Introduction

Soybean is Missouri’s most economically important crop. In 2021, farmers planted over 5.7 million acres (about 2.3 ha) of soybean, worth $3.68 billion (MU Extension 2022; USDA 2021). Weed interference poses the most significant threat to soybean yield. Left uncontrolled, weeds can reduce soybean yields in Missouri by 52% and cause a potential loss in value of $1.06 billion annually (Soltani et al. Reference Soltani, Dille, Burke, Everman, VanGessel, Davis and Sikkema2017).

Decades of reliance on herbicides have led to the selection of herbicide-resistant weed species. Currently, 50 herbicide-resistant species weeds infest soybean globally, and waterhemp is the most common and troublesome weed species encountered in U.S. soybean production (Heap Reference Heap2022; Van Wychen Reference Van Wychen2019). Waterhemp has evolved resistance to seven different herbicide mechanisms of action. In many instances, a single population can possess resistance to multiple herbicide mechanisms of action (Heap Reference Heap2022). In 2018, a Missouri waterhemp population was confirmed with resistance to six different classes of herbicides (Shergill et al. Reference Shergill, Barlow, Bish and Bradley2018), whereas in 2019 an Illinois population was documented with seven-way resistance (Strom et al. Reference Strom, Gonzini, Mitsdarfer, Davis, Riechers and Hager2019). No novel herbicide mechanism of action has been discovered since the 1980s, leaving growers with few effective herbicide options for weed control in soybean. A more integrated approach to weed management is needed to extend the effectiveness of the current chemistries available. Integrated weed management (IWM) is a sustainable, effective approach that utilizes multiple strategies that consider all available chemical, mechanical, cultural, and biological methods.

Harvest weed seed control (HWSC) is one method of IWM with the ultimate objective of destroying or collecting weed seed at harvest. This approach targets seed from weed escapes that survived weed management strategies applied early and that remain at harvest; such weeds are more likely to retain herbicide resistance traits and, if allowed to set seed, would contribute to the development of herbicide resistance in subsequent growing seasons (Jasieniuk et al. Reference Jasieniuk, Brûlé-Babel and Morrison1996; Shergill et al. Reference Shergill, Bejleri, Davis and Mirsky2019). Seed that is not destroyed at harvest will return to the soil seed bank and will have the ability to persist for years (Buhler and Hartzler Reference Buhler and Hartzler2001; Burnside et al. Reference Burnside, Wilson, Weisberg and Hubbard1996). The soil seed bank is a natural storage of weed seed and is influenced by previous cropping systems and environmental conditions (Schwartz et al. Reference Schwartz, Gibson, Gage, Matthews, Jordan, Owen, Shaw, Weller, Wilson and Young2015).

One method of HWSC is the use of on-combine impact mills that are designed to devitalize weed seed that exit the combine during grain harvest. Impact mills are integrated into the rear of the combine and utilize a set of rotating and stationary bars to render nonviable weed seed residing in the chaff upon exiting the system. Impact mills were first developed in Western Australia and have been highly adopted across that region. The impact mills on the market today that are usually used are the Seed Terminator™, Redekop™ Seed Control Unit, and iHSD®. In Australia, impact mills are used during small-grain and oilseed harvest to limit the spread of multiple-resistant weed species like rigid ryegrass (Lolium rigidum Gaudin). Walsh et al. (Reference Walsh, Harrington and Powles2012) previously reported that the use of impact mills in Australia successfully destroyed 93% to 99% of seed from economically important weed species during commercial grain harvest of wheat (Triticum aestivum L.), barley (Hordeum vulgare L.), and lupin (Lupinus angustifolius L.). Stationary testing of the iHSD® was also found to be successful in destroying 97.5% to 100% of weed seed from species commonly found in soybean and rice (Oryza sativa L.) production systems in the mid-southern United States (Schwartz-Lazaro et al. Reference Schwartz-Lazaro, Norsworthy, Walsh and Bagavathiannan2017).

Sparse information is available on the effectiveness of impact mills used in U.S. soybean production systems. In 2019 and 2020, we evaluated the effectiveness of the Seed Terminator™ impact mill on five weed species commonly encountered in Missouri soybean production fields. The objectives of this research were to: (i) quantify header loss of weed seed during soybean harvest, (ii) determine the effectiveness of the Seed Terminator™ at destroying weed seed and reducing weed seed banks following soybean harvest, (iii) determine the effects of the Seed Terminator™ on combine performance, and (iv) determine the fixed and operating costs of harvesting soybean with a combine equipped with a Seed Terminator™ compared to a conventional combine.

