Article contents

Ex and in situ investigations on the role of persistent slip bands and grain boundaries in fatigue crack initiation

Published online by Cambridge University Press: 05 September 2017

Abstract

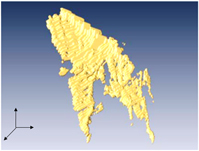

Polycrystalline copper (99.9%) was fatigued at a total strain amplitude of 0.1 and 0.2%, respectively. The tests were performed in situ under vacuum in a Large Chamber-Scanning Electron Microscope. By a repeated combination of in situ fatigue testing and ex situ focused ion beam milling, a deep insight into the mechanism of fatigue crack initiation and early stages of crack initiation at persistent slip bands (PSBs) and their interaction with grain boundaries was obtained. The EBSD-technique showed early slip activation and the exclusive formation of extrusions in favorably oriented grains until a certain extrusion height was reached. At the total strain amplitude of 0.2%, extrusions are formed not only in favorably oriented grains but also in grains with a lower Schmid factor due to high compatibility stresses at the grain boundaries. Extrusion growth through grain boundaries is affected by the orientation of the primary slip systems in the neighboring grains and the additional anisotropy stresses. It is concluded that early stages of crack initiation are the consequence of the formation of extrusions at PSBs in combination with the clustering of vacancies along the PSB boundaries, as it was proposed by the well-known Essmann–Gösele–Mughrabi model.

Keywords

Information

- Type

- Review

- Information

- Journal of Materials Research , Volume 32 , Issue 23: Focus Issue: Mechanical Properties and Microstructure of Advanced Metallic Alloys—in Honor of Prof. Haël Mughrabi PART A , 14 December 2017 , pp. 4276 - 4286

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

This author was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

Contributing Editor: Lei Lu

This section of Journal of Materials Research is reserved for papers that are reviews of literature in a given area.

Dedicated to Prof. Dr. Haël Mughrabi on the occasion of his 80th birthday.

References

REFERENCES

- 19

- Cited by