No CrossRef data available.

Article contents

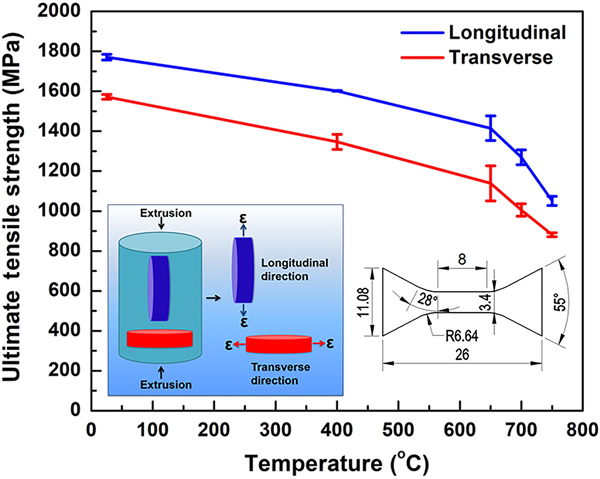

Anisotropic behavior of tensile properties in a hot-extruded polycrystalline nickel-base superalloy

Published online by Cambridge University Press: 06 November 2019

Abstract

The authors report an unexpected anisotropy in tensile properties of a polycrystalline nickel-base superalloy after hot extrusion. The tensile strength of longitudinal specimens (parallel to extrusion direction) is 170–276 MPa higher than that of the transverse counterparts at the temperature ranging from 25 to 750°C. Microstructural investigation excludes possible causes leading to this phenomenon such as variation in the grain size, texture, and γ′ precipitates in two orientations. However, further transmission electron microscopy observation reveals that plenty of twins uniquely exist in longitudinal tensile samples after deformation which are probably responsible for the mechanical gap between the two orientations.

Information

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2019