Materials and Methods

Site Description

Field trials were conducted in commercial soybean production fields near Columbia (38.90°N, 92.21°W), New Florence (38.89°N, 91.42°W), Montgomery City (39.00°N, 91.50°W), and Hallsville (39.12°N, 92.22°W), MO, in 2019, and repeated in fields near Columbia, New Florence, and Montgomery City in 2020. Consecutive years of research were conducted within the same fields at the Columbia and New Florence sites; however, different neighboring fields were used near Montgomery City in 2019 and 2020. Global positioning system coordinates were used to record plot boundaries at the Columbia and New Florence sites to conduct consecutive seasons of research. At each site, individual plots were 0.6 ha and were arranged in a randomized complete block design with four replications at all sites, except for Montgomery City in 2019, where size constraints limited the experiment to three replications.

Harvests of each 0.6-ha plot were conducted with a Case IH Axial-Flow 8250 combine equipped with a 9.7-m-wide TerraFlex™ draper head (Case IH, 700 State Street, Racine, WI 53404) and an on-combine Seed TerminatorTM impact mill (23 Aldershot Road, Lonsdale SA 5160, Australia) (Figure 1). The two treatments evaluated at each site were harvesting with the Seed TerminatorTM engaged or harvesting with the Seed TerminatorTM impact mill disengaged as would occur in a conventionally harvested soybean field. The Seed Terminator™ is not capable of disengaging whenever the combine is harvesting. So, for the conventional harvest treatment, a steel plate was fastened over the Seed Terminator™ to prevent chaff and weed seed from passing through the implement. The Seed Terminator was still spinning during conventional treatments, but nothing was passing through the mills, which are belt-driven.

Figure 1. A Case IH 8250 combine equipped with a Seed Terminator™ implement.

Waterhemp was present at all sites at the time of harvest. Waterhemp plant characteristics are listed in Table 1, along with harvest dates at each site. In addition to waterhemp, the Montgomery City site contained natural infestations of ivyleaf, pitted, and tall morningglory species [Ipomoea hederacea Jacq., I. lacunosa L., I. purpurea (L.) Roth)], velvetleaf (Abutilon theophrasti Medik.), and giant foxtail (Setaria faberi Herrm.) in 2019, and the same morningglory species and common lambsquarters (Chenopodium album L.) in 2020. The plant characteristics of the weeds evaluated at the Montgomery City sites are listed in Table 2.

Table 1. Site information and waterhemp plant characteristics at each research site in Missouri in 2019 and 2020.

a Average waterhemp plant produces ∼250,000 seeds and loses 6% each week after soybean maturity (Schwartz-Lazaro et al., Reference Schwartz-Lazaro, Shergill, Evans, Bagavathiannan, Beam, Bish, Bond, Bradley, Curran, Davis, Everman, Flessner, Haring, Jordan, Korres, Lindquist, Norsworthy, Sanders, Steckel, VanGessel, Young and Mirsky2021a).

Table 2. Plant characteristics of other weed species at the Montgomery City site in 2019 and 2020.

a Average giant foxtail plant produces ∼900 seeds and loses 12.1% each week after soybean maturity (Schwartz-Lazaro et al. Reference Schwartz-Lazaro, Shergill, Evans, Bagavathiannan, Beam, Bish, Bond, Bradley, Curran, Davis, Everman, Flessner, Haring, Jordan, Korres, Lindquist, Norsworthy, Sanders, Steckel, VanGessel, Young and Mirsky2021b).

b Morningglory spp. was present at harvest, but no measurements were recorded in 2019.

c Average velvetleaf plant produces ∼5,500 seeds and loses 9.7% each week after soybean maturity (Schwartz-Lazaro et al. Reference Schwartz-Lazaro, Shergill, Evans, Bagavathiannan, Beam, Bish, Bond, Bradley, Curran, Davis, Everman, Flessner, Haring, Jordan, Korres, Lindquist, Norsworthy, Sanders, Steckel, VanGessel, Young and Mirsky2021a).

