Published online by Cambridge University Press: 11 May 2018

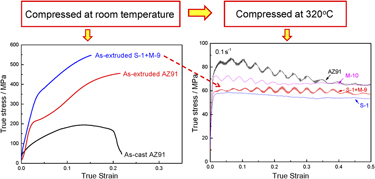

To obtain a fine-grained Mg matrix, the (submicron + micron) bimodal size SiC particle reinforced AZ91 (SiCp/AZ91) composite was subjected to forging followed by the extrusion process first. Then, the fine-grained bimodal size SiCp/AZ91 composite was compressed at 270–370 °C with 0.1–0.001 s−1. The result indicated that the refinement of the Mg matrix contributed to its deteriorated strength at high temperature. However, the grain size is not the only factor influencing flow stress but the SiCp also plays an important role. The effect of SiCp on the fine grained Mg matrix depends on grain size and dislocation density, both of which strongly depend on temperature and strain rate. As compared with the fine grained Mg matrix reinforced by single size SiCp, the one with bimodal size SiCp unusually exhibit lower flow stress during hot compression. The calculated activation energy of the bimodal size SiCp/AZ91 composite is higher than the micron SiCp/AZ91 composite; however, nearly the same as the submicron SiCp/AZ91 composite, and the deformation of which was thought to be controlled by ∼1 vol% submicron SiCp.