Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Krauskopf, Thorben

Richter, Felix H.

Zeier, Wolfgang G.

and

Janek, Jürgen

2020.

Physicochemical Concepts of the Lithium Metal Anode in Solid-State Batteries.

Chemical Reviews,

Vol. 120,

Issue. 15,

p.

7745.

Wang, Yikai

Dang, Dingying

Xiao, Xingcheng

and

Cheng, Yang-Tse

2020.

Structure and mechanical properties of electroplated mossy lithium: Effects of current density and electrolyte.

Energy Storage Materials,

Vol. 26,

Issue. ,

p.

276.

He, Yaolong

Li, Shufeng

Zhou, Sihao

and

Hu, Hongjiu

2020.

Mechanical Integrity Degradation and Control of All-Solid-State Lithium Battery with Physical Aging Poly (Vinyl Alcohol)-Based Electrolyte.

Polymers,

Vol. 12,

Issue. 9,

p.

1886.

Wang, Michael J.

Chang, Jiun-Yeu

Wolfenstine, Jeffrey B.

and

Sakamoto, Jeff

2020.

Analysis of elastic, plastic, and creep properties of sodium metal and implications for solid-state batteries.

Materialia,

Vol. 12,

Issue. ,

p.

100792.

Liu, Qiunan

Zhang, Liqiang

Sun, Haiming

Geng, Lin

Li, Yanshuai

Tang, Yushu

Jia, Peng

Wang, Zaifa

Dai, Qiushi

Shen, Tongde

Tang, Yongfu

Zhu, Ting

and

Huang, Jianyu

2020.

In Situ Observation of Sodium Dendrite Growth and Concurrent Mechanical Property Measurements Using an Environmental Transmission Electron Microscopy–Atomic Force Microscopy (ETEM-AFM) Platform.

ACS Energy Letters,

Vol. 5,

Issue. 8,

p.

2546.

Mistry, Aashutosh

and

Mukherjee, Partha P.

2020.

Molar Volume Mismatch: A Malefactor for Irregular Metallic Electrodeposition with Solid Electrolytes.

Journal of The Electrochemical Society,

Vol. 167,

Issue. 8,

p.

082510.

Fincher, Cole D.

Ojeda, Daniela

Zhang, Yuwei

Pharr, George M.

and

Pharr, Matt

2020.

Mechanical properties of metallic lithium: from nano to bulk scales.

Acta Materialia,

Vol. 186,

Issue. ,

p.

215.

Nagy, Kyle S.

and

Siegel, Donald J.

2020.

Anisotropic Elastic Properties of Battery Anodes.

Journal of The Electrochemical Society,

Vol. 167,

Issue. 11,

p.

110550.

Fincher, Cole D.

Zhang, Yuwei

Pharr, George M.

and

Pharr, Matt

2020.

Elastic and Plastic Characteristics of Sodium Metal.

ACS Applied Energy Materials,

Vol. 3,

Issue. 2,

p.

1759.

Veeraraghavan, Vijay D.

Frenck, Louise

Maslyn, Jacqueline A.

Loo, Whitney S.

Parkinson, Dilworth Y.

and

Balsara, Nitash P.

2021.

Evolution of Protrusions on Lithium Metal Anodes Stabilized by a Solid Block Copolymer Electrolyte Studied Using Time-Resolved X-ray Tomography.

ACS Applied Materials & Interfaces,

Vol. 13,

Issue. 23,

p.

27006.

Albertus, Paul

2021.

Soft and liquid metals.

Nature Energy,

Vol. 6,

Issue. 3,

p.

225.

Pang, Mei-Chin

Yang, Kai

Brugge, Rowena

Zhang, Teng

Liu, Xinhua

Pan, Feng

Yang, Shichun

Aguadero, Ainara

Wu, Billy

Marinescu, Monica

Wang, Huizhi

and

Offer, Gregory J.

2021.

Interactions are important: Linking multi-physics mechanisms to the performance and degradation of solid-state batteries.

Materials Today,

Vol. 49,

Issue. ,

p.

145.

Carmona, Eric A.

Wang, Michael J.

Song, Yueming

Sakamoto, Jeff

and

Albertus, Paul

2021.

The Effect of Mechanical State on the Equilibrium Potential of Alkali Metal/Ceramic Single‐Ion Conductor Systems.

Advanced Energy Materials,

Vol. 11,

Issue. 29,

Kalnaus, Sergiy

Westover, Andrew S.

Kornbluth, Mordechai

Herbert, Erik

and

Dudney, Nancy J.

2021.

Resistance to fracture in the glassy solid electrolyte Lipon.

Journal of Materials Research,

Vol. 36,

Issue. 4,

p.

787.

Papakyriakou, Marc

Lu, Mu

Liu, Yuhgene

Liu, Zhantao

Chen, Hailong

McDowell, Matthew T.

and

Xia, Shuman

2021.

Mechanical behavior of inorganic lithium-conducting solid electrolytes.

Journal of Power Sources,

Vol. 516,

Issue. ,

p.

230672.

Wang, Michael J.

Kazyak, Eric

Dasgupta, Neil P.

and

Sakamoto, Jeff

2021.

Transitioning solid-state batteries from lab to market: Linking electro-chemo-mechanics with practical considerations.

Joule,

Vol. 5,

Issue. 6,

p.

1371.

Mallakpour, Fereshteh

Kasraie, Masoud

Herbert, Erik G.

Phani, P. Sudharshan

and

Hackney, Stephen A.

2021.

Length-scale-dependent stress relief mechanisms in indium at high homologous temperatures.

Journal of Materials Research,

Vol. 36,

Issue. 12,

p.

2444.

Wang, Hongchun

Gao, Haowen

Chen, Xiaoxuan

Zhu, Jianping

Li, Wangqin

Gong, Zhengliang

Li, Yangxing

Wang, Ming‐Sheng

and

Yang, Yong

2021.

Linking the Defects to the Formation and Growth of Li Dendrite in All‐Solid‐State Batteries.

Advanced Energy Materials,

Vol. 11,

Issue. 42,

Raj, Rishi

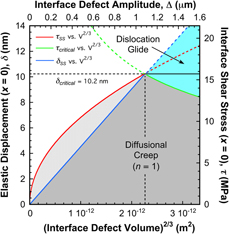

2021.

Stack Pressure and Critical Current Density in Li-metal Cells: The Role of Mechanical Deformation.

Acta Materialia,

Vol. 215,

Issue. ,

p.

117076.

Vadhva, Pooja

Boyce, Adam M.

Hales, Alastair

Pang, Mei-Chin

Patel, Anisha N.

Shearing, Paul R.

Offer, Gregory

and

Rettie, Alexander J. E.

2022.

Towards Optimised Cell Design of Thin Film Silicon-Based Solid-State Batteries via Modelling and Experimental Characterisation.

Journal of The Electrochemical Society,

Vol. 169,

Issue. 10,

p.

100525.