Published online by Cambridge University Press: 23 May 2016

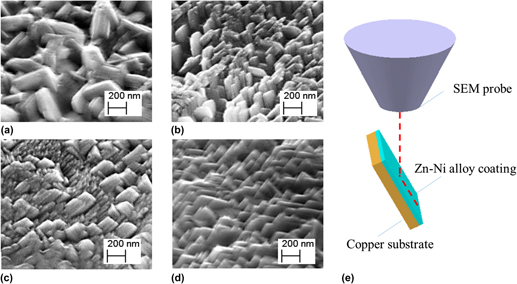

Zn–Ni alloy coatings were deposited on rolled copper foil via electro-brush plating with different micro-force. Surface morphologies, microhardness, roughness, and bending performance were characterized. Mechanisms and influences of electro–brush plating micro-force on coatings performances were investigated and revealed. With the increase of electro-brush plating micro-force, surface morphologies of coatings become smooth and dense, and the grain size was refined. Microhardness of coatings had a gradually increasing tendency when the increasing amplification was reduced. However, surface roughness of coatings as well as bending performance increased firstly and then decreased. The mechanisms of micro-force generation and action were explained by mechanics theory and principle model. Plastic deformation and work hardening are generated and performances are improved. Consequently, the performance of electro-brush plating coatings has a tight relevance with micro-force.