History of the lithium-ion battery

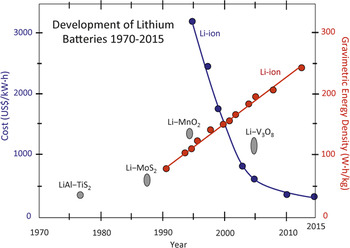

The story of the lithium-ion (Li-ion) battery is a fascinating study in how science and technology transform expansive general ideas into specific technology outcomes, advanced by many scientific disciplines and players in diverse international settings. The final product, what is now called the Li-ion battery (illustrated in Figure 1 ), continues to have a transformational impact on personal electronics, affecting communication, computation, entertainment, information, and the fundamental ways in which we interact with information and people. In recounting this story, we acknowledge the basic themes it illustrates: vision, challenges, course-changing discoveries, outcomes that miss intended targets yet have transformational impacts, and compelling opportunities left on the table.

Figure 1. (a) Lithium-ion battery, using singly charged Li+ working ions. The structure comprises (left) a graphite intercalation anode; (center) an organic electrolyte consisting of (for example) a mixture of ethylene carbonate and dimethyl carbonate as the solvent and LiPF6 as the salt; and (right) a transition-metal compound intercalation cathode, such as layered CoO2, FePO4, the three-dimensional spinel Mn2O4, or a mixture of cobalt, nickel, and manganese oxides. On discharging, Li+ ions flow inside the battery from anode to cathode; on charging, they flow from cathode to anode. Electrons flow outside the battery in the same directions to maintain charge neutrality. (b) A pouch containing several anode–electrolyte–cathode assemblies, creating a rectangular format that can be (c) enclosed in a hard plastic container. Cylindrical formats where the anode–electrolyte–cathode assembly is wound around a central spindle are also popular. (a–b) Courtesy of Argonne National Laboratory. (c) Obtained from Wikimedia Commons.

Several accounts of the history of Li-ion batteries have recently appeared. Reference Goodenough and Park1–Reference Yoshino9 This article presents a brief overview of the motivations, challenges, and unexpected solutions in Li-ion battery development, as well as the failures and triumphs that have marked their trajectory from conceptualization through commercialization to their dominant place in the market today.

The concept: Li-metal anodes and intercalation cathodes

It is easy to understand the appeal of Li as a battery material. As the most reducing element and the lightest metal in the periodic table, Li promises high operating voltage, low weight, and high energy-storage density. These appealing features of Li have been known and discussed for use in primary (nonrechargeable) and secondary (rechargeable) batteries since the 1950s, Reference Hughes, Hampson and Karunathilaka10–Reference Winter, Besenhard, Spahr and Novak12 and several primary batteries reacting Li with cathodes such as (CF) n , MnO2, aluminum, and iodine were proposed or developed in the 1960s. Reference Whittingham13 Early work on Li rechargeable batteries used molten lithium and molten sulfur as electrodes, separated by a molten salt as the electrolyte, operating at ∼450°C. Reference Whittingham13

A pathway for using lithium in room-temperature rechargeable batteries was established in the early 1970s, when Whittingham and others realized that electrochemical intercalation of guest molecules into layered hosts, previously viewed as a synthesis technique, could also be used to store and release energy in battery electrodes. Reference Lerf7,Reference Whittingham8,Reference Whittingham13–Reference Whittingham16 One of the triggers for this intellectual leap was the synthesis of more than 50 new superconductors through the intercalation of organic molecules between the layers of transition-metal dichalcogenide hosts. Reference Gamble, Osiecki, Cais, Pisharody, DiSalvo and Geballe17 Chemical intercalation—inserting guest molecules into hosts by chemical reaction, often at high temperatures to overcome reaction barriers—enabled the controlled adjustment of the electron density of the host with minimal structural change, thus allowing for intentional tuning of electronic properties such as the density of electronic states, conductivity, and superconducting transition temperature. Reference Dresselhaus and Dresselhaus18

Electrochemical intercalation—inserting guest ions into the host structure using an electric field to overcome reaction barriers—and its reverse, deintercalation, opened a new horizon for batteries, enabling the reversible storage and release of significant amounts of energy at near-ambient temperatures. The high energies and large compositional ranges associated with some intercalations, facile reversibility, relatively stable crystal structures, and predictable electronic structures are compelling features for battery storage system design. Whittingham described the origin and emergence of the concept of electrochemical intercalation as a dominant theme for storing and releasing energy in the cathode of a rechargeable battery. Reference Whittingham13

The original vision for lithium batteries based on intercalation comprised a pure metal lithium anode, an organic electrolyte to transport Li ions but not electrons between an anode and a cathode, and an intercalation cathode based on a layered transition-metal compound. Reference Loeffler, Bresser and Passerini6,Reference Whittingham8,Reference Broussely, Biensan and Simon11,Reference Winter, Besenhard, Spahr and Novak12,Reference Nishi19,Reference Nishi20 Pure lithium offers unsurpassed energy density at the anode, as it contains no inactive atoms to dilute its storage capacity. Organic electrolytes offer operating voltages (the “electrochemical window” within which the electrolyte is neither reduced nor oxidized) of 4 V or higher between anode and cathode; water, the obvious alternative, decomposes by electrolysis at 1.23 V. In the 1970s, while working at Exxon, Whittingham developed the first intercalation cathode, TiS2. Reference Whittingham8,Reference Whittingham14–Reference Whittingham16 It was appealing for many reasons: its operating voltage of 2.2 V against lithium metal, its capacity to intercalate lithium as Li x TiS2 over the full range of 0 < x < 1 without a phase transformation, and its semimetallic conductivity that provided an easy conducting pathway for electrons from the external circuit to recombine with the intercalated Li ions.

