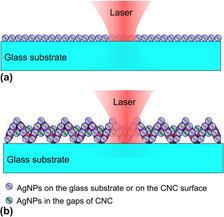

SEM image of AgNPs on TiO2-CNCs substrates, formed in 3 mM AgNO3 solution with UV light irradiation for 2 h, where TiO2 is formed by sputtering for 150 min. [D. Li, L. Pan, S. Wu, and S. Li: An active surface enhanced Raman scattering substrate using carbon nanocoils. p. 2113.]

Invited Feature Paper

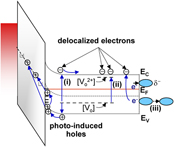

Photo-bias instability of metal oxide thin film transistors for advanced active matrix displays

-

- Published online by Cambridge University Press:

- 06 August 2013, pp. 2071-2084

-

- Article

- Export citation

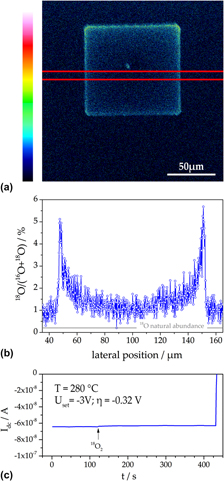

Thin film cathodes in SOFC research: How to identify oxygen reduction pathways?

-

- Published online by Cambridge University Press:

- 27 August 2013, pp. 2085-2105

-

- Article

- Export citation

Articles

Wet-chemical preparation of digold bismuthide, gold diantimonide, and gold ditelluride particles

-

- Published online by Cambridge University Press:

- 29 July 2013, pp. 2106-2112

-

- Article

- Export citation

An active surface enhanced Raman scattering substrate using carbon nanocoils

-

- Published online by Cambridge University Press:

- 06 August 2013, pp. 2113-2123

-

- Article

- Export citation

The multilayered structure of ultrathin amorphous carbon films synthesized by filtered cathodic vacuum arc deposition

-

- Published online by Cambridge University Press:

- 07 August 2013, pp. 2124-2131

-

- Article

- Export citation

Hyperbranched polyurethane/Fe3O4 nanoparticles decorated multiwalled carbon nanotube thermosetting nanocomposites as microwave actuated shape memory materials

-

- Published online by Cambridge University Press:

- 07 August 2013, pp. 2132-2141

-

- Article

- Export citation

Impact strength, microstructure, and water absorption properties of kenaf/polyethylene terephthalate (PET) fiber-reinforced polyoxymethylene (POM) hybrid composites

-

- Published online by Cambridge University Press:

- 07 August 2013, pp. 2142-2146

-

- Article

- Export citation

Structural characterization of a new acentric protonated garnet: Li6−xHxCaLa2Nb2O12

-

- Published online by Cambridge University Press:

- 27 August 2013, pp. 2147-2153

-

- Article

- Export citation

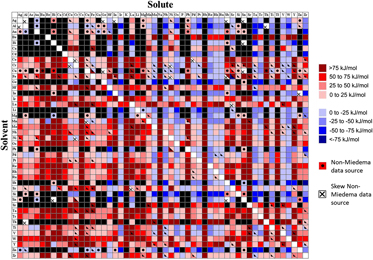

Estimation of grain boundary segregation enthalpy and its role in stable nanocrystalline alloy design

-

- Published online by Cambridge University Press:

- 06 August 2013, pp. 2154-2163

-

- Article

-

- You have access

- HTML

- Export citation

Effect of MoO3 addition on the microstructure and mechanical properties of Ti2A1C prepared by reactive hot pressing

-

- Published online by Cambridge University Press:

- 27 August 2013, pp. 2164-2170

-

- Article

- Export citation

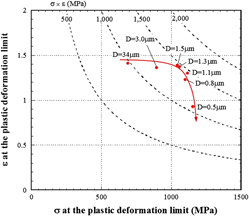

Effect of ferrite grain size on the estimated true stress–true strain relationship up to the plastic deformation limit in low carbon ferrite–cementite steels

-

- Published online by Cambridge University Press:

- 13 August 2013, pp. 2171-2179

-

- Article

- Export citation

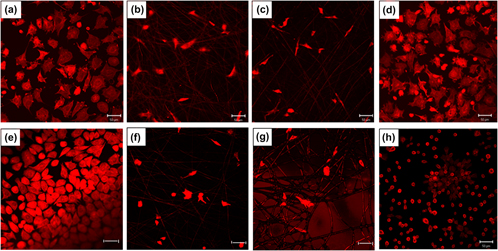

The role of alternating current electric field for cell adhesion on 2D and 3D biomimetic scaffolds based on polymer materials and adhesive proteins

-

- Published online by Cambridge University Press:

- 09 August 2013, pp. 2180-2186

-

- Article

- Export citation

Front Cover (OFC, IFC) and matter

JMR volume 28 issue 16 Cover and Front matter

-

- Published online by Cambridge University Press:

- 27 August 2013, pp. f1-f4

-

- Article

-

- You have access

- Export citation

Back Cover (OBC, IBC) and matter

JMR volume 28 issue 16 Cover and Back matter

-

- Published online by Cambridge University Press:

- 27 August 2013, pp. b1-b4

-

- Article

-

- You have access

- Export citation