance of lower-frequency instability waves. When a downstream compression ramp is added to the slice, the expanded boundary layer shows enhanced susceptibility to separation such that separation is observed at a  $10^{\circ }$ deflection, which is smaller than expected for turbulent conditions. For a

$10^{\circ }$ deflection, which is smaller than expected for turbulent conditions. For a  $30^{\circ }$ ramp, boundary-layer separation occurs further upstream where the heat flux contours show a decrease in heating that is characteristic of a transitional separation. These results demonstrate the effect of relaminarization caused by an upstream expansion on a subsequent shock-wave/boundary-layer interaction.

$30^{\circ }$ ramp, boundary-layer separation occurs further upstream where the heat flux contours show a decrease in heating that is characteristic of a transitional separation. These results demonstrate the effect of relaminarization caused by an upstream expansion on a subsequent shock-wave/boundary-layer interaction.

Information

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2024. Published by Cambridge University Press

References

- 3

- Cited by