Dendrites: The challenge for Li-metal anodes

Exxon commercialized this Li–TiS2 battery in 1977, less than a decade after the concept of energy storage by intercalation was formulated. Reference Whittingham8,Reference Pereira, Amatucci, Whittingham and Hamlen21–Reference Fouchard and Taylor23 During commercialization, however, a fatal flaw emerged: the nucleation of dendrites at the lithium-metal anode upon repeated cycling. With continued cycling, these dendrites eventually lost mechanical or electrochemical contact with the anode or grew across the electrolyte to the cathode and short-circuited the battery, causing fires. Reference Winter, Besenhard, Spahr and Novak12 Exxon replaced pure Li with a lithium–aluminum alloy as the anode to avoid dendrite growth, at the expense of shortening the cycle life. Reference Whittingham8 Eliminating Li dendrite growth became a major quest of battery research and development, Reference Besenhard and Eichenger24 as pure metal anodes provide the highest energy density compared with alternatives obtained by alloying or intercalation, which introduce inactive materials in the anode that dilute energy density. Reference Li, Huang, Liaw, Metzler and Zhang25,Reference Xu, Wang, Ding, Chen, Nasybulin, Zhangad and Zhang26

Three additional commercial Li-ion batteries based on Li-metal anodes failed after being brought to market. Li–MoS2 and Li–V3O8 batteries were discontinued for safety reasons. Reference Brandt and Laman27,Reference Robillard28 Li–MnO2 batteries included an internal safety system Reference Mengeritsky, Dan, Weissman, Zaban and Aurbach29,Reference Dan, Mengeritsky, Geronov, Aurbach and Weisman30 but were a commercial failure because of the several-hour charging time required to maintain the cycle life of the Li-metal anode. Reference Aurbach, Zinigrad, Teller and Dan31 These four failed Li-metal-anode rechargeable batteries using cathodes of TiS2, MoS2, V3O8, and MnO2 symbolize the challenges of commercializing batteries with Li-metal anodes. Although the promise of metallic Li anodes is clear and compelling, their use in batteries remains out of reach; they have become the “holy grail” of Li battery research. Reference Thackeray, Wolverton and Isaacs4 The first successful Li-ion batteries commercialized by Sony in 1991 used a carbon host structure containing lithium at the anode instead of metallic lithium. The quest for Li-metal anodes continues today, with recent developments offering new possible solutions. Reference Li, Huang, Liaw, Metzler and Zhang25,Reference Xu, Wang, Ding, Chen, Nasybulin, Zhangad and Zhang26,Reference Zhang, Qian, Xu, Russell, Chen, Nasybulin, Bhattacharya, Engelhard, Mei, Cao, Ding, Cresce, Xu and Zhang32–Reference Qian, Henderson, Xu, Bhattachary, Engelhard, Borodin and Zhang34

High-voltage metal-oxide cathodes

The first step on the road to today’s Li-ion battery was the discovery of a new class of cathode materials, layered transition-metal oxides, such as Li x CoO2, reported in 1980 by Goodenough and collaborators. Reference Mizushima, Jones, Wiseman and Goodenough35 These layered materials intercalate Li at voltages in excess of 4 V, delivering higher voltage and energy density than TiS2. This higher energy density, however, is balanced by disadvantages: Li x CoO2 is not metallic for all x, requiring dilution with a conducting material such as carbon black to deliver electrons from the external circuit to the intercalated Li ions. Recombination of these electrons with the Li ions can take place only at a three-phase boundary of the Li x CoO2, the electrolyte, and the conducting diluent, limiting the charge/discharge rate. Furthermore, Li x CoO2 undergoes a structural phase transition at x ≈ 0.5, limiting the practical operating range to 0.5 < x < 1, reducing capacity. Another disadvantage is the possibility of thermal runaway, an exothermal oxidation of the electrolyte by oxygen released from the Li x CoO2 cathode, which leads to fires—a significant safety concern. Despite these disadvantages, Sony adopted Li x CoO2 for the first commercial Li-ion battery, and it and its analogues remain the dominant cathodes today.

The high operating voltage of metal-oxide cathodes required a compatible electrolyte with a sufficiently wide electrochemical window. Alkyl carbonates, esters, and ethers emerged as leading contenders because of their high oxidation potentials against metal-oxide cathodes. Among these, alkyl carbonates such as propylene carbonate react with metal-oxide cathodes to form a passivating solid-electrolyte interphase (SEI) layer, allowing charging as high as 4.5 V, significantly above the nominal electrochemical window of the alkyl carbonate itself. Reference Aurbach, Talyosef, Markovsky, Markevich, Zinigrad, Asraf, Gnanaraj and Kim36 Propylene carbonate solvent with LiPF6 salt emerged as the standard electrolyte for metal-oxide cathodes because of the low viscosity and high ionic conductivity of their solutions, a reasonable temperature range between freezing and boiling points, sufficiently low toxicity, and acceptable safety performance. Reference Aurbach, Talyosef, Markovsky, Markevich, Zinigrad, Asraf, Gnanaraj and Kim36

Carbon intercalation anodes: The Li-ion battery

Finding a suitable anode to replace Li metal was the last major hurdle for the Li-ion battery. Although Li metal is the ideal anode choice, Reference Thackeray, Wolverton and Isaacs4,Reference Li, Huang, Liaw, Metzler and Zhang25,Reference Xu, Wang, Ding, Chen, Nasybulin, Zhangad and Zhang26,Reference Cheng and Zhang33 the difficult dendrite challenge motivated searches for alternatives. Reference Winter, Besenhard, Spahr and Novak12 The concept of an intercalation anode, where Li ions are stored between the layers of a suitable host, introduced the “rocking-chair” battery, Reference Lazzari and Scrosati37 in which Li ions intercalate alternately into the anode and cathode, storing and releasing energy as the battery “rocks” back and forth between its two states. Intercalation anodes presented a possibly workable but much lower-capacity opportunity, a significant compromise from the vision of Li-metal anodes.

