Article contents

Significant influence of fluid viscoelasticity on flow dynamics past an oscillating cylinder

Published online by Cambridge University Press: 16 November 2023

Abstract

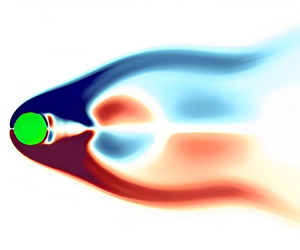

This study focuses on numerically investigating the impact of fluid viscoelasticity on the flow dynamics around a transversely forced oscillating cylinder operating in the laminar vortex shedding regime at a fixed Reynolds number of  $Re = 100$. Specifically, we explore how fluid viscoelasticity affects the boundary between the lock-in and no lock-in regions and the corresponding wake characteristics compared with a simple Newtonian fluid. Our findings reveal that fluid viscoelasticity enables the synchronization of the vortex street with the cylinder motion at lower oscillation frequencies than those required for a Newtonian fluid. Consequently, the lock-in region boundary for a viscoelastic fluid differs from that of a Newtonian fluid and expands in the non-dimensional cylinder oscillation amplitude and frequency parameter space. In the primary synchronization region, the wake of a Newtonian fluid exhibits ‘2S’ (two single vortices) and ‘P+S’ (a pair of vortices and a single vortex) shedding modes. In contrast, a ‘2P’ (two pairs of vortices) vortex mode is observed for a viscoelastic fluid within the same region. To gain a deeper understanding of the differences in the coherent flow structures and their associated frequencies between the two fluids, we employ the data-driven reduced-order modelling technique, known as the dynamic mode decomposition (DMD) technique. Utilizing this technique, we successfully extract and visualize the two competing fundamental frequencies (cylinder oscillation and natural vortex shedding frequencies) and their associated flow structures in the case of the no lock-in state, whereas only the dominant cylinder oscillation frequency and associated flow structure in the case of the lock-in state. Furthermore, we propose that the presence of excess strain resulting from the stretching of polymer molecules in viscoelastic fluids leads to a distinct difference in the wake structure compared with Newtonian fluids. This observation aligns with the findings obtained from the

$Re = 100$. Specifically, we explore how fluid viscoelasticity affects the boundary between the lock-in and no lock-in regions and the corresponding wake characteristics compared with a simple Newtonian fluid. Our findings reveal that fluid viscoelasticity enables the synchronization of the vortex street with the cylinder motion at lower oscillation frequencies than those required for a Newtonian fluid. Consequently, the lock-in region boundary for a viscoelastic fluid differs from that of a Newtonian fluid and expands in the non-dimensional cylinder oscillation amplitude and frequency parameter space. In the primary synchronization region, the wake of a Newtonian fluid exhibits ‘2S’ (two single vortices) and ‘P+S’ (a pair of vortices and a single vortex) shedding modes. In contrast, a ‘2P’ (two pairs of vortices) vortex mode is observed for a viscoelastic fluid within the same region. To gain a deeper understanding of the differences in the coherent flow structures and their associated frequencies between the two fluids, we employ the data-driven reduced-order modelling technique, known as the dynamic mode decomposition (DMD) technique. Utilizing this technique, we successfully extract and visualize the two competing fundamental frequencies (cylinder oscillation and natural vortex shedding frequencies) and their associated flow structures in the case of the no lock-in state, whereas only the dominant cylinder oscillation frequency and associated flow structure in the case of the lock-in state. Furthermore, we propose that the presence of excess strain resulting from the stretching of polymer molecules in viscoelastic fluids leads to a distinct difference in the wake structure compared with Newtonian fluids. This observation aligns with the findings obtained from the  $Q$-criterion and vorticity transport analysis of the wake.

$Q$-criterion and vorticity transport analysis of the wake.

JFM classification

Information

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2023. Published by Cambridge University Press

References

- 3

- Cited by