Article contents

Growth of TiO2 nanotube arrays in semiconductor porous anodic alumina templates

Published online by Cambridge University Press: 29 October 2014

Abstract

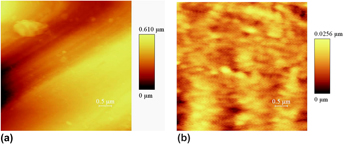

The aim of this research study is to produce high-quality TiO2 nanotube arrays using porous alumina templates. The templates are fabricated through anodizing bulk aluminum foils which can be utilized for the production of thick alumina templates. To produce the nanotube arrays, the alumina template pores are filled with the precursor sol by applying a DC electric field. Then, the deposited nanotubes are heat treated at 320 °C for 2 h and, subsequently, sintered for 2 h at 400 and 750 °C to obtain nanotubes with pure anatase and rutile phases, respectively, as confirmed by x-ray diffraction data. Scanning and transmission electron microscopy (SEM and TEM) investigations show that the nanotubes have been deposited in the channels of the nanoporous alumina template. Also, SEM investigations show the existence of a vast area of TiO2 nanotube arrays when we use semiconductor alumina templates.

Information

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2014

References

REFERENCES

- 4

- Cited by