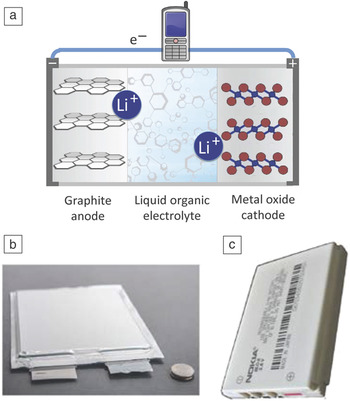

Carbon materials of various kinds were attractive for intercalation anodes by virtue of their ability to accept Li ions by insertion or intercalation with little volume change at an electrochemical potential near that of Li metal. Reference Loeffler, Bresser and Passerini6,Reference Flandrois and Simon38 Although graphite seemed to be an obvious choice because it is the simplest and most highly ordered carbon material, it presented severe challenges because of the many detrimental ways in which it can interact with electrolytes. These interactions include co-intercalation of solvent along with Li+, as illustrated in Figure 2a, Reference Vetter, Novak, Wagner, Veitb, Moller, Besenhard, Winter, Wohlfahrt-Mehrens, Vogler and Hammouched39 which leads to exfoliation of graphite as the intercalated organic molecules form ternary compounds with Li and carbon that decompose at lower potentials in the discharge cycle. Reference Flandrois and Simon38

Figure 2. Scenarios for graphite–electrolyte interaction. (a) Exfoliation due to co-intercalation of solvent with Li+, formation of a solid electrolyte interphase (SEI) layer from electrolyte decomposition by reaction with graphite, (b) SEI stabilization and growth, (c) SEI dissolution and precipitation with charge/discharge cycling, and (d) Li plating on SEI and subsequent corrosion. Reproduced with permission from Reference Reference Vetter, Novak, Wagner, Veitb, Moller, Besenhard, Winter, Wohlfahrt-Mehrens, Vogler and Hammouched39. © 2005 Elsevier.

The easy side reactions of graphite with Li+ and propylene carbonate at reducing potentials lead to the formation of rogue SEI layers at the surface of the graphite anode, which grow by precipitation and shrink by dissolution during the charge/discharge cycle, as shown in Figure 2a–c. The SEI layer can block Li+ from intercalating and deintercalating, and the growth and shrinkage of the SEI layer can fracture it, exposing additional graphite to the electrolyte and promoting continued side reactions that consume the anode and electrolyte. At high rates of charge, Li+ can plate on the outside of the SEI layer instead of intercalating into the underlying graphite, disabling its energy-storage function and causing corrosion, as shown in Figure 2d. Generally, unwanted side reactions of graphite with electrolytes consume carbon that would otherwise remain active for Li storage by intercalation, creating significant “irreversible capacity” that reduces the useful “reversible capacity.” Reference Vetter, Novak, Wagner, Veitb, Moller, Besenhard, Winter, Wohlfahrt-Mehrens, Vogler and Hammouched39

In addition to graphite, disordered forms of carbon are attractive as anodes, because their disordered surfaces resist reaction with electrolytes and their disordered interiors do not easily accommodate intercalated electrolyte. Reference Flandrois and Simon38 Disordered carbon has a higher capacity for Li insertion, as much as three times that of graphite, Reference Loeffler, Bresser and Passerini6 for a variety of possible structural reasons. Reference Winter, Besenhard, Spahr and Novak12 This attractive higher capacity is balanced by the challenges of identifying and controlling disorder to achieve consistently reliable performance: significant porosity that reduces the density of the carbon host, large quantities of impurity atoms such as hydrogen, nitrogen, sulfur, and oxygen that are left over from the preparation process, and low electrical conductivity due to the disordered structure.

Several potential solutions to the puzzle of finding a suitable anode were in play, including graphite, “soft” carbon (moderately disordered and converted to graphite by heat treatment around 2300°C), Reference Loeffler, Bresser and Passerini6 and “hard” carbon (highly disordered and not easily converted to graphite), illustrated in Figure 3 . The latter alternatives birthed the early Li-ion technologies but were ultimately replaced by graphite. Sony’s first Li-ion battery used soft carbon as the anode, which had no detrimental side reactions with propylene carbonate as the electrolyte and achieved an energy density of 80 W•h/kg. Reference Nishi20,Reference Ozawa40 For its second-generation Li-ion battery, Sony replaced soft carbon with hard carbon to take advantage of the latter’s higher voltage and capacity for Li insertion, increasing the energy density from 80 kW•h/kg to 120 kW•h/kg. Reference Loeffler, Bresser and Passerini6,Reference Nishi20 For its third generation, Sony used graphite, which has a flatter discharge voltage profile and higher capacity above 3.0 V than does hard carbon. The transition to graphite was as much a market decision as a technological decision: Many cell phones require a minimum of 3.0 V to operate, favoring the greater capacity of graphite at these higher voltages. Reference Pereira, Amatucci, Whittingham and Hamlen21

Figure 3. Schematic representations of graphite, soft carbon, and hard carbon used for anodes in Li-ion batteries. Adapted with permission from Reference Reference Nishi20. © 2001 Wiley.