Pre-Harvest Measurements

To determine the average weed density at the time of harvest, six 1-m2 counts of each weed species were recorded within each 0.6-ha plot. The average moisture content of each weed species present at the time of harvest was determined by collecting 16 plants of each of the predominant weed species present at each site. Collections were accomplished by cutting plants at the soil surface, weighing them, and recording each plant’s fresh weight. Plants were then placed in a paper bag and dried in a forced-air oven at 37 C for 48 h. Weights were recorded every 48 h until a constant weight was achieved. After the samples were dried entirely, moisture content was determined by the difference in fresh and dry weights. Seedheads of each plant were threshed to establish a baseline of seed per plant at the time of harvest. In 2019, seeds per plant data were lost for three of the sites. Estimations for these sites were based on a multi-state study that documented the weed seed retention rate of broadleaf and grass species at soybean maturity (Schwartz-Lazaro et al. Reference Schwartz-Lazaro, Shergill, Evans, Bagavathiannan, Beam, Bish, Bond, Bradley, Curran, Davis, Everman, Flessner, Haring, Jordan, Korres, Lindquist, Norsworthy, Sanders, Steckel, VanGessel, Young and Mirsky2021a, 2021b).

Harvest Sampling

At all sites, the combine was operated under a uniform set of harvest settings and similar speed, whether or not the Seed TerminatorTM impact mill was engaged while harvesting. The reel speed was operated at 38 rpm, and the position of the reel extended over the cutting bar by 14 cm. Harvest occurred at approximately 6 km h–1.

Header Loss

To measure header loss of weed seed, two metal trays, each measuring 1 m2 by 2 cm deep, were placed between soybean rows prior to harvest. For collection, the combine was operated at full capacity and normal speed until the header passed over the collection trays. Once the header completely passed over the trays, the combine was abruptly stopped to prevent contamination of crop residues and any weed seed exiting the rear of the combine. All weed seed and plant material collected in the trays were emptied into paper bags and stored until subsequent processing to determine the amount of weed seed present in each sample. The number of seed in header loss samples was determined by weighing and counting 0.1g, 5.0 g, 0.5 g, 0.5 g, and 0.1 g of waterhemp, morningglory spp., velvetleaf, giant foxtail, and common lambsquarters seed, respectively. After seed was weighed and counted, the count was then extrapolated to calculate the amount in the entire sample. Three header loss subsamples were taken per 0.6-ha plot at each site.

Threshing Loss

We have defined threshing losses of weed seed for this study as all weed seed that passed through the combine and were expelled from the straw spreader and/or Seed TerminatorTM back onto the ground. Threshing losses were determined by placing two 1-m2 collection trays behind either side of the rear of the combine as it was actively harvesting at full capacity and at a uniform operating speed soybean while the Seed Terminator™ was engaged and disengaged. All weed seed and chaff material collected in the trays were emptied into labeled paper bags and stored until subsequent processing for determining the amount of weed seed in the sample. Six random threshing loss subsamples were taken per 0.6-ha at each site. Header loss and threshing loss samples represent the total percent of weed seed collected in the field at each site. Percent of nondamaged and damaged seed in each sample was determined by weighing and counting 0.1 g, 5.0 g, 0.5 g, 0.5 g, and 0.1 g of waterhemp, morningglory spp., velvetleaf, giant foxtail, and common lambsquarters seed, respectively. After seed was weighed and counted, the count was then extrapolated to calculate the amount in the entire sample. Threshing loss samples were also used to compare the amount of nondamaged weed seed returning to the soil between conventional and Seed Terminator™ treatments.

Seed Terminator™ Efficacy

Two insect sweep nets (Flinn Scientific, 770 N Raddant Road, Batavia, IL 60510) were used to evaluate the efficacy of the Seed Terminator™ by holding these nets over each rear exit chute for approximately 10 s as the combine was actively harvesting. All material collected in the nets was emptied into labeled plastic bags and stored until subsequent processing. Six subsamples were collected per 0.6-ha plot for which the Seed Terminator™ was engaged at each site. Seed Terminator efficacy was determined by weighing and counting 0.1 g, 2.0 g, 0.75 g, 0.5g, 0.25g of waterhemp, morningglory spp., velvetleaf, giant foxtail, and common lambsquarters seed, respectively. After the seed was weighed and counted, the count was then extrapolated to calculate the percent of damaged seed in the sample.

