Article contents

Comparing the atomic and macroscopic aging dynamics in an amorphous and partially crystalline Zr44Ti11Ni10Cu10Be25 bulk metallic glass

Published online by Cambridge University Press: 22 May 2017

Abstract

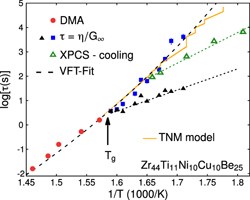

Several recent X-ray photon correlation spectroscopy works have reported an anomalous atomic dynamics in hyperquenched metallic glasses. Here, we compare and contrast these microscopic dynamics with that found in a Zr44Ti11Ni10Cu10Be25 bulk metallic glass, prepared with a cooling rate some 6 orders of magnitude lower. In both cases, structural relaxation in the glass is governed by internal stresses, giving rise to highly compressed density correlation functions. Differently from the fast aging reported in previous studies, here the atomic dynamics displays a slow linear atomic-level aging, while not affecting the shape parameter. Traditional macroscopic phenomenological models fail to capture the temperature dependence of the microscopic structural relaxation time, suggesting a length scale dependence of the aging. Interestingly, the dynamics does not seem to be affected by the presence of a low percentage of frozen nanocrystals and displays a temperature dependence similar to that observed in macroscopic viscosity measurements.

- Type

- Invited Papers

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 7

- Cited by