Using graphite required the identification of a replacement electrolyte that does not co-intercalate with Li and whose initial reaction with graphite forms a passivating SEI layer that prevents further reaction. As described next, the SEI layer that was ultimately realized allowed graphite to operate a few tenths of a volt below the electrochemical window of the electrolyte, contributing to an energy density of 155 W•h/kg. Reference Nishi20

Graphite remains the standard anode for Li-ion batteries today. The problem of detrimental side reactions with propylene carbonate was solved by using ethylene carbonate (EC) instead. Reference Winter, Besenhard, Spahr and Novak12 This electrolyte reacts with graphite and dissolved Li salts to produce an SEI layer that is unexpectedly beneficial. It conducts Li ions between the anode and electrolyte but is insulating to electrons and also blocks solvent molecules that would otherwise co-intercalate with Li. Reference Agubra and Fergus41,Reference Verma, Maire and Novák42 Furthermore, the SEI layer passivates the graphite surface, stopping further reaction with EC, and extends the lower limit of the EC electrochemical window by a few tenths of a volt, as noted earlier. The downside of EC (i.e., it is solid at ambient temperatures) required dilution with a low-viscosity liquid electrolyte such as dimethoxyethane, diethyl carbonate, or dimethyl carbonate. Reference Etacheri, Marom, Elazari, Salitra and Aurbach5,Reference Flandrois and Simon38

The particular combination of graphite and EC turned normally detrimental side reactions of anode and electrolyte into remarkably positive benefits. Side reactions in batteries are typically harmful, consuming both electrolyte and the electrochemically active materials that are essential for storing and releasing energy and frequently poisoning the operation of the electrodes by coating them with gratuitous reaction products. The side reactions of graphite with EC, however, were surprisingly and exceptionally beneficial. These powerful advantages, unforeseen before their serendipitous discovery, show how the fortunes of battery research can turn on fortuitous developments. The negatives of anode–electrolyte interactions were turned into positives, not by conscious innovation but by exploitation of lucky circumstance. In spite of their fortuitous origins, graphite anodes were a landmark achievement in the postcommercialization development of the Li-ion battery and remain a fixture today. Reference Nishi19,Reference Nishi20,Reference Johnson and White43

Although electrochemical intercalation of Li in graphite had been known since 1976, Reference Besenhard44 carbon materials were not demonstrated as an anode in a lithium battery configuration until 1981, in a patent issued to Bell Labs. Reference Basu45,Reference Yazami and Touzain46 In 1985, the patent that eventually led to commercial Li-ion batteries was issued to Asahi Kasei, Reference Yoshino, Sanechika and Nakajima47 and in 1991, Sony commercialized the first Li-ion battery.

Advanced cathodes

Alternative cathodes for the Li-ion battery represent a vibrant research opportunity Reference Ellis, Lee and Nazar48 and were being explored even before commercialization. In 1983, Thackeray and Goodenough discovered that Li could be intercalated into the manganese oxide spinel Mn2O4 (see Figure 4 ). Unlike layered CoO2, this spinel is a three-dimensional compound, where Li intercalates along a network of channels intersecting in three dimensions instead of between weakly bound two-dimensional layers. Reference Thackeray, David, Bruce and Goodenough50–Reference Bruce53 Manganese is 100 times more abundant in Earth’s crust than cobalt and is consequently lower in cost, making it appealing for widespread Li-ion battery deployment in vehicles or the electricity grid. The intersecting three-dimensional intercalation pathways enable high charge and discharge rates. Its high level of safety and modest environmental impact are also attractive. It has a lower energy density, however, and it suffers from the dissolution of manganese in many electrolytes. Alloys with nickel, such as LiMn1.5Ni0.5O4, make available the nickel(IV)–nickel(II) formal valences at about 4.7 V versus Li+/Li. This system represents an intriguing opportunity for achieving two-electron electrochemistry, with twice the charge storage per cathode formula unit. Reference Fergus54,Reference Zaghib, Mauger, Groult, Goodenough and Julien55

Figure 4. Comparison of the (a) charge/discharge performance and (b) attributes of alternative cathodes in Li-ion batteries: Mn2O4 spinel, Mn1/3Co1/3Ni1/3O2, Ni0.8Co0.15Al0.05O2, and FePO4 olivine. Reproduced with permission from Reference Reference Tran, Täubert and Wohlfahrt-Mehrens49. © 2014 Elsevier.

The olivine material Li x FePO4 was identified as an alternate cathode for Li-ion batteries in 1997, six years after commercialization of the original Li-ion battery (see Figure 4). Reference Padhi, Nanjundaswamy and Goodenough56 LiFePO4 has high thermal and cycling stability, comprises elements that are abundant, inexpensive, and environmentally benign, and does not react with oxygen up to 350°C. Reference Yuan, Wang, Zhang, Hu, Chen, Huang and Goodenough57 These features make Li x FePO4 an attractive cathode from the perspectives of safety, cost, environment, and lifetime.