Combine Performance

The Case IH 8250 combine was equipped with an on-board computer with the ability to record an array of data points while in use. The data points that were used to evaluate combine performance in this research were engine load (%), productivity (ha h–1), and fuel consumption (L ha–1 and L h–1). Engine load is described as an external restraining torque being applied to the engine. So, whenever an external force acts on the engine, the engine load increases. These data were recorded in separate, “bulk” areas of the soybean fields in areas outside of the research trials. At each site, the combine harvested approximately 2 ha for comparison of conventional harvesting and harvesting with the Seed Terminator™ engaged. The number of data points subject to analysis was n = 13,481 for both years at all sites. Data were trimmed to exclude data points taken when the combine was not harvesting at full capacity. Separate files were made in the on-board computer for each location and were saved for subsequent data analysis.

Post-harvest Sampling

In the spring following each harvest, soil core samples were collected from conventional and Seed Terminator™ plots to assess potential differences in the density of germinable weed seed in the soil seed bank. Sites were separated for soil core analysis due to the variation in starting densities of seed in the soil. Six subsamples (7-cm diam by 10-cm depth) were collected with a soil auger (W.W. Grainger, Inc., 100 Grainger Parkway, Lake Forest, IL 60045) per 0.6-ha plot. All samples were stored in labeled plastic bags at –5 C until further analysis. Soil samples were then spread evenly over individual 54 cm by 27 cm by 6 cm greenhouse flats (Hummert International, 4500 Earth City Expressway, Earth City, MO 63045) previously filled with a commercial potting medium (Pro-Mix BX Mycorrhizae; Premier Tech Horticulture, 127 S Fifth Street, Quakertown, PA 18951). Flats were maintained in the greenhouse at 30 C with natural light supplemented with metal-halide lamps (600 μmol photon m–2 s–1) providing a 14-h photoperiod and were watered as needed. Weed seedling emergence was determined in each flat for 3 wk following planting.

