Article contents

Modelling the effect of soluble surfactants on droplet deformation and breakup in simple shear flow

Published online by Cambridge University Press: 24 July 2024

Abstract

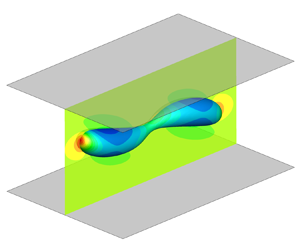

A hybrid lattice Boltzmann and finite difference method is applied to study the influence of soluble surfactants on droplet deformation and breakup in simple shear flow. First, the influence of bulk surfactant parameters on droplet deformation in two-dimensional shear flow is investigated, and the surfactant solubility is found to influence droplet deformation by changing average interface surfactant concentration and non-uniform effects induced by non-uniform interfacial tension and Marangoni forces. In addition, the droplet deformation first increases and then decreases with Biot number, increases significantly with adsorption number  $k$ and decreases with Péclet number or adsorption depth; and among the parameters,

$k$ and decreases with Péclet number or adsorption depth; and among the parameters,  $k$ is the most influential one. Then, we consider three-dimensional shear flow and investigate the roles of surfactants on droplet deformation and breakup for different capillary numbers and viscosity ratios. Results show that in the soluble case with

$k$ is the most influential one. Then, we consider three-dimensional shear flow and investigate the roles of surfactants on droplet deformation and breakup for different capillary numbers and viscosity ratios. Results show that in the soluble case with  $k=0.429$, the droplet exhibits nearly the same deformation as in the insoluble case due to the balance between surfactant adsorption and desorption; upon increasing

$k=0.429$, the droplet exhibits nearly the same deformation as in the insoluble case due to the balance between surfactant adsorption and desorption; upon increasing  $k$ from 0.429 to 1, the average interface surfactant concentration is greatly enhanced, leading to significant increase in droplet deformation. The critical capillary number of droplet breakup

$k$ from 0.429 to 1, the average interface surfactant concentration is greatly enhanced, leading to significant increase in droplet deformation. The critical capillary number of droplet breakup  $C{{a}_{cr}}$ is identified for varying viscosity ratios in clean, insoluble and soluble (

$C{{a}_{cr}}$ is identified for varying viscosity ratios in clean, insoluble and soluble ( $k=0.429$ and 1) systems. As the viscosity ratio increases,

$k=0.429$ and 1) systems. As the viscosity ratio increases,  $C{{a}_{cr}}$ first decreases and then increases rapidly in all systems. The addition of surfactants always favours droplet breakup, and increasing solubility or

$C{{a}_{cr}}$ first decreases and then increases rapidly in all systems. The addition of surfactants always favours droplet breakup, and increasing solubility or  $k$ could further reduce

$k$ could further reduce  $C{{a}_{cr}}$ by increasing average interface surfactant concentration and local surfactant concentration near the neck during the necking stage.

$C{{a}_{cr}}$ by increasing average interface surfactant concentration and local surfactant concentration near the neck during the necking stage.

Information

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2024. Published by Cambridge University Press

References

- 6

- Cited by