However, Li x FePO4 intercalates Li in nonintersecting one-dimensional channels along the crystallographic b-axis, making the channels susceptible to blocking by ionic disorder, second phases, or stacking faults, potentially inhibiting its ionic conductivity. In addition, the electrical conductivity of Li x FePO4 is inherently low.

This low ionic conductivity is partially compensated by the natural tendency of Li x FePO4 to form platelets with the short dimension along the intercalation channels, a serendipitous feature that can be exploited further by shrinking the platelets to nanoscale dimensions. The low electronic conductivity can be overcome by enclosing the Li x FePO4 platelets in a conductive coating such as carbon. Reference Tran, Täubert and Wohlfahrt-Mehrens49,Reference Ravet, Chouinard, Magnan, Besner, Gauthier and Armand58 With these modifications, Li x FePO4 exhibits high charging and discharging rates, which are appealing for frequency regulation and other applications on the electricity grid. Reference Fergus54,Reference Zaghib, Mauger, Groult, Goodenough and Julien55 However, its low volumetric energy density has precluded its use in most portable devices, including cars.

Composites of the transition-metal oxides Li x MO2, where M = Ni, Mn, or Co, are finding favor because of their higher energy densities, greater stability against oxidation of electrolytes, and lower costs (see Figure 4). LiNiO2 has 20% higher gravimetric energy density than LiCoO2 but is less stable against the standard electrolytes. It is also more disordered, with nickel atoms occupying sites in the Li plane. Adding cobalt to LiNiO2 encourages nickel atoms to remain in the nickel/cobalt plane, increasing order and lithiation performance. Adding a small amount of aluminum to create Li x (Ni0.8Co0.15Al0.05)O2 increases the discharge capacity and lengthens the cycle life; adding aluminum also makes the system much safer, as it prevents all of the lithium from being removed. Reference Tran, Täubert and Wohlfahrt-Mehrens49,Reference Fergus54,Reference Zaghib, Mauger, Groult, Goodenough and Julien55

LiMnO2 forms in a monoclinic structure that is incompatible with the layered structure of LiCoO2 and LiNiO2, but adding nickel and cobalt transforms it into the same structure, allowing composites of the form Li(Ni,Mn,Co)O2 to be formed. The most common of these cathodes, Li(Ni1/3Mn1/3Co1/3)O2, has a high capacity and good rate capability and can operate at high voltages. A qualitatively different composite is formed by adding excess lithium and manganese to the mix, which enables the formation of the structurally compatible Li2MnO3, which is very stable and electrochemically inactive over the range from 2 V to 4.4 V and electrochemically active above 4.5 V. Reference Croy, Gallagher, Balasubramanian, Long and Thackeray59 The extra electrochemical activity at high voltage provides higher capacity and energy density when cycled between 2 V and 4.8 V. This interesting class of cathodes offers many still-to-be-explored opportunities for achieving higher performance. Reference Fergus54,Reference Zaghib, Mauger, Groult, Goodenough and Julien55,Reference Yan, Liu and Li60

The Li-ion battery in perspective

The story of the Li-ion battery offers many lessons. It is by far the best-performing rechargeable battery technology in terms of energy density developed to date, as illustrated in Figure 5 . Reference Zu and Li61 It not only outperforms its closest ambient-temperature competitors, nickel–cadmium and nickel metal hydride, by a factor of nearly two, but its energy density also continues to be improved at the rate of 5–10% per year. The Li-ion battery will soon replace both of its competitors for nearly all uses. The single charge on Li and the capacities of Li intercalation compounds, however, will eventually cap performance at perhaps 50–100% higher than the present level.

Figure 5. History of the development of the energy density of secondary batteries based on different chemistries. The dashed line shows the progress of the past 80 years, and the solid line shows the progress in Li-ion batteries from commercialization in 1991 to 2010. Reproduced with permission from Reference Reference Zu and Li61. © 2011 Royal Society of Chemistry.

Despite their phenomenal performance and transformational impact, Li-ion batteries fall far short of their original expectations. The original vision called for a pure Li-metal anode with a theoretical capacity of 3860 mA•h/g, but the so-far-intractable challenge of dendrite growth forced the use of graphite intercalation anodes with a capacity of 372 mA•h/g, a factor of 10 lower than that of Li metal. Moreover, the most widely used cathode, Li x CoO2, can reversibly intercalate Li over only half its range, 0.5 > x > 1, reducing its practical capacity to 140–180 mA•h/g, Reference Whittingham13 approximately half its theoretical capacity. Thus, Li-ion batteries might be considered to have failed their two most important metrics for energy-storage density, the capacities of the anode and cathode, and yet they still made a transformational impact on energy storage.

The incubation period for developing Li-ion batteries was about 20 years from conceptualization in the early 1970s to commercialization in 1991, as noted earlier. This 20-year interval from conceptualization to commercialization is surprisingly consistent for many new materials and ideas and might represent a fundamental limitation of the structure of the research, development, demonstration, and deployment (RDDD) enterprise as it is currently practiced.

One important limitation of the current RDDD enterprise is the speed at which information travels among the players, who are typically in disparate institutions and locations with infrequent scientific and social contact. The pace of communication determines the pace of innovation; full communication of scientific details to the broad community through the peer-review process can take months at its fastest and years at its slowest, whereas informal social communication transmits the same or a higher level of detail in hours or days. There are few examples of rapid and effective social communication among all of the players in the development process for comparison, but intuition and common sense suggest that greater communication would dramatically increase the pace of discovery and innovation. The Joint Center for Energy Storage Research Reference Crabtree62 is an experiment in accelerating the development of next-generation “beyond-lithium-ion” battery technology that combines discovery science, battery design, research prototyping, and manufacturing collaboration in a single, highly interactive organization. The outcomes of this experiment could provide insights, best practices, and guidelines for reducing the incubation time that can be applied to other energy challenges of national importance.