Processing Harvest Samples

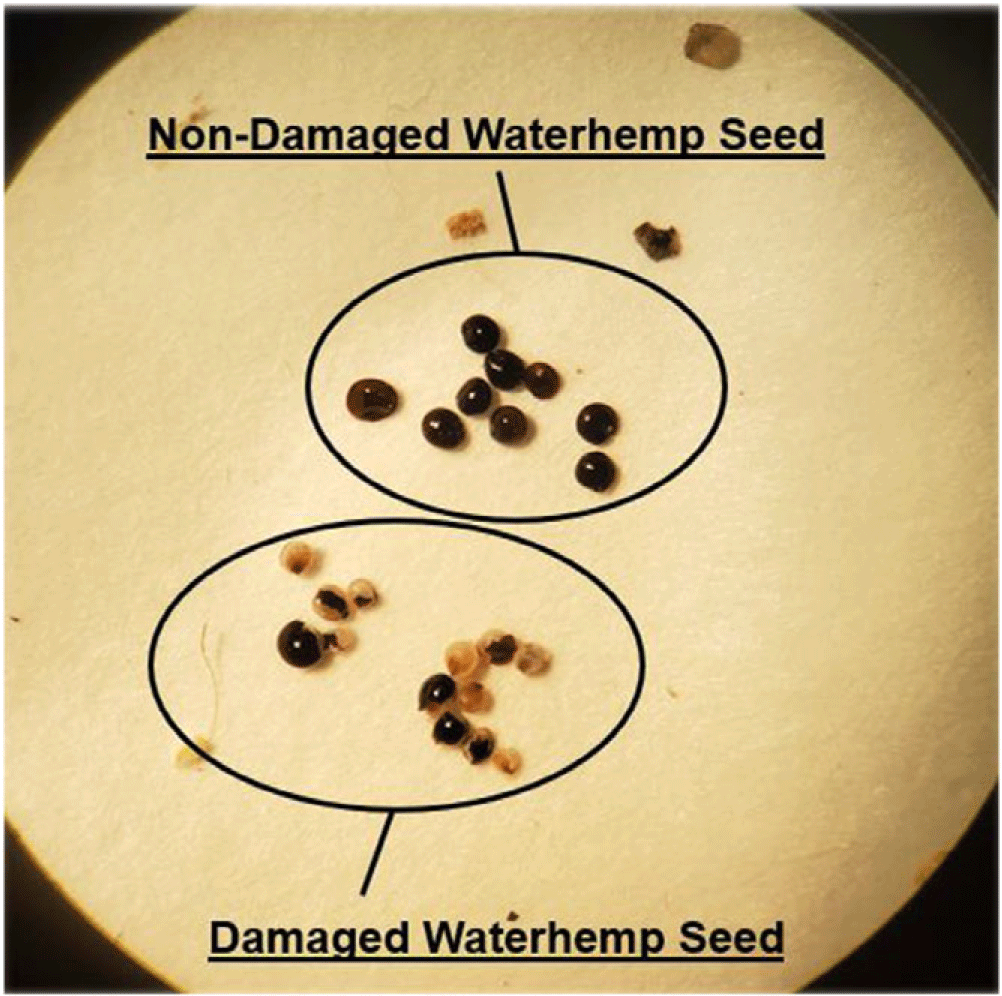

All header loss, threshing loss, and Seed Terminator™ samples were sifted through a series of sieves, ranging from 8 mm to 0.35 mm (Seedburo Equipment Company, 2293 Mt Prospect Road, Des Plaines, IL 60018), to separate larger pieces of chaff and debris from weed seed in the sample. After each sample was sieved, the sample was passed through an air column (South Dakota Seed Blower, Seedburo Equipment Company, 2293 Mt Prospect Road, Des Plaines, IL 60018) to remove finer material and obtain a purer sample of weed seed. Samples were then examined for the number of weed seed and the percentage of damaged seed. Seed was classified as damaged if it was less than half the size of a typical seed and/or if 50% of the seed coat was missing (Figure 2). Weed seed that meets this criterion is expected to be nonviable (Davis et al. Reference Davis, Schutte, Iannuzzi and Renner2008; Schutte et al. Reference Schutte, Rashid, Wood and Marquez2020; Walsh et al. Reference Walsh, Broster and Powles2018).

Figure 2. Damaged and nondamaged waterhemp seed collected from a Seed Terminator™ threshing loss sample. Waterhemp seed is black to dark red in color and measure 0.8-1.0 mm diam.

Statistical Analysis

All weed seed and soil core samples were subject to analysis in SAS 9.4 (SAS Institute Inc., 100 SAS Campus Drive, Cary, NC 27513) using the PROC TTEST procedure, P ≤ 0.05. For soil core analysis, sites were considered fixed effects. This consideration is due to the variation in density of the weed seed bank at each site. However, sites were considered random for combine performance. Sites were considered random for combine performance to observe effects over a wider range of environments, rather than site-specific. Seed Terminator™ treatments were considered fixed effects, whereas year and replication were considered random effects. Year was considered a random effect in the model to make conclusions over a broader range of environments (Blouin et al. Reference Blouin, Webster and Bond2011; Carmer et al. Reference Carmer, Nyquist and Walker1989).

Results and Discussion

Header and Threshing Loss of Weed Seed

Header loss is usually associated with loss of grain during harvest. In this experiment, header loss is defined as weed seed lost at the combine head due to shatter. Regardless of whether the harvest occurred conventionally or with the Seed Terminator™, if weed seed is lost at the head, the seed will return to the soil seed bank and potentially persist for subsequent growing seasons. Threshing loss in these experiments was defined as any weed seed expelled from the rear of the combine through the straw spreader and/or Seed Terminator™ back to the soil surface. For a conventional soybean harvest, the combination of header and threshing loss measurements helps to illustrate the overall percent of seed lost at the head and/or deposited from the straw spreader returning to the soil surface.

Waterhemp

Figure 3 illustrates the fate of waterhemp seed that returns to the soil seed bank when soybean is harvested with a conventional combine. Across 7 site-years, on average 31% of waterhemp seed that remained at harvest was lost at the combine head due to shatter. In other words, whether a producer is using conventional harvesting methods or a harvest weed seed destruction implement, nearly one-third of the waterhemp seed will be lost at the head. The remaining 69% of waterhemp seed passes through the combine and is expelled from the rear, which gives growers an opportunity to target and destroy the seed. The three sites where the highest plant moisture was documented (Columbia 2019, New Florence 2019 and 2020) all exhibited the lowest amount of header loss, whereas the lowest plant moisture content and highest waterhemp seed header loss occurred in Columbia in 2020 (Table 1, Figure 3). Based on these observations, harvesting when waterhemp has higher plant moisture content and before complete plant senescence has occurred will increase the number of seed entering the combine.

Figure 3. Header and threshing loss of waterhemp seed at seven Missouri sites harvested with a conventional combine in 2019 and 2020. Asterisks indicates significant difference between paired bars based on t-test analysis.

