Published online by Cambridge University Press: 19 November 2019

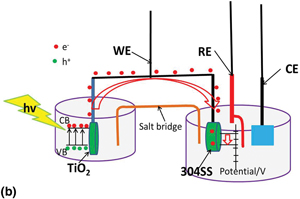

This paper proposes to improve the corrosion resistance of stainless steel using the photocathodic protection (PCP) method with CdS/PbS/titanium dioxide (TiO2) as the photoanode material. Cadmium sulfide (CdS)/lead sulfide (PbS) quantum dot (QD) heterostructure layered on TiO2 enhanced the photoelectrochemical performance and improved the PCP of 304 stainless steel. The photoanode film can protect 304 stainless steel for a period of upto 3 months against corrosion. This work demonstrates that CdS/PbS/TiO2 tandem heterostructure is a promising durable and stable photoanode, which can protect stainless steel in both dark and illuminated conditions.