The final incarnation of the Li-ion battery looked nothing like its original vision. The initial concept of the Li-metal anode was ultimately abandoned for a soft-carbon intercalation anode, which was itself abandoned for a hard-carbon anode and then a graphite anode. The first intercalation cathode, TiS2, was in many ways superior to its replacement, CoO2, by virtue of its full intercalation range without a phase transition and its metallic character that does not require dilution with a percolating conducting network. These fundamental advantages, however, were overshadowed by a significantly higher working voltage for CoO2, making it the favored cathode, while TiS2 has played at best a supporting role. The fact that Li-metal anodes and TiS2 cathodes, the original standards, have been so thoroughly displaced by graphite and CoO2 in commercial Li-ion batteries indicates the profound value of agile, flexible, and creative thinking over dedication and loyalty to preconceived outcomes. The elusive Li-metal anode, the holy grail of battery research, suffered four commercial failures and still has not been realized a quarter-century after graphite anodes were brought to market. Had the community remained fixated on the clearly much more impactful Li-metal anode technology, the Li-ion revolution might never have occurred.

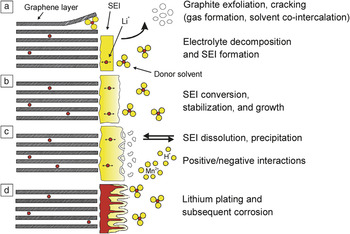

Commercialization was far from the end of the story for Li-ion technology. Figure 6 demonstrates the extent to which its performance and cost have improved, by a factor of three in energy density and a factor of 10 in cost, 63–67 enabling continued and unprecedented progress in personal electronics. These advancements after commercialization reflect a level of scientific engagement, creativity, and innovation that equals what transpired before commercialization. Commercialization was an important landmark, generating economic growth in the sale not only of batteries but also of several generations of smart phones, camcorders, and laptop and tablet computers, but it was not the end of battery development. One could argue that the economic benefits of the improvements in the performance and cost of Li-ion battery technology after commercialization have equaled or exceeded those arising from its initial commercialization.

Figure 6. Development of lithium batteries during the period of 1970–2015, showing the cost (blue, left axis) and gravimetric energy density (red, right axis) of Li-ion batteries following their commercialization by Sony in 1991.The gravimetric energy densities of Li- or LiAl-metal anode batteries against four cathodes, commercialized in the years indicated and withdrawn from the market for reasons of safety or market appeal, are shown in gray and refer to the right axis. Sources: LiAl–TiS2, Reference Reference Pereira, Amatucci, Whittingham and Hamlen21; Li–MoS2, References Reference Fouchard and Taylor23 and Reference Brandt and Laman27; Li–MnO2, References Reference Mengeritsky, Dan, Weissman, Zaban and Aurbach29 and Reference Dan, Mengeritsky, Geronov, Aurbach and Weisman30; Li–V3O8, Reference Reference Robillard28; Li-ion battery cost 1995–2005, Figure 36 in Reference 63; Li-ion battery cost 2008–2014, market-leading BEV manufacturers in Reference Reference Nykvist and Nilsson64; Li-ion battery gravimetric energy density References Reference Loeffler, Bresser and Passerini6, Reference Nishi20, Reference Ozawa40, and Reference Megahed and Scrosati65 (1991, Sony); Reference Reference Kinoshita66 (1994–2008, Sanyo 18650 battery); and Reference 67 (2012, Panasonic 18650 battery).

The steady increase in gravimetric energy density illustrated in Figure 6 is due not only to incremental improvements in engineering and manufacturing of the original 1991 Li-ion battery, but also to new materials for the cathode, anode, and electrolyte. The transitions from soft and hard carbon to graphite for the anode, accompanied by the replacement of propylene carbonate with ethylene carbonate in the electrolyte, were instrumental in the initial increases in energy density. The increases in the voltage and capacity of cathodes using mixed transition-metal oxides have been critical for more recent advances. Mixing silicon into graphite as described in the next section promises significant further increases in anode capacity, and continued tuning of the transition-metal-oxide composition will further increase cathode voltage and capacity. These incremental improvements with each new generation of anode, cathode, and electrolyte represent hard-won materials research advances and drive the remarkably consistent improvement in the energy density of Li-ion batteries.

The twists and turns that have marked the development of Li-ion batteries illustrate the need for balancing exploratory divergent research and focused convergent research to reach a targeted outcome. As the concept of intercalation as an energy-storage platform emerged in the early 1970s, the opportunities were all divergent; there were a host of possible anodes, cathodes, and electrolytes, all untested. The favored vision included a Li-metal anode and a transition-metal-disulfide cathode, because these were the highest-energy-density opportunities at the time. Whittingham and others saw the potential for a convergence of technologies, identifying TiS2 and tetramethylboride salt in a dioxolane solvent as the cathode and electrolyte to pair with a Li-metal anode. Reference Whittingham8

This convergent path was abandoned for safety reasons in 1977 with the previously mentioned discovery of Li dendrites growing on the anode upon repeated cycling, ultimately causing performance degradation, short circuits, and fires. Three more convergent paths reached commercialization, pairing Li anodes with MoS2, V3O8, and MnO2 cathodes, only to fail for reasons of safety or low market appeal. Divergent research seeking a practical route to circumvent dendrites began immediately after the first Li-anode failure, as scientists considered alloying, protective layers, and solid electrolytes among other possible solutions. Nearly 40 years after identifying the dendrite challenge, none of these divergent opportunities has converged on a solution, and divergent research continues to seek new and viable routes to Li-metal anodes.