Other Weed Species

Other weed species evaluated at the Montgomery City sites were morningglory spp., velvetleaf, and giant foxtail in 2019, and morningglory spp. and common lambsquarters in 2020 (Figure 4). By far, the highest header loss of weed seed occurred with velvetleaf in 2019 (89%), which may be related to the high density of this weed at this site and low plant moisture content at the time of harvest (Table 2). Header loss of morningglory spp. seed was 48% and 58% in 2019 and 2020, respectively, whereas giant foxtail header loss was 52% in 2019. Header loss of common lambsquarters was 34% in 2020. Of the weed species evaluated in this research, common lambsquarters seed are perhaps most comparable in size to waterhemp, which may explain the similarity in header loss percentage of the two species (Figures 3 and 4).

Figure 4. Comparison of header and threshing loss of weed seed with a conventional combine at Montgomery City sites in 2019 and 2020. Asterisks indicates significant difference between paired bars based on t-test analysis.

Efficacy of the Seed Terminator™

Waterhemp

The Seed Terminator™ was highly effective in destroying the vast majority of weed seed passing through the combine. The implement was able to destroy an average of 94% of waterhemp seed across 7 site-years, with damage percentages ranging from 77% to 99% (Table 3). These results are consistent with findings from Schwartz-Lazaro et al. (Reference Schwartz-Lazaro, Norsworthy, Walsh and Bagavathiannan2017), where the iHSD® mill was able to destroy 98.4% of waterhemp seed in stationary testing. Only 77% of waterhemp seed at the 2019 Columbia site were damaged to the extent that they were considered nonviable. It is not clear why this percentage was so much lower than the remaining sites, as waterhemp plant moisture at the time of harvest was 54%, which was similar to or lower than the plant moisture content of waterhemp at New Florence in 2019 and 2020. Continued testing of the Seed Terminator™ and other impact mill implements will be needed to fully understand their efficacy on waterhemp in other geographies and cropping systems, and to better understand the role of plant moisture content in seed destruction.

Table 3. Damaged weed seed exiting the Seed Terminator™ at each research site in Missouri in 2019 and 2020.

a Values in parentheses indicate ± standard error of the mean.

Other Weed Species

Of the weed species evaluated in this research, common lambsquarters seed are perhaps next largest in size to waterhemp, and damage to the seed of this species by the mill system was 97% at the Montgomery City site in 2020 (Table 3). The Seed Terminator™ was able to destroy 94% and 99% of morningglory spp. seed in 2019 and 2020, respectively. Schwartz-Lazaro et al. (Reference Schwartz-Lazaro, Norsworthy, Walsh and Bagavathiannan2017) reported the iHSD® was able to destroy 100% of morningglory species seeds in stationary testing. Schwartz-Lazaro et al. (Reference Schwartz-Lazaro, Norsworthy, Walsh and Bagavathiannan2017) also reported 100% destruction of velvetleaf, but in this research we only recorded 80% damage to velvetleaf seed at the Montgomery City site in 2019. The average damage percentage for giant foxtail seed was 98% in 2019. Walsh et al. (Reference Walsh, Broster and Powles2018) also reported that the iHSD® was able to successfully destroy 96% to 99% of grass weed seeds commonly found in Australian cropping systems. In stationary testing, Schwartz-Lazaro et al. (Reference Schwartz-Lazaro, Norsworthy, Walsh and Bagavathiannan2017) found the iHSD® was able to destroy 99% to 100% of grass species encountered in the mid-southern U.S. rice and soybean cropping systems. Overall, the Seed Terminator™ was able to damage the vast majority of weed seeds commonly encountered in Missouri soybean production systems.