One divergent research concept, namely replacing Li metal with intercalation anodes (i.e., the rocking-chair battery Reference Lazzari and Scrosati37 ), provided the route to today’s Li-ion battery. This vision produced three consecutive convergent paths using soft disordered carbon, hard disordered carbon, and ordered graphite, which emerged as the dominant anode. The lesson is that divergent research to identify multiple paths to solutions must accompany convergent research for a favored outcome. As the Li-ion story shows, well-chosen convergent paths often fail, requiring a reserve of divergent research on alternative paths that ultimately enable success.

Advanced Li-ion batteries

The adoption of Li-ion batteries by the consumer, in part driven by the revolution in small portable electronics that these batteries enabled, has been profound. As consumers, we have grown accustomed to rechargeable batteries fading over time. We expect (and get) longer-lasting batteries as new devices are commercialized. The battery-performance improvements that we have grown to expect with new devices are a testament to the vibrant communities of basic and applied battery science making steady advances through research.

Opportunities to further improve Li-ion batteries remain. Researchers seek to implement higher-capacity anode and cathode materials (i.e., materials that store more lithium ions per unit mass or volume than those used today) and process improvements that coax the full theoretical energy density from existing commercial materials. Graphite anodes, which still rule commercial Li-ion negative electrodes, are nearly achieving their 372 mA•h/g theoretical density. Reference Dahn, Sleigh, Shi, Way, Weydanz, Reimers, Zhong, von Sacken and Pistoia68 Scientists are intensely pursuing research on silicon materials, Reference Liang, Liu and Xu69 which have about 10 times the gravimetric specific capacity of graphite, rivaling that of the long-sought Li-metal anode. Silicon-anode research often addresses structural and lifetime issues, owing to the large and deleterious volume changes associated with silicon lithiation and delithiation. Reference Szczech and Jin70 Although the all-silicon anode has so far eluded battery manufacturers, varying amounts of silicon are being added to graphite electrodes to boost anode capacities on an experimental basis. Reference Park, Kim, Kim and Sohn71 Implementing higher-capacity materials, in turn, necessitates consideration of new electrode fabrication, electrolyte formulation, and battery control systems. Diverse expertise is required to address the battery as a whole.

Controlling side reactions associated with the electrolytes used in Li-ion batteries is a major part of enabling the adoption of new battery materials. In the silicon-anode example, during lithiation (i.e., alloying of silicon with lithium), the parent anode material expands by over 100% Reference Brushett, Trahey, Xiao and Vaughey72 to accommodate lithium into the host structure, and it contracts accordingly upon discharge. Such appreciable material size changes, which are also well-documented for tin-based anodes, lead all too easily to particle fracture and electronic isolation. Reference Su, Wu, Li, Xiao, Lott, Lu, Sheldon and Wu73 Material expansion also exposes fresh anode surface to the electrolyte at low cell voltages. Electrolyte components will reduce on conductive surfaces at low voltages, leaving solid organic films on the interfaces. These films are electronically insulating in nature, which increases the impedance of the electrodes, leading to a loss of usable energy over time. Reference Trahey, Kung, Thackeray and Vaughey74

Electrolyte reduction onto graphite anodes occurs in the same manner as for silicon anodes, but the resulting organic layer forms primarily on the first cycle and is stable, conducting Li ions from the electrolyte to the graphite anode, which intercalates them into its existing structure with little volume change. Research aimed at stabilizing silicon-anode surfaces through tailored, often fluorinated electrolyte components that improve the properties of the reduced organic layer on silicon surfaces is ongoing. Reference Zhang75,Reference Bottcher, Duda, Kalinovich, Kazakova, Ponomarenko, Vlasov, Winter and Roschenthaler76 Fluorinated electrolytes are also attractive for their high-voltage oxidative stability. Reference Tan, Ji, Zhang and Yang77 High-voltage cathode materials are sought, but those that have been considered lithiate and delithiate at voltages that slightly exceed the oxidative stability of conventional electrolytes, resulting in the oxidative breakdown of electrolytes on the cathode surface. Hence, research on new electrode materials is an essential part of research on new or modified electrolytes to identify and control their side reactions in an operating battery.

Inside each Li-ion battery is a complex array of science. Improving anode and cathode materials requires expertise in materials chemistry, whereas creating new nonaqueous electrolytes lies in the realm of organic chemistry. Analytical chemistry, microscopy, and synchrotron science are often called upon to reveal reaction mechanisms and probe material degradation. Engineering is needed to effectively incorporate materials into electrodes, electrodes into cells, and cells into high-performance battery packs. Condensed-matter physics and materials science are useful for predicting new materials and understanding complex phenomena. All battery researchers need familiarity with electrochemistry. To build a battery, no single area can be advanced faster than the others. In short, full-component battery research requires an interactive multidisciplinary team.

Beyond Li-ion batteries: Opportunities and challenges

Although Li-ion batteries have enabled the field of personal electronics, their performance and cost fall short of satisfying transportation and electricity-grid needs. For all-electric cars, range and cost are major barriers to widespread penetration. The least expensive electric cars such as the Nissan Leaf and the BMW i3 cost more than conventional gasoline cars, yet can drive only approximately 80 mi (130 km) on a single charge, whereas gasoline cars drive 300–500 mi (480–800 km) on a single tank of fuel. High-end electric cars such as the Tesla Model S increase their range to 250 mi (400 km) or more on a single charge by simply adding more conventional batteries, while simultaneously increasing the purchase price beyond the reach of most consumers. A factor-of-five increase in energy density is needed to achieve the range of a gasoline car without increasing battery size; a similar significant decrease in cost is needed to achieve a competitive purchase price.

Energy storage for the electricity grid offers a new horizon of flexibility, breaking the century-old constraint of generating electricity at the same rate as it is used. This constraint is quite expensive, as without storage, grid infrastructure must be built for peak demand, about twice the average demand. Renewable wind and solar generation brings a further need for storage, as the variability of these sources in widespread deployment threatens the stability and reliability of the grid. Coupling wind and solar generation with storage converts these variable sources into dispatchable sources, making them readily accessible when needed to respond to changes in demand. Even without wind and solar generation, storage reduces the carbon footprint of the grid by replacing the old, inefficient, and high-carbon-emitting “peaker” plants used only a few hours a day during peak demand with batteries charged at night with low-cost, cleaner electricity.

The challenge for grid storage is competition with less expensive forms of generation, such as gas turbines, that supply electricity costing about five times less than that supplied by currently available batteries. If economics were the only consideration, generating electricity when needed from gas turbines would be favored over charging batteries with excess electricity in off-peak times for release during peak times. To compete with gas turbines, the cost of batteries for the grid must be reduced by approximately a factor of five.

Although Li-ion batteries have seen remarkable increases in energy density and reductions in cost (as shown in Figure 6), additional factors-of-five improvements cannot be achieved. Theoretical limits on the performance of the active ingredients in Li-ion batteries allow performance increases by 50–100%. To transform transportation and the electricity grid, a new generation of beyond-Li-ion batteries is needed.

Conclusions

This overview of the development of Li-ion battery technology offers insights into the task of developing next-generation batteries with transformational cost and performance to serve electric-vehicle and electricity-grid technology needs. The opportunity is clear: The energy used by personal electronics represents approximately 2% of total US energy use, Reference Urban, Shmakova, Lim and Roth78 whereas transportation and the grid comprise two-thirds of US energy use. Storing half of the energy used by transportation and the grid creates a market at least 10 times larger than the present Li-ion market serving personal electronics. The transportation and grid markets need dramatically higher battery performance to reach the tipping point of widespread deployment of electric cars, wind and solar electricity, and new operating paradigms that break the constraint of instantaneously generating electricity at the same rate that it is used. A new generation of storage is needed that provides hundreds of miles of driving range for cars instead of tens of miles, charging in tens of minutes instead of hours, and storing and releasing electricity on the grid at costs comparable to those of natural-gas generation. These demands are beyond the reach of Li-ion technology, presenting a daunting challenge, not unlike the challenge of powering personal electronics in the 1990s that ultimately was met by Li-ion technology.

As we pursue beyond-Li-ion technologies that will meet the needs of transportation and the grid, we should build on the lessons of the Li-ion experience. A balance of convergent and divergent research is needed, as many, perhaps most, convergent paths end in failure, and divergent alternatives are essential. Integration of the people, ideas, strategies, and techniques spanning discovery science, battery design, research prototyping, and manufacturing collaboration has the potential to reduce communication time from years to months and significantly shorten the 20-year incubation period for developing new technologies. Tenacious pursuit of superior but unproductive convergent pathways could distract researchers from recognizing and pursuing alternative solutions that are less appealing but still transformational; adherence to the quest for Li-metal anodes, for example, could have delayed the development of intercalation anodes that created the Li-ion battery and transformed personal electronics.

A diverse mix of disciplines, including chemistry, electrochemistry, materials science, physics, engineering, and manufacturing, is required to meet the challenges of complex systems such as those in beyond-Li-ion batteries. Commercialization, a critical landmark for transformation, is only the beginning of the journey; a vibrant engagement in discovery science, battery design, research prototyping, and manufacturing is essential for rapid improvements in performance and cost after commercialization. New tools such as genomic simulation of electrodes and electrolytes, techno-economic models of the performance and cost of battery systems, state-of-the-art characterization of electrochemical interfaces, and innovative use of emerging techniques such as coherent light sources and application of more than a decade of nanoscience advances offer significantly more powerful vision and insights than were available before 1991 for Li-ion development. The new paradigms for battery research, development, demonstration, and deployment that we develop based on the lessons of Li-ion experience can serve as models not only for beyond-Li-ion battery development but also for other rich and ripe technology transformations that promise high environmental, economic, and human returns.

Acknowledgments

This work was supported as part of the Joint Center for Energy Storage Research, an Energy Innovation Hub funded by the US Department of Energy, Office of Science, Basic Energy Sciences. The submitted manuscript was created by UChicago Argonne, LLC, Operator of Argonne National Laboratory (“Argonne”). Argonne, a US Department of Energy Office of Science laboratory, is operated under Contract DE-AC02-06CH11357. We also thank Stan Whittingham, Mike Thackeray, Kevin Gallagher, and Venkat Srinivasan for valuable discussions on the history and postcommercialization development of Li-ion batteries.