Reduction of Weed Seed Returning to the Soil Seed Bank

Nondamaged Seed in Threshing Loss Samples

Threshing loss samples allowed us to evaluate everything that is dispensed from the rear of the combine, whether it was from the straw spreader and/or the Seed Terminator™ when it was engaged. Overall, the results from these experiments show that not all chaff and weed seed is directed into the Seed Terminator™ when it is engaged; a portion of the weed seed is lost and expelled from the straw spreader. Similar results were observed in Arkansas, where 85%, 9%, and 6% of the Palmer amaranth seed collected in soybean harvest fractions was collected from the upper sieve, straw spreader, and grain tank, respectively (Green et al. Reference Green, Norsworthy and Walsh2020). Table 4 provides a comparison of nondamaged weed seed collected in conventional and Seed Terminator™ threshing samples. Whenever harvest occurred with the Seed Terminator™ engaged, there was a 63% to 97% reduction in the amount of nondamaged waterhemp seed exiting the rear of the combine. When averaged across all sites, this equated to an average reduction of 82% less waterhemp seed exiting the combine. When considering the 31% of waterhemp seed that is lost at the combine head as a result of shattering (Figure 3), this equates to a total of 56% less waterhemp seed returning to the soil when harvesting with a Seed Terminator™ compared to harvesting with a conventional combine. The Seed Terminator™ was also able to reduce the amount of viable morningglory species, velvetleaf, giant foxtail, and common lambsquarters seed exiting the combine and returning to the soil surface by an average of 91%, 97%, 78%, and 95%, respectively (Table 4).

Table 4. Comparison of nondamaged weed seed deposited from the rear of the combine in conventionally harvested and Seed Terminator™ threshing samples.

a Values in parentheses indicate ± standard error of the mean.

Post-harvest Sampling

After one season of use of the Seed Terminator™, there was a reduction in the waterhemp seed bank at the Montgomery City site in 2020, but not at Hallsville in 2020 or Montgomery City in 2021 (Figure 5). At the Columbia and New Florence locations, we were able to evaluate the effectiveness of the Seed Terminator at reducing the weed seed bank in consecutive seasons. A statistical reduction was not observed in the first year but was observed in the second year at both sites. We speculate that the increase of waterhemp seed in the soil seed bank at the Columbia site in 2021 was due to seed loss and seed shattering that occurred with a November harvest date after a killing frost (Table 1). Although it would have been ideal to harvest with the Seed Terminator™ for more than two consecutive seasons, logistical complications prevented this from occurring. Nevertheless, these results indicate that consecutive seasons of harvest with the Seed Terminator™ will result in substantial reductions in the amount of waterhemp seed returning to the soil seed bank. Walsh et al. (Reference Walsh, Aves and Powles2017) also found that the use of HWSC systems reduced population densities of rigid ryegrass by an average of 60% in subsequent growing seasons using either impact mills, chaff carts, or narrow-windrow burning in Australia. Additionally, another study performed over 10 consecutive seasons found that the use of herbicides combined with HWSC tactics reduced the average density of annual ryegrass from 35 plants m–2 in 2002 to less than 1 plant m–2 (Walsh et al. Reference Walsh, Newman and Powles2013).

Figure 5. Comparison of waterhemp plants emerged from soil cores (7 cm by 10 cm) collected the spring following harvest. Cores were collected from conventional and Seed Terminator™ plots at soybean harvest sites in Missouri. Asterisks indicate significant differences between paired bars based on t-test analysis.

Combine Performance

An increase in engine load and fuel consumption was observed at all sites when the Seed Terminator™ was engaged. When averaged over 7 site-years, engine load for the Seed Terminator™ was 86%, as opposed to 73% with conventional harvesting (Figure 6A). Increased fuel consumption was also observed in both liters per hectare and liters per hour whenever the Seed Terminator™ was engaged. Harvesting with the Seed Terminator™ engaged resulted in 1 L ha–1 and 11.3 L h–1 greater fuel consumption than harvesting with a conventional combine (Figure 6B, C). Productivity values for conventional and Seed Terminator™ harvesting were 5.7 ha h–1 and 5.9 ha h–1, respectively (Figure 6D). Evaluating combine performance between conventional and newly discovered harvest technologies has been done in previous research. Chegini and Mirnezami (Reference Chegini and Mirnezami2016) evaluated combine performance during wheat harvest with a conventional header and stripper header and found that use of the stripper header resulted in lower fuel consumption, a faster rate of harvest, and higher harvest efficiency. Producers will need to take into account all of these factors when considering the use of any new technology.

Figure 6. Performance of a conventional combine compared to a combine equipped with a Seed Terminator™. Results are combined from 7 site-years. Asterisks indicates significant difference between paired bars based on t-test analysis.

Cost Analysis

Fixed costs of the Seed Terminator™ were estimated using ASABE equations and coefficients. The Seed Terminator™ has an initial purchase price of approximately $80,000. Because the Seed Terminator™ is a relatively new implement, estimates of cost are subject to change due to uncertainties in this market. The price of new technologies usually decreases as the rate of adoption increases. Salvage value ($5,000) and expected life (10 yr) are estimates based on analogous equipment. Interest and taxes and insurance rates were 6% and 2%, respectively, of the average annual per-hectare investment. ASABE repair factors for a forage harvester were used to estimate repair costs. Depreciation, interest, taxes, and insurance were estimated at $8.01 ha–1 for the Seed Terminator™ implement. Repairs were estimated at $5.11 ha–1.

Operating costs ($ ha–1) were estimated by joining the machinery operation cost model from Lazarus (Reference Lazarus2021), with the combine engine performance data observed with and without the Seed Terminator™ engaged during conventional soybean harvest. Fuel and labor attributed to the Seed Terminator™ were based on changes in fuel use and harvest efficiency when the Seed Terminator™ was in use vs not in use. Fuel use increased from 12.4 L ha–1 to 13.4 L ha–1 when the Seed Terminator™ was engaged, resulting in increased fuel costs of $1.06 ha–1. Labor cost did not increase, because combine productivity was statistically the same whenever the Seed Terminator™ was engaged. (Figure 6D). Overall, the estimated increased operating cost of using a Seed Terminator™ is $14.18 ha–1 compared to harvesting with a conventional combine alone (Table 5). This is comparable to estimates that were developed in Western Australia where, depending on the HWSC control tool, costs can range from $7 to $19 ha–1 (Newman, Reference Newman2020).

Table 5. Comparison of fixed and operating costs between conventional harvesting and harvesting with the addition of a Seed Terminator™ implement. Calculations are based on Lazarus (Reference Lazarus2021) machinery cost estimates.

a Cost parameters from Lazarus (Reference Lazarus2021)

As a result of the predominance of herbicide-resistant weed species in U.S. agriculture, harvest weed seed control implements will have utility in U.S. soybean production systems. Limiting the number of seed lost at the head of the combine will be key for limiting the number of seed returning to the soil. Our results documented that 22% to 40% of the available waterhemp seed in the field at harvest is lost as a result of shatter during soybean harvest. The Seed Terminator™ was able to successfully damage an average of 97%, 98%, 97%, 80%, and 94% of common lambsquarters, giant foxtail, morningglory spp., velvetleaf, and waterhemp seed, respectively. Although not all of the weed seed is directed into the Seed Terminator™, some of the chaff and weed seed escapes through the straw spreader. However, whenever the Seed Terminator™ was engaged, it was able to reduce the amount of common lambsquarters, giant foxtail, morningglory spp., velvetleaf, and waterhemp seed exiting the rear of the combine by 95%, 78%, 91%, 97%, and 82%, respectively, compared to conventional harvesting. In three of the five locations we observed a significant reduction of waterhemp seed in the soil seed bank following either one or two consecutive seasons of use. In locations with high initial seed bank densities, our results indicate it will likely take two consecutive seasons of use of the Seed TerminatorTM before substantial reductions will occur. We were also able to determine that engine load was 12.5% higher, fuel consumption was 11.3 L h–1 greater, 1 L ha–1 greater and that there was no difference in productivity when harvesting with the Seed TerminatorTM compared to a conventional combine. Using implements like the Seed Terminator™ will prove useful in limiting the return of weed seed to the soil seed bank and by doing so will likely extend the effectiveness of current herbicides by reducing selection pressure (Jasieniuk et al. Reference Jasieniuk, Brûlé-Babel and Morrison1996; Shergill et al. Reference Shergill, Bejleri, Davis and Mirsky2019). Continued research with these implements should be conducted across other cropping systems and geographies to determine their efficacy among other weed species in diverse environments within the United States.

Practical Implications

On-combine impact mills are designed to devitalize weed seed that exit the combine during grain harvest. These devices have been extensively researched and adopted in Australian wheat fields, but very little in U.S. soybean production systems. This research indicates that one of these commercially available impact mills, the Seed TerminatorTM, is highly effective at devitalizing that portion of weed seed that are directed into the implement when harvesting soybean. However, a substantial portion of weed seed is lost because of shatter at the combine header as the reel encounters weed seedheads during typical harvest operations. This research also indicates that soil seed bank reductions can occur after either one or two consecutive seasons of harvest with on-combine impact mills, given the seed production that typically occurs with our most troublesome Amaranthus species encountered in U.S. soybean.

Acknowledgments

This project was funded in part by the Missouri Soybean Merchandising Council and the United Soybean Board. The authors do not declare any other conflicts of interest.